24v 7ah lead acid battery charger

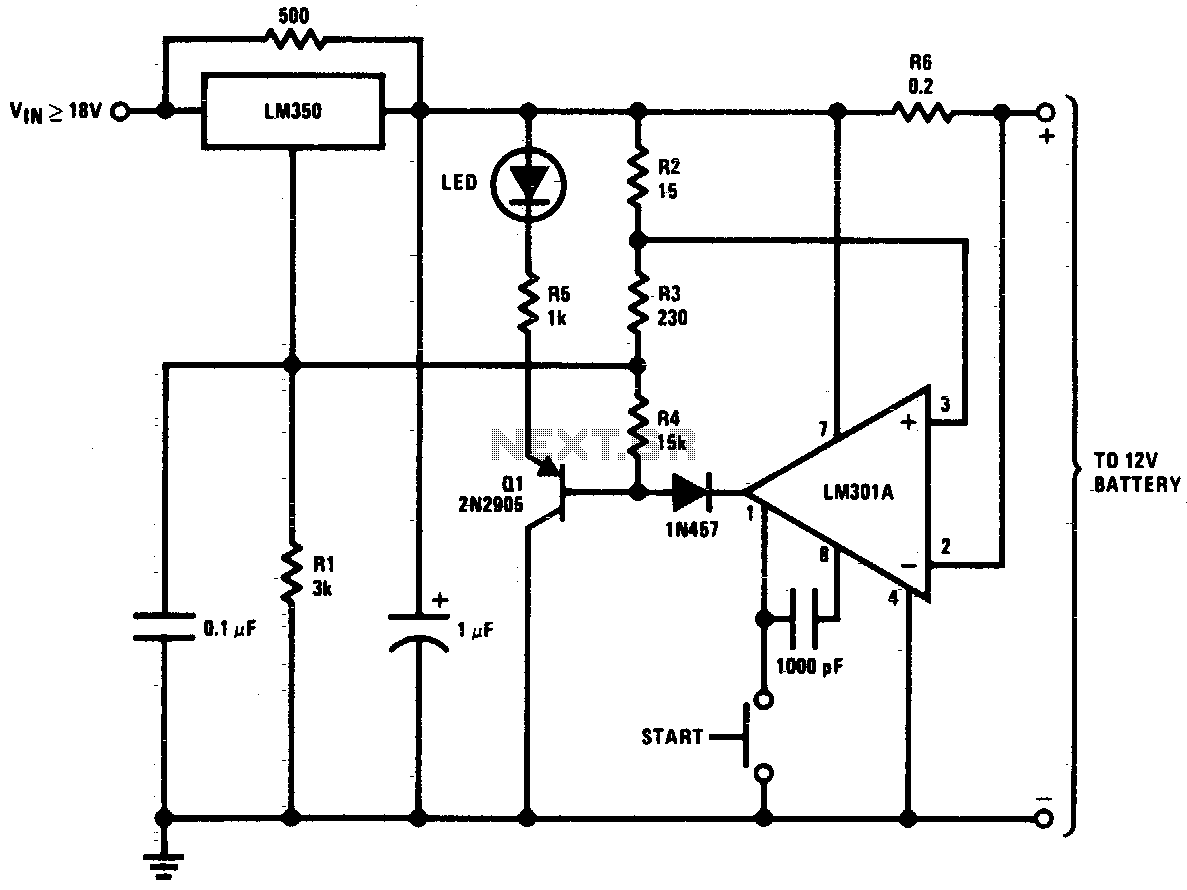

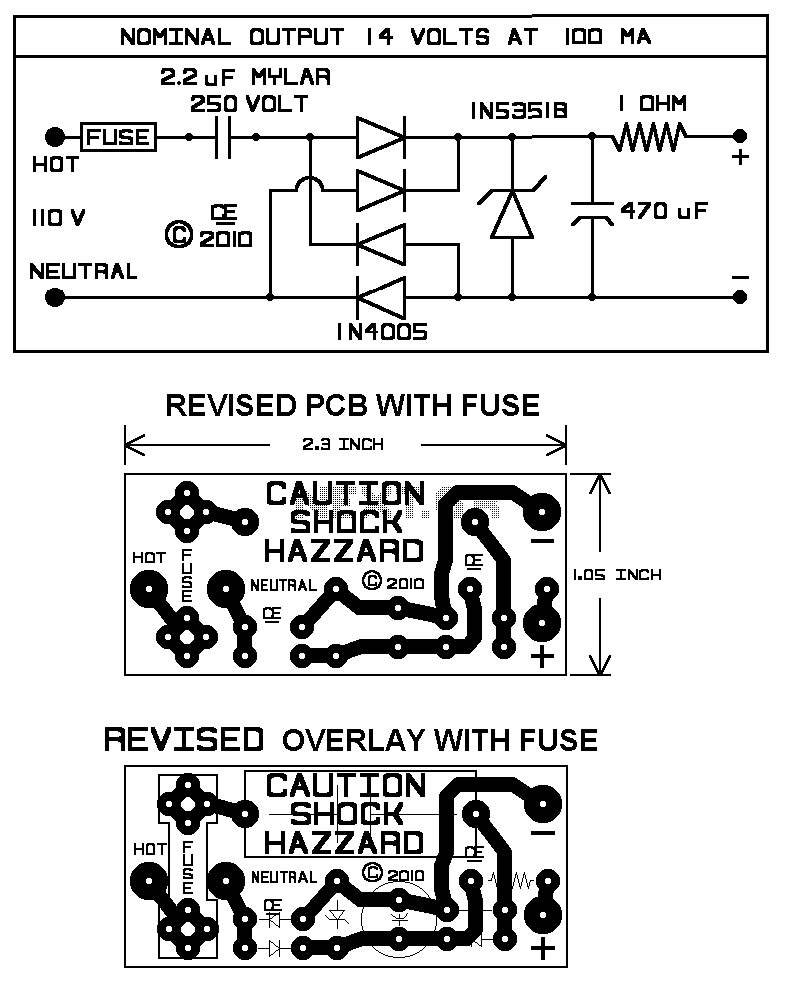

This lead-acid battery charger circuit is designed based on a request from Mr. Devdas C. His requirement was for a circuit to charge two 12V/7AH lead-acid batteries connected in series. However, the number of cells in each 12V battery was not specified. It is important to note that each 12V battery typically contains 6 cells. When two batteries are connected in series, the voltage adds up while the current capacity remains the same. Therefore, two 12V/7AH batteries in series can be treated as a single 24V/7AH battery. The circuit presented is a current-limited lead-acid battery charger utilizing the well-known variable voltage regulator IC LM317. The charging current is determined by the value of resistor R2, which is set to 700mA. Resistor R3 and potentiometer R4 control the charging voltage. Transformer T1 steps down the mains voltage, and bridge rectifier D1 handles the rectification process. Capacitor C1 acts as a filter capacitor. Diode D1 prevents reverse current flow from the battery when the charger is turned off or when mains power is unavailable. To set the charging voltage, power on the charger and connect a voltmeter across the output terminals, then adjust R4 until the voltmeter reads 28V. The charger is now ready for battery connection.

The lead-acid battery charger circuit is structured to efficiently charge two 12V lead-acid batteries connected in series, effectively creating a 24V charging system. The use of the LM317 voltage regulator allows for adjustable output voltage and current, which is crucial for optimizing the charging process and prolonging battery life. The design incorporates a current-limiting feature through resistor R2, which is critical for preventing overcurrent conditions that could damage the batteries.

The transformer T1 is selected based on the required input voltage and output current specifications, ensuring that it can adequately handle the mains voltage while providing the necessary reduced voltage for charging. The bridge rectifier D1 converts the AC voltage from the transformer into DC voltage, which is essential for charging lead-acid batteries. The filtering action of capacitor C1 smooths out any ripple in the rectified output, providing a more stable voltage to the batteries.

The inclusion of diode D1 is an essential safety feature, protecting the circuit from potential damage due to reverse current flow when the charger is not in operation. This prevents the batteries from discharging back through the charger, which could lead to reduced battery performance or failure.

The adjustable voltage output, controlled via potentiometer R4, allows the user to set the charging voltage to 28V, which is appropriate for charging two 12V batteries in series. This flexibility is particularly beneficial for various battery conditions and states of charge. The circuit design emphasizes user safety and battery health, making it suitable for home or workshop applications where lead-acid batteries are commonly used.This lead acid battery charger circuit is designed in response to a request from Mr. Devdas. C. His requirement was a circuit to charge two 12V/7AH lead acid batteries in series. Anyway he did not mentioned the no of cells per each 12V battery. The no of cells/battery is also an important parameter and here I designed the circuit assuming each 12V b attery containing 6 cells. When two batteries are connected in series, the voltage will add up and the current capacity remains same. So two 12V/7AH batteries connected in series can be considered as a 24V/7AH battery. The circuit given here is a current limited lead acid battery charger built around the famous variable voltage regulator IC LM 317.

The charging current depends on the value of resistor R2 and here it is set to be 700mA. Resistor R3 and POT R4 determines the charging voltage. Transformer T1 steps down the mains voltage and bridge D1 does the job of rectification. C1 is the filter capacitor. Diode D1 prevents the reverse flow of current from the battery when charger is switched OFF or when mains power is not available. To setup the charging voltage, power ON the charger and hook up a voltmeter across the output terminals and adjust R4 to make the voltmeter read 28V.

Now the charger is ready and you can connect the batteries. 🔗 External reference

The lead-acid battery charger circuit is structured to efficiently charge two 12V lead-acid batteries connected in series, effectively creating a 24V charging system. The use of the LM317 voltage regulator allows for adjustable output voltage and current, which is crucial for optimizing the charging process and prolonging battery life. The design incorporates a current-limiting feature through resistor R2, which is critical for preventing overcurrent conditions that could damage the batteries.

The transformer T1 is selected based on the required input voltage and output current specifications, ensuring that it can adequately handle the mains voltage while providing the necessary reduced voltage for charging. The bridge rectifier D1 converts the AC voltage from the transformer into DC voltage, which is essential for charging lead-acid batteries. The filtering action of capacitor C1 smooths out any ripple in the rectified output, providing a more stable voltage to the batteries.

The inclusion of diode D1 is an essential safety feature, protecting the circuit from potential damage due to reverse current flow when the charger is not in operation. This prevents the batteries from discharging back through the charger, which could lead to reduced battery performance or failure.

The adjustable voltage output, controlled via potentiometer R4, allows the user to set the charging voltage to 28V, which is appropriate for charging two 12V batteries in series. This flexibility is particularly beneficial for various battery conditions and states of charge. The circuit design emphasizes user safety and battery health, making it suitable for home or workshop applications where lead-acid batteries are commonly used.This lead acid battery charger circuit is designed in response to a request from Mr. Devdas. C. His requirement was a circuit to charge two 12V/7AH lead acid batteries in series. Anyway he did not mentioned the no of cells per each 12V battery. The no of cells/battery is also an important parameter and here I designed the circuit assuming each 12V b attery containing 6 cells. When two batteries are connected in series, the voltage will add up and the current capacity remains same. So two 12V/7AH batteries connected in series can be considered as a 24V/7AH battery. The circuit given here is a current limited lead acid battery charger built around the famous variable voltage regulator IC LM 317.

The charging current depends on the value of resistor R2 and here it is set to be 700mA. Resistor R3 and POT R4 determines the charging voltage. Transformer T1 steps down the mains voltage and bridge D1 does the job of rectification. C1 is the filter capacitor. Diode D1 prevents the reverse flow of current from the battery when charger is switched OFF or when mains power is not available. To setup the charging voltage, power ON the charger and hook up a voltmeter across the output terminals and adjust R4 to make the voltmeter read 28V.

Now the charger is ready and you can connect the batteries. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713