assembly language for wiper based 8051 microcontroller

Microcontroller-based water tank filler circuit diagram. Differences between microprocessors and microcontrollers, parallel port interfacing projects using microcontrollers, applications of microcontrollers in real life, circuit diagram of AVR microcontroller trainer, 8086 microcontroller, microcontroller-based drip irrigation system circuit, design of pulse oximeter with PIC microcontroller, projects utilizing speed input from LM2907, PowerPoint examples of lab prepared by assembly programming for 8051 microcontroller code free download, data transfer with PIC microcontroller using USB and IrDA.

The microcontroller-based water tank filler circuit is designed to automate the filling of water tanks while preventing overflow. The circuit typically utilizes a microcontroller, which serves as the central processing unit, to monitor water levels through sensors and control the operation of a pump.

The primary components of this circuit include:

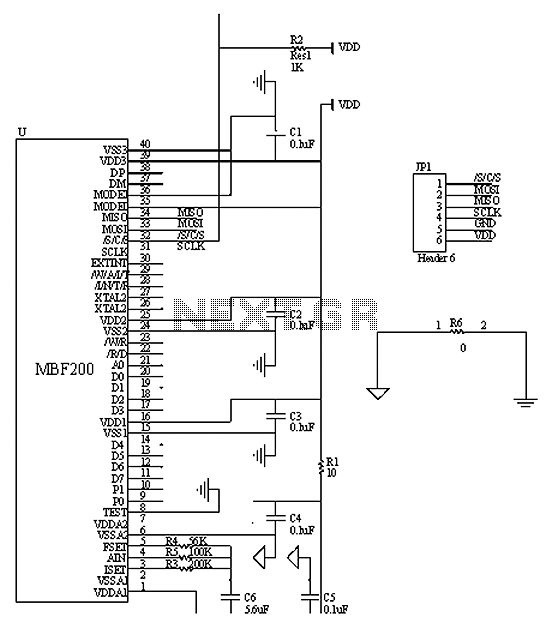

1. **Microcontroller**: Acts as the brain of the system, processing inputs from the water level sensors and controlling the pump's operation based on predefined conditions.

2. **Water Level Sensors**: These sensors detect the water level within the tank. Common types include float switches, ultrasonic sensors, or capacitive sensors. The microcontroller interprets signals from these sensors to determine whether the tank is full or empty.

3. **Pump**: An electric pump is used to fill the tank with water. The microcontroller sends a signal to activate the pump when the water level falls below a certain threshold and deactivates it when the desired level is reached.

4. **Power Supply**: Provides the necessary voltage and current to the microcontroller and pump. Adequate power management is crucial to ensure reliable operation.

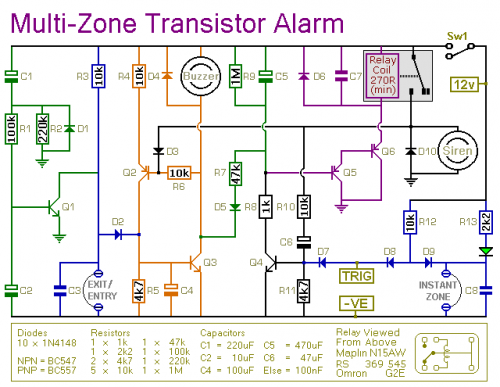

5. **Control Circuitry**: This may include relays or transistors that interface between the microcontroller and the pump, allowing the low-power microcontroller to control the higher-power pump.

6. **Programming Interface**: The microcontroller is programmed with specific algorithms to manage the filling process, handle sensor inputs, and ensure safety features are in place to prevent overflow.

In addition to the water tank filler circuit, the input data also references various applications and projects involving microcontrollers. These include interfacing projects with parallel ports, real-life applications of microcontrollers, and specific projects such as drip irrigation systems and pulse oximeter designs using PIC microcontrollers. Each of these applications leverages the unique capabilities of microcontrollers, such as their ability to process inputs, control outputs, and communicate with other devices, making them versatile tools in modern electronics.

The design of such systems often involves careful consideration of the microcontroller's architecture, programming techniques, and interfacing methods to ensure optimal performance and reliability.Microcontroller based old water tank fillercircuit diagram. difference between microprocessor and microcontrollerppt, parallel port interfacing projects with microcontroller, microcontroller use in real live, circuit diagram of avr microcontroller trainer, 8086 of microcontroller, microcontroller based drip irrigation systemcircuit, design of pulse oximeter with pic microcontroller, microcontroller projects using speed input of lm2907, ppt examplesof lab prepared by by assembly programming 8051 microcontroller codefree download, data transfer pic microcontroller using usb irda.. 🔗 External reference

The microcontroller-based water tank filler circuit is designed to automate the filling of water tanks while preventing overflow. The circuit typically utilizes a microcontroller, which serves as the central processing unit, to monitor water levels through sensors and control the operation of a pump.

The primary components of this circuit include:

1. **Microcontroller**: Acts as the brain of the system, processing inputs from the water level sensors and controlling the pump's operation based on predefined conditions.

2. **Water Level Sensors**: These sensors detect the water level within the tank. Common types include float switches, ultrasonic sensors, or capacitive sensors. The microcontroller interprets signals from these sensors to determine whether the tank is full or empty.

3. **Pump**: An electric pump is used to fill the tank with water. The microcontroller sends a signal to activate the pump when the water level falls below a certain threshold and deactivates it when the desired level is reached.

4. **Power Supply**: Provides the necessary voltage and current to the microcontroller and pump. Adequate power management is crucial to ensure reliable operation.

5. **Control Circuitry**: This may include relays or transistors that interface between the microcontroller and the pump, allowing the low-power microcontroller to control the higher-power pump.

6. **Programming Interface**: The microcontroller is programmed with specific algorithms to manage the filling process, handle sensor inputs, and ensure safety features are in place to prevent overflow.

In addition to the water tank filler circuit, the input data also references various applications and projects involving microcontrollers. These include interfacing projects with parallel ports, real-life applications of microcontrollers, and specific projects such as drip irrigation systems and pulse oximeter designs using PIC microcontrollers. Each of these applications leverages the unique capabilities of microcontrollers, such as their ability to process inputs, control outputs, and communicate with other devices, making them versatile tools in modern electronics.

The design of such systems often involves careful consideration of the microcontroller's architecture, programming techniques, and interfacing methods to ensure optimal performance and reliability.Microcontroller based old water tank fillercircuit diagram. difference between microprocessor and microcontrollerppt, parallel port interfacing projects with microcontroller, microcontroller use in real live, circuit diagram of avr microcontroller trainer, 8086 of microcontroller, microcontroller based drip irrigation systemcircuit, design of pulse oximeter with pic microcontroller, microcontroller projects using speed input of lm2907, ppt examplesof lab prepared by by assembly programming 8051 microcontroller codefree download, data transfer pic microcontroller using usb irda.. 🔗 External reference