120Khz-500w-induction-heater

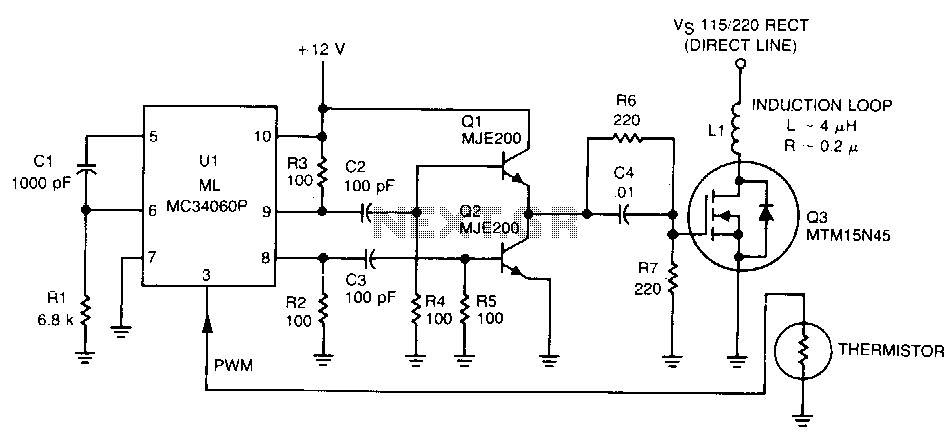

Variable width pulses with fast rise times are generated by the UL and MC34060 operating at 120 kHz, which is the optimal frequency for heating aluminum alloy containers. The pulse width is modulated by monitoring the temperature of the target using a thermistor, which has a negative temperature coefficient that alters the pulse duration. The MC34060 delivers output pulses that are AC-coupled to push-pull MJE200 transistors Q1 and Q2. This integrated circuit supplies the necessary current to ensure rapid switching for the MTM15N45 TMOS power FET Q3. The estimated efficiency is 80%, considering switching losses and a maximum R_ON of 0.4 ohms. The MTM15N45, rated for a maximum of 15 A and 450 V, was selected because the induction heater may operate from either 115 V or 220 V sources. A modest heatsink is required due to the 100 W dissipated in the power FETs at a full output power of 500 W.

The circuit operates by utilizing the MC34060 as a pulse width modulation (PWM) controller, generating variable frequency signals that are essential for controlling the heating process. The choice of 120 kHz is significant as it aligns with the resonant frequency for efficient energy transfer in heating applications, particularly for aluminum alloys.

The thermistor plays a critical role in feedback control, allowing the system to dynamically adjust the pulse width in response to temperature changes in the target material. This ensures that the heating is both efficient and responsive, preventing overheating and allowing for precise temperature control.

The output stage of the circuit features push-pull configuration using MJE200 transistors, which are capable of amplifying the PWM signals from the MC34060. This configuration enhances the drive capability for the MTM15N45 TMOS power FET, which is responsible for delivering the actual power to the induction heating coil. The use of a TMOS FET is advantageous due to its high efficiency and fast switching characteristics, which contribute to the overall performance of the induction heater.

The design accommodates a wide range of input voltages (115 V or 220 V), making it versatile for different operational environments. The MTM15N45 is selected not only for its high voltage and current ratings but also for its low on-resistance, which minimizes power losses during operation. The 80% efficiency rating indicates that a significant portion of the input power is converted into useful heating, with the remaining power dissipated as heat in the FETs.

Thermal management is addressed through the inclusion of a heatsink, which is essential to maintain the reliability of the power FETs under full load conditions. The estimated 100 W dissipation at maximum output necessitates careful thermal design to ensure that the FETs operate within safe temperature limits, thereby prolonging their operational lifespan and maintaining consistent performance.

In summary, this circuit design effectively integrates temperature sensing, PWM control, and efficient power switching to create a reliable induction heating system tailored for aluminum alloy containers.Variable width pulses with fast rise times are provided by Ul, and MC34060 operating at 120kHz, the optimum frequency for heating aluminum alloy containers. The pulse width is modulated by sensing the temperature of the target with a thermistor, using its negative temperature coefficient to change pulse duration.

The MC34060 produces output pulses that are ac-coupled to push-pull MJE200 transistors Q1 and Q2. This IC provides the current needed to ensure fast switching for MTM15N45 TMOS power FET Q3. The estimated efficiency is 80%, based on switching losses and an RoN of 0.4 0 (max). The MTM15N45, with maximum ratings of 15 A and 450 V, was chosen because the induction heater might be operated from either 115 or 220 V sources. A modest heatsink is required because 100 W is dissipated in the power FETs at a full output power of 500 W.

The circuit operates by utilizing the MC34060 as a pulse width modulation (PWM) controller, generating variable frequency signals that are essential for controlling the heating process. The choice of 120 kHz is significant as it aligns with the resonant frequency for efficient energy transfer in heating applications, particularly for aluminum alloys.

The thermistor plays a critical role in feedback control, allowing the system to dynamically adjust the pulse width in response to temperature changes in the target material. This ensures that the heating is both efficient and responsive, preventing overheating and allowing for precise temperature control.

The output stage of the circuit features push-pull configuration using MJE200 transistors, which are capable of amplifying the PWM signals from the MC34060. This configuration enhances the drive capability for the MTM15N45 TMOS power FET, which is responsible for delivering the actual power to the induction heating coil. The use of a TMOS FET is advantageous due to its high efficiency and fast switching characteristics, which contribute to the overall performance of the induction heater.

The design accommodates a wide range of input voltages (115 V or 220 V), making it versatile for different operational environments. The MTM15N45 is selected not only for its high voltage and current ratings but also for its low on-resistance, which minimizes power losses during operation. The 80% efficiency rating indicates that a significant portion of the input power is converted into useful heating, with the remaining power dissipated as heat in the FETs.

Thermal management is addressed through the inclusion of a heatsink, which is essential to maintain the reliability of the power FETs under full load conditions. The estimated 100 W dissipation at maximum output necessitates careful thermal design to ensure that the FETs operate within safe temperature limits, thereby prolonging their operational lifespan and maintaining consistent performance.

In summary, this circuit design effectively integrates temperature sensing, PWM control, and efficient power switching to create a reliable induction heating system tailored for aluminum alloy containers.Variable width pulses with fast rise times are provided by Ul, and MC34060 operating at 120kHz, the optimum frequency for heating aluminum alloy containers. The pulse width is modulated by sensing the temperature of the target with a thermistor, using its negative temperature coefficient to change pulse duration.

The MC34060 produces output pulses that are ac-coupled to push-pull MJE200 transistors Q1 and Q2. This IC provides the current needed to ensure fast switching for MTM15N45 TMOS power FET Q3. The estimated efficiency is 80%, based on switching losses and an RoN of 0.4 0 (max). The MTM15N45, with maximum ratings of 15 A and 450 V, was chosen because the induction heater might be operated from either 115 or 220 V sources. A modest heatsink is required because 100 W is dissipated in the power FETs at a full output power of 500 W.