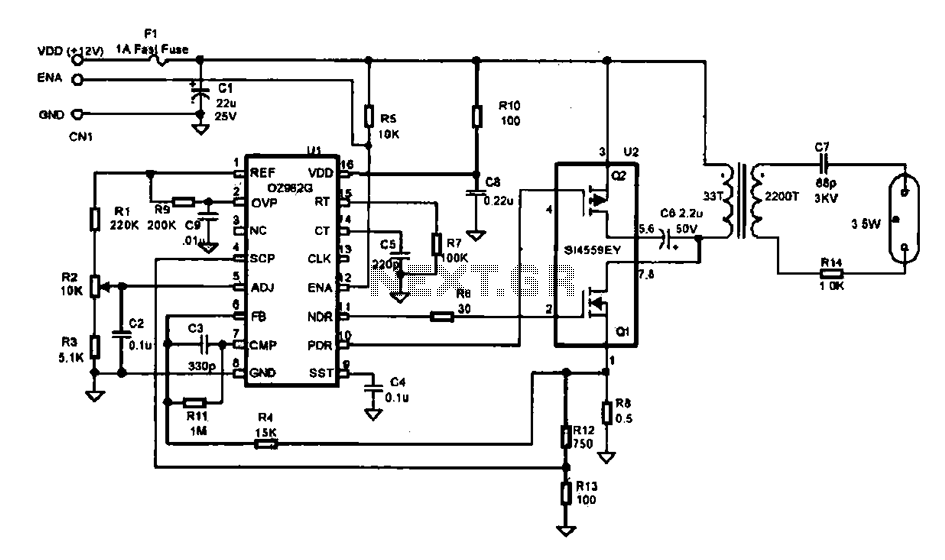

Efficient inverter control circuit

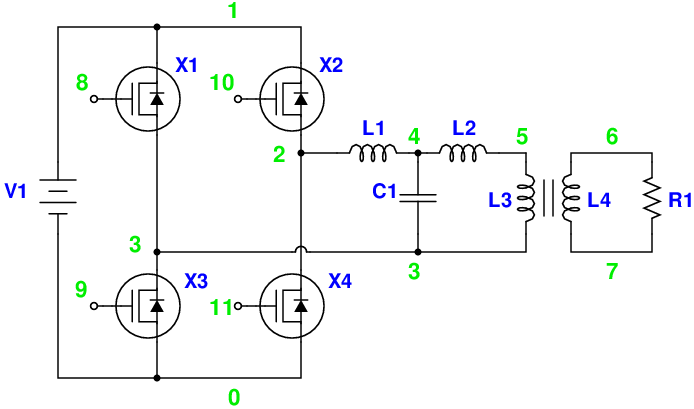

This document describes an efficient inverter control circuit designed for use as an LCD backlight power supply. The circuit is primarily managed by the chip UL (02962G), which interfaces with a driving field-effect transistor (U2), a voltage transformer, the backlight lamp, and various associated circuitry. The circuit operates by sending +1V DC power through a filter capacitor (C1) to the integrated circuit (IC) UL and the driving field-effect transistor. A start signal (ENA) is transmitted to the UL chip to control the operation of the inverter circuit. Once the inverter power supply is functioning properly, the UL chip generates a PWM pulse signal from its output pin, which drives the field-effect transistor. This interaction with the step-up transformer increases the voltage to approximately 800V, providing the necessary power for the backlight lamp.

The efficient inverter control circuit described operates as a critical component in providing power to LCD backlight systems. The circuit architecture begins with a +1V DC input, which is filtered through capacitor C1 to ensure a stable voltage supply for the UL (02962G) integrated circuit. This IC serves as the control unit, utilizing a start signal (ENA) to enable or disable the inverter circuit based on operational requirements.

The driving field-effect transistor (U2) plays a vital role in modulating the power delivered to the step-up transformer. When the inverter is activated by the ENA signal, the UL chip produces a pulse-width modulation (PWM) signal at its output pin. This PWM signal controls the switching of the field-effect transistor, allowing it to efficiently manage the energy transfer to the transformer.

The step-up transformer is designed to amplify the voltage generated by the field-effect transistor to approximately 800V. This high voltage is essential for powering the backlight lamp, which illuminates the LCD display. The configuration of the transformer and the associated circuitry is optimized to ensure minimal losses and high efficiency in the energy conversion process.

Overall, this inverter control circuit is engineered to provide reliable and effective power management for LCD backlighting applications, ensuring that the display operates at optimal brightness levels while maintaining energy efficiency.Efficient inverter control circuit It shows a highly efficient inverter control circuit, which is used as the LCD backlight power supply circuit, which is mainly controlled by the chip Ul (02962G), the driving field effect transistor U2, Dan-voltage transformer, the backlight lamp and associated circuitry configuration. After the DC power sent by the +1V DC voltage through the filter capacitor Cl integrated circuit Ul and driving power field-effect transistor; start signal (ENA) will be sent to the U1 feet for controlling the inverter circuit opens, stop.

When the inverter power supply is normal, after receiving the start signal from the Ul of ? foot guard pin output PWM pulse signal interaction, after driving into the field effect transistor amplifier in step-up transformer, the pulse from the step-up transformer voltage up to about 800 V, power supply for the backlight lamp.

The efficient inverter control circuit described operates as a critical component in providing power to LCD backlight systems. The circuit architecture begins with a +1V DC input, which is filtered through capacitor C1 to ensure a stable voltage supply for the UL (02962G) integrated circuit. This IC serves as the control unit, utilizing a start signal (ENA) to enable or disable the inverter circuit based on operational requirements.

The driving field-effect transistor (U2) plays a vital role in modulating the power delivered to the step-up transformer. When the inverter is activated by the ENA signal, the UL chip produces a pulse-width modulation (PWM) signal at its output pin. This PWM signal controls the switching of the field-effect transistor, allowing it to efficiently manage the energy transfer to the transformer.

The step-up transformer is designed to amplify the voltage generated by the field-effect transistor to approximately 800V. This high voltage is essential for powering the backlight lamp, which illuminates the LCD display. The configuration of the transformer and the associated circuitry is optimized to ensure minimal losses and high efficiency in the energy conversion process.

Overall, this inverter control circuit is engineered to provide reliable and effective power management for LCD backlighting applications, ensuring that the display operates at optimal brightness levels while maintaining energy efficiency.Efficient inverter control circuit It shows a highly efficient inverter control circuit, which is used as the LCD backlight power supply circuit, which is mainly controlled by the chip Ul (02962G), the driving field effect transistor U2, Dan-voltage transformer, the backlight lamp and associated circuitry configuration. After the DC power sent by the +1V DC voltage through the filter capacitor Cl integrated circuit Ul and driving power field-effect transistor; start signal (ENA) will be sent to the U1 feet for controlling the inverter circuit opens, stop.

When the inverter power supply is normal, after receiving the start signal from the Ul of ? foot guard pin output PWM pulse signal interaction, after driving into the field effect transistor amplifier in step-up transformer, the pulse from the step-up transformer voltage up to about 800 V, power supply for the backlight lamp.