Automobile-air-conditioner

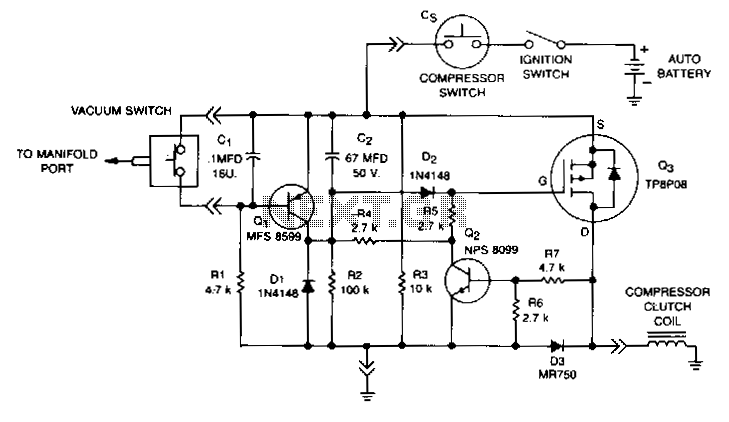

This circuit disables the air conditioner compressor when additional engine power is required. It does so by monitoring the engine vacuum at the intake manifold. If the vacuum drops to 40% of its normal level, the compressor clutch is disabled, removing the air conditioner load from the engine. After the engine returns to the normal vacuum level, there is a 6-second delay before the compressor clutch is enabled again, reactivating the air conditioner. This allows for an additional 6 seconds of power, approximately 500 feet at 60 MPH, which increases the safety margin when passing another vehicle. The loss of cooling is minimal because the air conditioner fan continues to operate. When the engine accelerates, manifold vacuum decreases, causing vacuum switch VS to open at 40% of the normal manifold pressure. This action turns on transistor Q1, discharging capacitor C2 and turning off transistor Q3 via diode D2. When Q3 turns off, transistor Q2 also turns off. Once the engine reaches its normal operating vacuum, vacuum switch VS closes, turning off Q1 and allowing capacitor C2 to charge for 6 seconds until Q3 is activated again.

The circuit operates primarily through a feedback mechanism that utilizes a vacuum switch (VS) to monitor the engine's intake manifold pressure. The threshold level is set at 40% of the normal vacuum, which is a critical point where the engine requires additional power, typically during acceleration or when under load. When the vacuum switch detects this drop, it activates transistor Q1, which plays a pivotal role in controlling the discharge of capacitor C2. The discharge of C2 results in the deactivation of transistor Q3, which subsequently disables the compressor clutch.

The delay mechanism is essential for maintaining a balance between performance and comfort. By incorporating a 6-second delay after the vacuum returns to normal levels, the circuit ensures that the air conditioning system does not reactivate instantaneously, which could lead to a sudden increase in load on the engine. This feature allows for a smoother transition back to normal operating conditions, ensuring that the engine can maintain optimal performance without the burden of the air conditioning load.

Moreover, the design minimizes the impact on cooling performance. The air conditioning fan remains operational, providing continuous airflow and mitigating any significant loss of cooling during the brief period when the compressor is disabled. The use of diode D2 ensures that the control signals are directed appropriately, preventing any unwanted feedback that could lead to erratic behavior in the circuit.

Overall, this circuit design effectively enhances vehicle performance during critical driving situations while maintaining passenger comfort, illustrating a well-thought-out approach to automotive electronic control systems.This circuit disables the air conditioner compressor when additional engine power is required. It does so by monitoring the engine vacuum at the intake manifold. Ifthe vacuum drops to 40% of its normal level, the compressor clutch is disabled, removing the air conditioner load from the engine. After the engine returns to normal vacuum level, there is a 6 second delay before the compressor clutch is enabled and the air conditioner is reactivated.

This allows 6 seconds of extra power, about 500 ft at 60 MPH, which increases the safety margin when passinganother vehicle. Loss of cooling is minimal because the air conditioner fan is not interrupted. When the engine is accelerated, manifold vacuum drops and vacuum switch VS opens to 40% of the normal manifold pressure. This causes Ql to turn on, discharging C2 and turning off Q3 via diode D2. When Q3 turns off, sn does Q2. When the engine reaches its normal operating vacuum, VS closes and Ql turns off, allowing C2 to charge for 6 seconds until Q3 turns on again.

The circuit operates primarily through a feedback mechanism that utilizes a vacuum switch (VS) to monitor the engine's intake manifold pressure. The threshold level is set at 40% of the normal vacuum, which is a critical point where the engine requires additional power, typically during acceleration or when under load. When the vacuum switch detects this drop, it activates transistor Q1, which plays a pivotal role in controlling the discharge of capacitor C2. The discharge of C2 results in the deactivation of transistor Q3, which subsequently disables the compressor clutch.

The delay mechanism is essential for maintaining a balance between performance and comfort. By incorporating a 6-second delay after the vacuum returns to normal levels, the circuit ensures that the air conditioning system does not reactivate instantaneously, which could lead to a sudden increase in load on the engine. This feature allows for a smoother transition back to normal operating conditions, ensuring that the engine can maintain optimal performance without the burden of the air conditioning load.

Moreover, the design minimizes the impact on cooling performance. The air conditioning fan remains operational, providing continuous airflow and mitigating any significant loss of cooling during the brief period when the compressor is disabled. The use of diode D2 ensures that the control signals are directed appropriately, preventing any unwanted feedback that could lead to erratic behavior in the circuit.

Overall, this circuit design effectively enhances vehicle performance during critical driving situations while maintaining passenger comfort, illustrating a well-thought-out approach to automotive electronic control systems.This circuit disables the air conditioner compressor when additional engine power is required. It does so by monitoring the engine vacuum at the intake manifold. Ifthe vacuum drops to 40% of its normal level, the compressor clutch is disabled, removing the air conditioner load from the engine. After the engine returns to normal vacuum level, there is a 6 second delay before the compressor clutch is enabled and the air conditioner is reactivated.

This allows 6 seconds of extra power, about 500 ft at 60 MPH, which increases the safety margin when passinganother vehicle. Loss of cooling is minimal because the air conditioner fan is not interrupted. When the engine is accelerated, manifold vacuum drops and vacuum switch VS opens to 40% of the normal manifold pressure. This causes Ql to turn on, discharging C2 and turning off Q3 via diode D2. When Q3 turns off, sn does Q2. When the engine reaches its normal operating vacuum, VS closes and Ql turns off, allowing C2 to charge for 6 seconds until Q3 turns on again.