Digital Potentiometers

1. Definition and Principle of Operation

1.1 Definition and Principle of Operation

Digital potentiometers are essential components in modern electronics, providing a means to manipulate resistance values electronically without the need for physical adjustments. Unlike their analog counterparts, which rely on mechanical movement to change resistance, digital potentiometers use digital signals to achieve similar functionality, thus allowing for greater precision and control in various applications. The control of resistance is primarily implemented through binary operations, making these devices integral in digital circuits.

At their core, digital potentiometers operate on the principle of digitally controlling taps along a resistive material. Typically, a digital potentiometer comprises a resistive element and a series of switches or a decoder that selects the appropriate resistor tap based on digital input signals. This system is often managed through standard digital communication protocols such as I²C, SPI (Serial Peripheral Interface), or simple binary signals, allowing easy integration with microcontrollers and digital systems.

Construction and Working Principle

The construction of a digital potentiometer typically includes a resistive network formed by multiple resistors in series. The key to its operation lies in the number of taps or positions available, which dictate how finely the resistance can be adjusted. For example, an 8-position digital potentiometer allows for resistance changes in 1/8 increments relative to the total resistance value of the device.

When a specific tap is selected, digital logic provides a path through a switch that connects to the desired resistor segment. This effectively alters the resistance value observed on the output terminals. The combination of resistive segments and digital controls provides a method to achieve not just simple volume control in audio applications, but also complex signal conditioning and calibration processes in instrumentation and control systems.

Mathematical Representation

To quantitatively describe the behavior of a digital potentiometer, let’s consider a potentiometer with a total resistance \( R_{total} \) and \( N \) taps. The effective resistance \( R_{out} \) at the output can generally be represented as:

Here, \( k \) is an integer that indicates which tap is being selected, ranging from \( 0 \) to \( N-1 \). By adjusting \( k \), you control the output resistance, making this device highly versatile.

Applications of Digital Potentiometers

Digital potentiometers find wide applications across a multitude of fields:

- Audio Systems: Used for volume control and equalization.

- Signal Conditioning: Fine-tuning parameters in sensors and data acquisition devices.

- Calibration Circuits: Providing adjustable reference voltages and resistances in testing and calibration processes.

- Embedded Systems: Easily interfaced with microcontrollers to perform automated adjustments.

As technology progresses, the implementation of digital potentiometers continues to evolve, finding novel uses in IoT devices, automotive applications, and robotics. Their role in facilitating precise control mechanisms highlights their significance in contemporary electronics design and application.

1.2 Types of Digital Potentiometers

Digital potentiometers are an essential component in modern electronic systems, providing precise control over resistance values and enabling programmable applications. Understanding the different types of digital potentiometers is crucial for engineers and physicists who aim to utilize them effectively in various designs. Broadly, digital potentiometers can be classified based on their operational mechanism and integration methodology, primarily into resistive and non-resistive types.

Resistive Digital Potentiometers

The resistive type, sometimes referred to as the switched or variable resistor type, employs a fixed resistor track with taps or switches controlled either digitally or via a microcontroller. These devices utilize various configurations to enable adjustment of resistance between the wiper terminal and two end terminals. The principal designs include:

- Binary-weighted DACs: These utilize resistors in a binary-weighted configuration to achieve different resistance values, efficiently translating digital inputs into analog outputs. The resolution and capability are directly affected by the number of bits employed.

- Digital Rheostats: Providing resistance adjustment with no set end points, these are often utilized in applications that require dynamic range, such as setting gain levels.

Resistive digital potentiometers communicate values typically through SPI (Serial Peripheral Interface) or I²C (Inter-Integrated Circuit) protocols. The operational complexity inherent in these devices enhances flexibility and control, making them ideal for audio systems, sensor calibration, and other applications requiring adjustable analog values.

Non-Resistive Digital Potentiometers

In contrast, non-resistive digital potentiometers utilize other forms of mechanisms to achieve resistance values without employing a physical resistive track. They often include:

- Capacitive Digital Potentiometers: These devices make use of capacitance variations to control output levels. They can be advantageous in applications requiring low resistance and high-frequency performance.

- Memristive Digital Potentiometers: Utilizing memristors, this innovative type relies on a resistance change approximately related to the history of the voltage and current applied, providing unique nonlinear resistance characteristics.

Non-resistive types are especially significant in applications demanding precision and miniaturization—the response times and resolutions can also vary depending on the design, which must be closely matched to the application requirements.

Integrated Digital Potentiometers

Further expanding upon the categories, integrated digital potentiometers are those embedded within specific systems, often combining functionalities with operational amplifiers or microcontrollers on a single chip. This integration greatly reduces design complexities and board space, enabling high-performance applications in consumer electronics, automotive systems, and industrial automation.

Additionally, the selection of a digital potentiometer must consider critical parameters such as resolution, temperature coefficient, and power rating to optimize for specific applications. The dynamic range, noise characteristics, and form factor also play pivotal roles in practical deployment. As we delve into practical applications and use cases in subsequent sections, it becomes evident how pivotal these classifications are in shaping effective electronic solutions.

1.3 Key Specifications and Parameters

Digital potentiometers are intricate components that serve as electronically controllable variable resistors. Understanding their key specifications is essential for effectively integrating them into various applications, such as audio level control, sensor calibration, and automated instrumentation. This section explores the pivotal specifications and parameters that define the performance and utility of digital potentiometers.Resolution

One of the most critical specifications of a digital potentiometer is its resolution, which indicates the number of discrete steps that the potentiometer can take. Typically represented in bits, the resolution defines how precisely the output resistance can be adjusted. For instance, an 8-bit digital potentiometer can theoretically output 256 distinct resistance values, while a 10-bit device can yield 1024 steps. Mathematically, we can express the number of discrete levels $$N$$ for a given resolution $$R$$ in bits as:End-to-End Resistance

The end-to-end resistance refers to the total resistance offered by the digital potentiometer between its terminals. This value is crucial as it directly impacts the range of potential outputs that can be achieved in a circuit. Typical values range between a few kilohms to several megaohms, depending on the specific application and topology of the circuit. For example, a digital potentiometer with a 100 kΩ end-to-end resistance may be utilized in audio applications to achieve desirable volume levels without significant signal losses. Understanding the appropriate resistance for your application is vital to maintain signal integrity and circuit efficiency.Power Consumption

Evaluating the power consumption is vital, particularly in portable and battery-operated devices. Digital potentiometers typically consume less power than their analog counterparts due to their digitally controlled mechanisms. However, it is still essential to consider the static power dissipation (when not switching) and dynamic power dissipation (when performing adjustments). Power consumption, represented as a function of voltage and current, can be expressed with the formula:Operating Voltage Range

The operating voltage range defines the acceptable input voltage range over which a digital potentiometer can operate effectively. Typically, this may vary from 3 V to 15 V, although specialized models exist for more extreme conditions. This specification is crucial as it determines the compatibility of the digital potentiometer with different circuit designs. For instance, devices operating at lower voltages can be better suited for portable applications, while those with broader ranges provide more flexibility in professional and industrial settings. Matching the operating voltage to application requirements ensures reliability and performance stability.Total Nonlinearity

Total Nonlinearity (TNL) refers to how closely the output resistance values adhere to the intended linear scaling. Ideally, a digital potentiometer should have a linear response to the input digital signals. Nonlinearities can introduce discrepancies, affecting the effectiveness of applications that depend on precise adjustment capabilities. TNL is typically expressed as a percentage and is critical to assess when ensuring the reliability of functionalities that rely on consistent behavior across the entire operating range. Understanding this parameter is vital for professionals designing precise instruments or control mechanisms.Interface Type and Communication Protocols

Digital potentiometers utilize various interface types for communication, such as I²C, SPI, and UART. The choice of interface affects the design complexity and performance of the application. For high-speed applications, SPI may be advantageous due to its rapid data transfer capabilities. In contrast, I²C allows for simpler wiring with multiple devices on the same bus, making it popular for systems where space and complexity need to be minimized. As the development of applications advances, selecting a digital potentiometer with a compatible communication protocol enhances functionality and flexibility while reducing integration challenges.Conclusion

Understanding the key specifications and parameters of digital potentiometers is paramount for advanced-level readers seeking to implement these devices into sophisticated systems. By focusing on aspects such as resolution, end-to-end resistance, power consumption, operating voltage range, total nonlinearity, and interface types, engineers can make informed decisions that enhance the performance of their applications. As you proceed with your design endeavors, consider these specifications as cornerstones in achieving precision and reliability in your electronic circuits.2. Audio Volume Control

2.1 Audio Volume Control

In modern audio systems, the need for precise and reliable volume control is paramount to enhance user experience and maintain sound fidelity. Digital potentiometers (digital pots) play an essential role in sophisticated volume control mechanisms within audio applications. Their ability to provide variable resistance via digital inputs enables advanced functionalities that surpass the capabilities of traditional analog counterparts.

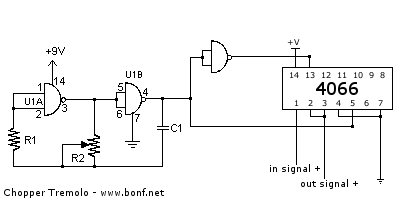

With conventional potentiometers, volume control involves a linear adjustment of resistance, which translates to a direct change in amplitude. However, digital potentiometers, using a binary method, allow for more granular control over audio levels, better noise performance, and increased durability due to no moving parts. In addition, they can be remote-controlled, integrating easily with microcontrollers and digital signal processors.

Mechanics of Digital Potentiometers in Audio Applications

The operation of a digital potentiometer is based on a series of resistor networks that can be manipulated electronically. Typically, these devices include a series of resistors connected in a specific configuration, often in a ladder-like structure, which is controlled through a digital interface such as I2C or SPI. The digital input can be adjusted programmatically to change the resistance value and subsequently control the audio signal flow. This adjustment is accomplished by selecting specific tap points on the resistor ladder.

For clarity, let’s envision the control scheme: the digital potentiometer is placed in series with the audio signal path. When the resistance is altered, the voltage division principle dictates that the output voltage (and hence audio level) changes proportionally. The relationship can be expressed mathematically as:

Where \(V_{out}\) is the audio output level, \(V_{in}\) is the input audio level, \(R_1\) is the resistance from the wiper to ground, and \(R_2\) is the resistance from the wiper to the source voltage. By selecting different resistance values via digital control, we can manipulate the output volume smoothly without altering the audio signal's quality.

Practical Implications and Configurations

One practical application of digital potentiometers in audio systems is the establishment of a programmable volume control in devices such as audio mixers and home theater systems. By utilizing a digital potentiometer with feedback circuitry, systems can automatically adjust volume levels in response to environmental noise or user preferences, showcasing how these devices can optimize audio experiences dynamically.

Moreover, digital pots can be combined with microcontroller-based systems for enhanced functionality. For instance, a user can adjust volume via a smartphone app, which communicates with a microcontroller that interfaces with the digital potentiometer. This remote control capability facilitates greater convenience and adaptability in modern audio system design.

Conclusion

Digital potentiometers serve as a pivotal component in achieving advanced audio volume control within contemporary electronic designs. Their digital nature offers significant advantages over traditional potentiometers, providing precise, flexible, and reliable volume adjustment mechanisms. As audio technology continues to evolve, the role of digital potentiometers will likely expand further, enabling richer and more immersive sound experiences.

2.2 Signal Conditioning

Signal conditioning plays a crucial role in the operation of digital potentiometers. It involves manipulating a signal to make it suitable for processing and interfacing with other electronic components, ensuring the integrity of the signal throughout various stages in a circuit. In systems where precision and accuracy are paramount, effectively conditioning signals ensures reliable performance, particularly in applications involving sensors, audio devices, and control systems.

Basics of Signal Conditioning

At its core, signal conditioning refers to the processes applied to signals to enhance their quality and functionality. This encompasses various operations such as filtering, amplification, and voltage level shifting. For digital potentiometers, effective signal conditioning is essential in translating analog signals into digital representations without introducing noise or undesired alterations.

Filtering

One significant aspect of signal conditioning is filtering, which helps eliminate unwanted frequency components that can distort the desired signal. The choice of filter depends on the specific application. For instance:

- Low-pass filters can be used to allow signals below a certain frequency to pass while blocking higher frequencies, reducing noise.

- High-pass filters perform the opposite, enabling only high frequencies to pass, which can be useful for removing DC offsets.

Using digital potentiometers in conjunction with active or passive filters can optimize signal fidelity in circuits, paving the way for clearer data interpretation.

Amplification

In many applications, particularly those involving sensors, signals may need to be amplified to be properly interpreted. Amplification can be achieved using operational amplifiers (op-amps) configured for various gains. The gain can typically be defined by the feedback network of resistors—this is critical when integrating with digital potentiometers, as the potentiometer’s output is often sourced from the amplified signal.

Here, \( V_{out} \) is the output voltage, \( V_{in} \) is the input voltage, \( R_f \) is the feedback resistor, and \( R_i \) is the input resistor. Properly setting these resistors allows for high precision in the output, which is essential in control systems that utilize digital potentiometers.

Voltage Level Shifting

As systems integrate components with varying voltage levels, voltage level shifting becomes necessary to maintain compatibility across different parts of the circuit. For digital potentiometers, which may operate at different logic levels compared to other devices in a circuit, employing level shifters or voltage dividers can help in transferring signals without damaging sensitive components. This ensures that the digital control signals align correctly with analog input requirements, thereby preserving system integrity.

Practical Applications of Signal Conditioning in Digital Potentiometers

Understanding and implementing signal conditioning in systems that leverage digital potentiometers opens doors to various applications:

- Audio Processing: Digital potentiometers can be used in volume control, where conditioned signals improve the clarity of audio transients and reduce noise.

- Sensors: In applications such as temperature sensing, efficient signal conditioning can enhance sensitivity and accuracy, allowing digital potentiometers to adjust calibration settings.

- Automation: In automated control systems, such as robotic arms or temperature controllers, essential feedback loops are improved through effective signal conditioning, ensuring stable operation.

In conclusion, signal conditioning is a vital process that enhances the functionality of digital potentiometers within a circuit, facilitating improved performance and reliability in various advanced applications.

2.3 Sensor Calibration

In advanced electronic systems, particularly those utilizing digital potentiometers, sensor calibration serves as an essential process that refines the accuracy and reliability of measurements. Digital potentiometers, unlike their analog counterparts, are controlled through digital signals, which allows for more precise adjustments. However, accurate performance relies on meticulous calibration to ensure that the digital outputs correspond effectively to the physical parameters being measured or controlled. Calibration of sensors in electronics typically involves comparing the sensor's output against a known standard or reference value. This process is crucial because sensors can drift over time due to environmental changes, manufacturing variances, or aging components, leading to inaccurate readings. In this subsection, we will explore the principles of sensor calibration with a focus on digital potentiometers, highlighting methods and practical implementations.Understanding Calibration Principles

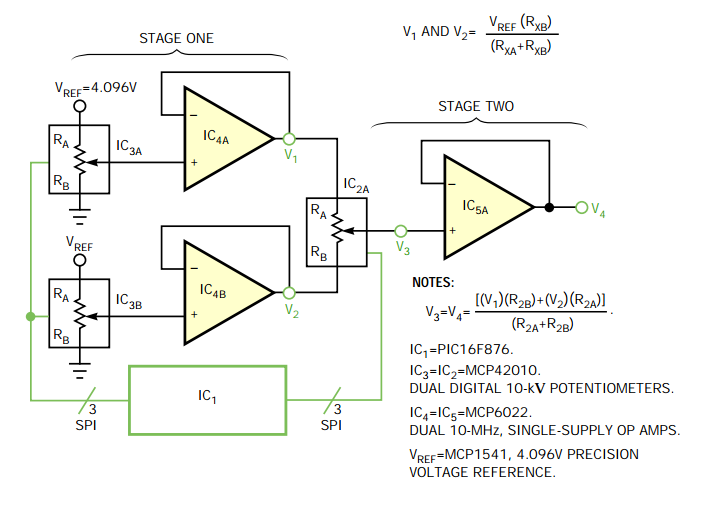

Calibration often involves a systematic process characterized by the following key steps: 1. Reference Availability: Accurate calibration requires a well-defined reference standard that represents the true value of the measured quantity. 2. Mapping Output: This entails plotting the sensor's output against the reference values, usually determined on a two-dimensional graph where the x-axis represents the reference value and the y-axis represents the sensor output. 3. Applying Corrections: Once the mapping is created, correction factors can be applied to align the sensor outputs with the reference values. Mathematically, this can be expressed as:Practical Calibration Techniques for Digital Potentiometers

Calibration of digital potentiometers involves specific methodologies that cater to their unique operation. Here are some widely adopted techniques: 1. Single-point Calibration: This technique involves adjusting the output of the digital potentiometer to match a known standard at one selected point in the output range. While easy to implement, it can provide satisfactory results, primarily when used in applications with narrow operational ranges. 2. Multi-point Calibration: A more comprehensive approach, where multiple known standards are applied across the entire range of the potentiometer. This method allows for the creation of a detailed calibration curve. Multiple readings give rise to a polynomial fit, enabling the determination of more complex relationships between output and input signals. 3. Feedback Calibration: Often used in closed-loop systems, feedback calibration dynamically adjusts the digital potentiometer’s settings based on real-time sensor feedback. This method continuously ensures that measured outputs remain aligned with the desired outputs, substantially mitigating errors due to external factors.Real-World Applications

The principles and techniques discussed have vast implications across various fields: - Audio Engineering: Calibration of digital potentiometers is critical in audio systems where precise volume control can significantly affect performance and user experience. - Industrial Automation: In robotic systems, sensor feedback directly influences the operation of actuators; thus, calibration ensures that the robotic response accurately corresponds to the sensor inputs. - Medical Devices: Devices such as blood pressure monitors utilize digital potentiometers for precise control of sensor readings, ensuring the accuracy necessary for diagnostics. The integration of robust calibration techniques within networks of digital potentiometers not only enhances accuracy but ensures the overall reliability of complex electronic systems. As technology evolves, the continuous development of more sophisticated calibration methods remains a focal point within the field of electronics and sensor systems.3. Choosing the Right Digital Potentiometer

3.1 Choosing the Right Digital Potentiometer

Choosing the appropriate digital potentiometer is crucial for the successful implementation of electronic systems, particularly in applications that require precision in adjustment of resistance values. Digital potentiometers serve as electronically controlled variable resistors, providing flexibility and enhanced performance over traditional mechanical potentiometers. When selecting a digital potentiometer, several factors demand consideration due to their significant influence on functionality, reliability, and application suitability. To begin with, it is essential to evaluate the resistance range of the digital potentiometer. Typically, these components come in resistance values ranging from several ohms up to millions of ohms. Applications demanding fine control, such as audio engineering or sensor calibrations, may favor low-resistance potentiometers, while high-resistance variants are suitable for applications like biasing in high-impedance inputs. The number of steps or resolution is another vital consideration in your selection process. Digital potentiometers are often specified in terms of their steps (also called tap points), with common configurations exhibiting 256 to 1024 steps. This resolution defines how finely one can adjust the output resistance. For applications demanding high precision, such as active filter designs, a digital potentiometer with a higher number of steps would be beneficial. The next crucial aspect lies in the interface type. Digital potentiometers commonly employ various communication protocols, including I2C, SPI, and even simple PWM signals. Choose an interface compatible with your microcontroller or other digital interfaces in your application. For instance, I2C applications can greatly benefit from its ability to connect multiple devices on a single bus, providing scalability. Given the diverse operational environments, assessing the voltage rating and power dissipation specifications is equally essential. Each digital potentiometer has defined limits for voltage and current that it can handle safely. Exceeding these limits may lead to overheating or permanent failure. It is advisable to operate these components within a conservative range to ensure long-term reliability and performance. In conjunction with voltage limits, reviewing the temperature coefficient is imperative for precision applications. Non-linearities in resistance values can arise due to temperature variations, and digital potentiometers may have different thermal characteristics. Selecting devices with low temperature coefficients can enhance the stability of your circuitry in fluctuating environments. Another factor involves the wiper modes (volatile vs. non-volatile). Non-volatile potentiometers retain their last set state even after power is removed, making them ideal for applications requiring memory retention. In contrast, volatile types reset to a default state upon power loss, which might be acceptable for less critical applications. Finally, consider the physical package type and footprint of the digital potentiometer. Depending on your design requirements—such as PCB space constraints or mount type—ensuring compatibility with existing designs can save time and increase efficiency in development. In summary, the choice of digital potentiometer can profoundly affect the performance and reliability of your application. By carefully assessing the resistance range, resolution, interface type, voltage rating, power dissipation, temperature coefficient, wiper modes, and physical packaging, engineers can select the best component tailored to their specific needs. This thoughtful selection process not only enhances product performance but can also streamline the development process, avoiding common pitfalls in the design phase. Understanding these factors will empower you to make informed choices that align with your project goals for optimal results.3.2 Integration with Microcontrollers

Digital potentiometers offer a distinct advantage in modern embedded systems, particularly when integrating with microcontrollers. Unlike traditional analog potentiometers, which require manual adjustments, digital potentiometers can be controlled via digital signals, enhancing the flexibility and automation of circuit designs. This section will delve into the methodologies for interfacing digital potentiometers with microcontrollers, practical use cases, and considerations for implementation.

Understanding the Interface

To begin integrating a digital potentiometer with a microcontroller, it is essential to understand the communication protocols involved. Most digital potentiometers utilize either the I2C or SPI bus protocol. These protocols facilitate communication between the microcontroller and the digital potentiometer, allowing for adjustments to resistance levels and ultimately controlling various electrical parameters such as voltage or current.

I2C versus SPI

I2C (Inter-Integrated Circuit) is a two-wire protocol that allows multiple devices to be connected on the same bus. Its advantages include simplicity in wiring and addressing multiple devices by unique addresses. In contrast, SPI (Serial Peripheral Interface) is a faster, four-wire protocol that allows for higher data transfer rates, albeit at the cost of more complex wiring and device addressing. The choice between I2C and SPI depends on the application's requirements, such as speed versus simplicity.

Practical Implementation

When designing a system that incorporates a digital potentiometer, the selection of components is critical. Ensure that the microcontroller supports the chosen protocol natively. For instance, an MCU like the Arduino family supports I2C and SPI directly, allowing for straightforward integration. Below, we examine the connection schematics for both types of protocols using a common digital potentiometer, the MCP41010.

For I2C connections, a simplified schematic would feature:

- VDD: Connected to microcontroller power supply

- GND: Ground connection

- SDA (Data line): Connected to the microcontroller's SDA pin

- SCL (Clock line): Connected to the microcontroller's SCL pin

For SPI, the connections would appear as follows:

- VDD: Connected to microcontroller power supply

- GND: Ground connection

- SCK (Clock): Connected to the microcontroller's SCK pin

- SDI (Data In): Connected to the microcontroller's MOSI pin

- SDO (Data Out): Connected to the microcontroller's MISO pin

- CS (Chip Select): Connected to a GPIO pin for enabling communication

Programming the Microcontroller

Once the hardware connections are established, programming the microcontroller to interact with the digital potentiometer is the next step. A typical task might involve adjusting the resistance based on sensor readings. The implementation will vary based on the programming environment but could look like this in an Arduino sketch:

#include <SPI.h>

#include <Wire.h> // For I2C

void setup() {

pinMode(SS, OUTPUT); // Set the Chip Select pin as output

digitalWrite(SS, HIGH); // Deselect the device

SPI.begin(); // Initialize SPI

}

void loop() {

byte value = analogRead(A0) / 4; // Read analog value and scale it

digitalWrite(SS, LOW); // Select the device

SPI.transfer(value); // Send the scaled value

digitalWrite(SS, HIGH); // Deselect the device

delay(100); // Delay for stability

}

This programming snippet demonstrates how to read an analog input and subsequently use that value to control the resistance of the potentiometer. The division by 4 is necessary to map the 10-bit ADC value (0-1023) into a 8-bit value (0-255), which is typical for many digital potentiometers.

Conclusion

Integrating digital potentiometers with microcontrollers significantly enhances circuit control and automation capabilities. By choosing appropriate communication protocols and understanding the hardware and software requirements, engineers and designers can create sophisticated systems that respond dynamically to changes in their environment, leading to innovations across various applications, from consumer electronics to industrial automation.

3.3 Circuit Design and Layout Guidelines

Designing circuits that incorporate digital potentiometers (DPOTs) requires careful consideration of several factors to ensure optimal performance. Understanding the characteristics and limitations of these components plays a crucial role in achieving desired outcomes in various applications. Below, we elaborate on key guidelines that should be followed during the circuit design and layout process.

Understanding the Working Principle

Digital potentiometers function through inherent characteristics similar to their analog counterparts, but with added digital control capabilities. The fundamental operation of a DPOT splits the resistance into several discrete steps controlled by digital inputs (usually serial or parallel). This makes them valuable in applications ranging from audio volume control to signal processing and sensor calibration.

Design Guidelines

- Power Supply Decoupling: DPOTs often require stable voltage to function correctly. Integrating decoupling capacitors close to the power pins of the device can significantly reduce noise susceptibility and transient responses. Typically, a combination of a 0.1 μF ceramic capacitor and a larger electrolytic capacitor (e.g., 10 μF) provides effective decoupling.

- Signal Integrity: Due to their digital nature, care should be taken to minimize signal degradation. Implementing proper grounding techniques and using short traces on the PCB can help to maintain signal integrity and prevent interference from other components.

- Control Component Placement: Since DPOTs are often interfaced with microcontrollers, it is prudent to position the control IC and the DPOT close together. This reduces the trace length for digital signals, minimizing delay and potential errors.

Layout Considerations

The PCB layout for a circuit using a digital potentiometer must prioritize thermal management and electromagnetic compatibility (EMC). Utilize the following recommendations:

- Thermal Management: DPOTs, while typically low-power, can generate heat under certain conditions. Ensure adequate spacing between heat-generating components and utilize thermal vias if necessary.

- Ground Plane: Employing a solid ground plane helps in reducing parasitic inductances and resistances, and contributes to an overall reduction of electromagnetic interference (EMI).

- Via Configuration: Minimize the number of vias in critical signal paths to prevent unwanted capacitance and inductance, which can introduce unwanted delays and reflections in the signal.

Practical Applications

Digital potentiometers are found in a broad range of applications, from consumer electronics to industrial automation systems. For instance, in audio devices, they can precisely control volume levels and equalization parameters, while in automotive systems, DPOTs can be used for tuning sensors and actuators. Each application requires careful design considerations tailored to specific requirements.

Conclusion

Incorporating digital potentiometers into designs presents several advantages, but it requires a thorough understanding of their operational nuances. By adhering to these design and layout guidelines, engineers can harness the full potential of DPOTs in their projects. The principles described relay not only the technicalities but also practical insights that enhance reliability and efficiency in electronic designs.

4. Noise and Signal Integrity Issues

4.1 Noise and Signal Integrity Issues

Digital potentiometers are increasingly utilized in various applications for their ability to provide precision resistance adjustment in compact forms. However, when integrating these devices into electronic systems, users should be cognizant of noise and signal integrity issues that can critically impact performance. To begin with, it is important to define what noise and signal integrity mean in the context of digital potentiometers. Noise refers to any unwanted electrical signal that interferes with the desired signal, often manifesting as random fluctuations that can distort data. Signal integrity, on the other hand, pertains to the quality and reliability of signals as they travel through a circuit, often degraded by factors such as reflections, electromagnetic interference (EMI), and crosstalk. One of the main sources of noise in digital potentiometers is the inherent quantization noise that arises during the digital-to-analog conversion (DAC) process. Each step change on the digital potentiometer results in a fixed change in output voltage which can lead to discrepancies when precise analog voltages are desired. The quantization error can be expressed mathematically as:4.2 Interface Compatibility

In an era where digital systems are omnipresent, understanding the interface compatibility of digital potentiometers is quintessential for engineers and researchers alike. At the core, compatibility refers to the ability of these components to communicate and function seamlessly with other digital systems and devices. This section delves into the various protocols and standards that dictate how digital potentiometers interface with controllers and sensors.Protocols for Digital Communication

Digital potentiometers primarily utilize specific communication protocols which govern the data exchange process. The two most common protocols employed in digital potentiometers are I²C (Inter-Integrated Circuit) and SPI (Serial Peripheral Interface). I²C is a synchronous, multi-master, multi-slave protocol that facilitates communication over two wires, minimizing the number of connections required. This is particularly advantageous in embedded systems where space and pin-count are critical. On the other hand, SPI offers higher data rates by utilizing a full-duplex communication model, allowing simultaneous data transmission and reception, which is advantageous in high-speed applications. Understanding the differences between these protocols is fundamental. I²C is typically simpler to implement due to its lower pin-count requirements, but it may be limited by inherent bus speed and device addressing mechanics. Conversely, while SPI demands more lines (at least four lines for a basic setup), it excels in speed and noise immunity, making it suitable for performance-sensitive applications.Electrical Compatibility and Signal Levels

Consideration must also be given to electrical compatibility when choosing a digital potentiometer for an application. Digital potentiometers come in various voltage ranges, typically operating within 3.3V to 5V levels. Ensuring that the chosen digital potentiometer matches the logic levels of the microcontroller or the digital system it’s paired with is vital to maintaining signal integrity and preventing potential damage to the components. In instances where mismatched voltage levels occur, solutions like level shifters can be employed to facilitate proper communication. Level shifters effectively translate the high and low states between devices operating at different voltage levels, ensuring reliable data transmission.Interfacing with Microcontrollers and FPGA

When integrating digital potentiometers with microcontrollers or FPGAs, it is imperative to be cognizant of the specific requirements for configuration and control. Many microcontrollers, such as the Arduino or PIC series, come equipped with libraries that simplify the task of interfacing with I²C and SPI devices. These libraries offer pre-defined functions that abstract the complexities of direct communication, significantly enhancing development speed. For FPGA implementations, custom logic may be required to handle the control signals efficiently. Here, understanding timing constraints and signal propagation delays becomes crucial, as FPGAs can operate at much higher frequencies compared to traditional microcontrollers.Real-World Applications

The practical implications of interface compatibility are vast. For instance, in automotive applications, digital potentiometers are often employed within electronic control units (ECUs) that manage everything from engine performance to infotainment systems. Compatibility with existing communication protocols like CAN (Controller Area Network) is critical in ensuring reliable performance across various vehicle subsystems. Moreover, in audio equipment, digital potentiometers enable precise volume adjustments in conjunction with DSP (Digital Signal Processing) systems, improving user experience through seamless integration. Through this examination, it becomes evident that interface compatibility is not merely a technical requirement but a significant factor that can dictate the success of digital potentiometer integration into larger systems. Mastery of these interfaces opens the door to innovation and efficiency across a range of applications. In summary, by considering both communication protocols and electrical compatibility, engineers can ensure that their designs are robust, efficient, and ready for future advancements in digital technology.4.3 Calibration and Linearity Problems

Digital potentiometers, while offering significant advantages over their analog counterparts, bring with them unique calibration and linearity challenges that engineers must address for optimal performance. Calibration ensures that the digital output precisely corresponds to the desired resistance value across its operating range, while linearity concerns the proportionality of changes in digital input with changes in output resistance.

Understanding Calibration

Calibration involves setting the output of a device to a known standard. In terms of digital potentiometers, which utilize a series of resistive elements and a digital control interface, this process is crucial to achieving accurate functionality. Most digital potentiometers use a built-in Digital-to-Analog Converter (DAC) mechanism, wherein changes in a digital input signal directly map to adjustments in resistance.

The necessity for calibration arises due to various manufacturing tolerances, temperature fluctuations, and inherent non-linearities in the electronic components themselves. Calibration can typically be accomplished through a two-point or multi-point method:

- Two-point calibration: Involves setting the zero and full-scale resistance values with respect to a precision reference.

- Multi-point calibration: Applies adjustments at multiple points within the operational range, ensuring accuracy at various points of interest.

Linearity Issues

Linearity refers to the relationship between the digital input value and the output resistance of the potentiometer. Ideally, this relationship should be linear, meaning a change in digital value should result in a proportional change in resistance. However, many factors can contribute to non-linearity:

- Resolution and quantization error: The finite steps of the digital potentiometers cause small errors, particularly at lower values where changes can have more significant impacts.

- Temperature sensitivity: Resistance values can drift with temperature changes, leading to malalignment of the expected linear response.

- Component tolerances: Variations in the manufacturing process of the resistive elements may lead to deviations from the expected behavior.

One effective method to assess linearity is through the method of least squares or regression analysis, comparing the actual output curve against a theoretical line. Mathematically, if we define the relationship between the digital input \( x \) and output resistance \( R(x) \) as a linear function:

Where \( a \) and \( b \) are coefficients determined from the calibration process, one can use regression analysis to minimize the differences between the actual output values and the values predicted by this linear model. The residuals can be assessed to quantify linearity errors.

Practical Solutions

Addressing calibration and linearity issues often requires a combination of hardware adjustments and software algorithms:

- Hardware averaging: Implementing averaging techniques on the signal can reduce the effects of random fluctuations in resistance readings.

- Temperature compensation: Utilizing temperature sensors to correct or offset resistance values based on temperature data can substantially enhance performance.

- Calibration algorithms: Incorporating advanced algorithms allows for real-time adaptations and corrections of the output resistance based on predefined models or user-defined profiles.

By understanding and effectively managing calibration and linearity issues, engineers can enhance the performance of digital potentiometers, ensuring precision and reliability in applications ranging from audio engineering to medical devices and industrial automation. As technology continues to advance, ongoing research in this field promises even more robust solutions for future implementations.

5. Technical Articles and Journals

5.1 Technical Articles and Journals

- Analog Devices Education Library — A valuable collection of technical articles, tutorials, and reference materials focusing on digital potentiometers and other analog devices.

- Microchip Technology Technical Documents — Comprehensive resources offering insights into the application and functionality of digital potentiometers in various electronic circuits.

- Digital Potentiometer Basics - EDN Network — An overview of the principles and applications of digital potentiometers, highlighting practical design considerations.

- Digital Potentiometer Characteristics and Applications - EEWeb — Detailed exploration of the characteristics, specifications, and diverse applications of digital potentiometers in electronics systems.

- IEEE Xplore: Digital Potentiometer Designs — An academic journal article discussing advanced designs and custom applications for digital potentiometers.

- Electronics Tutorials: Digital Potentiometers — A comprehensive tutorial that covers fundamental concepts, types, and applications of digital potentiometers with examples.

- ScienceDirect: Digital Potentiometer Overview — Extensive scholarly articles providing detailed theoretical and practical insights into the use of digital potentiometers in engineering.

5.2 Online Resources and Communities

For advanced learners and professionals delving into the world of digital potentiometers, a rich ecosystem of online resources and communities can facilitate deep learning, peer-led knowledge sharing, and troubleshooting. Here, we will explore a curated list of high-quality web resources, communities, and forums that are invaluable for engineers, physicists, researchers, and graduate students looking to expand their understanding of digital potentiometers. Digital Potentiometer Resources- Analog Devices - Digital Potentiometers — Offers technical articles, datasheets, and product highlights of digital potentiometers, including application notes detailing integration into circuits.

- Microchip Technology - Digital Potentiometers — Provides a comprehensive overview of digital potentiometer offerings with detailed documentation, application insights, and tutorial videos.

- EE Times - A Guide to Digital Potentiometers — An in-depth article explaining the operations, applications, and design considerations when using digital potentiometers in an engineering context.

- Maxim Integrated - Digital Potentiometer Tutorial — A step-by-step guide to understanding and implementing digital potentiometers in circuit designs, alongside practical examples and use cases.

- All About Circuits - Digital Potentiometers — Covers the basic operation principles and typical applications of digital potentiometers, tailored for both newcomers and seasoned engineers.

- EEVblog Electronics Community Forum — A vibrant community forum where electronics enthusiasts and professionals discuss a vast array of topics, including digital potentiometers, with extensive archives of shared projects and advice.

- Electronics Stack Exchange - Digital Potentiometer — A question-and-answer site for electronics design questions, providing peer-supported advice and problem-solving for issues related to digital potentiometers.

- Reddit Electronics and Electrical Engineering — An active subreddit where enthusiasts and professionals share insights, resources, and solve queries on a wide range of topics including digital potentiometers.

5.3 Manufacturer Documentation

Manufacturer documentation is an essential resource for understanding the detailed specifications and operational capabilities of digital potentiometers. These documents provide a comprehensive guide on how to integrate and leverage the full potential of digital potentiometers in electronic designs. This section will explore the critical components of manufacturer documentation and highlight their practical relevance for engineers and researchers.

Understanding Manufacturer Data Sheets

The data sheet of a digital potentiometer typically includes several key specifications that are critical for advanced applications:

- Resistance Range and Resolution: Data sheets specify the range of resistance values that the digital potentiometer can offer. Additionally, they describe the resolution, typically given in bits, which determines the smallest change in resistance that can be digitally controlled.

- Programming Interface: Detailed descriptions of interfaces such as I2C, SPI, or UP/DOWN interfaces are provided. This includes timing diagrams, command sets, and communication protocols that guide engineers in implementing efficient control mechanisms.

- Electrical Characteristics: Critical parameters such as supply voltage, power consumption, and temperature operating range are included, which are pivotal for ensuring the component's reliability and compatibility with other system elements.

- Error and Noise Characteristics: These specifications detail the level of noise introduced by the device and provide guidelines on minimizing errors arising from digital-to-analog conversion processes.

Application Notes and Design Guides

In addition to data sheets, manufacturers often provide application notes and design guides. These documents extend the utility of digital potentiometers by offering:

- Practical Application Circuits: Real-world circuit examples demonstrate how to use digital potentiometers in various configurations, such as voltage dividers or replaceable analog potentiometers in audio applications.

- Integration Techniques: Guidance on integrating digital potentiometers with microcontrollers and other digital logic is typically included to facilitate accurate electronic control.

- Calibration and Fine-Tuning: Procedures for calibrating the digital potentiometer within different applications help ensure accurate and reliable performance across varied use cases.

A Deeper Dive into Technical Specifications

In professional settings, understanding the technical specifications found in manufacturer documentation is vital for ensuring the optimal use of digital potentiometers:

- Non-linearity and Drift: Documents often address how the resistance value can drift with time or temperature and how it deviates from a perfectly linear transfer function. This is crucial for applications requiring high precision.

- Tolerances and Limits: Specified tolerances reflect the allowable deviations within which the digital potentiometer operates correctly. Understanding these tolerances helps prevent potential failures in high-stakes applications.

Real-World Relevance

Understanding manufacturer documentation is vital for advanced readers as it directly impacts the design and troubleshooting phases of electronics projects. For instance, in automotive applications, where digital potentiometers might be used in sensor calibration or to adjust damping in electronic suspension systems, precise knowledge of device parameters can significantly affect system performance and reliability. Furthermore, in academic research, these documents provide the data needed to compare devices and determine their suitability for experimental setups.

Thus, proper interpretation of manufacturer documentation allows engineers and researchers to select appropriate components, design circuits with confidence, and innovate effectively in their respective fields.