Detecting liquified petroleum gas (LPG)

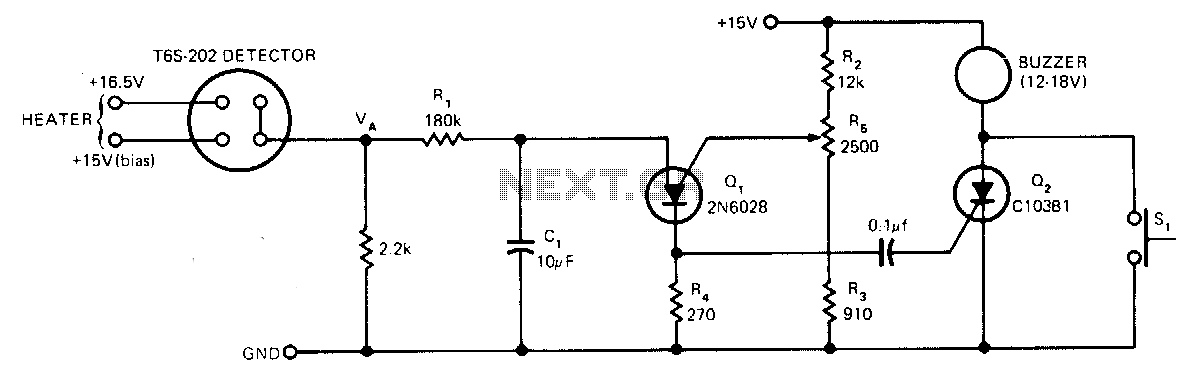

Figaro manufactures sensors that can detect various types of gases (e.g., hydrogen, methane, carbon monoxide, etc.). A simple circuit has been designed around the Figaro LPM2610 module, which will activate an alarm if the level of liquefied petroleum gas (LPG) in the kitchen exceeds a predetermined threshold. The dimensions of the module were known from the datasheet, but the actual size was surprising; it is compact, which is advantageous as it avoids the need for a large daughter board on the main board. The surface mount components consist solely of resistors, with no electrostatic discharge sensitive parts. The thermistor is identified as the unmarked black chip in the upper left corner. The Figaro module incorporates the TGS2610 sensor and various resistors to create two voltage dividers: one for the sensor output and another for the reference voltage. When the sensor voltage (VOUT) equals the temperature-compensated reference voltage, it indicates that the LPG concentration in the air is theoretically 10% of the lower explosive limit (LEL) of isobutane. According to the datasheet, the LEL for butane is 18,000 ppm, equivalent to 1.8% by volume, although some sources suggest it may be 16,000 ppm or 1.6%. The Application Note for LP Gas Detectors using the TGS2610 from Figaro provides extensive information to facilitate application development. A critical recommendation is that the TGS2610 requires a warm-up time to reach its operational temperature, with Figaro advising a wait of 2.5 minutes, during which the sensor output is unreliable. The Application Note also suggests circuits for detecting heater and sensor failures. The datasheet indicates that the typical current through the heater at 5.0V is 56mA. While Figaro recommends a 3.57-ohm current sense resistor for detecting heater failure, a couple of 2-ohm resistors are currently available. The voltage drop across the current sense resistor is calculated as 56mA x 2 ohms = 112mV, thus requiring a VDD of approximately 5.1V to achieve a voltage drop of around 5.0V across the heater. A power supply was configured using an LM317 voltage regulator to provide this voltage. VOUT and VREF were buffered at unity gain, while the current sense voltage was amplified by a factor of 20. The outputs of the operational amplifiers were connected to a Dataq DI-145 for value recording. A cold start was conducted to ensure the module was at room temperature. During the warm-up phase, VOUT gradually stabilized (approximately 0.3 to 0.4V) over more than 100 seconds. Notably, the voltage across the heater current sense resistor exhibited a spike upon power-up before settling exponentially. This inrush current indicates that the heater's cold resistance is lower than its hot resistance, similar to an incandescent lamp filament. Additionally, VOUT remained nearly at zero volts (about 20 to 30mV) for roughly one second before rising. This behavior suggests that the semiconductor sensor (RS), in series with the load resistor (RL), has a very high resistance at room temperature, which drops significantly as it heats up, functioning like a negative temperature coefficient (NTC) thermistor. As it reaches a specific temperature, the resistance begins to increase. Figaro provides a brief introduction to the construction and operating principles of its sensors. Given the suggestions in the Application Note for detecting sensor failures, this appears to be a plausible concern. Utilizing a quad operational amplifier (MCP609), an unused device was employed to connect VOUT, configuring it to have the same gain as the amplifier for the heater current sense resistor. Normally, the output of this non-inverting amplifier would be close to VDD. However, in the event of a sensor failure, the output of the op-amp will deviate from this expected behavior.

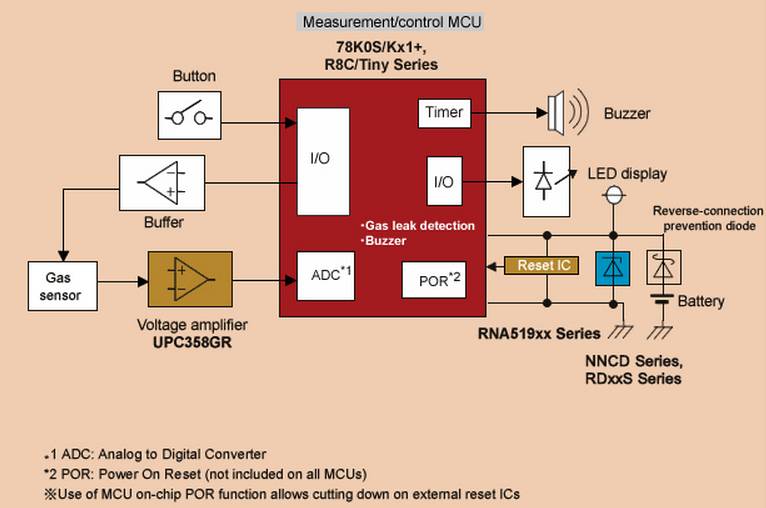

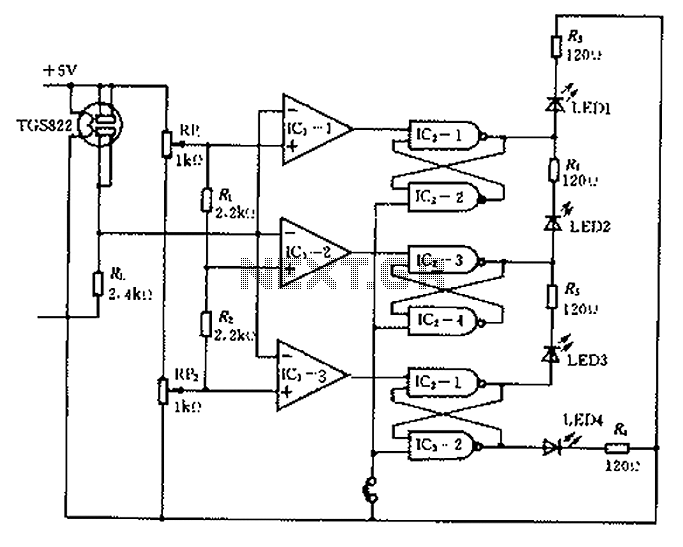

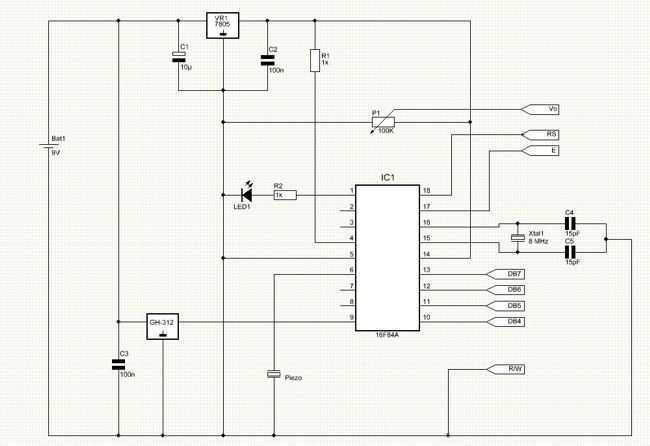

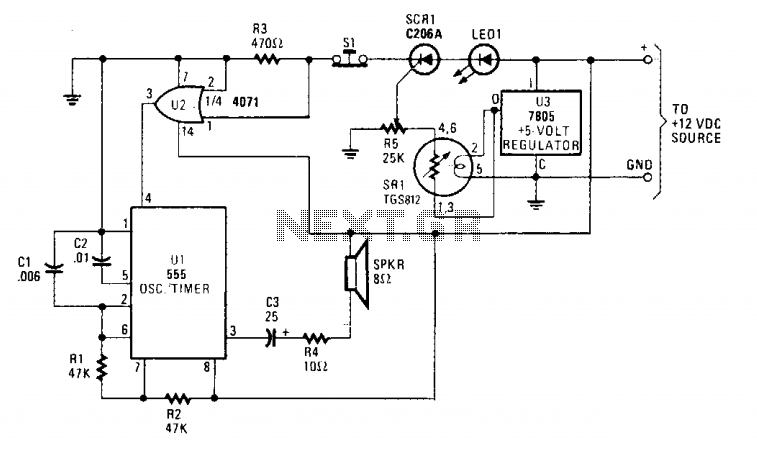

The circuit design for the LPG detection system utilizes the Figaro LPM2610 module, which is equipped with the TGS2610 gas sensor, known for its sensitivity to LPG. The circuit is designed to monitor the sensor's output voltage (VOUT) against a reference voltage (VREF) derived from a voltage divider. The operational amplifiers are configured to buffer these signals, ensuring that the output is stable and accurate for further processing.

The heater within the TGS2610 sensor is critical for its operation, as it must reach a specific temperature for the sensor to function correctly. The LM317 voltage regulator is employed to maintain the necessary voltage supply, while the current sense resistors allow for monitoring the heater's operational status. The design anticipates potential failures, incorporating feedback mechanisms to detect anomalies in the heater's performance.

Data acquisition is achieved through the Dataq DI-145, which records the output voltages, allowing for analysis of the sensor's performance over time, particularly during the warm-up period. The initial behavior of the sensor output provides insights into its thermal characteristics and response dynamics, which are essential for ensuring reliable operation in detecting LPG concentrations.

The overall schematic is designed for simplicity and effectiveness, focusing on essential components that contribute to the reliable detection of gas levels while maintaining a compact footprint suitable for integration into various applications. The use of surface mount technology minimizes space requirements and enhances the robustness of the circuit against environmental factors.Figaro manufactures sensors that can sniff out various kinds of gases (e. g. hydrogen, methane, carbon monoxide, etc. ). I`ve designed a simple circuit built around the Figaro LPM2610 module which will sound an alarm if and when the level of liquified petroleum gas (LPG) in the kitchen rises above a certain predetermined level. I knew the dimensions of the module from the datasheet but when they arrived I was still quite surprised they`re tiny. Nothing against it of course. I don`t want a huge daughter board sitting on my main board. The surface mount chips are all resistors. No electrostatic discharge sensitive components here at all. The thermistor is the unmarked black chip at the upper left corner. The Figaro module contains the TGS2610 sensor and various resistors to create two voltage dividers-one for the sensor output and the other for the reference voltage. Whenever sensor voltage VOUT is equal to the temperature-compensated reference voltage this indicates the LPG concentration in the air is (theoretically) 10% of the lower explosive limit (LEL) of isobutane.

As per the datasheet, butane LEL is 18, 000 ppm which is equivalent to 1. 8% by volume (although one website puts it at 16, 000 ppm or 1. 6%). In Application Note for LP Gas Detectors using TGS2610 Figaro provides a wealth of information to get an application up and running. One of the more important tips therein is that the TGS2610 needs a warm up time to get the sensor up to its working temperature.

Figaro recommends waiting 2. 5 minutes. During this preheating stage the sensor`s output is unreliable. In the same AN Figaro suggests circuits to detect heater as well as sensor failures. According to the datasheet the typical current through the heater @5. 0V is 56mA. Although Figaro suggests using a 3. 57-ohm current sense resistor to detect heater failure, at the moment what I have are a couple of 2 ohms. 56mA x 2 ohms = 112mV. Therefore, my VDD has to be around 5. 1V to obtain a voltage drop of ~5. 0V across the heater. So I configured a power supply using an LM317 voltage regulator to output this value. VOUT and VREF were unity-gain buffered while the current sense voltage was gained by 20. Output of the op amps were hooked up to a Dataq DI-145 to record the values. I then performed a cold start (i. e, the module had not been powered for at least an hour to make sure it`s at room temperature). In the screenshot below you can see that while the heater is ramping up to its working temperature VOUT gradually settles down (approx 0.

3 to 0. 4V). This takes >100sec. Interestingly, voltage across heater current sense resistor spikes upon power up and then exponentially settles. This inrush current suggests that the heater has a cold resistance lower than its hot resistance-just like the filament of an incandescent lamp.

What`s interesting in the image below is how VOUT stays at nearly zero volt (~20 to 30mV according to Windaq) for around 1 second before climbing. Since this is the voltage across the load resistor (RL), apparently the semiconductor sensor (RS) which is in series with RL has an extremely high resistance at room temperature which drops drops dramatically as it begins to heat up, thus behaving like a negative temperature coefficient (NTC) thermistor.

However, its resistance begins to gradually increase as it reaches a certain temperature. Figaro has this short intro to the construction and operating principles of its sensors Given that Figaro AN gives a suggestion on how to detect sensor failure, it must be that this is a distinct possibility. Since I`m using a quad op amp ( MCP609 ) I decided to make use of what would be an unused device and connected VOUT to it and then configured it to have the same gain as the amplifier for the heater current sense resistor.

Normally the output of this noninverting amplifier would be close to VDD. However, when the sensor does fail op amp output will b 🔗 External reference

The circuit design for the LPG detection system utilizes the Figaro LPM2610 module, which is equipped with the TGS2610 gas sensor, known for its sensitivity to LPG. The circuit is designed to monitor the sensor's output voltage (VOUT) against a reference voltage (VREF) derived from a voltage divider. The operational amplifiers are configured to buffer these signals, ensuring that the output is stable and accurate for further processing.

The heater within the TGS2610 sensor is critical for its operation, as it must reach a specific temperature for the sensor to function correctly. The LM317 voltage regulator is employed to maintain the necessary voltage supply, while the current sense resistors allow for monitoring the heater's operational status. The design anticipates potential failures, incorporating feedback mechanisms to detect anomalies in the heater's performance.

Data acquisition is achieved through the Dataq DI-145, which records the output voltages, allowing for analysis of the sensor's performance over time, particularly during the warm-up period. The initial behavior of the sensor output provides insights into its thermal characteristics and response dynamics, which are essential for ensuring reliable operation in detecting LPG concentrations.

The overall schematic is designed for simplicity and effectiveness, focusing on essential components that contribute to the reliable detection of gas levels while maintaining a compact footprint suitable for integration into various applications. The use of surface mount technology minimizes space requirements and enhances the robustness of the circuit against environmental factors.Figaro manufactures sensors that can sniff out various kinds of gases (e. g. hydrogen, methane, carbon monoxide, etc. ). I`ve designed a simple circuit built around the Figaro LPM2610 module which will sound an alarm if and when the level of liquified petroleum gas (LPG) in the kitchen rises above a certain predetermined level. I knew the dimensions of the module from the datasheet but when they arrived I was still quite surprised they`re tiny. Nothing against it of course. I don`t want a huge daughter board sitting on my main board. The surface mount chips are all resistors. No electrostatic discharge sensitive components here at all. The thermistor is the unmarked black chip at the upper left corner. The Figaro module contains the TGS2610 sensor and various resistors to create two voltage dividers-one for the sensor output and the other for the reference voltage. Whenever sensor voltage VOUT is equal to the temperature-compensated reference voltage this indicates the LPG concentration in the air is (theoretically) 10% of the lower explosive limit (LEL) of isobutane.

As per the datasheet, butane LEL is 18, 000 ppm which is equivalent to 1. 8% by volume (although one website puts it at 16, 000 ppm or 1. 6%). In Application Note for LP Gas Detectors using TGS2610 Figaro provides a wealth of information to get an application up and running. One of the more important tips therein is that the TGS2610 needs a warm up time to get the sensor up to its working temperature.

Figaro recommends waiting 2. 5 minutes. During this preheating stage the sensor`s output is unreliable. In the same AN Figaro suggests circuits to detect heater as well as sensor failures. According to the datasheet the typical current through the heater @5. 0V is 56mA. Although Figaro suggests using a 3. 57-ohm current sense resistor to detect heater failure, at the moment what I have are a couple of 2 ohms. 56mA x 2 ohms = 112mV. Therefore, my VDD has to be around 5. 1V to obtain a voltage drop of ~5. 0V across the heater. So I configured a power supply using an LM317 voltage regulator to output this value. VOUT and VREF were unity-gain buffered while the current sense voltage was gained by 20. Output of the op amps were hooked up to a Dataq DI-145 to record the values. I then performed a cold start (i. e, the module had not been powered for at least an hour to make sure it`s at room temperature). In the screenshot below you can see that while the heater is ramping up to its working temperature VOUT gradually settles down (approx 0.

3 to 0. 4V). This takes >100sec. Interestingly, voltage across heater current sense resistor spikes upon power up and then exponentially settles. This inrush current suggests that the heater has a cold resistance lower than its hot resistance-just like the filament of an incandescent lamp.

What`s interesting in the image below is how VOUT stays at nearly zero volt (~20 to 30mV according to Windaq) for around 1 second before climbing. Since this is the voltage across the load resistor (RL), apparently the semiconductor sensor (RS) which is in series with RL has an extremely high resistance at room temperature which drops drops dramatically as it begins to heat up, thus behaving like a negative temperature coefficient (NTC) thermistor.

However, its resistance begins to gradually increase as it reaches a certain temperature. Figaro has this short intro to the construction and operating principles of its sensors Given that Figaro AN gives a suggestion on how to detect sensor failure, it must be that this is a distinct possibility. Since I`m using a quad op amp ( MCP609 ) I decided to make use of what would be an unused device and connected VOUT to it and then configured it to have the same gain as the amplifier for the heater current sense resistor.

Normally the output of this noninverting amplifier would be close to VDD. However, when the sensor does fail op amp output will b 🔗 External reference