build a blinking safety light for your bicycle

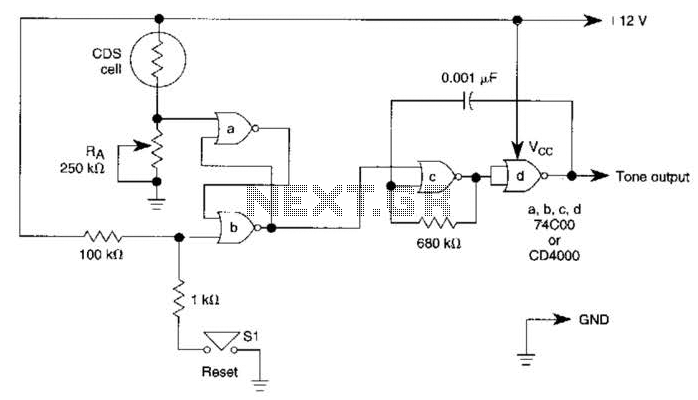

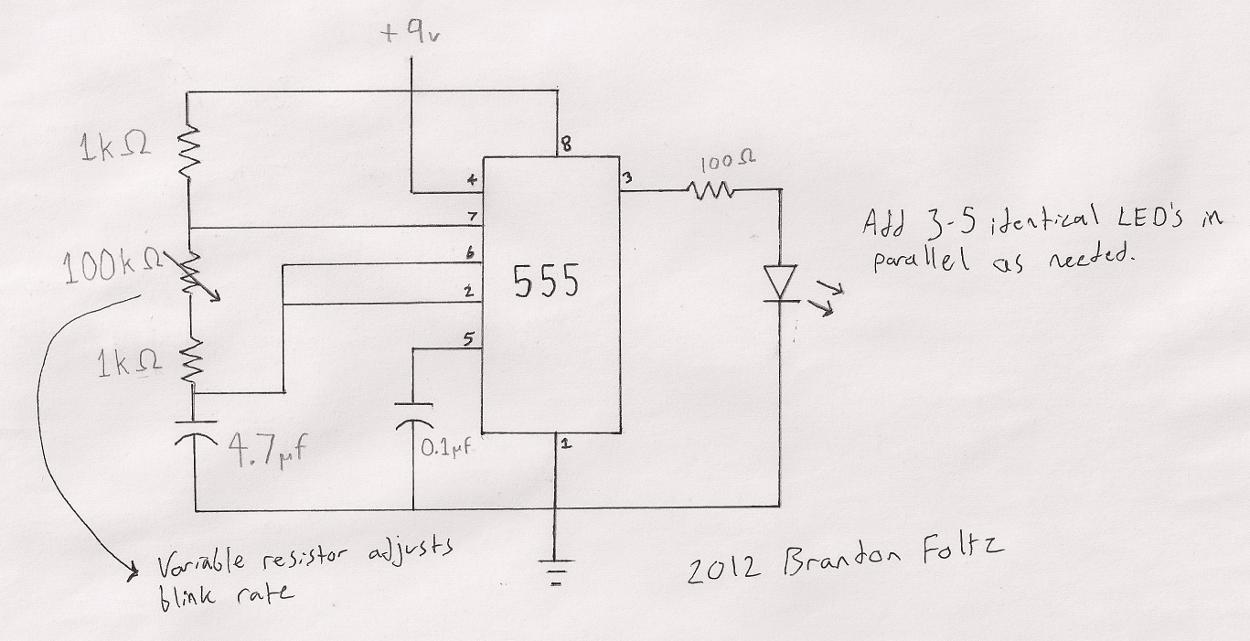

The circuit utilized is a commonly known design. A search for "555 timer LED blinker" will yield numerous schematics that are suitable for this application. The specific schematic presented includes a variable resistor (100K) that allows for user-adjustable blink rates ranging from approximately 1 Hz to several hundred hertz. Mounting hardware is not included in the parts list, as the user must determine how the enclosure will attach to their bicycle. In this instance, a small metal piece above the rear tire with pre-existing holes provided an ideal location for attachment using a nut and bolt. The circuit should be assembled on a perfboard and placed in the enclosure for mounting on the bicycle. It is important to wire the LEDs in parallel. Testing was conducted on a breadboard with a 9V DC wall adapter, which differs from battery use as it can deliver around 14V to a lightly-loaded circuit. Initially, the LEDs were wired in series, which worked with the wall adapter; however, when powered by a 9V battery, the combined voltage drop of four series-wired LEDs exceeded the supply voltage, causing circuit failure. The solution was to wire the LEDs in parallel, ensuring that collectively they would only drop the same voltage as a single LED (approximately 1.5 volts). The layout of the components in the enclosure is visible in the provided photo. The circuit was soldered to the perfboard before trimming excess material with a Dremel tool. Due to misalignment of the screw holes on the board and the enclosure, only one corner screw was used for securing it. Although space was limited, it was utilized efficiently. A quarter-inch hole is present for the bolt used for bicycle attachment, and an additional smaller hole above the screw head on the trimpot allows for blink rate adjustment with a screwdriver without removing the device from the bicycle. The completed project is depicted in the accompanying image.

The circuit operates based on the well-known 555 timer IC, configured in astable mode to create a square wave output that controls the blinking of the LEDs. The variable resistor (trimpot) adjusts the timing of the output signal, thus varying the blink rate. The circuit can be powered by a 9V battery or an adapter, but care must be taken to ensure that the LED configuration matches the power supply voltage to avoid exceeding the voltage drop limits.

The schematic includes the 555 timer connected to a capacitor and resistors that determine the frequency of oscillation. The output pin of the 555 timer connects directly to the anodes of the parallel-wired LEDs, while the cathodes are connected to ground. This configuration allows each LED to receive the same voltage, ensuring they operate correctly regardless of variations in supply voltage.

For mounting, the enclosure should be designed to withstand environmental factors such as moisture and vibration common to bicycle use. Choosing a durable material and ensuring all components are securely fastened will enhance the longevity of the device. The design also allows for easy access to the trimpot for adjustments, ensuring that the user can modify the blink rate as needed while riding.

In conclusion, this LED blinker circuit is a practical application of the 555 timer, showcasing versatility in design and functionality while emphasizing user customization and ease of installation on a bicycle.The circuit I used is a very common one. You can do a google search for 555 timer LED blinker and find hundreds of schematis that will fit the bill. Here is the schematic for my particular flavor of LED blinker: The variable resistor (100K) in the schematic above may not be included in other designs with a fixed blink rate, I included it here so that the blink rate

can be user adjustable from about 1hz to several hundred hertz. I didn`t include mounting hardware in the parts list because you will need to do some thought on your own to decide how your enclosure will attach to your particular bicycle. My bike has a small metal piece above the rear tire with holes in it, so it was only logical to attach my enclosure here with a nut and bolt.

Wire this circuit up on your perfboard and insert it into your enclosure. Mount it on your bike and you`ll hopefully have something like this! Make sure you wire your LED`s in parallel! I had been testing the circuit on my breadboard with a 9v DC wall adapter as the power supply, this is slightly different from using a battery, as it will deliver ~14v to a lightly-loaded circuit. I had wired my LED`s in series, and with the wall adapter everything worked fine. However, when powered by a 9 volt, the four LED`s I had wired in series dropped more voltage than the 9 volt could deliver, so the circuit failed to operate.

The easy fix for this is of course to wire the LED`s in parallel, so that collectively they can only drop the same voltage as a single LED would (which is ~1. 5 volts). You can see how everything is laid out in the enclosure in the photo above. I soldered the circuit to the perfboard before cutting the excess off with a Dremel. The screw holes on the board don`t line up with the holes in the enclosure perfectly, so I only used one corner screw to hold it in place.

It`s a pretty tight fit for everything, but at least no space was wasted. I don`t have a photo of the back panel, but there is a quarter-inch hole for the bolt that is used to attach it to my bicycle. Your bike might not have the same mounting mechanism, so as I mentioned above you will have to figure out how to mount it yourself.

There is also a smaller hole directly above the screw head on the trimpot, this is so that you can adjust the blink rate with a screwdriver without ever taking the device off your bike. The finished project looks like this! 🔗 External reference

The circuit operates based on the well-known 555 timer IC, configured in astable mode to create a square wave output that controls the blinking of the LEDs. The variable resistor (trimpot) adjusts the timing of the output signal, thus varying the blink rate. The circuit can be powered by a 9V battery or an adapter, but care must be taken to ensure that the LED configuration matches the power supply voltage to avoid exceeding the voltage drop limits.

The schematic includes the 555 timer connected to a capacitor and resistors that determine the frequency of oscillation. The output pin of the 555 timer connects directly to the anodes of the parallel-wired LEDs, while the cathodes are connected to ground. This configuration allows each LED to receive the same voltage, ensuring they operate correctly regardless of variations in supply voltage.

For mounting, the enclosure should be designed to withstand environmental factors such as moisture and vibration common to bicycle use. Choosing a durable material and ensuring all components are securely fastened will enhance the longevity of the device. The design also allows for easy access to the trimpot for adjustments, ensuring that the user can modify the blink rate as needed while riding.

In conclusion, this LED blinker circuit is a practical application of the 555 timer, showcasing versatility in design and functionality while emphasizing user customization and ease of installation on a bicycle.The circuit I used is a very common one. You can do a google search for 555 timer LED blinker and find hundreds of schematis that will fit the bill. Here is the schematic for my particular flavor of LED blinker: The variable resistor (100K) in the schematic above may not be included in other designs with a fixed blink rate, I included it here so that the blink rate

can be user adjustable from about 1hz to several hundred hertz. I didn`t include mounting hardware in the parts list because you will need to do some thought on your own to decide how your enclosure will attach to your particular bicycle. My bike has a small metal piece above the rear tire with holes in it, so it was only logical to attach my enclosure here with a nut and bolt.

Wire this circuit up on your perfboard and insert it into your enclosure. Mount it on your bike and you`ll hopefully have something like this! Make sure you wire your LED`s in parallel! I had been testing the circuit on my breadboard with a 9v DC wall adapter as the power supply, this is slightly different from using a battery, as it will deliver ~14v to a lightly-loaded circuit. I had wired my LED`s in series, and with the wall adapter everything worked fine. However, when powered by a 9 volt, the four LED`s I had wired in series dropped more voltage than the 9 volt could deliver, so the circuit failed to operate.

The easy fix for this is of course to wire the LED`s in parallel, so that collectively they can only drop the same voltage as a single LED would (which is ~1. 5 volts). You can see how everything is laid out in the enclosure in the photo above. I soldered the circuit to the perfboard before cutting the excess off with a Dremel. The screw holes on the board don`t line up with the holes in the enclosure perfectly, so I only used one corner screw to hold it in place.

It`s a pretty tight fit for everything, but at least no space was wasted. I don`t have a photo of the back panel, but there is a quarter-inch hole for the bolt that is used to attach it to my bicycle. Your bike might not have the same mounting mechanism, so as I mentioned above you will have to figure out how to mount it yourself.

There is also a smaller hole directly above the screw head on the trimpot, this is so that you can adjust the blink rate with a screwdriver without ever taking the device off your bike. The finished project looks like this! 🔗 External reference