LCD to a PC Parallel Port

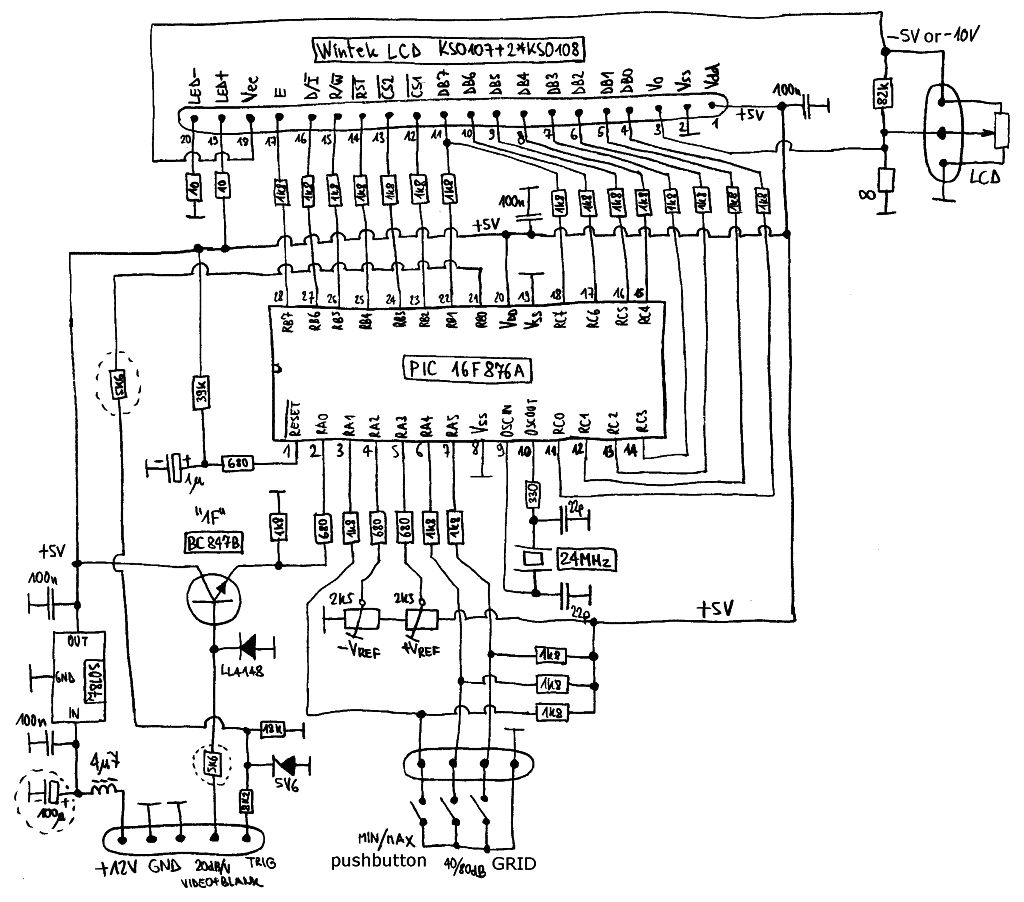

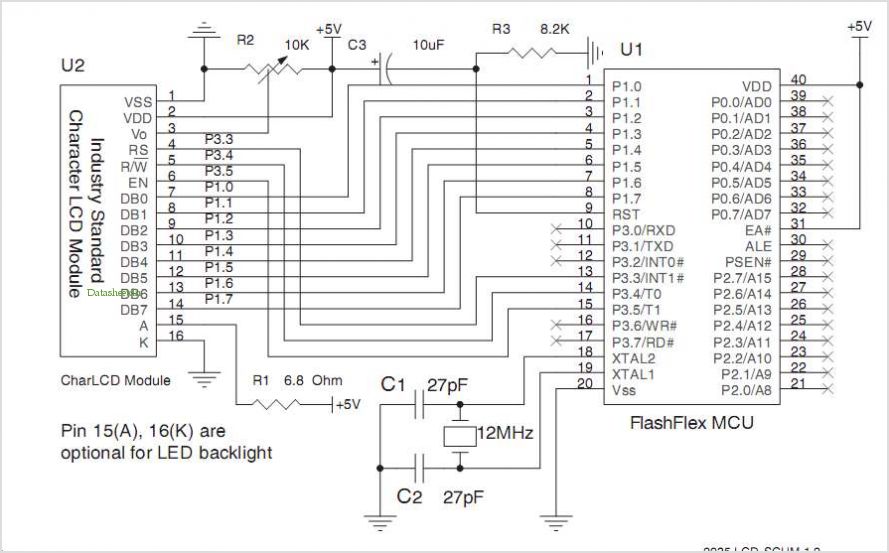

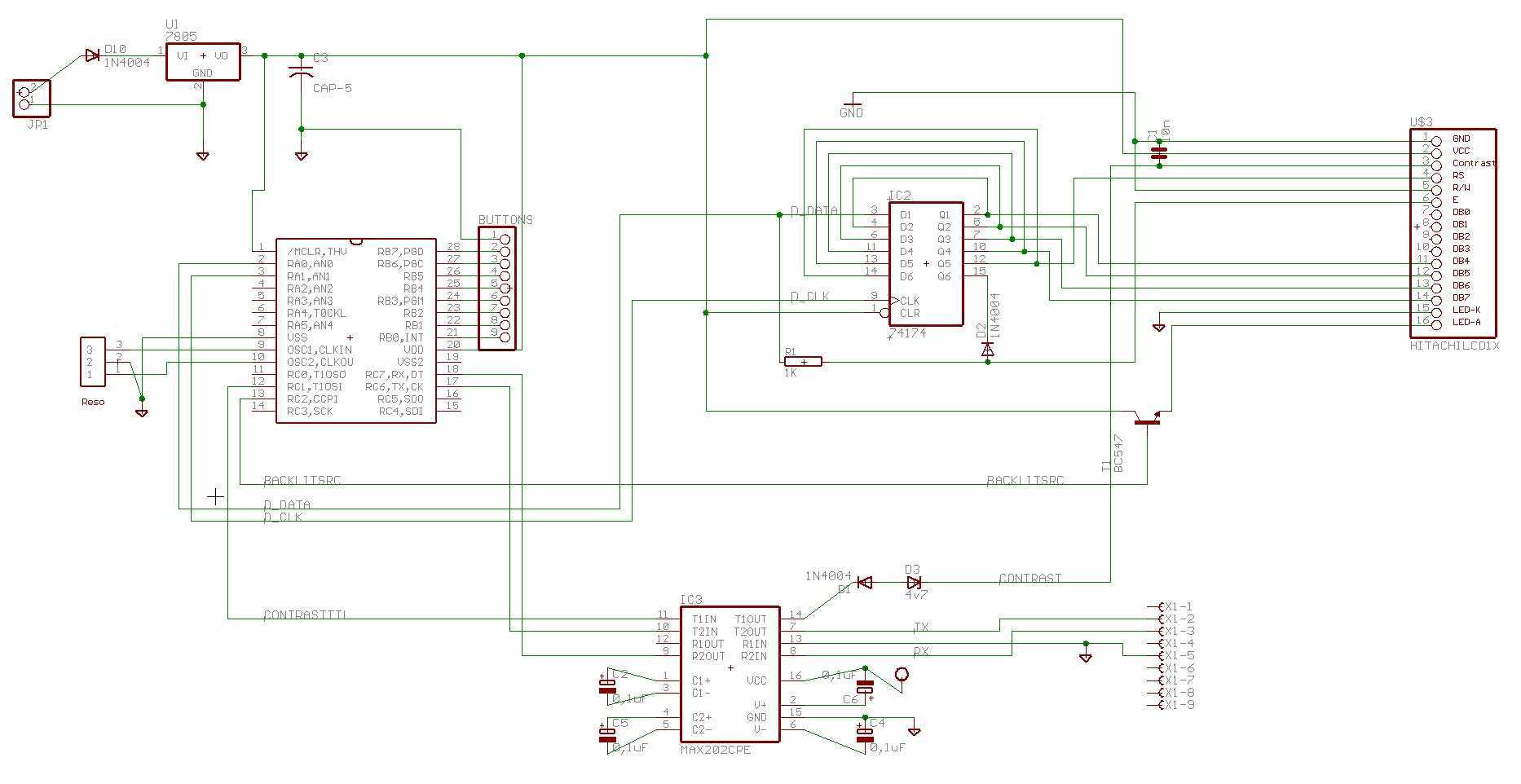

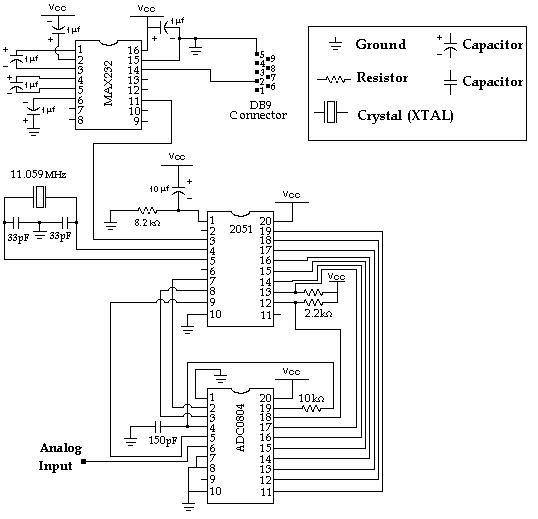

The circuit is pretty simple. The data lines on the LCD match up well with the data lines of the parallel port, and extra parallel port I/O lines can be used to simulate the RS, R/W, and E signals on the LCD. The LCD module is pretty low-lower (with the exception of the backlight), so I found that it can be powered from most parallel ports. It worked fine with all the desktop PCs I tried it with, but a laptop I tried (a Toshiba something-or-other) just didn't have enough oomph to power the LCD. The 10K pot controls the contrast of the LCD, though, in practice, I've found that it usually ends up at the ground rail, so you might be able to get by without the pot, and just tie VLC to ground. The diode from pin 17 of the printer port to pin 2 of the LCD simply blocks voltage from flowing back into the printer port (in case you hook up an external power supply). If you use an external supply, it's intended to connect to the place on the schematic labeled "+5V". This external supply can also be used to power the LCD's LED backlight (through a current-limiting resistor -- 100 ohms is probably too high, but it will turn the backlight on at least dimly). I built this circuit up on a little Radio Shack protoboard, using a DB25 for the printer port connector, and a 16-pin terminal strip for the LCD connector, with the interconnects on the back. Not pretty, but it works fine.

The circuit described integrates an LCD module with a parallel port interface, utilizing the data lines of the parallel port to communicate with the LCD. The connections between the LCD and the parallel port are straightforward, with data lines directly matched. Additional I/O lines from the parallel port are repurposed to simulate the control signals required by the LCD, specifically the RS (Register Select), R/W (Read/Write), and E (Enable) signals.

The LCD module's power requirements are minimal, allowing it to be powered directly from the parallel port in most desktop configurations. However, it is noted that certain laptops may not provide sufficient current to power the LCD adequately. A 10K potentiometer is included in the design to adjust the contrast of the display. Although it is recommended for flexibility, practical experience suggests that the potentiometer often ends up being set to ground, indicating that a direct connection to ground for the contrast pin (VLC) may suffice in many applications.

To protect the parallel port from potential backflow of voltage, a diode is connected from pin 17 of the printer port to pin 2 of the LCD. This diode serves as a safeguard in scenarios where an external power supply is used. In cases where an external supply is utilized, it should be connected to the designated "+5V" point on the schematic. This external power source can also be employed to drive the LCD's backlight, which requires a current-limiting resistor. It is suggested that a resistor value of 100 ohms, while possibly too high, will still allow the backlight to function, albeit at a reduced brightness.

The physical assembly of the circuit is accomplished using a protoboard, with a DB25 connector for the printer port and a 16-pin terminal strip for the LCD connections. The interconnects are managed on the reverse side of the protoboard, resulting in a functional, albeit not aesthetically refined, implementation.The circuit is pretty simple. The data lines on the LCD match up well with the data lines of the parallel port, and extra parallel port I/O lines can be used to simulate the RS, R/W, and E signals on the LCD. The LCD module is pretty low-lower (with the exception of the backlight), so I found that it can be powered from most parallel ports.

It worked fine with all the desktop PC's I tried it with, but a laptop I tried (a Toshiba something-or-other) just didn't have enough oomph to power the LCD The 10K pot controls the contrast of the LCD, though, in practice, I've found that it usually ends up at the ground rail, so you might be able to get by without the pot, and just tie VLC to ground. The diode from pin 17 of the printer port to pin 2 of the LCD simply blocks voltage from flowing back into the printer port (in case you hook up an external power supply).

If you use an external supply, it's intended to connect to the place on the schematic labeled "+5V". This external supply can also be used to power the LCD's LED backlight (through a current-limiting resistor -- 100 ohms is probably too high, but it will turn the backlight on at least dimly). I built this circuit up on a little Radio Shack protoboard, using a DB25 for the printer port connector, and a 16-pin terminal strip for the LCD connector, with the interconnects on the back.

Not pretty, but it works fine ... 🔗 External reference

The circuit described integrates an LCD module with a parallel port interface, utilizing the data lines of the parallel port to communicate with the LCD. The connections between the LCD and the parallel port are straightforward, with data lines directly matched. Additional I/O lines from the parallel port are repurposed to simulate the control signals required by the LCD, specifically the RS (Register Select), R/W (Read/Write), and E (Enable) signals.

The LCD module's power requirements are minimal, allowing it to be powered directly from the parallel port in most desktop configurations. However, it is noted that certain laptops may not provide sufficient current to power the LCD adequately. A 10K potentiometer is included in the design to adjust the contrast of the display. Although it is recommended for flexibility, practical experience suggests that the potentiometer often ends up being set to ground, indicating that a direct connection to ground for the contrast pin (VLC) may suffice in many applications.

To protect the parallel port from potential backflow of voltage, a diode is connected from pin 17 of the printer port to pin 2 of the LCD. This diode serves as a safeguard in scenarios where an external power supply is used. In cases where an external supply is utilized, it should be connected to the designated "+5V" point on the schematic. This external power source can also be employed to drive the LCD's backlight, which requires a current-limiting resistor. It is suggested that a resistor value of 100 ohms, while possibly too high, will still allow the backlight to function, albeit at a reduced brightness.

The physical assembly of the circuit is accomplished using a protoboard, with a DB25 connector for the printer port and a 16-pin terminal strip for the LCD connections. The interconnects are managed on the reverse side of the protoboard, resulting in a functional, albeit not aesthetically refined, implementation.The circuit is pretty simple. The data lines on the LCD match up well with the data lines of the parallel port, and extra parallel port I/O lines can be used to simulate the RS, R/W, and E signals on the LCD. The LCD module is pretty low-lower (with the exception of the backlight), so I found that it can be powered from most parallel ports.

It worked fine with all the desktop PC's I tried it with, but a laptop I tried (a Toshiba something-or-other) just didn't have enough oomph to power the LCD The 10K pot controls the contrast of the LCD, though, in practice, I've found that it usually ends up at the ground rail, so you might be able to get by without the pot, and just tie VLC to ground. The diode from pin 17 of the printer port to pin 2 of the LCD simply blocks voltage from flowing back into the printer port (in case you hook up an external power supply).

If you use an external supply, it's intended to connect to the place on the schematic labeled "+5V". This external supply can also be used to power the LCD's LED backlight (through a current-limiting resistor -- 100 ohms is probably too high, but it will turn the backlight on at least dimly). I built this circuit up on a little Radio Shack protoboard, using a DB25 for the printer port connector, and a 16-pin terminal strip for the LCD connector, with the interconnects on the back.

Not pretty, but it works fine ... 🔗 External reference