Automobile-ignition

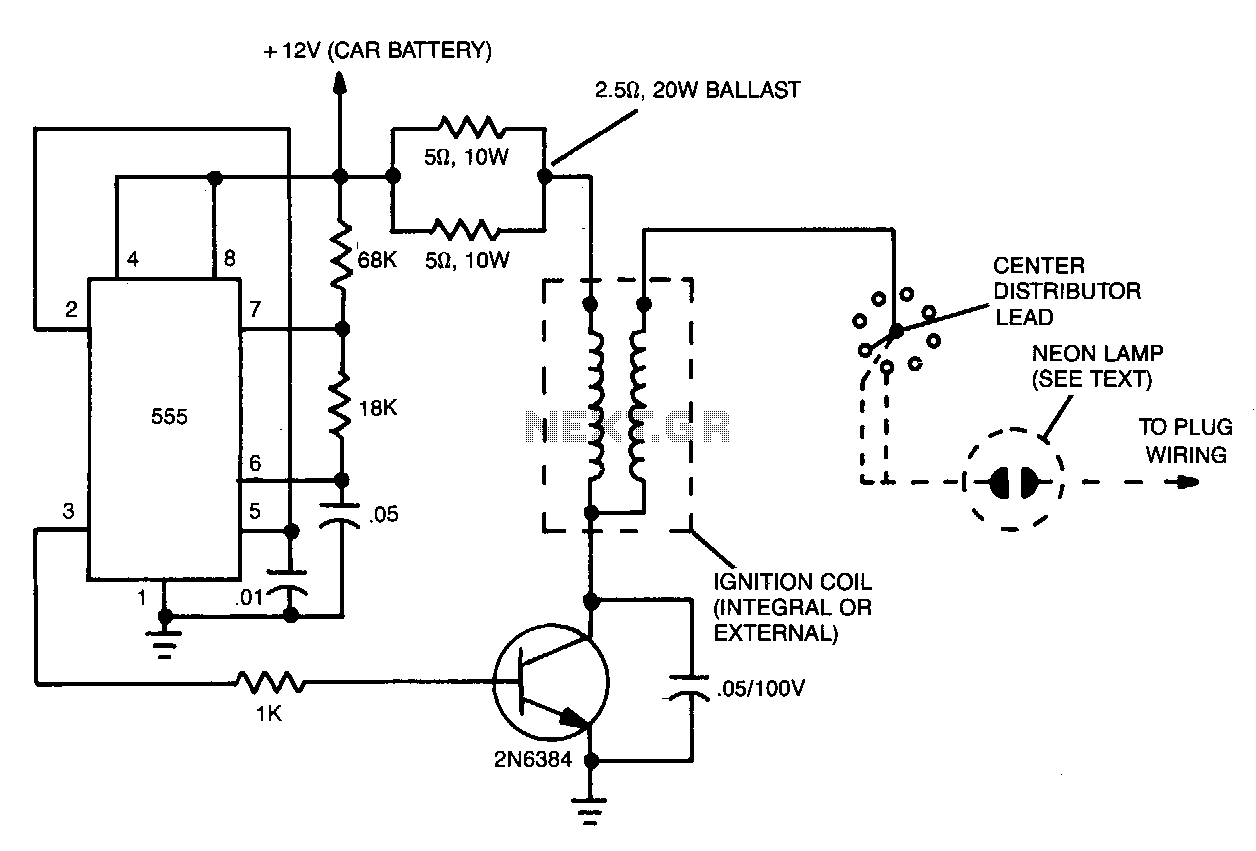

The ignition substitute provides a constant power source for the ignition coil. Its frequency, 0.5-1.0 kHz, is that used by an 8-cylinder engine with an idling speed of 650 RPM, and the unit provides a rapid spark at a 17% duty cycle while staying within the power dissipation limits of the components. The circuit consists of a 555 timer IC configured as an astable free-running multivibrator that is used to drive a high-current NPN transistor, such as a 2N6384. The transistor should be heavily heatsinked because it might be drawing several amps over quite a long period of time. The coil ballast can be from 0.68 to 6.5 ohms, depending on what is available. The 2.5-ohm, 20-W ballast shown works well. All the other resistors can be either 1/4 or 1/2-W devices, and the capacitor between pins 1 and 5 of the 555 can range from 0.01 to 0.051 µF. Do not omit the 100-V, 0.05-µF capacitor across the transistor; it prevents voltage spikes from damaging the device. Although designed for an 8-cylinder engine, this device can be used with other types. In addition, a neon bulb can be added to the circuit to verify the presence of a spark.

The ignition substitute circuit operates by generating a square wave signal using a 555 timer IC, which is configured in an astable mode. This configuration allows the timer to produce a continuous oscillation that switches between high and low states at the specified frequency of 0.5-1.0 kHz. This frequency is particularly suitable for 8-cylinder engines operating at an idling speed of 650 RPM, ensuring that the ignition coil receives a consistent and rapid pulse to generate the necessary spark for ignition.

The output of the 555 timer drives a high-current NPN transistor, such as the 2N6384. The transistor acts as a switch, controlling the power delivered to the ignition coil. Given that the transistor may conduct several amps for extended periods, it is crucial to utilize an adequate heatsink to dissipate heat effectively and maintain operational reliability.

The circuit incorporates a ballast resistor, which can vary from 0.68 to 6.5 ohms, depending on availability and specific requirements. A 2.5-ohm, 20-W ballast resistor is recommended for optimal performance. The resistors used in the circuit can be rated at either 1/4 or 1/2 watt, providing flexibility in component selection based on availability and design constraints.

The capacitor connected between pins 1 and 5 of the 555 timer is critical for determining the frequency of oscillation. This capacitor can have a value ranging from 0.01 to 0.051 µF, allowing for fine-tuning of the pulse width and frequency output. Additionally, a 100-V, 0.05-µF capacitor should be placed across the transistor to suppress voltage spikes that could potentially damage the transistor during operation.

While the circuit is optimized for an 8-cylinder engine, it can be adapted for use with different engine configurations. To enhance functionality, a neon bulb can be integrated into the circuit to provide a visual indication of spark generation, serving as a diagnostic tool for confirming operational status. This feature can be particularly useful during testing and troubleshooting of the ignition system.The ignition substitute provides a constant power source for the ignition coil. Its frequency, 0.5-1.0 kHz, is that used by an 8-cylinder engine with an idling speed of 650 RPM, and the unit provides a rapid spark at a 17% duty cycle, while staying within the power dissipation limits of the components. The circuit consists of a 555 timer IC configured as an astable free~running multivibrator that is used to drive a high-current npn transistor, such as a 2N6384.

The transistor should be heavily heatsinked because it might be drawing several amps over quite a long period of time. The coil ballast can be from 0.68 to 6.5 0, depending on what"s available. The 2.5-0, 20-W ballast shown works well. All the other resistors can be either 1/4-or 1/2-W devices, and the capacitor, between pins 1 and 5 of the 555, can range from 0.01 to 0.051"F. Do not omit the 100-V, 0.05-I"F capacitor across the transistor; it prevents voltage spikes from damaging the device.

Although designed for an 8-cylinder engine, this device can be used with other types. In addition, a neon bulb can be added to the circuit to verify the presence of a spark.

The ignition substitute circuit operates by generating a square wave signal using a 555 timer IC, which is configured in an astable mode. This configuration allows the timer to produce a continuous oscillation that switches between high and low states at the specified frequency of 0.5-1.0 kHz. This frequency is particularly suitable for 8-cylinder engines operating at an idling speed of 650 RPM, ensuring that the ignition coil receives a consistent and rapid pulse to generate the necessary spark for ignition.

The output of the 555 timer drives a high-current NPN transistor, such as the 2N6384. The transistor acts as a switch, controlling the power delivered to the ignition coil. Given that the transistor may conduct several amps for extended periods, it is crucial to utilize an adequate heatsink to dissipate heat effectively and maintain operational reliability.

The circuit incorporates a ballast resistor, which can vary from 0.68 to 6.5 ohms, depending on availability and specific requirements. A 2.5-ohm, 20-W ballast resistor is recommended for optimal performance. The resistors used in the circuit can be rated at either 1/4 or 1/2 watt, providing flexibility in component selection based on availability and design constraints.

The capacitor connected between pins 1 and 5 of the 555 timer is critical for determining the frequency of oscillation. This capacitor can have a value ranging from 0.01 to 0.051 µF, allowing for fine-tuning of the pulse width and frequency output. Additionally, a 100-V, 0.05-µF capacitor should be placed across the transistor to suppress voltage spikes that could potentially damage the transistor during operation.

While the circuit is optimized for an 8-cylinder engine, it can be adapted for use with different engine configurations. To enhance functionality, a neon bulb can be integrated into the circuit to provide a visual indication of spark generation, serving as a diagnostic tool for confirming operational status. This feature can be particularly useful during testing and troubleshooting of the ignition system.The ignition substitute provides a constant power source for the ignition coil. Its frequency, 0.5-1.0 kHz, is that used by an 8-cylinder engine with an idling speed of 650 RPM, and the unit provides a rapid spark at a 17% duty cycle, while staying within the power dissipation limits of the components. The circuit consists of a 555 timer IC configured as an astable free~running multivibrator that is used to drive a high-current npn transistor, such as a 2N6384.

The transistor should be heavily heatsinked because it might be drawing several amps over quite a long period of time. The coil ballast can be from 0.68 to 6.5 0, depending on what"s available. The 2.5-0, 20-W ballast shown works well. All the other resistors can be either 1/4-or 1/2-W devices, and the capacitor, between pins 1 and 5 of the 555, can range from 0.01 to 0.051"F. Do not omit the 100-V, 0.05-I"F capacitor across the transistor; it prevents voltage spikes from damaging the device.

Although designed for an 8-cylinder engine, this device can be used with other types. In addition, a neon bulb can be added to the circuit to verify the presence of a spark.