Adding sync pulses to the video signal

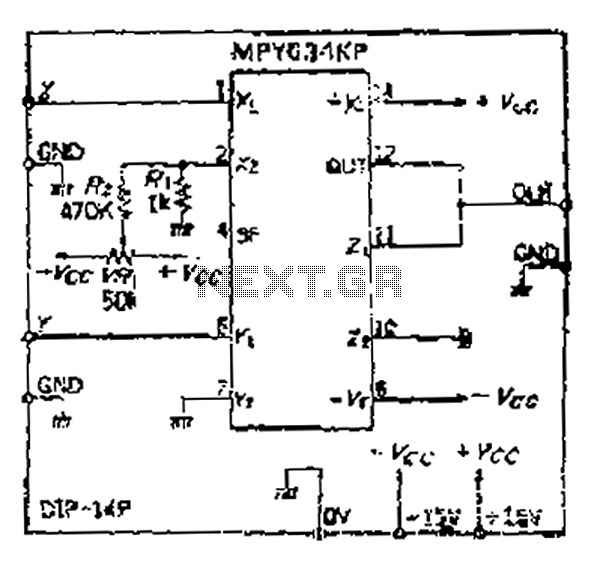

This section provides details for generating a composite video output signal from a camera to drive an external monitor. The circuit, designed by Peter Smith, integrates a DC-restorer, a switchable gamma corrector, and a video/sync mixer using a photodiode and LED. This setup senses the 32 holes around the circumference of the disc to generate the necessary sync pulses. The amplifier IC1 and diode D1 clamp the negative excursion of the video signal from the camera head to 0.8 volts. The black level clamp is determined by the ratio of resistors R2 to R1, which also influences the amplitude of the sync pulses. The video signal amplitude is adjusted by RV1. IC2 functions as a nonlinear DC-amplifier, with diodes D2 to D4 and resistors R11 to R13 approximating a square root response (gamma = ½). RV1 should be set for 1V peak-to-peak video output to ensure the gamma correction circuit operates correctly. When the switch is set to R5, the response becomes linear (gamma = 1). The strobe pin 8 of the second CA3140 is connected to the output of the photodiode via transistor Q1. The sync hole detector components, PD1 and LED1, must be precisely aligned with the sync holes in the disc. In some instances, the sync pulses produced by this arrangement may be excessively long, resulting in a broad sync bar at the bottom of the picture that occupies valuable display area. Masking the surrounding area of the TIL100 detector's light-sensitive "hot spot" with a small (2mm) hole can mitigate this issue.

The circuit described is a sophisticated solution for generating a composite video output signal suitable for external monitoring applications. It employs a combination of active and passive components to achieve the desired signal quality. The integration of a DC-restorer ensures that the video signal maintains a consistent black level, which is critical for accurate image reproduction. The adjustable resistor RV1 allows for fine-tuning of the video amplitude, accommodating variations in signal strength from different camera sources.

The nonlinear DC-amplifier configuration of IC2, along with the associated diodes and resistors, provides a gamma correction feature that is essential for enhancing image contrast and fidelity. The ability to switch between different gamma settings (gamma = ½ and gamma = 1) allows for flexibility depending on the specific requirements of the display medium or viewer preferences.

The alignment of the photodiode and LED with the sync holes is a crucial aspect of the design, as any misalignment can lead to synchronization issues, affecting the overall performance of the video output. The use of a masking technique to define the light-sensitive area is an effective approach to optimize the sync pulse duration, thereby preventing unnecessary wastage of screen space.

Overall, this circuit serves as a comprehensive solution for composite video output, effectively combining synchronization, signal conditioning, and gamma correction in a single design, making it suitable for a variety of applications in video processing and display technologies.This section contains details for providing a composite video output signal from the camera to drive an external monitor. The circuit described below, designed by Peter Smith, is a combined DC-restorer, switchable gamma corrector and video/sync mixer using a photodiode and LED to sense the 32 holes around the disc`s circum-ference to generate the

required sync pulses. The negative excursion of the video signal from the camera head is clamped to 0. 8 of a volt by the action of the amplifier IC1 and the diode D1. The black level clamp is set by the ratio of R2 to R1. This determines the amplitude of the resulting sync pulses. The amplitude of the video component of the signal is set by RV1. IC2 is configured as a non linear DC-amplifier. Diodes D2 to 4 and resistors R11 to 13 approximate a square root response (gamma = ½). RV1 should be adjusted for 1V pp video out to ensure proper operation of the gamma correction circuit. With the switch to R5 the response is linear (gamma = 1). The strobe pin 8 of the second CA3140 is connected to the output of the photo diode via Q1. The sync hole detector components PD1 and LED1 must be carefully aligned with the sync holes in the disc.

In some cases the duration of the sync pulses obtained by this arrangement may be rather long, leading to a broad sync bar at the bottom of the picture that wastes valuable picture area. Masking the surrounding area of the TIL100 detector `hot spot`, so that the light sensitive area is defined by a small (2mm) hole, can cure this problem.

🔗 External reference

The circuit described is a sophisticated solution for generating a composite video output signal suitable for external monitoring applications. It employs a combination of active and passive components to achieve the desired signal quality. The integration of a DC-restorer ensures that the video signal maintains a consistent black level, which is critical for accurate image reproduction. The adjustable resistor RV1 allows for fine-tuning of the video amplitude, accommodating variations in signal strength from different camera sources.

The nonlinear DC-amplifier configuration of IC2, along with the associated diodes and resistors, provides a gamma correction feature that is essential for enhancing image contrast and fidelity. The ability to switch between different gamma settings (gamma = ½ and gamma = 1) allows for flexibility depending on the specific requirements of the display medium or viewer preferences.

The alignment of the photodiode and LED with the sync holes is a crucial aspect of the design, as any misalignment can lead to synchronization issues, affecting the overall performance of the video output. The use of a masking technique to define the light-sensitive area is an effective approach to optimize the sync pulse duration, thereby preventing unnecessary wastage of screen space.

Overall, this circuit serves as a comprehensive solution for composite video output, effectively combining synchronization, signal conditioning, and gamma correction in a single design, making it suitable for a variety of applications in video processing and display technologies.This section contains details for providing a composite video output signal from the camera to drive an external monitor. The circuit described below, designed by Peter Smith, is a combined DC-restorer, switchable gamma corrector and video/sync mixer using a photodiode and LED to sense the 32 holes around the disc`s circum-ference to generate the

required sync pulses. The negative excursion of the video signal from the camera head is clamped to 0. 8 of a volt by the action of the amplifier IC1 and the diode D1. The black level clamp is set by the ratio of R2 to R1. This determines the amplitude of the resulting sync pulses. The amplitude of the video component of the signal is set by RV1. IC2 is configured as a non linear DC-amplifier. Diodes D2 to 4 and resistors R11 to 13 approximate a square root response (gamma = ½). RV1 should be adjusted for 1V pp video out to ensure proper operation of the gamma correction circuit. With the switch to R5 the response is linear (gamma = 1). The strobe pin 8 of the second CA3140 is connected to the output of the photo diode via Q1. The sync hole detector components PD1 and LED1 must be carefully aligned with the sync holes in the disc.

In some cases the duration of the sync pulses obtained by this arrangement may be rather long, leading to a broad sync bar at the bottom of the picture that wastes valuable picture area. Masking the surrounding area of the TIL100 detector `hot spot`, so that the light sensitive area is defined by a small (2mm) hole, can cure this problem.

🔗 External reference

.png)