control the speed of an AC BRUSHLESS motor

A small scroll saw is intended to be equipped with a cost-effective speed controller. The saw operates using an AC motor that seems to be brushless based on the examination conducted during disassembly.

To design a speed controller for an AC brushless motor, it is essential to understand the operational characteristics of the motor and the requirements of the scroll saw. Brushless AC motors typically require a specific type of controller known as a brushless DC (BLDC) motor controller, which can effectively manage the speed and torque of the motor.

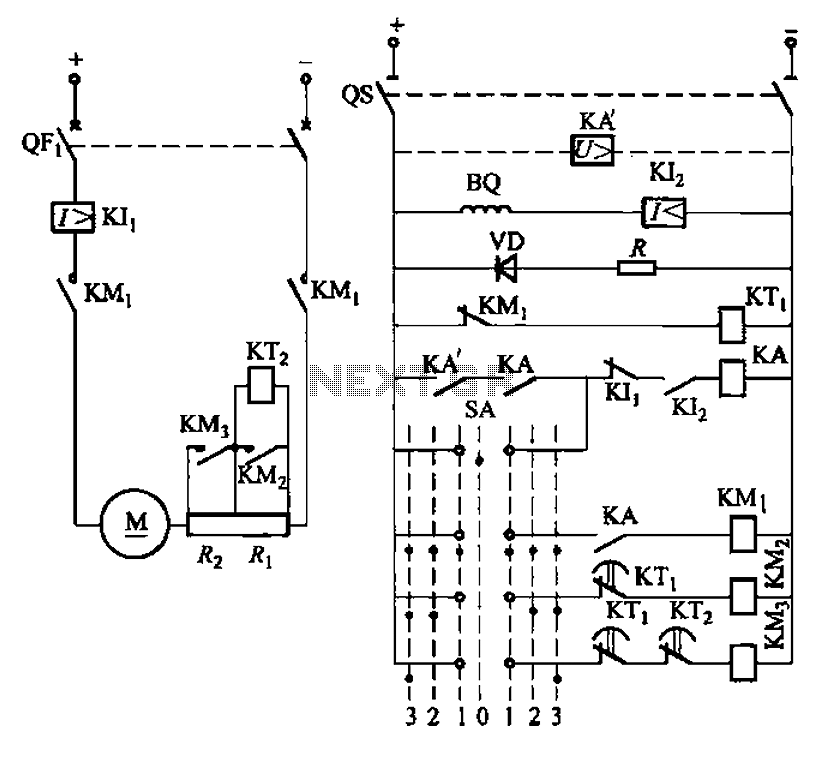

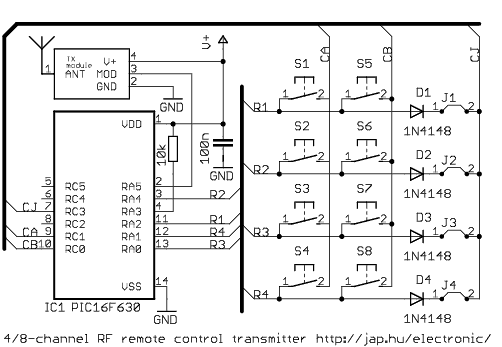

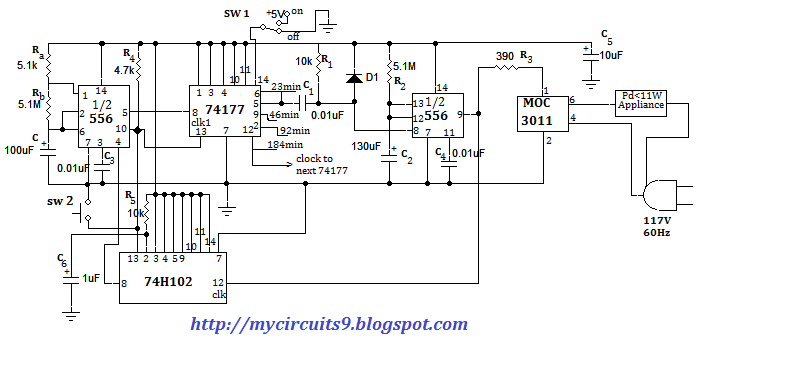

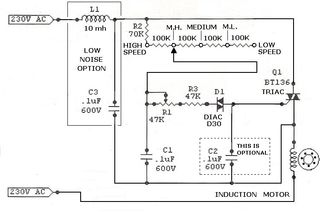

The proposed speed controller circuit may utilize a microcontroller or a dedicated integrated circuit (IC) designed for motor control. The microcontroller can be programmed to adjust the duty cycle of a pulse-width modulation (PWM) signal, which in turn controls the effective voltage and speed of the motor. The circuit will include the following essential components:

1. **Microcontroller**: A suitable microcontroller (e.g., Arduino, PIC, or similar) to generate PWM signals based on user input for speed adjustment.

2. **Power Stage**: A bridge rectifier to convert AC to DC if necessary, followed by an H-bridge configuration to control the direction and speed of the motor. MOSFETs or IGBTs can be used in the H-bridge to handle the power requirements efficiently.

3. **Feedback Mechanism**: Incorporation of a feedback system, such as a tachometer or Hall effect sensor, to monitor the motor speed and provide data to the microcontroller, enabling closed-loop control for improved performance.

4. **User Interface**: A simple user interface consisting of a potentiometer or buttons to allow the operator to set the desired speed of the scroll saw.

5. **Protection Circuitry**: Implementing overcurrent protection, thermal shutdown, and other safety features to prevent damage to the motor and controller.

The circuit should be designed with proper thermal management and layout considerations to ensure reliable operation. Additionally, filtering capacitors should be placed near the power terminals of the motor to reduce electrical noise and improve performance.

Overall, this approach will create a functional and efficient speed controller for the scroll saw, enhancing its versatility and usability for various woodworking tasks.I have a small scroll saw i would like to build a cheap speed controler for It uses an AC motor which appears to be brushless when i dismantled it C.. 🔗 External reference

To design a speed controller for an AC brushless motor, it is essential to understand the operational characteristics of the motor and the requirements of the scroll saw. Brushless AC motors typically require a specific type of controller known as a brushless DC (BLDC) motor controller, which can effectively manage the speed and torque of the motor.

The proposed speed controller circuit may utilize a microcontroller or a dedicated integrated circuit (IC) designed for motor control. The microcontroller can be programmed to adjust the duty cycle of a pulse-width modulation (PWM) signal, which in turn controls the effective voltage and speed of the motor. The circuit will include the following essential components:

1. **Microcontroller**: A suitable microcontroller (e.g., Arduino, PIC, or similar) to generate PWM signals based on user input for speed adjustment.

2. **Power Stage**: A bridge rectifier to convert AC to DC if necessary, followed by an H-bridge configuration to control the direction and speed of the motor. MOSFETs or IGBTs can be used in the H-bridge to handle the power requirements efficiently.

3. **Feedback Mechanism**: Incorporation of a feedback system, such as a tachometer or Hall effect sensor, to monitor the motor speed and provide data to the microcontroller, enabling closed-loop control for improved performance.

4. **User Interface**: A simple user interface consisting of a potentiometer or buttons to allow the operator to set the desired speed of the scroll saw.

5. **Protection Circuitry**: Implementing overcurrent protection, thermal shutdown, and other safety features to prevent damage to the motor and controller.

The circuit should be designed with proper thermal management and layout considerations to ensure reliable operation. Additionally, filtering capacitors should be placed near the power terminals of the motor to reduce electrical noise and improve performance.

Overall, this approach will create a functional and efficient speed controller for the scroll saw, enhancing its versatility and usability for various woodworking tasks.I have a small scroll saw i would like to build a cheap speed controler for It uses an AC motor which appears to be brushless when i dismantled it C.. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713