beztlacitkova klavesnice

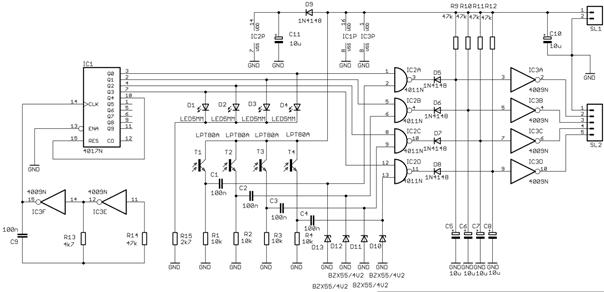

There are several applications in which a buttonless keyboard might be useful. In exteriors, they can capitalize on the fact that without buttons the keyboard can be fully closed and therefore it is weather resistant. Moreover, they seem to be easily made in vandalism resistant forms. Their considerable advantage also lies in the fact that they can be made in various design concepts. Usually, several approaches to buttonless keyboards are practiced. This paper describes a design of a simple optical-based keyboard. The principle of operation of such an optical push button is rather obvious. When a reflective object (a finger) moves close to the evanescent field, the light emitted by the LED is reflected into a photo sensor that drives the proper logical circuits. This technology is relatively new, with only a few existing prototypes in this research field. The solution is based on time division multiplexing. The keyboard consists of four pairs of LEDs and a photo sensor. The working period of the keyboard consists of four timeslots. In each timeslot, only one LED is activated, and when the appropriate button is pressed, the logical circuit detects which LED's light is being reflected to the photo sensor. A block diagram of this solution is depicted in the accompanying figure. The testing circuit can be divided into several blocks. The operating period is driven by a clock signal source, which drives a Johnson counter that ensures sequential activation of the appropriate LEDs. The reflections of the light emitted by the LEDs are captured by photo sensors mounted close to the LEDs. The combinatorial logic then compares the waveforms of the signals present at the output of the Johnson counter and the output of the photo sensors. When compliance between the signals is detected, the appropriate output of the output buffer is activated with a short logic signal. The output of the circuit can then be monitored by an oscilloscope or a multichannel logic probe. The sample circuit consists of three CMOS logic integrated circuits: the Johnson counter IC1, a quadruple NAND gate IC2, and a sextuple NOT gate IC3. All three ICs are inexpensive and readily available. The clock signal generator is made of IC3E and IC3F inverters and operates at a frequency of approximately 1 kHz, driving the Johnson counter IC1, whose number of possible states is restricted to four by connecting its Q4 output to its RESET input. Its outputs Q0 to Q3 are sequentially driven high, each for a period of approximately 250 µs. The prospective LEDs D1 to D4 illuminate when powered by a high-level signal. The R15 resistor limits the current to the LEDs and ensures an appropriate high signal level at the outputs of IC1, which might fall below the threshold of IC2 if the outputs were overly loaded. The LEDs must therefore be capable of operating with low currents. Complementary photo sensors are mounted close to the LEDs. These photo sensors are based on phototransistors T1 to T4 with resistors R1 to R4 connected in their emitters. These resistors establish 100% negative feedback, which decreases the circuit's sensitivity to ambient light. Normally, when no object reflecting the light from the LEDs to the phototransistors is present, the phototransistors are variously opened, resulting in varying voltage levels at their emitters.

The buttonless optical keyboard design leverages innovative technology to enhance usability in diverse environments. The absence of mechanical buttons allows for a sealed construction, providing protection against environmental factors such as moisture and dirt. This feature is particularly advantageous for outdoor applications, where traditional keyboards may fail due to exposure.

The optical push-button mechanism operates by utilizing a light-emitting diode (LED) and a phototransistor. When a finger approaches the sensor area, the light from the LED is reflected, triggering the phototransistor. The system employs time division multiplexing to efficiently manage the activation of multiple LEDs, ensuring that only one LED is active at any given time. This method reduces power consumption and minimizes interference between the signals.

The Johnson counter serves as the core timing mechanism, controlling the sequence in which the LEDs are activated. The use of inexpensive CMOS technology ensures that the components are accessible and cost-effective for various applications. The design also incorporates a feedback mechanism that stabilizes the operation of the phototransistors, enhancing the system's reliability in fluctuating lighting conditions.

In summary, this optical-based buttonless keyboard offers a modern solution to traditional input methods, combining robustness, versatility, and efficiency. Its design principles can be adapted for various applications, making it a valuable addition to the field of user interface technology. The schematic design, along with its operational principles, presents a clear pathway for implementation in both commercial and industrial settings.There are several applications in which a buttonless keyboard might be useful. In exteriors, they can capitalize on the fact that without buttons the keyboard can be fully closed and therefore it is weather resistant. Moreover, they seem to be easily made in vandalism resistant forms. Their considerable advantage also lies in the fact that they ca n be made in various design conceptions. Usually, several approaches to the buttonless keyboards are practiced. In this paper a design of a simple optical-based keyboard is described. KlG vesnice bez mechanickG½ch tla Gtek mohou nalG©zt uplatn ›nG v nemG lo aplikacGch. V exteriG©rech t › G z toho, e je lze jednodu e vyrobit ve zcela uzav ™enG©m provedenG, a tGm pG dem odolnG© proti vliv m po asG, p ™Gpadn › i vandalismu. VneposlednG ™ad › je lze vyrG b ›t vr znG½ch designovG½ch provedenGch. Voblasti tG©to konstrukce tla Gtek existuje nemG lo p ™Gstup, p ™i em vtomto lG nku je popsG n nG vrh jednoduchG© a snadno sestrojitelnG© klG vesnice, kterG pracuje na optickG©m principu.

The principle of operation of such optical push button is rather obvious. When a reflective object (a finger) moves close to the evanescent field, the light emitted by the LED is reflected into a photo sensor that drives the proper logical circuits. As stated in [1], this technology is rather new with only a few existing prototypes in this research field.

The solution is based on a time division multiplex. The keyboard consists of 4 couples of LEDs and a photo sensor. The working period of the keyboard consists of 4 timeslots. In each of them only one LED is driven and when the appropriate button is activated, the logical circuit detects that one the light of which is being reflected to the photo sensor. A block diagram of this solution is depicted in Fig. 2. As can be seen in Fig. 2, the testing circuit can be divided into several blocks. The operating period is driven by a clock signal source. This source drives the Johnson`s counter that ensures sequential driving of appropriate LEDs. The reflections of the light emitted by the LEDs are captured by the photo sensors that are mounted close to the LEDs.

The combinatorial logic then compares the waveforms of the signals that are present at the output of the Johnson`s counter and the output of the set of the photo sensors. When compliance between the signals is detected, the proper output of the output buffer is driven with a short logic signal.

The output of the circuit can be then monitored by an oscilloscope or a multichannel logical probe. The sample circuit consists of three CMOS logical integrated circuits Johnson`s counter IC1, quadruple NAND gate IC2 and sextuple NOT gate IC3. All three ICs are cheap and readily available. The clock signal generator is made of IC3E and IC3F inverters. It runs with the frequency of approximately 1 kHz and drives the Johnsons`s counter IC1 whose number of possible states is restricted to 4 by connecting its Q4 output to its RESET input.

Its outputs Q0 to Q3 are sequentially driven high, each for a period of approximately 250 µs. The prospective LEDs D1 to D4 glow when fed by the H level signal. The R15 resistor limits the current of the LEDs and ensures the appropriate level of the H signal at the outputs of IC1 which might fall below the IC2 threshold if the prospective outputs were loaded too much. The LEDs must therefore be capable of operation with low currents. Close to the LEDs complementary photo sensors are mounted. These photo sensors are based on phototransistors T1 to T4 with resistors R1 to R4 connected in their emitters.

These resistors establish 100% negative feedback which decreases the sensitivity of the circuit to the ambient light. Normally, when no obstacle reflecting the light from the LEDs to the phototransistors is present, the phototransistors are variously opened which means that the voltage level at their emitters may var

🔗 External reference

The buttonless optical keyboard design leverages innovative technology to enhance usability in diverse environments. The absence of mechanical buttons allows for a sealed construction, providing protection against environmental factors such as moisture and dirt. This feature is particularly advantageous for outdoor applications, where traditional keyboards may fail due to exposure.

The optical push-button mechanism operates by utilizing a light-emitting diode (LED) and a phototransistor. When a finger approaches the sensor area, the light from the LED is reflected, triggering the phototransistor. The system employs time division multiplexing to efficiently manage the activation of multiple LEDs, ensuring that only one LED is active at any given time. This method reduces power consumption and minimizes interference between the signals.

The Johnson counter serves as the core timing mechanism, controlling the sequence in which the LEDs are activated. The use of inexpensive CMOS technology ensures that the components are accessible and cost-effective for various applications. The design also incorporates a feedback mechanism that stabilizes the operation of the phototransistors, enhancing the system's reliability in fluctuating lighting conditions.

In summary, this optical-based buttonless keyboard offers a modern solution to traditional input methods, combining robustness, versatility, and efficiency. Its design principles can be adapted for various applications, making it a valuable addition to the field of user interface technology. The schematic design, along with its operational principles, presents a clear pathway for implementation in both commercial and industrial settings.There are several applications in which a buttonless keyboard might be useful. In exteriors, they can capitalize on the fact that without buttons the keyboard can be fully closed and therefore it is weather resistant. Moreover, they seem to be easily made in vandalism resistant forms. Their considerable advantage also lies in the fact that they ca n be made in various design conceptions. Usually, several approaches to the buttonless keyboards are practiced. In this paper a design of a simple optical-based keyboard is described. KlG vesnice bez mechanickG½ch tla Gtek mohou nalG©zt uplatn ›nG v nemG lo aplikacGch. V exteriG©rech t › G z toho, e je lze jednodu e vyrobit ve zcela uzav ™enG©m provedenG, a tGm pG dem odolnG© proti vliv m po asG, p ™Gpadn › i vandalismu. VneposlednG ™ad › je lze vyrG b ›t vr znG½ch designovG½ch provedenGch. Voblasti tG©to konstrukce tla Gtek existuje nemG lo p ™Gstup, p ™i em vtomto lG nku je popsG n nG vrh jednoduchG© a snadno sestrojitelnG© klG vesnice, kterG pracuje na optickG©m principu.

The principle of operation of such optical push button is rather obvious. When a reflective object (a finger) moves close to the evanescent field, the light emitted by the LED is reflected into a photo sensor that drives the proper logical circuits. As stated in [1], this technology is rather new with only a few existing prototypes in this research field.

The solution is based on a time division multiplex. The keyboard consists of 4 couples of LEDs and a photo sensor. The working period of the keyboard consists of 4 timeslots. In each of them only one LED is driven and when the appropriate button is activated, the logical circuit detects that one the light of which is being reflected to the photo sensor. A block diagram of this solution is depicted in Fig. 2. As can be seen in Fig. 2, the testing circuit can be divided into several blocks. The operating period is driven by a clock signal source. This source drives the Johnson`s counter that ensures sequential driving of appropriate LEDs. The reflections of the light emitted by the LEDs are captured by the photo sensors that are mounted close to the LEDs.

The combinatorial logic then compares the waveforms of the signals that are present at the output of the Johnson`s counter and the output of the set of the photo sensors. When compliance between the signals is detected, the proper output of the output buffer is driven with a short logic signal.

The output of the circuit can be then monitored by an oscilloscope or a multichannel logical probe. The sample circuit consists of three CMOS logical integrated circuits Johnson`s counter IC1, quadruple NAND gate IC2 and sextuple NOT gate IC3. All three ICs are cheap and readily available. The clock signal generator is made of IC3E and IC3F inverters. It runs with the frequency of approximately 1 kHz and drives the Johnsons`s counter IC1 whose number of possible states is restricted to 4 by connecting its Q4 output to its RESET input.

Its outputs Q0 to Q3 are sequentially driven high, each for a period of approximately 250 µs. The prospective LEDs D1 to D4 glow when fed by the H level signal. The R15 resistor limits the current of the LEDs and ensures the appropriate level of the H signal at the outputs of IC1 which might fall below the IC2 threshold if the prospective outputs were loaded too much. The LEDs must therefore be capable of operation with low currents. Close to the LEDs complementary photo sensors are mounted. These photo sensors are based on phototransistors T1 to T4 with resistors R1 to R4 connected in their emitters.

These resistors establish 100% negative feedback which decreases the sensitivity of the circuit to the ambient light. Normally, when no obstacle reflecting the light from the LEDs to the phototransistors is present, the phototransistors are variously opened which means that the voltage level at their emitters may var

🔗 External reference