Cimbali D/1 circuit hack

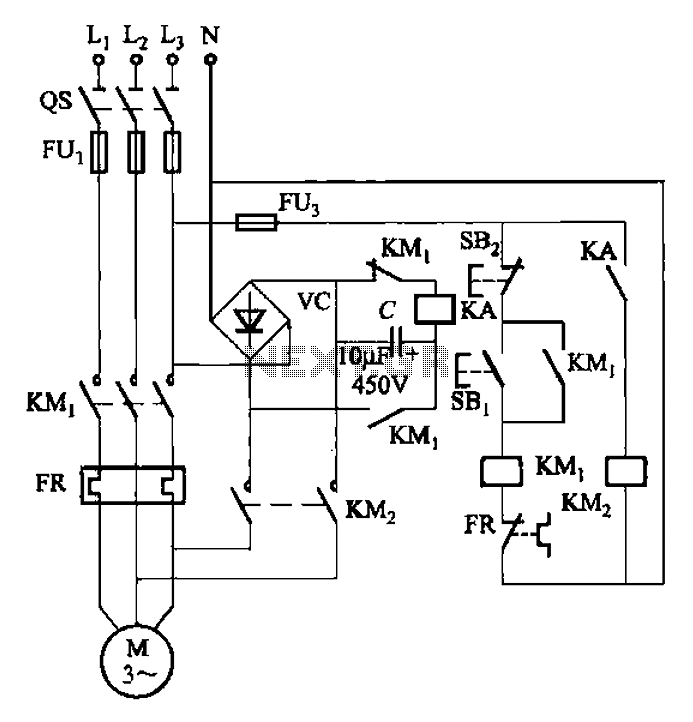

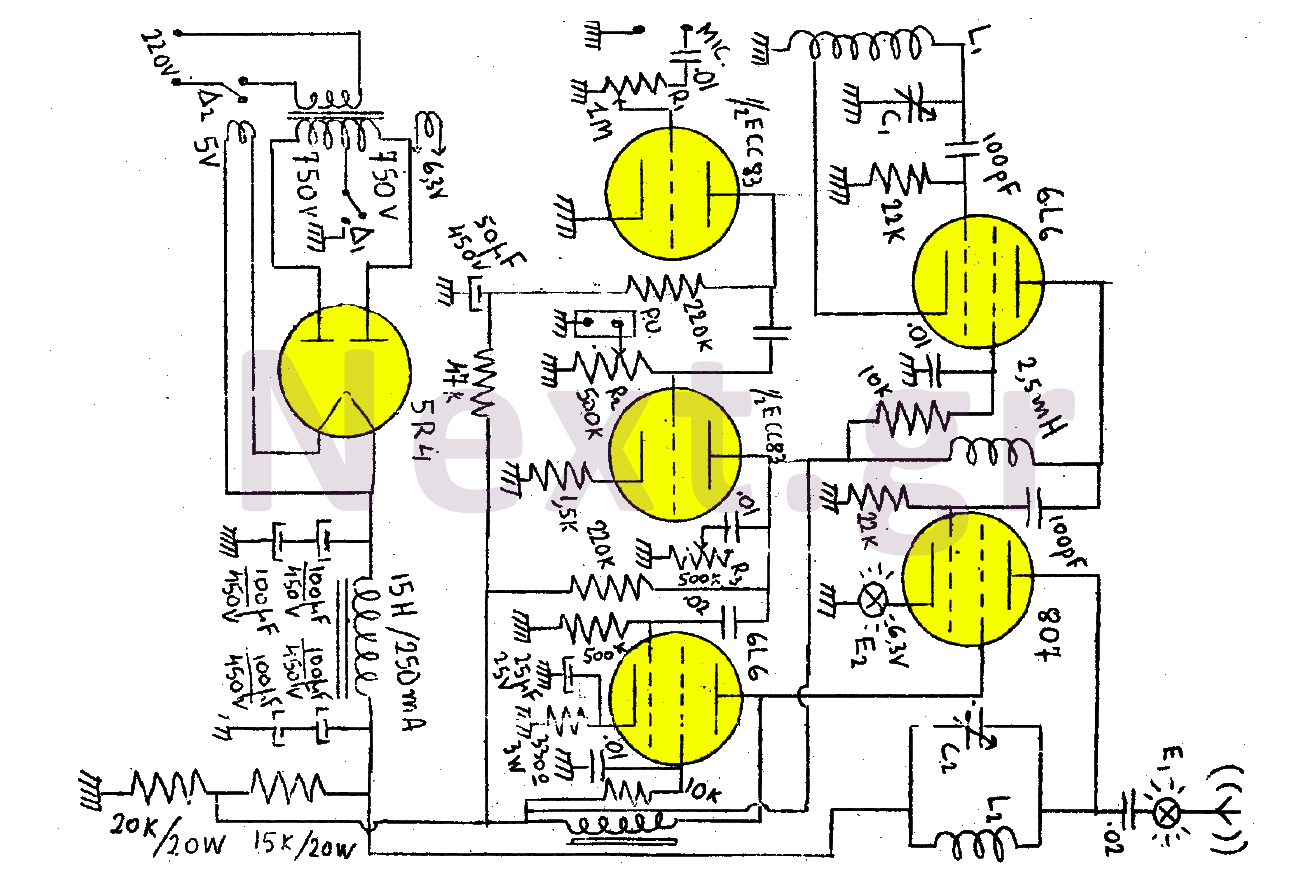

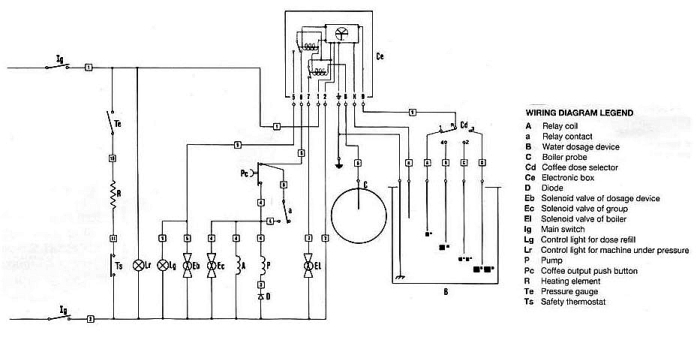

The pump is designed to stop only when the volume set by the four-position selector switch has been reached. However, it will also stop if certain conditions are met. Pressing the brew button (`Pc`) momentarily closes the circuit, sending power to the group solenoid (`Ec`), the pump (`P`), and the relay coil (`A`), which closes the relay contact (`a`). This action sends power to the electronics box (`Ce`), where other relays maintain power to the group solenoid, pump, and relay coil even after the brew button is released. Pressing the brew button again while the pump is operating will not have any effect, as the relay contact remains closed until the water level set by the coffee dose selector (`Cd`) is reached. The M30 Dosatron operates similarly, with five buttons for each group—four for dosing and one for off/on. To stop a preset dose, the off/on button must be pressed rather than the dose button used to initiate it. In contrast, the La Spaziale Rapid EK allows starting and stopping any dose with the same button or the off/on button. There is uncertainty as to why Cimbali chose this design, and there is interest in modifying it to operate like the La Spaziale model. Initially, there was an instinct to stop the brew by pressing the brew button a second time upon seeing the brew go blonde, but this has led to ongoing issues. According to the manual, backflushing must be performed by turning off the machine during a shot due to the lack of shot interruption. After doing this, the boiler did not stop filling, leading to unresolved issues. The solenoid valve is functioning properly as disconnecting it stops the boiler from filling. The water quality is sufficient for the probe to detect the water level. The suspicion lies with the electronics regulating the solenoid for boiler fill, but there is insufficient familiarity with the electronics. The machine is rarely used now due to the auto-fill being disabled. Suggestions for improvement are welcomed, and a request for a clearer electronic diagram has been made, as the current one is illegible. The inability to simply turn the pump on and off for quick tasks, such as making a ristretto or cleaning, is viewed as inconvenient. Backflushing is done with a blind filter or equivalent, brewing a shot and turning off the machine after a few seconds, which has been successful. It is advised to ensure all connections to the boiler level probe are intact and clean. If the auto-fill does not stop, it may appear as if the probe is disconnected. A suspected doser solenoid valve malfunction was tested by disconnecting it and connecting it to 220V, which indicated that the solenoid was not malfunctioning. With low water pressure and solenoid issues ruled out, attention was directed to the electrical box under the drip tray, where a smaller black box is located.

The described system involves a pump control mechanism that relies on a four-position selector switch, a brew button, and a relay system to manage the operational state of the pump and solenoid. The relay contact is a crucial component that maintains the power supply to the pump even after the initial activation through the brew button. The functionality of the system is designed to ensure that the pump only operates within the predetermined volume range, enhancing the precision of the brewing process.

In a typical schematic of this system, the brew button (`Pc`) would be connected to a relay that, when activated, energizes the group solenoid (`Ec`), the pump (`P`), and the relay coil (`A`). The relay contact (`a`) would be depicted as a normally open (NO) contact that closes upon activation, allowing current to flow to the electronics box (`Ce`). The electronics box would contain additional relays that maintain the operational state of the pump and solenoid until the coffee dose selector (`Cd`) indicates that the desired water level has been achieved.

The backflushing procedure and the issue with the boiler fill can be represented in the schematic by including the boiler level probe, which signals the electronics to control the solenoid valve for the boiler fill. If the probe is malfunctioning or disconnected, the system may continuously fill the boiler, leading to potential overflow or operational issues.

To address the problems encountered, it is critical to ensure that all electrical connections are secure, particularly those related to the boiler level probe. Additionally, understanding the circuitry within the electronics box may provide insights into the functioning of the solenoid and the relay system. A detailed electronic diagram would facilitate troubleshooting and modifications to enhance the system's functionality, possibly allowing for more intuitive operation similar to other models such as the La Spaziale.By design, the pump will stop only if the volume set by the four position selector switch has been reached. Notwithstanding, it will also stop if: From what I think I understand, pressing `Pc` (brew button) sets it `closed` momentarily, sending power to `Ec` (group solenoid), `P` (pump) and `A` (relay coil) which sets `a` (relay contact) to `closed`.

This sends power to `Ce` (electronics box) where other relay/s take over, maintaining power to `Ec` (group solenoid), `P` (pump) and `A` (relay coil) after `Pc` returns to `open` when you let it go. Pressing `Pc` (brew button) again while the pump is working will not do anything as `a` (relay contact) will remain `closed` till the water level set by `Cd` (coffee dose selector) is met.

My M30 Dosatron operates in the same way. Each group has 5 buttons - 4 dosing and one off/on. In order to stop a preset dose you have to press the off/on button and not the dose button you pressed to initiate it. My La Spaziale Rapid EK operates differently. You can start and stop any dose with the same button or the off/on button. I`m not sure why Cimbali opted this route but if there is a way to modify it to operate like the LaSpaz then I would love to try it out.

To the extent of, when I first installed it, automatically and without a second thought insisting on stopping the brew by hitting the brew button a second time as I saw it go blonde. Still haven`t found another solution for the problem. But have encountered another problem. According to the manual (one sent to me through mail by Jorgen) backflushing has to be done by switching of the machine during a shot.

This of course because there is no shot interruption. The second time I did this my boiler would not stop filling. A problem I still haven`t managed to solve. The solenoid valve is not stuck because once I disconnect it the boiler stops filling. The water is also hard enough for the probe to detect the water level. Only thing I can think of is the electronics, regulating the solenoid of the boiler fill. There lies the problem: I am not familiar enough with the electronics. Now only on special occasions have I used this beautiful refurbished machine by disabling the auto fill. Any suggestions Also, could you (civ) send me the file with the electronic diagram, my copy is so poorly scanned that it is illegible.

I`ll PM you with my e-mail address. I find it rather annoying (used to less expensive/elaborate home machines) that I cannot just turn on/off the pump, be it to make a ristretto on the fly or clean the screen/pf with `just` a squirt of water. I do my backflushing by putting a blind filter or equivalent and brewing a shot, which I cut short (as per the manual`s instructions) by turning the machine off after a few seconds and repeat this a couple of times, waiting a few moments between each time.

No problems. I think you should try and make sure that all the connections to the boiler level probe are intact and that the probe is clean. It the autofill does not stop, it`s as if the probe were disconnected. I then suspected a doser solenoid valve malfuncion, so with the machine `unplugged` (read again: unplugged, ok ) I disconnected the lugs to the solenoid and connected them to 220v.

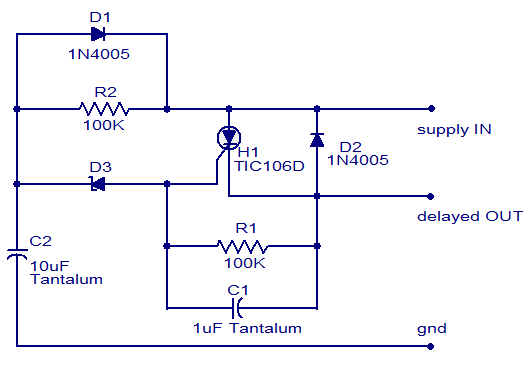

At that point, the deposit started to fill so a solenoid malfunction (stuck or with a dead coil) was ruled out. Not being low water pressure problem or solenoid malfunction the next thing was to follow the black cables to the electricals box under the drip tray, where you will find yet another much smaller black box

🔗 External reference

The described system involves a pump control mechanism that relies on a four-position selector switch, a brew button, and a relay system to manage the operational state of the pump and solenoid. The relay contact is a crucial component that maintains the power supply to the pump even after the initial activation through the brew button. The functionality of the system is designed to ensure that the pump only operates within the predetermined volume range, enhancing the precision of the brewing process.

In a typical schematic of this system, the brew button (`Pc`) would be connected to a relay that, when activated, energizes the group solenoid (`Ec`), the pump (`P`), and the relay coil (`A`). The relay contact (`a`) would be depicted as a normally open (NO) contact that closes upon activation, allowing current to flow to the electronics box (`Ce`). The electronics box would contain additional relays that maintain the operational state of the pump and solenoid until the coffee dose selector (`Cd`) indicates that the desired water level has been achieved.

The backflushing procedure and the issue with the boiler fill can be represented in the schematic by including the boiler level probe, which signals the electronics to control the solenoid valve for the boiler fill. If the probe is malfunctioning or disconnected, the system may continuously fill the boiler, leading to potential overflow or operational issues.

To address the problems encountered, it is critical to ensure that all electrical connections are secure, particularly those related to the boiler level probe. Additionally, understanding the circuitry within the electronics box may provide insights into the functioning of the solenoid and the relay system. A detailed electronic diagram would facilitate troubleshooting and modifications to enhance the system's functionality, possibly allowing for more intuitive operation similar to other models such as the La Spaziale.By design, the pump will stop only if the volume set by the four position selector switch has been reached. Notwithstanding, it will also stop if: From what I think I understand, pressing `Pc` (brew button) sets it `closed` momentarily, sending power to `Ec` (group solenoid), `P` (pump) and `A` (relay coil) which sets `a` (relay contact) to `closed`.

This sends power to `Ce` (electronics box) where other relay/s take over, maintaining power to `Ec` (group solenoid), `P` (pump) and `A` (relay coil) after `Pc` returns to `open` when you let it go. Pressing `Pc` (brew button) again while the pump is working will not do anything as `a` (relay contact) will remain `closed` till the water level set by `Cd` (coffee dose selector) is met.

My M30 Dosatron operates in the same way. Each group has 5 buttons - 4 dosing and one off/on. In order to stop a preset dose you have to press the off/on button and not the dose button you pressed to initiate it. My La Spaziale Rapid EK operates differently. You can start and stop any dose with the same button or the off/on button. I`m not sure why Cimbali opted this route but if there is a way to modify it to operate like the LaSpaz then I would love to try it out.

To the extent of, when I first installed it, automatically and without a second thought insisting on stopping the brew by hitting the brew button a second time as I saw it go blonde. Still haven`t found another solution for the problem. But have encountered another problem. According to the manual (one sent to me through mail by Jorgen) backflushing has to be done by switching of the machine during a shot.

This of course because there is no shot interruption. The second time I did this my boiler would not stop filling. A problem I still haven`t managed to solve. The solenoid valve is not stuck because once I disconnect it the boiler stops filling. The water is also hard enough for the probe to detect the water level. Only thing I can think of is the electronics, regulating the solenoid of the boiler fill. There lies the problem: I am not familiar enough with the electronics. Now only on special occasions have I used this beautiful refurbished machine by disabling the auto fill. Any suggestions Also, could you (civ) send me the file with the electronic diagram, my copy is so poorly scanned that it is illegible.

I`ll PM you with my e-mail address. I find it rather annoying (used to less expensive/elaborate home machines) that I cannot just turn on/off the pump, be it to make a ristretto on the fly or clean the screen/pf with `just` a squirt of water. I do my backflushing by putting a blind filter or equivalent and brewing a shot, which I cut short (as per the manual`s instructions) by turning the machine off after a few seconds and repeat this a couple of times, waiting a few moments between each time.

No problems. I think you should try and make sure that all the connections to the boiler level probe are intact and that the probe is clean. It the autofill does not stop, it`s as if the probe were disconnected. I then suspected a doser solenoid valve malfuncion, so with the machine `unplugged` (read again: unplugged, ok ) I disconnected the lugs to the solenoid and connected them to 220v.

At that point, the deposit started to fill so a solenoid malfunction (stuck or with a dead coil) was ruled out. Not being low water pressure problem or solenoid malfunction the next thing was to follow the black cables to the electricals box under the drip tray, where you will find yet another much smaller black box

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713