Capacitive Power Supply

1. Basic Principles of Capacitive Power Supply

1.1 Basic Principles of Capacitive Power Supply

Capacitive power supplies are crucial components in modern electronics, providing an alternative to traditional transformer-based power supply systems. They capitalize on the principles of capacitance, where electrical energy is stored in an electric field between two conductive plates separated by an insulating material. Understanding the foundation of capacitive power supplies necessitates a grasp of several key concepts: capacitance, impedance, and energy storage and conversion.

Capacitance and Its Role

At the core of any capacitive power supply is the capacitor, a two-terminal passive electronic component characterized by its ability to store charge. The capacitance (C) of a capacitor is defined by the equation:

where Q is the charge stored on the capacitor, and V is the voltage across its terminals. Capacitors are typically rated in farads (F); however, practical values often range from picofarads (pF) to microfarads (µF) in consumer electronics. A larger capacitance allows for greater energy storage, making it essential for smoothing out voltage fluctuations in power supplies.

Impedance and Frequency Response

When capacitors are charged and discharged in an AC circuit, the concept of impedance (Z) comes into play. The impedance of a capacitor at a frequency (f) is given by:

where j is the imaginary unit, and ω (omega) equals 2πf. This relationship underscores how capacitors behave differently at varying frequencies. In a capacitive power supply, designing with frequency in mind is crucial, as different load characteristics can impact circuit performance.

Energy Storage and Conversion

Capacitors not only store energy but can also influence the efficiency of power conversion in electronic circuits. The energy (E) stored in a capacitor can be expressed mathematically as:

This formula highlights that energy storage is directly proportional to both the capacitance and the square of the voltage. In capacitive power supplies, the rapid discharging of capacitors enables instantaneous power delivery, which is particularly useful in applications requiring fast response times, such as LED drivers and audio amplification.

Real-World Applications

Capacitive power supplies are found extensively in various applications. They are commonly used in:

- LED Lighting: Capacitive power supplies provide suitable low-voltage power for LED operations, enabling dimming and color temperature control.

- Switching Power Supplies: In high-frequency conversion and regulation, capacitors are vital for filtering and stability.

- Portable Electronics: The lightweight and compact design of capacitive power supplies is beneficial for battery-operated devices.

Through understanding the basic principles behind capacitive power supplies, designers and engineers can innovate and improve the performance of electronic devices, addressing challenges with efficiency and reliability.

1.2 Differences Between Capacitive and Other Power Supplies

The advent of electronic devices has led to the evolution of several power supply architectures, each designed to meet the distinct requirements of various applications. Among these, capacitive power supplies hold a unique position. In this section, we will explore the differences between capacitive power supplies and other common types—namely, linear and switch-mode power supplies—and highlight their respective advantages and disadvantages.

Capacitive Power Supplies: An Overview

Capacitive power supplies utilize capacitors as the primary energy storage component. They are typically characterized by a straightforward design and the absence of inductive elements. Unlike linear power supplies, which regulate output voltage through thermal dissipation and transformers, capacitive supplies rely on capacitors to charge and discharge energy directly into the load, often leading to higher efficiency in simpler applications.

Key Differences

- Complexity: Capacitive power supplies are generally simpler, with fewer components compared to linear and switch-mode power supplies. The absence of inductive elements reduces the complexity of design and increases reliability.

- Efficiency: Capacitive designs can provide significant efficiency in low-power applications due to reduced energy losses. Linear power supplies, on the other hand, often waste energy as heat in their voltage regulation process.

- Output Voltage Regulation: While capacitive power supplies offer basic voltage regulation, they lack the fine-tuning capability present in switch-mode power supplies, which utilize feedback mechanisms for precise output control.

- Ripple Voltage: One notable disadvantage of capacitive power supplies is the higher ripple voltage present at the output, which can lead to an unstable supply in sensitive applications. In contrast, switch-mode supplies can achieve better regulation and reduced ripple.

- Size and Weight: Capacitive power supplies are typically smaller and lighter than linear power supplies, making them ideal for compact applications. However, switch-mode supplies offer better size optimization due to their ability to operate at higher frequencies.

- Cost: With fewer components needed, capacitive power supplies can be less expensive to manufacture. Linear supplies are generally more costly due to their complexity, while switch-mode supplies fall somewhere in between but provide flexibility.

Real-World Applications

Capacitive power supplies find their niche in applications where simplicity and size matter, such as:

- LED lighting systems, where low power supply requirements coexist with minimal space.

- Small battery chargers, which can be efficient and cost-effective.

- Low-power consumer electronics that do not require intricate voltage regulation.

By understanding these differences, engineers and designers can make more informed decisions about selecting the appropriate power supply architecture for their specific application needs. Each type of power supply presents unique benefits and trade-offs, paving the way for advancements in electronic device design.

2. Capacitors: Types and Functions

2.1 Capacitors: Types and Functions

Capacitors are essential components in electrical circuits, utilized for a variety of functions such as energy storage, filtering, and voltage smoothing. Their operation hinges on the separation of electric charge, leading to the buildup of an electric field which can be harnessed in various applications.

Types of Capacitors

Broadly, capacitors can be classified into several categories based on their construction, dielectric material, and applications:

- Electrolytic Capacitors: These capacitors use a liquid or gel electrolyte. They have high capacitance values, making them suitable for power supply filtering and energy storage applications.

- Ceramic Capacitors: Known for their stability and reliability, these capacitors are frequently used in high-frequency applications due to their low equivalent series resistance (ESR).

- Tantalum Capacitors: Similar to electrolytic but constructed from tantalum metal, they offer higher performance and are used in compact electronic devices for energy storage.

- Film Capacitors: Utilizing thin plastic films as the dielectric, these capacitors provide excellent voltage stability, making them ideal for audio applications and timing circuits.

- Supercapacitors: Also known as ultracapacitors, these devices bridge the gap between traditional capacitors and batteries, allowing for rapid charging and discharging, and are increasingly used in renewable energy systems.

Functions of Capacitors

The versatility of capacitors enables them to perform various critical functions in electrical circuits:

- Energy Storage: Capacitors store energy when charged and release it rapidly when needed. This characteristic is pivotal in applications such as camera flashes and power supplies.

- Filtering: Capacitors are widely used in power supply circuits to filter out noise and smooth voltage fluctuations, ensuring that sensitive electronic devices operate correctly.

- Timing Applications: In combination with resistors, capacitors can create time delays, which are essential in oscillators and timers.

- Signal Coupling and Decoupling: In communication circuits, capacitors allow AC signals to pass while blocking DC, thus facilitating the transmission of information across different components.

Understanding the types and functions of capacitors lays the groundwork for their application in capacitive power supplies. They not only act as energy reservoirs but also enhance the stability and performance of electronic devices.

Here, C represents the capacitance in farads, Q is the charge in coulombs, and V is the voltage in volts. This fundamental relationship underscores the capacitor's ability to store charge and informs practical design considerations in circuit applications.

2.2 Diodes and Their Role in Power Supply

Diodes are semiconductor devices that play a crucial role in power supply systems, including capacitive power supplies. Their fundamental function is to control the direction of current flow, effectively allowing current to pass in one direction while blocking it in the opposite direction. Understanding the behavior of diodes is essential for advanced applications in electronic circuit design and energy management systems.

Functionality of Diodes

A diode acts as a one-way valve for electric current. When forward-biased, meaning the anode is at a higher voltage than the cathode, it conducts current. Conversely, when reverse-biased, the current is curtailed. This property is instrumental in converting alternating current (AC) to direct current (DC), which is essential for powering devices that require a consistent voltage level, such as microcontrollers and sensors.

Diodes are characterized by their voltage-current (I-V) relationship, typically exhibiting a threshold voltage (often around 0.7V for silicon diodes) that must be overcome for conduction to occur. This relationship can be represented mathematically as:

where:

- I = current through the diode

- Is = reverse saturation current

- q = charge of an electron (1.6 x 10-19 coulombs)

- V = voltage across the diode

- k = Boltzmann's constant (1.38 x 10-23 J/K)

- T = absolute temperature in Kelvin

Types of Diodes in Power Supply Applications

Different types of diodes serve various functions in power supply applications:

- Rectifier Diodes: These are designed to convert AC to DC and are used widely in power supply circuits. High current capabilities make them suitable for heavy-duty applications.

- Zener Diodes: Employed for voltage regulation, Zener diodes maintain a constant output voltage even as input voltage changes, making them valuable in stabilizing power supplies.

- Schottky Diodes: Known for their fast switching speed and low forward voltage drop, Schottky diodes are crucial in high-frequency applications, reducing energy loss in power supply circuits.

Practical Considerations in Diode Selection

When designing a capacitive power supply, the selection of diodes must consider factors such as:

- Current Rating: Ensure the diode can handle the maximum current expected during operation.

- Reverse Voltage Rating: The diode must withstand the peak reverse voltage without breakdown.

- Switching Speed: For high-frequency applications, select faster diodes to minimize switching losses.

For instance, in a power supply that uses a capacitive dropper circuit, selecting the right rectifier diode ensures efficiency while minimizing heat generation which can compromise reliability. An effective design would typically use a silicon diode for the rectification stage and consider employing a Zener diode for subsequent voltage regulation.

Applications of Diodes in Capacitive Power Supplies

In a capacitive power supply, diodes are critical for converting the AC voltage obtained from the mains supply into the desired DC voltage for downstream circuitry. Often, this involves creating a bridge rectifier configuration that employs four diodes to manage both halves of the AC waveform, thus improving the rectification efficiency.

A typical application of this circuitry can be found in low-power, compact devices such as LED drivers, where the conversion is done in a minimal footprint without the need for traditional transformers, yielding a lightweight and cost-effective solution. The mentioned technologies elucidate how diodes facilitate modern energy solutions in everyday applications.

2.3 Resistors and Inductors in Circuits

In the realm of capacitive power supply circuits, the integration of resistors and inductors plays a crucial role. These two fundamental components are essential in controlling current flow, managing voltage levels, and defining the behavior of a circuit under various operating conditions. Understanding their interplay provides engineers and researchers with the critical insights needed to design efficient and reliable power supply systems.The Role of Resistors

Resistors serve as the most straightforward component to control current within a circuit. In a capacitive power supply, they are often employed for current limiting and voltage division. The relationship governing the behavior of resistors is described by Ohm's Law, which can be expressed as:Inductors: Their Purpose and Functionality

Inductors, functioning on the principle of electromagnetism, store energy in a magnetic field when an electrical current passes through them. They are primarily used in capacitive power supplies for filters and energy storage devices. This property enables them to resist changes in current, thereby stabilizing the power supply output. The behavior of inductors is characterized by the inductance \( L \), defined by:Series and Parallel Configurations

When integrating resistors and inductors in a circuit, their configuration (series or parallel) significantly alters the overall impedance and, consequently, the circuit's behavior. - Series Configuration: When resistors and inductors are connected in series, the total resistance (\( R_{\text{total}} \)) is the sum of individual resistances. The inductor adds its impedance to the total resistance seen by an AC current source, which can be represented as:Real-World Applications

In many applications such as power supplies for telecommunications or electronics, using the right combination of resistors and inductors allows for precise control over power delivery. For instance, in a switching power supply, the combination of these components ensures efficient voltage regulation and minimizes losses. Additionally, capacitive power supplies are sensitive to the effects of inductance and resistance. For instance, resistors can be utilized in snubber circuits alongside inductors to protect switching components from voltage spikes and ringing. In summary, the understanding of how resistors and inductors interact in capacitive power supply circuits is pivotal. This knowledge allows engineers to design circuits that are not only functional but also resilient to the various challenges presented in real-world applications. As we delve deeper into capacitive power supplies, it becomes increasingly evident how these basic components shape circuit performance, efficiency, and reliability.3. Capacitive Voltage Divider Concept

3.1 Capacitive Voltage Divider Concept

The concept of a capacitive voltage divider is fundamental in understanding how capacitors can be employed to manage voltage levels in electronic circuits. This technique efficiently divides an input voltage into smaller output voltages across different capacitors, allowing effective signal processing and energy management. This subsection delves into the theoretical groundwork of the capacitive voltage divider, its mathematical formulation, and practical applications within capacitive power supplies.

Understanding the Capacitive Divider

A capacitive voltage divider consists of two or more capacitors arranged in series. When an AC voltage is applied across this series combination, the voltage drop across each capacitor is proportional to its capacitance. This principle arises from the behavior of capacitors in relation to alternating current. Generally, capacitors resist changes in voltage; thus, when subjected to a sinusoidal input, the voltage across each capacitor can be represented as:

where:

- V_C is the voltage across the capacitor.

- V_{in} is the input voltage across the entire divider.

- X_C is the reactance of the capacitor, defined as $$X_C = \frac{1}{\omega C}$$, where $$\omega$$ is the angular frequency and $$C$$ is the capacitance.

- X_C^{total} is the total capacitive reactance of the series configuration.

The Mathematical Derivation

To establish the voltage output across each capacitor, consider two capacitors, C1 and C2, connected in series. The total capacitive reactance in the circuit can be expressed as:

The output voltage across C1 can thus be derived as:

Now simplifying yields:

This equation demonstrates how the voltage is dependent on the ratio of the capacitances, allowing for custom output voltages based on chosen capacitor values, assuming the input voltage and frequency remain constant.

Practical Applications

The capacitive voltage divider finds utility in various applications:

- Signal Conditioning: Used in sensor circuits where voltage levels must be adjusted without changing the signal characteristics.

- Device Protection: Employed to limit voltage levels that different circuit components may encounter, effectively reducing the risk of damage.

- Power Supply Design: Integral in the design of capacitive power supplies, where stable DC output is derived from AC input, with capacitors aiding in voltage regulation.

This understanding of capacitive voltage dividers is vital for engineers working on electronic circuit design, energy management, and various other applications in the field of electronics. The flexibility offered by choosing different capacitive values allows for innovative solutions in myriad technological contexts.

3.2 Current Flow in Capacitive Power Supplies

Understanding the current flow in capacitive power supplies requires a merging of theoretical insights and practical applications. Capacitive power supplies, also known as capacitive dropper supplies, are favored for their simplicity and effectiveness in certain low-power applications. We will explore the fundamental behavior of current through such networks, how this behavior influences circuit performance, and real-world applications. When analyzing current flow, we start with the capacitor's unique ability to store energy in the electric field created between its plates. Current in a capacitive circuit is not continuous in the way it is in resistive circuits. Instead, it varies periodically as the charge on the capacitor changes. To illustrate this, we consider an AC input voltage \(V(t) = V_m \sin(\omega t)\), where \(V_m\) represents the peak voltage and \(\omega\) the angular frequency of the alternating current. The relationship between the current \(I(t)\) through a capacitor and the voltage \(V(t)\) across it is given by: $$ I(t) = C \frac{dV(t)}{dt} $$ where \(C\) is the capacitance. Substituting the AC voltage function, we arrive at:3.3 Output Voltage Regulation Techniques

In a capacitive power supply, effective output voltage regulation is critical for maintaining reliability and performance in various applications, from consumer electronics to industrial systems. Output voltage regulation ensures that the voltage remains stable and within specified limits, minimizing the risk of damage to connected loads or circuit components. Several techniques employed to achieve this stability can be broadly categorized into methods that utilize feedback mechanisms, line voltage regulation, and load regulation.Feedback Regulation Techniques

One of the most prevalent strategies for output voltage regulation is feedback-based control. Here, the actual output voltage is continuously monitored and compared with a reference voltage. If there is a discrepancy, the system automatically adjusts the output to bring it back in line with the desired value. The two most commonly used feedback methods are:- Linear Voltage Regulators: These devices utilize a voltage reference and a series pass element (such as a transistor) to adjust the output based on varying load conditions. They are characterized by low output noise and simplicity, making them suitable for sensitive applications.

- Switching Regulators: Unlike linear regulators, switching regulators operate by rapidly switching the pass element on and off. This method minimizes power loss as energy is transferred in discrete packets rather than dissipated as heat. This approach can achieve higher efficiency, making them ideal for power-sensitive applications.

Line Voltage Regulation

Capacitive power supplies often face challenges when the input line voltage fluctuates. To maintain output voltage stability, line voltage regulation techniques can be employed. Two common methodologies include:- Voltage Clamping: Devices like metal-oxide varistors (MOVs) or zener diodes can clamp excessive voltage spikes that might lead to overvoltage conditions, thereby protecting sensitive electronics.

- Active Line Regulation: This involves feedback from the input voltage to dynamically adjust the output, usually in conjunction with linear or switching regulators. A primary example is the use of operational amplifiers in conjunction with power components to actively counteract line voltage variations.

Load Regulation

Load regulation focuses on maintaining steady output voltage under varying load conditions. The performance of a capacitive power supply can change with different load resistances, leading to output voltage drops or spikes. Several strategies to enhance load regulation include:- Output Filtering Capacitors: Larger capacitance values can buffer small changes in load, preventing voltage dips during sudden load increases. However, excessively large capacitors may lead to increased inrush current during power-up situations.

- Active Load Sharing: In multi-output systems, active load sharing circuits can balance the outputs among various regulators, ensuring that the load is evenly distributed and preventing voltage discrepancies.

Conclusion

Combining these techniques provides a robust solution for maintaining output voltage in capacitive power supplies, ensuring optimal performance in various applications. Engineers must consider the application requirements, efficiency goals, and component costs when designing an effective voltage regulation strategy, balancing trade-offs between performance and complexity. Through understanding these regulation techniques, professionals in the field can significantly enhance the reliability and efficiency of their capacitive power supply systems, ultimately leading to improved product performance and customer satisfaction.4. Low-Power Devices

4.1 Low-Power Devices

Capacitive power supplies, known for their efficiency and compactness, are increasingly being utilized in low-power applications. These devices leverage the principles of capacitance and voltage, transforming AC voltage into a usable DC output with minimal components. As technology evolves, low-power devices are paramount in sectors such as consumer electronics, wearable technology, and Internet of Things (IoT) devices.

Understanding Capacitive Power Supplies

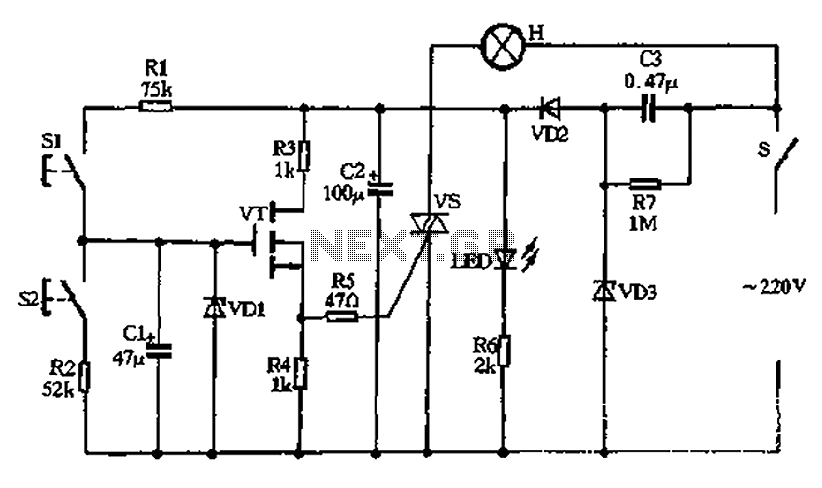

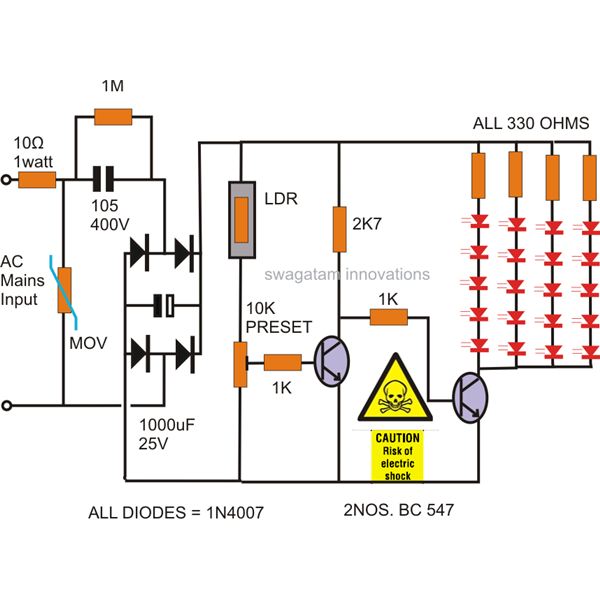

The basic principle of a capacitive power supply involves a capacitor that charges and discharges, providing an average output voltage. This process does not involve traditional transformer-based methods, thereby significantly reducing size and weight, which is essential for low-power devices. The circuit typically consists of an AC source, a capacitive reactance, a diode bridge rectifier, and a filter capacitor, wrapping up the functionality with a voltage regulator to ensure a stable output.

Key Components and Their Roles

- Capacitance: The key component that limits current flow, allowing for control over the output voltage. The value of the capacitor directly influences the load current and the output voltage level.

- Rectification: A diode bridge is utilized to convert AC to DC, allowing the circuit to produce a reasonably stable DC output from the AC input.

- Filtering: A filter capacitor smooths out the pulsating DC output from the rectifier, effectively reducing the ripple voltage observed.

- Voltage Regulation: To manage fluctuations, a voltage regulator is placed in the system, maintaining an output voltage suitable for the device’s operation.

Mathematical Formulation

The behavior of a capacitive power supply can be modeled with basic circuit theory. The voltage \( V \) across a capacitor is given by the formula:

where \( Q \) is the charge in coulombs, and \( C \) is the capacitance in farads. The current \( I \) can also be derived as:

In a capacitive power supply, if we assume a sinusoidal input voltage \( V_{in} = V_m \sin(\omega t) \), the effective output voltage (DC equivalent) can be approximated across the load as:

Real-World Applications

Low-power devices utilizing capacitive power supplies can be found in applications such as:

- LED lighting: Compact and efficient, capacitive supplies allow for effective voltage conversion in energy-saving lighting solutions.

- Mobile chargers: Many portable chargers encapsulate capacitive technology to charge small electronic devices efficiently.

- IoT sensors: The small footprint of capacitive power supplies suits devices that require low energy consumption while maintaining reliable operation over long cycles.

As functions become more integrated and the demand for efficiency grows, capacitive power supplies will undoubtedly play a crucial role in shaping the future of low-power device functionality.

4.2 Consumer Electronics

Capacitive power supplies have gained considerable attention in consumer electronics due to their unique characteristics, such as high efficiency, compact form factor, and the ability to operate without a transformer. Understanding their implementations in various consumer devices offers insights into modern electronic design and applications.

Capacitive Power Supply Fundamentals

At the core of capacitive power supplies is the principle of capacitive coupling, where AC voltage is transformed into a lower DC voltage suitable for powering low-energy devices. Unlike traditional transformer-based supplies, capacitive power supplies utilize capacitors to block direct current (DC) while allowing alternating current (AC) to pass through. This is accomplished through a straightforward circuit design incorporating a capacitor, a diode rectifier, and a filter capacitor.

The basic structure of such a power supply resembles the following:

- A capacitor (C) acts as the primary energy coupling element.

- A diode (D) rectifies the AC voltage generated by the capacitor.

- A filter capacitor smooths out the output voltage, providing a stable DC supply.

To derive the output voltage, consider the following relationships:

Here, \(V_{in}\) is the input voltage, and \(R_1\) and \(R_2\) are resistance values that determine the voltage division in the circuit. The efficiency of capacitive power supplies is largely dictated by the load conditions and the capacitor’s reactance.

Application in Consumer Electronics

Capacitive power supplies find widespread use in consumer electronics, particularly in devices requiring low power, such as:

- Wall adapters for charging devices like smartphones and tablets.

- LED lighting systems, which benefit from compact design and low heat generation.

- Bluetooth speakers or other portable audio devices, where space savings are critical.

For instance, within a smartphone charger, a capacitive power supply can efficiently convert the mains AC voltage to a usable DC voltage with minimal size and weight, thereby enhancing portability without sacrificing performance.

Real-World Example: Smartphone Chargers

The typical cellphone charger employs a component known as the capacitive divider. In a generic implementation, the charger consists of:

- A capacitive element that links directly to the mains voltage.

- A switching element to cater to the necessary voltage regulation.

- A filtering circuit to reduce output ripple.

This simplicity results in a lightweight, cost-effective solution without compromising safety regulations, provided they are designed within acknowledged standards.

Consideration and Safety

Despite their advantages, capacitive power supplies must be approached cautiously. Safety becomes a primary concern due to the high voltages involved. Engineers must ensure that isolation barriers meet regulatory standards to mitigate shock hazards during device operation. Components used in circuit design must also be rated for the expected voltage and current load to prevent failures.

Furthermore, thermal management should not be overlooked, as heightened temperatures can lead to capacitor degradation and failure. Adequate derating strategies are necessary to enhance reliability and longevity.

As consumer electronics continue to shrink in size and demand for energy efficiency grows, the role of capacitive power supplies will undoubtedly expand, intertwining with the ongoing evolution of electronics design.

4.3 Industrial Applications

The utilization of capacitive power supplies has surged in the industrial sector due to their operational efficiency, compact size, and versatility. Designed to handle various applications, these power supplies are integral in various industrial systems, delivering significant advantages over traditional power sources.

As industries strive for improved energy efficiency and lower operational costs, capacitive power supplies are often employed in applications requiring stable power conversion and excellent voltage regulation. Their design allows them to function effectively under different load conditions, making them particularly suitable for use in industries such as manufacturing, telecommunications, and renewable energy systems.

Manufacturing Industry

In the manufacturing sector, capacitive power supplies are primarily used in synchronization with automated systems and robotics. The inherent ability of capacitive power supplies to provide a smooth output voltage is vital for the accurate operation of frequency drives and programmable logic controllers (PLCs). This ensures that sensitive machinery operates reliably without the risk of voltage spikes, which can cause equipment damage or erratic performance.

Telecommunications

Telecommunications equipment demands reliability and efficiency, especially in signal processing and data transmission systems. Capacitive power supplies are favored in this sector for their compact design and ability to maintain stable voltage levels under varying load conditions. The integration of capacitive power supplies in base stations and data centers provides benefits such as reduced electromagnetic interference (EMI), which is crucial for maintaining signal integrity.

Renewable Energy Systems

As the world shifts towards sustainable energy sources, capacitive power supplies play a critical role in solar inverters and battery management systems. The ability of these supplies to effectively charge and discharge while maintaining high efficiency makes them ideal for energy storage solutions. In applications like solar energy harvesting, they help in converting and conditioning the DC output of solar panels to a usable AC form for grid integration or local consumption.

Case Study: Electric Vehicles

The automotive industry is witnessing a transformative shift with electric vehicles (EVs) becoming more mainstream. Capacitive power supplies are being used extensively in electric powertrains, where they provide the necessary voltage regulation and energy conditioning for the traction power controllers. By improving charge efficiency and reducing the weight of the power supply systems, capacitive technologies facilitate the development of lighter and more efficient EV designs, which ultimately enhance vehicle performance and range.

Future Trends

Looking towards the future, the adoption of advanced capacitive technologies in industrial applications is expected to grow. The advent of smart factories and Industry 4.0 concepts will likely necessitate more sophisticated capacitive power supply systems that can communicate with other devices to optimize energy use and improve operational efficiency. Integration with Internet of Things (IoT) technologies can further enhance monitoring and control capabilities, leading to smarter energy management solutions across various industries.

In conclusion, the diverse industrial applications of capacitive power supplies not only highlight their adaptability but also point towards a future that embraces efficiency, reliability, and sustainability. With ongoing advancements in technology, their role in shaping modern industries will only become more significant.

5. Maximum Load and Power Ratings

5.1 Maximum Load and Power Ratings

The performance of a capacitive power supply is intricately linked to its maximum load and power ratings. Understanding these parameters is essential not only for circuit design but also for ensuring reliable and efficient operation in real-world applications. This section delves into the principles governing these limits and how they affect the overall functionality of capacitive power supplies.

Understanding Maximum Load

The maximum load capacity of a capacitive power supply is determined by the voltage rating of the capacitors, the frequency of the AC input, and the overall design of the circuit. When assessing the maximum load, it is crucial to consider the effective load that the supply can handle without exceeding the voltage and current ratings of its components.

Load Calculation: The maximum load (in ohms) can be calculated using Ohm's law, which states that the current (I) through a circuit is directly proportional to the voltage (V) across it and inversely proportional to the resistance (R) of the circuit:

Where V is the supply voltage and Imax is the maximum current rating. This calculation provides insights into how much load the power supply can safely handle.

Power Ratings Explained

The power rating of a capacitive power supply reflects the maximum amount of power it can deliver safely without risking component failure. Power ratings take into account both the AC RMS voltage and the current capabilities, with the general formula for power being:

Where Pmax is the maximum power output, VRMS is the root mean square voltage, and IRMS is the root mean square current. This formula underscores the significance of choosing components that are rated for the operational conditions they will encounter.

Choosing the Right Components

In a capacitive power supply, the choice of capacitor types, such as electrolytic or ceramic, impacts both load capacity and power rating. Electrolytic capacitors, while generally offering higher capacitance values, may have lower voltage ratings and shorter lifetimes compared to ceramic options. Consequently, it is necessary to balance these factors against the expected operational environment.

Practical Implications

Real-world applications such as power supplies for industrial equipment, lighting systems, and consumer electronics depend on precise calculations of maximum load and power ratings. For instance, consider a capacitive power supply used in LED lighting. If the estimated load exceeds the maximum load rating, it can lead to component failure, overheating, or reduced efficiency. Therefore, engineers must ensure that their designs incorporate safety margins and consider transient behaviors in loads.

By accurately determining maximum load and power ratings, designers can enhance the reliability and performance of capacitive power supplies, making them suitable for a wide array of applications in modern electronic devices.

5.2 Safety Precautions and Potential Hazards

When discussing capacitive power supplies, rigorous attention must be paid to safety precautions and potential hazards that may arise during their operation. Capacitors, as critical components of these systems, store and release electrical energy, which can lead to hazardous situations if they are not handled correctly. One of the primary dangers associated with capacitive power supplies is electrical shock. Capacitors can retain charge long after the power supply has been turned off, particularly in large capacitors used for applications such as energy storage or power conditioning. The discharge of stored energy can be lethal. To mitigate this risk, engineers must ensure proper discharge circuits are incorporated and clearly marked on equipment enclosures. Additionally, overvoltage conditions can pose substantial dangers. If capacitors are subjected to voltages above their rated values, they can fail catastrophically, often resulting in explosions, release of toxic fumes, and physical damage to surrounding components. Engineers must thus engage in thorough design reviews and validate operational conditions, incorporating voltage protection devices such as surge suppressors. Another significant concern is thermal management. Capacitors generate heat during operation, particularly under high-frequency conditions or when undergoing rapid charging and discharging cycles. Excessive heat can lead to premature failure or even explosion. The integration of heat sinks or cooling fans can be vital in mitigating this risk. Thermal sensors can also be utilized in more advanced systems to monitor temperature and trigger systematic shutdowns when limits are approached. Moreover, the choice of dielectric material in capacitors affects their safety profiles. For example, electrolytic capacitors can fail if incorrectly oriented or if subjected to reverse polarity. Instances of installations involving high ripple currents or exposure to high temperatures can also lead to failure. Thus, engineers must ensure proper consultation of datasheets and compliance with manufacturer specifications when designing circuits. To provide practical relevance, consider the use of capacitive power supplies in renewable energy systems such as photovoltaic setups. The transition from direct current (DC) generated by solar panels into alternating current (AC) used in homes often involves capacitive power supply units. Here, safety precautions become paramount; a sudden failure could not only disrupt power distribution but also endanger technicians involved in system maintenance. In summary, adhering to robust safety protocols is indispensable when working with capacitive power supplies. This involves not only understanding the operating characteristics of the components but also incorporating design elements that prioritize user and system safety. Engineers must be diligent in evaluating both system configurations and environmental conditions to minimize potential hazards.Key Safety Guidelines

- Always discharge capacitors fully before working on circuits.

- Use appropriate personal protective equipment (PPE)—gloves and goggles are recommended.

- Employ voltage rating suitable for project specifications. Consider using capacitors with higher voltage ratings than required.

- Integrate appropriate thermal management solutions into designs.

- Be aware of dielectric polarity and ensure correct component orientation during installation.

5.3 Regulatory Standards for Capacitive Supplies

In the development and implementation of capacitive power supplies, compliance with regulatory standards is not merely a formality; it is essential for ensuring safety, functionality, and environmental sustainability. This subsection examines various regulatory frameworks that engineers and designers should consider when designing capacitive power supplies, emphasizing both regional and international standards.

Understanding Regulatory Standards

Regulatory standards serve multiple purposes, including establishing specifications for safety, performance, and interoperability. They are strategically important for market access and consumer trust. The standards applicable to capacitive power supplies include those from organizations such as:

- International Electrotechnical Commission (IEC) — Focused on international electrical and electronic standards.

- Institute of Electrical and Electronics Engineers (IEEE) — Provides guidelines predominantly relevant to electrical engineering practices.

- Underwriters Laboratories (UL) — Concentrates on product safety testing and certification.

Key International Standards

Several key standards are particularly relevant to capacitive power supplies:

- IEC 61000-3-2 — This standard relates to harmonic current emissions and outlines limits that devices like capacitive power supplies must adhere to, ensuring minimal interference with other electrical devices.

- IEC 60950-1 — This standard defines safety requirements for Information Technology Equipment, including capacitive power supplies, to protect against electric shock and fire hazards.

- UL 60950-1 — The UL counterpart to IEC 60950-1, it incorporates safety provisions specifically important in North America.

Safety and Performance Compliance

Compliance with these standards not only ensures safety but also affects the performance metrics of capacitive power supplies. For instance, the requirements regarding electromagnetic compatibility not only prevent interference with sensitive equipment but also improve product reliability in real-world applications.

To ensure compliance, manufacturers often conduct rigorous testing through certified laboratories, often replicating operational conditions that might be encountered in actual use. This thorough testing is crucial in fortifying the credibility of the product and ensuring peace of mind for end-users.

Regional Regulatory Bodies

In addition to international standards, various regional regulatory bodies impose specific requirements that must be adhered to:

- Federal Communications Commission (FCC) in the U.S. — Focused on regulating electromagnetic interference, it ensures that capacitive power supplies do not disrupt communication devices.

- European Committee for Electrotechnical Standardization (CENELEC) — Develops standards across Europe, promoting both safety and efficiency.

Practical Relevance of Regulatory Compliance

Understanding and integrating these standards into the design process of capacitive power supplies can significantly enhance the marketability of the product. It not only expands the operational territory by meeting legal requirements but also builds consumer confidence. For instance, safety certifications can be prominently displayed on the product, reassuring users of its compliance and reliability.

Furthermore, a non-compliance incident could lead to product recalls, legal liabilities, and significant financial losses. Therefore, proactively addressing these standards should be a core aspect of any designer or engineer's approach when working with capacitive power supplies.

In conclusion, awareness and understanding of both international and regional regulatory standards are integral for the successful deployment of capacitive power supplies. This conscientious approach not only guarantees compliance but also ensures that products are safe, efficient, and ready to meet consumer demands in various markets.

6. Common Faults and Indicators

6.1 Common Faults and Indicators

In the realm of capacitive power supplies, understanding the potential faults and their indicators is essential for ensuring reliable operation and longevity of the system. Capacitive power supplies utilize capacitors not only for energy storage but also for adjusting voltage and providing electrical isolation. However, these components can fail, and the indicators of these failures can sometimes be subtle, requiring a keen understanding to diagnose accurately.

Capacitor Failures and Their Symptoms

Capacitors can experience a variety of failure modes, each with its distinct set of symptoms. Common faults include:

- Dielectric Breakdown: This failure occurs when the insulating material between capacitor plates becomes conductive. Symptoms include overheating, bulging, and leakage of electrolyte in electrolytic capacitors, often leading to complete failure.

- Capacitance Drift: Over time, a capacitor may lose its specified capacitance due to aging, temperature changes, or operational stress. This drift can cause the power supply to output incorrect voltage levels, leading to failures in connected devices.

- ESR Increase: The equivalent series resistance (ESR) of capacitors can increase due to aging or overheating, leading to lower efficiency and increased heat generation. A significant increase in ESR can lead to overheating and reduced operational capabilities.

Indicators of Failure

Recognizing the indicators of these failures is critical for diagnosis. Key indicators include:

- Voltage Ripple: An increase in ripple voltage can suggest that capacitors are unable to perform their filtering function efficiently. This can be observed using an oscilloscope.

- Burnt Smell and Visual Inspection: A burnt smell or visual signs of damage, such as charring or discoloration on or around the capacitor, is a clear signal of failure.

- Thermal Imaging: Utilizing thermal cameras, technicians can identify hot spots on circuit boards, which may indicate faulty capacitors struggling to maintain their operational parameters.

Testing and Diagnosis

When a fault is suspected, some methods can be implemented to diagnose issues effectively:

- Capacitance Meter: Using a capacitance meter to verify the actual capacitance against the nominal value can help pinpoint drift issues.

- ESR Meter: This tool measures the ESR of capacitors, allowing quick identification of those that have degraded beyond acceptable limits.

- Leakage Current Measurement: High leakage current can be indicative of dielectric breakdown and can be measured with appropriate testing setups.

In summary, the health of a capacitive power supply hinges on the performance of its capacitors. Diagnosing faults early can prevent extensive damage to both the capacitors and the broader power supply system, enhancing reliability and operational stability. As you work with capacitive power supplies, keeping an eye out for these common failures and indicators can save time and resources in the long run.

6.2 Diagnostic Tools and Techniques

The complexity and operating principles of capacitive power supplies necessitate the use of precise diagnostic tools and techniques for effective analysis, troubleshooting, and optimization. Understanding the tools available to us enhances our ability to diagnose potential issues quickly and accurately, ultimately leading to improved reliability and performance. This section delves into various techniques, ranging from basic measuring instruments to sophisticated diagnostic methodologies used in the field.

Understanding the Role of Diagnostic Tools

Diagnostic tools play a pivotal role in assessing the health and functionality of capacitive power supplies. Key instruments utilized in this process include:

- Multimeters: Essential for measuring voltage, current, and resistance, multimeters can be used to ensure that the capacitive power supply is providing the expected output.

- Oscilloscopes: These provide visual representations of voltage waveforms, allowing for analysis of dynamic performance characteristics, ripple voltage, and transient responses.

- Function Generators: Useful for simulating input conditions and assessing the response of the power supply, particularly under varying loads.

- Capacitance Meters: Used to verify the capacitance values of the components involved, ensuring that they meet the specified ratings.

Basic Diagnostic Techniques

To effectively utilize these instruments, it is essential to implement structured diagnostic techniques:

- Routine Measurements: Performing routine checks using multimeters to ensure stability in voltage and current outputs. Any deviation from expected values could indicate component degradation.

- Waveform Analysis: Using oscilloscopes to evaluate the output waveform against expected profiles. Key parameters to analyze include the amplitude, frequency, and presence of unwanted noise or oscillations.

- Load Testing: Applying various resistive loads under controlled conditions to observe how the capacitive power supply reacts to sudden load changes and to assess its performance during these events.

Advanced Diagnostic Techniques

As power supply designs become more complex, advanced techniques may be required:

- Thermal Imaging: Infrared cameras can detect hotspots that may indicate failure points due to overheating components, which is invaluable for preventive maintenance.

- Signal Integrity Analysis: In high-frequency applications, analyzing signal integrity over interconnects helps in identifying issues that might cause performance degradation.

- Root Cause Analysis (RCA): Following systematic approaches to find the underlying causes of repeated failures, which can include fault tree analysis or the Ishikawa diagram method, can significantly improve maintenance strategies.

Real-World Applications

Effective application of these diagnostic tools and techniques is critical in scenarios such as:

- Renewable Energy Systems: Capacitive power supplies are integral to solar inverters and wind turbines. Diagnosing their performance ensures energy conversion efficiency.

- Medical Devices: Precision is paramount in medical electronics. Regular diagnostics help maintain device functionality, thereby ensuring patient safety.

- Consumer Electronics: Performance testing in everyday devices can lead to insights on improving efficiency and battery life, extending the lifetime of products.

Incorporating these diagnostic tools and techniques fosters a thorough understanding of capacitive power supplies, providing the foundation for innovative designs and effective troubleshooting methodologies. Ultimately, they are indispensable assets for engineers and researchers aiming to push the boundaries of efficiency and reliability in electronic systems.

6.3 Repair vs. Replacement Considerations

In the realm of capacitive power supplies, the decision between repairing a faulty component and replacing it entirely is one of significant importance. Depending on factors such as cost, efficiency, and reliability, engineers and technicians must weigh the options carefully.Understanding Failures

Capacitive power supplies, like all electronic devices, are prone to failures. These failures can arise from various culprits, including component degradation due to thermal stress, electrical overstress, or manufacturing defects. Identifying the root cause of a failure is crucial in deciding whether to repair or replace. For instance, capacitor failure often manifests as leakage or bulging, indicating that replacement might be necessary. On the other hand, a simple circuit board crack could potentially be repaired with soldering techniques.Cost-Benefit Analysis

When considering repair versus replacement, a thorough cost-benefit analysis must be conducted. Repairing components often incurs lower immediate costs; however, recurring failures can lead to increased long-term expenses. In contrast, newer replacement components may offer improved efficiency and reliability, potentially reducing operating costs and maintenance frequency. From a financial perspective, one might represent the total cost (\( C \)) associated with repair or replacement using the equation:Reliability and Lifecycle Considerations

Reliability is another crucial factor that significantly influences the decision-making process in repair versus replacement scenarios. Systems that operate in critical applications, such as medical devices or aerospace systems, may not afford the risk of using repaired components, particularly if those components have historically shown a high failure rate. It becomes a question of safety versus economy. A reliability analysis might involve calculating the Mean Time Between Failures (MTBF):Real-World Applications and Case Studies

In practical scenarios, various industries offer insights into this dilemma. For instance, in automotive electrics, a faulty capacitor in a charging system may lead technicians to replace the entire power supply unit to ensure optimal functioning. However, in consumer electronics, a simple solder fix might suffice for a failed capacitor, especially in products with shorter life cycles. The aerospace sector tends to follow stringent regulatory guidelines that may mandate component replacement, ensuring that only the highest quality parts are used for flight systems.Conclusion

In conclusion, the decision between repair and replacement in capacitive power supplies hinges on a careful assessment of costs, reliability, and operational impact. Knowing when to choose repair or replacement can help save costs while also maintaining the integrity and performance of electrical systems, underscoring the importance of this evaluation in both engineering and practical applications. Examining industry case studies offers further clarity, allowing engineers to draw parallels and lessons from real-world situations to inform their judgment in subsequent decisions regarding capacitive power supply management.7. Emerging Technologies and Innovations

7.1 Emerging Technologies and Innovations

As the demand for efficient power supply systems increases, various innovations in capacitive power supply technology emerge, pushing the boundaries of capability and application. Recent developments focus not only on enhancing performance metrics but also on addressing environmental concerns and system integration. These advancements indicate a shift towards sustainable and compact energy solutions that could revolutionize different domains.

Advancements in Capacitor Materials

New capacitor technologies that utilize advanced materials are a keystone for enhancing the energy density and reducing the size of the capacitive power supplies. Nanotechnology and polymer composites are being integrated into capacitor designs, potentially leading to capacitors with significantly higher capacitance per unit volume. This can be mostly attributed to:

- Graphene-Based Capacitors: Utilizing graphene, which has exceptional conductivity and surface area, leads to the development of supercapacitors that can store greater amounts of energy while maintaining fast charge/discharge capabilities.

- Solid-State Capacitors: These capacitors replace liquid and gel electrolytes with solid materials, which not only enhances safety by reducing the risk of leakage but also promotes higher operational temperatures and improved life cycle stability.

Emerging Topologies and Architectures

Another focus area in capacitive power supplies is the development of innovative circuit topologies that enhance efficiency. Multi-level converters are becoming commonplace, designed to manage the energy stored in capacitive systems more effectively. These converters can significantly reduce the stress on components and thus improve reliability.

Such advancements are particularly pertinent in the realm of renewable energy systems, where Variable Frequency Drives (VFDs) are used in wind and solar applications. Here, innovative topologies can increase the overall power quality while minimizing harmonic distortions.

Integrating Power Electronics and Capacitive Energy Storage

Recent trends also point toward the integration of power electronics with capacitive energy storage systems. By coupling power electronics directly with capacitive systems, engineers can create smart grids that dynamically allocate power based on real-time demand. This approach facilitates:

- Dynamic Voltage Control: Systems can adapt to fluctuations in the load without compromising stability, thereby improving efficiency across the infrastructure.

- Enhanced Grid Stability: Capacitors can provide ancillary services such as frequency regulation, which is critical for areas heavily relying on intermittent renewable energy sources.

Applications in Electric Vehicles and Consumer Electronics

The implications of these emerging technologies extend to practical applications, particularly in electric vehicles (EVs) and portable consumer electronics. Supercapacitors alongside conventional battery systems are now being explored, where they can handle peak power demands during acceleration or during the operation of high-drain appliances. This dual-system configuration not only enhances efficiency but also prolongs battery life.

Furthermore, wearables and IoT devices are beginning to integrate micro-capacitor technologies, achieving a balance between size and storage capabilities, which is essential as these devices continue to shrink in form factor while expanding functionality.

Conclusion

In summary, the emerging technologies in capacitive power supplies are poised to influence a wide range of applications from consumer electronics to large-scale renewable energy systems. The advancements in materials, circuit architectures, and integration methods offer promising pathways to more efficient, reliable, and sustainable power solutions.

7.2 Integration with Renewable Energy Sources

The integration of capacitive power supplies with renewable energy sources represents a transformative approach to energy management. This synergy not only furthers sustainability but also enhances the efficiency and reliability of energy systems. In this section, we will delve into how capacitive power supplies can be utilized in conjunction with various renewable energy sources such as solar panels and wind turbines. Understanding this integration opens up pathways for innovative applications and advanced energy solutions.

Understanding Capacitive Power Supplies

Capacitive power supplies operate by storing electrical energy in an electric field, created by a pair of conductive plates separated by an insulating material (dielectric). Unlike conventional power supplies that rely on electrochemical sources, capacitors deliver rapid bursts of energy, making them suitable for applications requiring dynamic load handling. Their compact size and high power density are particularly advantageous when integrated with renewable energy technologies.

Applications in Renewable Energy Systems

When interfacing with renewable energy sources, capacitive power supplies enhance performance in several key areas:

- Energy Storage: Capacitors can temporarily store excess energy generated during peak production hours (e.g., sunny or windy conditions), thereby stabilizing output and providing power during intermittent generation periods.

- Power Quality Improvement: By smoothing voltage fluctuations and reducing harmonics, capacitors help maintain the integrity of power flow, which is crucial in distributed generation systems.

- Transient Response: Capacitive power supplies can quickly respond to changes in load demand, improving the resilience of the energy supply chain.

Integration with Solar Energy Systems

In solar energy systems, capacitors can play pivotal roles in two primary configurations: standalone energy storage and grid-tied applications. A common application involves pairing capacitive storage with solar inverter systems. Here, capacitors can buffer the irregularities in energy production, thus ensuring a stable supply to the grid.

The equation governing the energy stored in a capacitor is given by:

Where:

- E: Energy stored (in joules)

- C: Capacitance (in farads)

- V: Voltage across the capacitor (in volts)

Case Study: Solar-Powered Capacitive Store

A notable example is the installation of capacitive power supplies in solar microgrid systems, particularly in rural areas where grid access is limited. By integrating capacitors to store energy from solar panels, these systems provide continuous power to homes and businesses. This not only enhances energy reliability but also contributes to cost savings by reducing dependence on diesel generators.

Integration with Wind Energy Systems

Similar to solar energy applications, capacitors can improve the efficiency of wind turbines by providing instantaneous power to the generator during periods of fluctuating wind speeds. This optimizes the overall output and reduces wear on the turbine mechanisms. Employing capacitive storage alongside traditional battery systems can lead to a more effective storage strategy, thereby increasing the reliability of wind energy supply.

When analyzing the dynamics of wind-powered systems, consider that the output power from a wind turbine can be expressed as:

Where:

- P: Power output (in watts)

- ρ: Air density (in kg/m3)

- A: Swept area of the turbine (in m2)

- v: Wind speed (in m/s)

Conclusion

Integrating capacitive power supplies with renewable energy sources offers profound benefits in energy storage, power quality, and transient response capabilities. As the demand for sustainable energy solutions grows, these technologies will be pivotal in advancing the efficiency and resilience of renewable energy systems. By adopting a capacitive approach, engineers and researchers can pave the way for innovative energy management solutions that address both current and future challenges in energy sustainability.

8. Key Texts and Books on Capacitive Power Supplies

8.1 Key Texts and Books on Capacitive Power Supplies

- Capacitive Power Supplies: Principles and Applications — This book provides an in-depth analysis of the fundamental principles underlying capacitive power supplies, along with discussions of advanced applications in modern electronics.

- Capacitive Power Transfer for Electric Vehicles — An IEEE article that examines the application of capacitive power transfer in electric vehicle charging systems, offering insights into efficiency improvements and system integration.

- Introduction to Capacitive Power Supplies — This introductory text covers the basics of capacitive power supply design, focusing on case studies and practical considerations for building robust electrical systems.

- Design and Analysis of Control Circuits for Capacitive Power Supplies — A comprehensive resource discussing the control circuit design and theoretical underpinnings of capacitive power supplies, suitable for practicing engineers and researchers.

- Wide Application of Capacitive Power Supplies in Engineering — A broad overview of how capacitive power supplies are used in various engineering fields, illustrated with practical examples and case studies.

- Advanced Design Techniques for DC-DC Converters — While focusing on DC-DC converters, this book provides valuable insights into integrating capacitive elements to enhance converter performance and efficiency.

- ASME Resources on Capacitive Power Supplies — The ASME digital collection offers several publications and resources that explore capacitive power supply technologies and advancements in industrial applications.

8.2 Research Papers and Articles

- Efficient Energy Conversion with Capacitive Power Supply — This paper explores the use of capacitive power supplies for energy conversion, emphasizing their applications in low-power devices. It includes experimental results validating the theoretical models.

- Capacitive Power Extraction with Practical Implementation — Focused on the design and implementation of capacitive power supplies for household electronics, this article covers theory and practical case studies to demonstrate efficiency improvements.

- Recent Advances in Capacitive Power Supply Technology — An in-depth review of recent advancements, offering a detailed analysis on components, design considerations, and future technologies associated with capacitive power supplies.

- Capacitive Power Supply Design for Energy Efficiency — This chapter discusses energy-efficient practices in the design of capacitive power supplies, including component selection and circuit configuration techniques that maximize performance.

- Passive Components in Capacitive Power Supplies — An article focusing on the role of passive components in capacitive power supplies, covering aspects such as capacitance calculation, thermal performance, and failure modes.

- Understanding Capacitive Power Supplies — This educational resource provides foundational knowledge on capacitive power supplies, suitable for both introductory learning and reference for advanced designs.

- Impact of Temperature on Capacitive Power Supply Performance — Investigates how temperature variations affect the performance of capacitive power supplies, with an emphasis on reliability and efficiency metrics under different environmental conditions.

8.3 Online Resources and Tutorials

For engineers, physicists, researchers, and graduate students looking to deepen their understanding of capacitive power supplies, there are several high-quality online resources and tutorials available. These resources cover a range of topics, including design principles, practical applications, and mathematical foundations. Below is a curated list of valuable links for further study:

- Electronic Design - Capacitive Power Supply Overview — This article provides an in-depth introduction to capacitive power supplies, discussing their design, advantages, and potential drawbacks.

- YouTube - Capacitor Power Supply Tutorial — A video tutorial that explores the assembly and functioning of capacitive power supplies, complete with visual demonstrations and a comprehensive explanation of the theory behind them.

- EDN Network - Designing Capacitive Power Supplies — This resource provides guidelines for designing efficient capacitive power supplies, highlighting the challenges and performance considerations in real-world applications.

- ScienceDirect - Research on Capacitive Power Supplies — An in-depth journal article examining the latest research innovations and theoretical advancements in the field of capacitive power supplies.

- All About Circuits - Capacitive Power Supply Basics — Offers a comprehensive tutorial on the basics of capacitive power supplies, including component selection, circuit design, and safety considerations.

- SparkFun - Capacitive Power Supply Tutorial — A hands-on guide that walks through the process of constructing a capacitive power supply, complete with schematics and component lists.

- Texas Instruments - Capacitive Power Supply Application Notes — Comprehensive application notes from TI detailing the implementation and optimization of capacitive power supplies in various applications.