Enclosure Design

1. Role of Enclosures in Protection

Role of Enclosures in Protection

Enclosures play a critical role in safeguarding electronic devices and components from environmental factors, electromagnetic interference, and physical damage. Understanding the fundamental aspects of enclosure design is essential for engineers and researchers to ensure the reliability and longevity of electronic systems.

Enclosures serve multiple purposes in electronic systems:

1. Environmental Protection

Enclosures shield electronic components from dust, moisture, dirt, and other contaminants present in the operating environment. This protection is vital for maintaining the performance and reliability of sensitive electronic equipment.

2. Electromagnetic Interference (EMI) Shielding

Enclosures act as barriers to block electromagnetic interference from external sources, preventing signal degradation and other malfunctions caused by electromagnetic noise. Properly designed enclosures help maintain signal integrity and reduce the risk of interference.

3. Physical Security

Enclosures provide physical security by preventing unauthorized access to internal components, reducing the risk of tampering, vandalism, or theft of sensitive equipment. They also protect components from accidental damage due to impact or mishandling.

4. Thermal Management

Enclosures assist in managing the thermal environment of electronic devices by dissipating heat generated during operation. Effective thermal design within enclosures helps prevent overheating, which can lead to component failure and reduced system performance.

By considering these crucial aspects of enclosures in protection, engineers can design robust and reliable electronic systems that meet stringent performance requirements even in challenging operating conditions.

Role of Enclosures in Protection

Enclosures play a critical role in safeguarding electronic devices and components from environmental factors, electromagnetic interference, and physical damage. Understanding the fundamental aspects of enclosure design is essential for engineers and researchers to ensure the reliability and longevity of electronic systems.

Enclosures serve multiple purposes in electronic systems:

1. Environmental Protection

Enclosures shield electronic components from dust, moisture, dirt, and other contaminants present in the operating environment. This protection is vital for maintaining the performance and reliability of sensitive electronic equipment.

2. Electromagnetic Interference (EMI) Shielding

Enclosures act as barriers to block electromagnetic interference from external sources, preventing signal degradation and other malfunctions caused by electromagnetic noise. Properly designed enclosures help maintain signal integrity and reduce the risk of interference.

3. Physical Security

Enclosures provide physical security by preventing unauthorized access to internal components, reducing the risk of tampering, vandalism, or theft of sensitive equipment. They also protect components from accidental damage due to impact or mishandling.

4. Thermal Management

Enclosures assist in managing the thermal environment of electronic devices by dissipating heat generated during operation. Effective thermal design within enclosures helps prevent overheating, which can lead to component failure and reduced system performance.

By considering these crucial aspects of enclosures in protection, engineers can design robust and reliable electronic systems that meet stringent performance requirements even in challenging operating conditions.

Thermal Management Considerations

In electronic system design, thermal management is a crucial aspect that cannot be overlooked. Efficient heat dissipation ensures optimal performance, longevity, and reliability of electronic devices. This subsection delves into the key considerations for managing heat within enclosures. Thermal management involves controlling the temperature of components within the enclosure to prevent overheating, which can lead to performance degradation or even component failure. Heat is generated within electronic components due to resistive losses, switching operations, and other factors, making it essential to dissipate this heat effectively. ### Heat Generation Mechanisms Electronic components such as processors, power transistors, and integrated circuits produce heat during operation. The primary sources of heat generation include: - Joule Heating: Resulting from current passing through resistive elements. - Switching Losses: Occur during the transition of components from on to off states. - Conduction Losses: Heat generated by conduction through semiconductor materials. - Radiation: Emitted by components due to their operating temperatures. ### Thermal Resistance and Conduction Thermal resistance characterizes a material's ability to conduct heat. Lower thermal resistance values indicate better heat conduction properties. In electronic systems, thermal interfaces and conductive materials play a vital role in managing heat flow between components and the enclosure. ### Heat Transfer Mechanisms Effective thermal management relies on various heat transfer mechanisms, including conduction, convection, and radiation. Conduction involves heat transfer through direct contact between materials, convection utilizes fluid flow for heat dissipation, and radiation emits heat in the form of electromagnetic waves. ### Enclosure Design Considerations When designing enclosures for electronic systems, several factors need to be considered for efficient thermal management: - Material Selection: Choose enclosure materials with good thermal conductivity. - Ventilation and Airflow: Ensure adequate ventilation to promote heat dissipation. - Heat Sinks and Thermal Pads: Use heat sinks and thermal pads to improve heat transfer. - Thermal Insulation: Prevent heat loss or gain from external sources to maintain a stable internal temperature. - Cooling Systems: Incorporate fans, heat exchangers, or liquid cooling systems for high-power applications. ### Simulation and Testing To validate the thermal design of an enclosure, engineers often use simulation software to predict temperature distributions and identify potential hotspots. Thermal testing under real-world conditions ensures that the design meets performance requirements and prevents overheating issues. ### Practical Applications Efficient thermal management is critical in various applications, including: - Server Rooms: Maintaining optimal temperatures to prevent server downtime. - LED Lighting: Preventing LEDs from overheating to ensure longevity. - Automotive Electronics: Managing heat in vehicle systems for reliability. By considering thermal management early in the design phase, engineers can create robust and reliable electronic systems that operate within safe temperature limits.Thermal Management Considerations

In electronic system design, thermal management is a crucial aspect that cannot be overlooked. Efficient heat dissipation ensures optimal performance, longevity, and reliability of electronic devices. This subsection delves into the key considerations for managing heat within enclosures. Thermal management involves controlling the temperature of components within the enclosure to prevent overheating, which can lead to performance degradation or even component failure. Heat is generated within electronic components due to resistive losses, switching operations, and other factors, making it essential to dissipate this heat effectively. ### Heat Generation Mechanisms Electronic components such as processors, power transistors, and integrated circuits produce heat during operation. The primary sources of heat generation include: - Joule Heating: Resulting from current passing through resistive elements. - Switching Losses: Occur during the transition of components from on to off states. - Conduction Losses: Heat generated by conduction through semiconductor materials. - Radiation: Emitted by components due to their operating temperatures. ### Thermal Resistance and Conduction Thermal resistance characterizes a material's ability to conduct heat. Lower thermal resistance values indicate better heat conduction properties. In electronic systems, thermal interfaces and conductive materials play a vital role in managing heat flow between components and the enclosure. ### Heat Transfer Mechanisms Effective thermal management relies on various heat transfer mechanisms, including conduction, convection, and radiation. Conduction involves heat transfer through direct contact between materials, convection utilizes fluid flow for heat dissipation, and radiation emits heat in the form of electromagnetic waves. ### Enclosure Design Considerations When designing enclosures for electronic systems, several factors need to be considered for efficient thermal management: - Material Selection: Choose enclosure materials with good thermal conductivity. - Ventilation and Airflow: Ensure adequate ventilation to promote heat dissipation. - Heat Sinks and Thermal Pads: Use heat sinks and thermal pads to improve heat transfer. - Thermal Insulation: Prevent heat loss or gain from external sources to maintain a stable internal temperature. - Cooling Systems: Incorporate fans, heat exchangers, or liquid cooling systems for high-power applications. ### Simulation and Testing To validate the thermal design of an enclosure, engineers often use simulation software to predict temperature distributions and identify potential hotspots. Thermal testing under real-world conditions ensures that the design meets performance requirements and prevents overheating issues. ### Practical Applications Efficient thermal management is critical in various applications, including: - Server Rooms: Maintaining optimal temperatures to prevent server downtime. - LED Lighting: Preventing LEDs from overheating to ensure longevity. - Automotive Electronics: Managing heat in vehicle systems for reliability. By considering thermal management early in the design phase, engineers can create robust and reliable electronic systems that operate within safe temperature limits.Enclosure Design: Aesthetic and Brand Identity

In the realm of enclosure design for electronic devices, aesthetics play a crucial role in shaping consumer perception and market appeal. Beyond mere functionality, the visual appeal and brand identity conveyed through the design of an enclosure can significantly impact the product's success in the market. ####Factors Influencing Aesthetics in Enclosure Design

Aesthetic considerations in enclosure design are broad and multidimensional, incorporating elements such as shape, color, texture, materials, and overall form factor. These factors are not only vital for enhancing the visual appeal of a product but also for reflecting the brand identity and positioning. One key aspect is color choice, which can evoke certain emotions or associations in consumers. Understanding color psychology and its impact on user experience is critical when selecting the palette for an enclosure. ####Brand Identity and Enclosure Design

The design of an enclosure should align seamlessly with the brand's identity and values. A well-executed enclosure design can effectively communicate the brand's ethos, target audience, and market positioning. Consistency between the physical product's design and the brand's overall image is paramount for reinforcing brand recognition and loyalty. ####Emotional Connection through Design

Beyond aesthetics and brand identity, enclosure design can establish an emotional connection with users. A well-crafted design that prioritizes user experience and ergonomics can evoke positive feelings and enhance the overall product perception. ####Integration of Functional and Aesthetic Elements

Successful enclosure design strikes a delicate balance between functionality and aesthetics. It involves integrating technical considerations, such as component placement and heat dissipation, with aesthetic features to create a harmonious and cohesive product design. Enclosure design is a fusion of art and engineering, where form follows function but aesthetics can elevate the user experience and reinforce brand identity.References and Further Reading:

- Color Psychology in Marketing: The Ultimate Guide — Explore how color choices impact consumer behavior and perception in marketing contexts.

- The Importance of Consistent Branding — Learn why consistent branding across products is critical for brand recall and consumer trust.

- IDEO — Discover how design firm IDEO integrates functionality and aesthetics in product design to create impactful user experiences.

- Smashing Magazine — Explore articles on the intersection of design, aesthetics, and user experience in digital and physical products.

Enclosure Design: Aesthetic and Brand Identity

In the realm of enclosure design for electronic devices, aesthetics play a crucial role in shaping consumer perception and market appeal. Beyond mere functionality, the visual appeal and brand identity conveyed through the design of an enclosure can significantly impact the product's success in the market. ####Factors Influencing Aesthetics in Enclosure Design

Aesthetic considerations in enclosure design are broad and multidimensional, incorporating elements such as shape, color, texture, materials, and overall form factor. These factors are not only vital for enhancing the visual appeal of a product but also for reflecting the brand identity and positioning. One key aspect is color choice, which can evoke certain emotions or associations in consumers. Understanding color psychology and its impact on user experience is critical when selecting the palette for an enclosure. ####Brand Identity and Enclosure Design

The design of an enclosure should align seamlessly with the brand's identity and values. A well-executed enclosure design can effectively communicate the brand's ethos, target audience, and market positioning. Consistency between the physical product's design and the brand's overall image is paramount for reinforcing brand recognition and loyalty. ####Emotional Connection through Design

Beyond aesthetics and brand identity, enclosure design can establish an emotional connection with users. A well-crafted design that prioritizes user experience and ergonomics can evoke positive feelings and enhance the overall product perception. ####Integration of Functional and Aesthetic Elements

Successful enclosure design strikes a delicate balance between functionality and aesthetics. It involves integrating technical considerations, such as component placement and heat dissipation, with aesthetic features to create a harmonious and cohesive product design. Enclosure design is a fusion of art and engineering, where form follows function but aesthetics can elevate the user experience and reinforce brand identity.References and Further Reading:

- Color Psychology in Marketing: The Ultimate Guide — Explore how color choices impact consumer behavior and perception in marketing contexts.

- The Importance of Consistent Branding — Learn why consistent branding across products is critical for brand recall and consumer trust.

- IDEO — Discover how design firm IDEO integrates functionality and aesthetics in product design to create impactful user experiences.

- Smashing Magazine — Explore articles on the intersection of design, aesthetics, and user experience in digital and physical products.

2. Material Selection for Enclosures

2.1 Material Selection for Enclosures

Enclosures play a crucial role in protecting electronic components from environmental factors, ensuring proper functionality and longevity. When selecting materials for enclosures, various factors such as mechanical strength, thermal conductivity, electrical insulation, and cost must be considered. This subsection delves into the key considerations for choosing suitable materials for enclosures.

Mechanical Properties

The mechanical strength of the enclosure material is vital in providing protection against physical impacts and environmental stresses. Materials like aluminum and steel offer robustness, while polymers like ABS and polycarbonate provide durability with lightweight properties, making them suitable for portable devices.

Thermal Conductivity

Effective heat dissipation is essential in electronic enclosures to prevent overheating of internal components. Materials with high thermal conductivity, such as aluminum, facilitate efficient heat transfer, ensuring optimal operating temperatures within the enclosure.

Electrical Insulation

Insulating properties are critical to prevent electrical interference and ensure safety within the enclosure. Materials like plastics and ceramics possess high dielectric strength, making them ideal choices for electrical insulation in enclosures housing sensitive electronics.

Environmental Resistance

Enclosures exposed to harsh environments require materials that offer resistance to factors like moisture, chemicals, UV radiation, and extreme temperatures. Stainless steel and fiberglass reinforced plastics excel in providing protection against environmental hazards, enhancing the longevity of electronic systems.

Cost Considerations

While considering material options for enclosures, cost-effectiveness is a crucial factor. Balancing the performance requirements with the budget constraints of the project is essential to ensure optimal functionality without exceeding financial limitations.

The Cost Performance Index (CPI) provides a quantitative measure for evaluating different material options based on functionality and cost, aiding in the decision-making process for material selection.

2.1 Material Selection for Enclosures

Enclosures play a crucial role in protecting electronic components from environmental factors, ensuring proper functionality and longevity. When selecting materials for enclosures, various factors such as mechanical strength, thermal conductivity, electrical insulation, and cost must be considered. This subsection delves into the key considerations for choosing suitable materials for enclosures.

Mechanical Properties

The mechanical strength of the enclosure material is vital in providing protection against physical impacts and environmental stresses. Materials like aluminum and steel offer robustness, while polymers like ABS and polycarbonate provide durability with lightweight properties, making them suitable for portable devices.

Thermal Conductivity

Effective heat dissipation is essential in electronic enclosures to prevent overheating of internal components. Materials with high thermal conductivity, such as aluminum, facilitate efficient heat transfer, ensuring optimal operating temperatures within the enclosure.

Electrical Insulation

Insulating properties are critical to prevent electrical interference and ensure safety within the enclosure. Materials like plastics and ceramics possess high dielectric strength, making them ideal choices for electrical insulation in enclosures housing sensitive electronics.

Environmental Resistance

Enclosures exposed to harsh environments require materials that offer resistance to factors like moisture, chemicals, UV radiation, and extreme temperatures. Stainless steel and fiberglass reinforced plastics excel in providing protection against environmental hazards, enhancing the longevity of electronic systems.

Cost Considerations

While considering material options for enclosures, cost-effectiveness is a crucial factor. Balancing the performance requirements with the budget constraints of the project is essential to ensure optimal functionality without exceeding financial limitations.

The Cost Performance Index (CPI) provides a quantitative measure for evaluating different material options based on functionality and cost, aiding in the decision-making process for material selection.

Structural Integrity and Rigidity

In designing enclosures, structural integrity and rigidity are paramount considerations, especially when housing sensitive electronic components or delicate instruments. The ability of an enclosure to withstand external forces, vibrations, and thermal variations directly impacts the longevity and performance of the enclosed devices. ###Material Selection and Properties

The choice of materials for an enclosure plays a critical role in determining its structural integrity. Metals like aluminum and steel are commonly used for their high strength-to-weight ratio and durability. Polymers such as ABS and polycarbonate offer lightweight alternatives with good impact resistance. The material properties, including Young's modulus, tensile strength, and hardness, directly influence the enclosure's ability to withstand mechanical stresses. Understanding these properties is essential for designing an enclosure that meets the desired structural requirements. ###Finite Element Analysis (FEA) for Structural Simulation

Finite Element Analysis (FEA) is a powerful tool used to simulate and analyze the structural behavior of an enclosure under various loading conditions. By dividing the enclosure into discrete elements and applying boundary conditions, FEA provides insights into stress distribution, deformation, and potential failure points. FEA helps engineers optimize the enclosure design by iteratively adjusting parameters such as wall thickness, ribbing, and support structures to enhance rigidity and reduce vulnerability to mechanical stresses. ###Joint Design and Fastening Techniques

The joints and fastening techniques used in assembling an enclosure significantly impact its overall rigidity. Screw fastenings, rivets, welds, and adhesives each have unique strengths and weaknesses in terms of load-bearing capacity, ease of assembly, and resistance to vibration-induced loosening. Proper joint design, including considerations for stress concentrations, material compatibility, and ease of disassembly, is crucial for maintaining the structural integrity of the enclosure over its operational lifespan. ###Thermal Expansion and Structural Stability

Temperature variations can induce thermal expansion or contraction in enclosure materials, leading to dimensional changes that affect structural stability. Accounting for thermal expansion coefficients during the design phase helps prevent buckling, warping, or mechanical failures due to excessive thermal stress. By selecting materials with compatible thermal expansion properties, engineers can ensure that the enclosure maintains its structural integrity across a range of operating temperatures, minimizing the risk of performance degradation or component damage. ---Structural Integrity and Rigidity

In designing enclosures, structural integrity and rigidity are paramount considerations, especially when housing sensitive electronic components or delicate instruments. The ability of an enclosure to withstand external forces, vibrations, and thermal variations directly impacts the longevity and performance of the enclosed devices. ###Material Selection and Properties

The choice of materials for an enclosure plays a critical role in determining its structural integrity. Metals like aluminum and steel are commonly used for their high strength-to-weight ratio and durability. Polymers such as ABS and polycarbonate offer lightweight alternatives with good impact resistance. The material properties, including Young's modulus, tensile strength, and hardness, directly influence the enclosure's ability to withstand mechanical stresses. Understanding these properties is essential for designing an enclosure that meets the desired structural requirements. ###Finite Element Analysis (FEA) for Structural Simulation

Finite Element Analysis (FEA) is a powerful tool used to simulate and analyze the structural behavior of an enclosure under various loading conditions. By dividing the enclosure into discrete elements and applying boundary conditions, FEA provides insights into stress distribution, deformation, and potential failure points. FEA helps engineers optimize the enclosure design by iteratively adjusting parameters such as wall thickness, ribbing, and support structures to enhance rigidity and reduce vulnerability to mechanical stresses. ###Joint Design and Fastening Techniques

The joints and fastening techniques used in assembling an enclosure significantly impact its overall rigidity. Screw fastenings, rivets, welds, and adhesives each have unique strengths and weaknesses in terms of load-bearing capacity, ease of assembly, and resistance to vibration-induced loosening. Proper joint design, including considerations for stress concentrations, material compatibility, and ease of disassembly, is crucial for maintaining the structural integrity of the enclosure over its operational lifespan. ###Thermal Expansion and Structural Stability

Temperature variations can induce thermal expansion or contraction in enclosure materials, leading to dimensional changes that affect structural stability. Accounting for thermal expansion coefficients during the design phase helps prevent buckling, warping, or mechanical failures due to excessive thermal stress. By selecting materials with compatible thermal expansion properties, engineers can ensure that the enclosure maintains its structural integrity across a range of operating temperatures, minimizing the risk of performance degradation or component damage. ---2.3 Sealing and Environmental Protection

In electronic enclosure design, sealing and environmental protection are crucial aspects that ensure the longevity and functionality of the enclosed components. Proper sealing techniques safeguard sensitive electronics from moisture, dust, and other environmental factors that could lead to malfunctions or failures.

When designing enclosures for electronic devices, considerations such as ingress protection (IP) rating, material selection, and sealing methods play a critical role in determining the overall effectiveness of the enclosure in harsh environments.

Understanding Ingress Protection (IP) Rating

One common standard used to classify the degree of protection an enclosure provides against foreign objects and moisture is the Ingress Protection (IP) rating system. The IP rating consists of two numbers: the first digit indicates the level of protection against solid particles, while the second digit denotes the level of protection against liquid ingress.

For example, an enclosure with an IP67 rating ensures complete protection against dust (6) and can withstand immersion in water up to 1 meter depth for 30 minutes (7). Understanding IP ratings is essential in choosing the right level of protection for specific environmental conditions.

Material Selection for Sealing

The choice of materials used in the construction of the enclosure greatly influences its sealing capabilities. Common materials for sealing include silicone gaskets, neoprene seals, and thermoplastic elastomers. These materials offer flexibility, resilience, and chemical resistance, essential for maintaining an effective seal over the lifetime of the enclosure.

Sealing Methods

Several sealing methods can be employed to ensure a robust and reliable seal in electronic enclosures:

- Compression Seals: Utilizing compression to create a tight seal, compression seals are effective in applications where the enclosure components fit tightly together.

- Gasket Seals: Gaskets made from materials such as rubber or silicone are placed between components to prevent the ingress of moisture and dust. These seals are often custom-designed to fit specific enclosure geometries.

- Adhesive Bonding: Adhesives can be used to bond enclosure components together, providing a strong seal against environmental elements. Proper surface preparation is crucial for the effectiveness of adhesive seals.

Environmental Testing and Certification

Prior to deployment, electronic enclosures often undergo environmental testing to validate their sealing efficacy and durability. Tests such as temperature cycling, humidity exposure, and water submersion are conducted to ensure the enclosure can withstand real-world conditions.

Certifications from organizations like UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission) confirm that the enclosure meets industry standards for environmental protection and safety.

2.3 Sealing and Environmental Protection

In electronic enclosure design, sealing and environmental protection are crucial aspects that ensure the longevity and functionality of the enclosed components. Proper sealing techniques safeguard sensitive electronics from moisture, dust, and other environmental factors that could lead to malfunctions or failures.

When designing enclosures for electronic devices, considerations such as ingress protection (IP) rating, material selection, and sealing methods play a critical role in determining the overall effectiveness of the enclosure in harsh environments.

Understanding Ingress Protection (IP) Rating

One common standard used to classify the degree of protection an enclosure provides against foreign objects and moisture is the Ingress Protection (IP) rating system. The IP rating consists of two numbers: the first digit indicates the level of protection against solid particles, while the second digit denotes the level of protection against liquid ingress.

For example, an enclosure with an IP67 rating ensures complete protection against dust (6) and can withstand immersion in water up to 1 meter depth for 30 minutes (7). Understanding IP ratings is essential in choosing the right level of protection for specific environmental conditions.

Material Selection for Sealing

The choice of materials used in the construction of the enclosure greatly influences its sealing capabilities. Common materials for sealing include silicone gaskets, neoprene seals, and thermoplastic elastomers. These materials offer flexibility, resilience, and chemical resistance, essential for maintaining an effective seal over the lifetime of the enclosure.

Sealing Methods

Several sealing methods can be employed to ensure a robust and reliable seal in electronic enclosures:

- Compression Seals: Utilizing compression to create a tight seal, compression seals are effective in applications where the enclosure components fit tightly together.

- Gasket Seals: Gaskets made from materials such as rubber or silicone are placed between components to prevent the ingress of moisture and dust. These seals are often custom-designed to fit specific enclosure geometries.

- Adhesive Bonding: Adhesives can be used to bond enclosure components together, providing a strong seal against environmental elements. Proper surface preparation is crucial for the effectiveness of adhesive seals.

Environmental Testing and Certification

Prior to deployment, electronic enclosures often undergo environmental testing to validate their sealing efficacy and durability. Tests such as temperature cycling, humidity exposure, and water submersion are conducted to ensure the enclosure can withstand real-world conditions.

Certifications from organizations like UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission) confirm that the enclosure meets industry standards for environmental protection and safety.

3. Injection Molding Techniques

Injection Molding Techniques

Injection molding is a widely used manufacturing process in creating intricate shapes and designs for enclosures in electronics. By understanding the principles behind injection molding, engineers can optimize the design process for producing high-quality enclosures.

Principles of Injection Molding

Injection molding involves injecting molten material into a mold cavity, allowing it to cool and solidify, resulting in the desired shape. Key factors affecting the process include:

- Mold Design: The mold determines the final shape and features of the enclosure.

- Material Selection: Choosing the right material properties is crucial for the functionality and durability of the enclosure.

- Injection Pressure and Temperature: Controlling these parameters ensures proper material flow and solidification.

Process Steps

The injection molding process typically involves several key steps:

- Clamping: The mold is held closed during injection to prevent leakage.

- Injection: Molten material is injected into the mold under high pressure.

- Cooling: The material solidifies and cools inside the mold cavity.

- Ejection: The finished part is ejected from the mold for further processing.

Key Considerations in Design

Designing for injection molding requires attention to detail and specific considerations to ensure successful production:

- Wall Thickness: Uniform wall thickness promotes even material flow and reduces defects.

- Undercuts: Limiting undercuts simplifies mold design and ejection process.

- Rounded Corners: Smooth corners facilitate material flow and ejection.

Real-World Applications

Injection molding is used extensively in various industries, including electronics, automotive, and consumer goods, to create enclosures for products such as smartphones, automotive components, and household appliances. Its versatility and efficiency make it a preferred manufacturing method for producing complex shapes at scale.

Injection Molding Techniques

Injection molding is a widely used manufacturing process in creating intricate shapes and designs for enclosures in electronics. By understanding the principles behind injection molding, engineers can optimize the design process for producing high-quality enclosures.

Principles of Injection Molding

Injection molding involves injecting molten material into a mold cavity, allowing it to cool and solidify, resulting in the desired shape. Key factors affecting the process include:

- Mold Design: The mold determines the final shape and features of the enclosure.

- Material Selection: Choosing the right material properties is crucial for the functionality and durability of the enclosure.

- Injection Pressure and Temperature: Controlling these parameters ensures proper material flow and solidification.

Process Steps

The injection molding process typically involves several key steps:

- Clamping: The mold is held closed during injection to prevent leakage.

- Injection: Molten material is injected into the mold under high pressure.

- Cooling: The material solidifies and cools inside the mold cavity.

- Ejection: The finished part is ejected from the mold for further processing.

Key Considerations in Design

Designing for injection molding requires attention to detail and specific considerations to ensure successful production:

- Wall Thickness: Uniform wall thickness promotes even material flow and reduces defects.

- Undercuts: Limiting undercuts simplifies mold design and ejection process.

- Rounded Corners: Smooth corners facilitate material flow and ejection.

Real-World Applications

Injection molding is used extensively in various industries, including electronics, automotive, and consumer goods, to create enclosures for products such as smartphones, automotive components, and household appliances. Its versatility and efficiency make it a preferred manufacturing method for producing complex shapes at scale.

3.2 CNC Machining Options

In the realm of enclosure design, CNC machining stands as a pivotal technique that offers precision, versatility, and efficiency in crafting custom enclosures for electronic devices. ### CNC Machining Overview Computer Numerical Control (CNC) machining utilizes pre-programmed computer software to dictate the movements of machinery and tools. This enables the creation of intricate designs with high accuracy and reproducibility. The process involves subtractive manufacturing, where material is carved away to achieve the final shape. ### CNC Router vs. CNC Milling CNC Routing primarily involves cutting and shaping flat sheet materials to create 2D and 3D designs. It excels in producing precise cuts on materials like wood, plastic, or aluminum. On the other hand, CNC Milling enables the creation of more complex 3D shapes by moving the cutting tool along multiple axes. It is suitable for materials like metals and harder plastics. ### CNC Machining Techniques #### 1. 3-Axis Machining For simpler geometries, 3-axis machining is often sufficient. The cutting tool moves along three axes (X, Y, Z) to carve out the desired shape. #### 2. 4-Axis Machining Introducing a rotational axis to the setup allows for more intricate designs and undercuts. This additional axis enables the tool to approach the material from different angles. #### 3. 5-Axis Machining The pinnacle of CNC machining, 5-axis capabilities provide unparalleled design freedom. It allows for complex geometries with undercuts and highly intricate details by combining three linear axes and two rotational axes. ### Practical Considerations When choosing a CNC machining option for your enclosure design, factors such as material type, design complexity, tolerances, and production volume play crucial roles. Understanding the capabilities and limitations of each machining technique is essential in achieving the desired outcome efficiently.3.2 CNC Machining Options

In the realm of enclosure design, CNC machining stands as a pivotal technique that offers precision, versatility, and efficiency in crafting custom enclosures for electronic devices. ### CNC Machining Overview Computer Numerical Control (CNC) machining utilizes pre-programmed computer software to dictate the movements of machinery and tools. This enables the creation of intricate designs with high accuracy and reproducibility. The process involves subtractive manufacturing, where material is carved away to achieve the final shape. ### CNC Router vs. CNC Milling CNC Routing primarily involves cutting and shaping flat sheet materials to create 2D and 3D designs. It excels in producing precise cuts on materials like wood, plastic, or aluminum. On the other hand, CNC Milling enables the creation of more complex 3D shapes by moving the cutting tool along multiple axes. It is suitable for materials like metals and harder plastics. ### CNC Machining Techniques #### 1. 3-Axis Machining For simpler geometries, 3-axis machining is often sufficient. The cutting tool moves along three axes (X, Y, Z) to carve out the desired shape. #### 2. 4-Axis Machining Introducing a rotational axis to the setup allows for more intricate designs and undercuts. This additional axis enables the tool to approach the material from different angles. #### 3. 5-Axis Machining The pinnacle of CNC machining, 5-axis capabilities provide unparalleled design freedom. It allows for complex geometries with undercuts and highly intricate details by combining three linear axes and two rotational axes. ### Practical Considerations When choosing a CNC machining option for your enclosure design, factors such as material type, design complexity, tolerances, and production volume play crucial roles. Understanding the capabilities and limitations of each machining technique is essential in achieving the desired outcome efficiently.3.3 3D Printing for Prototyping

When it comes to rapid prototyping in enclosure design, 3D printing has revolutionized the process. It allows engineers and designers to quickly iterate on designs, test fitment, and evaluate aesthetics before moving to production.

3D printing relies on additive manufacturing techniques, where a model is built layer by layer from a digital 3D model. This process provides significant flexibility in design complexity and material choices.

One of the key advantages of 3D printing in prototyping is the ability to create complex geometries that would be challenging or impossible with traditional manufacturing methods. This is particularly useful when designing custom enclosures for specific electronic components.

Engineers can leverage 3D printing to create prototypes with precise dimensions, intricate details, and custom features tailored to the requirements of the project. This iterative approach saves time and resources compared to traditional prototyping methods.

Here, \( V_{prototyping} \) represents the efficiency gain in prototyping with 3D printing over traditional methods, \( V_{3D\ printing} \) is the volume of successful prototypes produced using 3D printing, and \( V_{traditional\ prototyping} \) is the volume of successful prototypes produced using traditional methods.

Applications in Enclosure Design

The versatility of 3D printing extends to various aspects of enclosure design:

- Customization: Engineers can tailor enclosures to specific requirements, such as component layout, mounting points, and cable management.

- Integration: Different components can be seamlessly integrated into a single enclosure design, optimizing space and functionality.

- Prototyping Tools: 3D printing enables the creation of tooling, jigs, and fixtures that aid in the assembly and testing of electronic enclosures.

Materials and Processes

3D printing supports a wide range of materials suitable for enclosure prototyping:

- ABS: Known for its strength and durability, ABS is a popular choice for functional prototypes.

- PLA: Biodegradable and easy to print, PLA works well for concept models and non-functional prototypes.

- PC: Polycarbonate offers high impact strength and heat resistance, making it suitable for enclosures in harsh environments.

The choice of material depends on factors like durability requirements, environmental conditions, and post-processing needs.

Here, \( F_{material} \) represents the material selection factor, \( w_d \) is the weight density of the material, and \( E \) is the environmental durability index based on operating conditions.

Understanding material properties is crucial for designing enclosures that meet performance and environmental criteria.

Case Study: 3D Printed Enclosure for IoT Device

In a recent study, engineers developed a custom enclosure for an Internet of Things (IoT) device using 3D printing. The enclosure featured intricate internal supports for housing sensors, a secure compartment for the electronics board, and customizable access points for connectivity.

By utilizing 3D printing, the team rapidly iterated on design modifications based on feedback from field tests. This agile approach resulted in a final enclosure that met all functional requirements and aesthetic preferences of end-users.

The case study highlights the efficiency and effectiveness of 3D printing in creating tailored enclosures for specialized electronic devices.

3.3 3D Printing for Prototyping

When it comes to rapid prototyping in enclosure design, 3D printing has revolutionized the process. It allows engineers and designers to quickly iterate on designs, test fitment, and evaluate aesthetics before moving to production.

3D printing relies on additive manufacturing techniques, where a model is built layer by layer from a digital 3D model. This process provides significant flexibility in design complexity and material choices.

One of the key advantages of 3D printing in prototyping is the ability to create complex geometries that would be challenging or impossible with traditional manufacturing methods. This is particularly useful when designing custom enclosures for specific electronic components.

Engineers can leverage 3D printing to create prototypes with precise dimensions, intricate details, and custom features tailored to the requirements of the project. This iterative approach saves time and resources compared to traditional prototyping methods.

Here, \( V_{prototyping} \) represents the efficiency gain in prototyping with 3D printing over traditional methods, \( V_{3D\ printing} \) is the volume of successful prototypes produced using 3D printing, and \( V_{traditional\ prototyping} \) is the volume of successful prototypes produced using traditional methods.

Applications in Enclosure Design

The versatility of 3D printing extends to various aspects of enclosure design:

- Customization: Engineers can tailor enclosures to specific requirements, such as component layout, mounting points, and cable management.

- Integration: Different components can be seamlessly integrated into a single enclosure design, optimizing space and functionality.

- Prototyping Tools: 3D printing enables the creation of tooling, jigs, and fixtures that aid in the assembly and testing of electronic enclosures.

Materials and Processes

3D printing supports a wide range of materials suitable for enclosure prototyping:

- ABS: Known for its strength and durability, ABS is a popular choice for functional prototypes.

- PLA: Biodegradable and easy to print, PLA works well for concept models and non-functional prototypes.

- PC: Polycarbonate offers high impact strength and heat resistance, making it suitable for enclosures in harsh environments.

The choice of material depends on factors like durability requirements, environmental conditions, and post-processing needs.

Here, \( F_{material} \) represents the material selection factor, \( w_d \) is the weight density of the material, and \( E \) is the environmental durability index based on operating conditions.

Understanding material properties is crucial for designing enclosures that meet performance and environmental criteria.

Case Study: 3D Printed Enclosure for IoT Device

In a recent study, engineers developed a custom enclosure for an Internet of Things (IoT) device using 3D printing. The enclosure featured intricate internal supports for housing sensors, a secure compartment for the electronics board, and customizable access points for connectivity.

By utilizing 3D printing, the team rapidly iterated on design modifications based on feedback from field tests. This agile approach resulted in a final enclosure that met all functional requirements and aesthetic preferences of end-users.

The case study highlights the efficiency and effectiveness of 3D printing in creating tailored enclosures for specialized electronic devices.

4. Understanding CE Marking

4.1 Understanding CE Marking

In the realm of electronic enclosure design, understanding the implications and requirements of the CE marking is crucial. The CE marking is a mandatory conformity mark for products sold within the European Economic Area (EEA). This mark indicates that the product complies with relevant European Union (EU) directives regarding safety, health, and environmental protection.

Achieving CE compliance involves a detailed evaluation of the product against the applicable directives, standards, and regulations. This process ensures that the product meets essential requirements concerning safety, electromagnetic compatibility (EMC), and other relevant aspects.

The CE marking is not a quality mark but rather a declaration by the manufacturer that the product meets the essential requirements set out in the applicable directives. This mark enables the product to be freely marketed and sold within the EEA.

The key directives that often apply to electronic products in the context of enclosure design include the Low Voltage Directive (LVD), the Electromagnetic Compatibility Directive (EMC), and the Restriction of Hazardous Substances Directive (RoHS). Complying with these directives involves rigorous testing and documentation to ensure that the product poses no risks to users or the environment.

The process of obtaining CE marking involves several steps, including:

- Understanding the applicable directives and requirements for the specific product category.

- Conducting risk assessments and necessary tests to ensure compliance.

- Compiling technical documentation, including test reports and a Declaration of Conformity.

- Affixing the CE marking to the product, packaging, or accompanying documentation.

Designing enclosures with CE compliance in mind requires attention to detail in areas such as insulation, grounding, shielding, ventilation, and material selection. Ensuring proper EMC performance, thermal management, and safety features are essential considerations in achieving CE conformity for electronic products.

By understanding the intricacies of CE marking and integrating compliance measures early in the design process, engineers can create products that not only meet regulatory requirements but also uphold high standards of safety and quality in the market.

4.1 Understanding CE Marking

In the realm of electronic enclosure design, understanding the implications and requirements of the CE marking is crucial. The CE marking is a mandatory conformity mark for products sold within the European Economic Area (EEA). This mark indicates that the product complies with relevant European Union (EU) directives regarding safety, health, and environmental protection.

Achieving CE compliance involves a detailed evaluation of the product against the applicable directives, standards, and regulations. This process ensures that the product meets essential requirements concerning safety, electromagnetic compatibility (EMC), and other relevant aspects.

The CE marking is not a quality mark but rather a declaration by the manufacturer that the product meets the essential requirements set out in the applicable directives. This mark enables the product to be freely marketed and sold within the EEA.

The key directives that often apply to electronic products in the context of enclosure design include the Low Voltage Directive (LVD), the Electromagnetic Compatibility Directive (EMC), and the Restriction of Hazardous Substances Directive (RoHS). Complying with these directives involves rigorous testing and documentation to ensure that the product poses no risks to users or the environment.

The process of obtaining CE marking involves several steps, including:

- Understanding the applicable directives and requirements for the specific product category.

- Conducting risk assessments and necessary tests to ensure compliance.

- Compiling technical documentation, including test reports and a Declaration of Conformity.

- Affixing the CE marking to the product, packaging, or accompanying documentation.

Designing enclosures with CE compliance in mind requires attention to detail in areas such as insulation, grounding, shielding, ventilation, and material selection. Ensuring proper EMC performance, thermal management, and safety features are essential considerations in achieving CE conformity for electronic products.

By understanding the intricacies of CE marking and integrating compliance measures early in the design process, engineers can create products that not only meet regulatory requirements but also uphold high standards of safety and quality in the market.

4.2 RoHS Compliance

Manufacturers of electronic devices face stringent regulations that require compliance with directives such as the Restriction of Hazardous Substances (RoHS). RoHS compliance restricts the use of hazardous materials in electrical and electronic equipment, ensuring the protection of human health and the environment. Let's delve into the key aspects of RoHS compliance in electronics design. ### RoHS Directive Background The RoHS Directive originated in the European Union and aims to limit the use of certain hazardous substances like lead, mercury, cadmium, and others in electronic products. Compliance with RoHS is a legal requirement for products sold in the EU and often influences global manufacturing practices due to market demands. ### Importance of RoHS Compliance Ensuring RoHS compliance is crucial for electronic device manufacturers to access European markets and meet international environmental standards. Non-compliance can result in heavy fines, product recalls, damage to brand reputation, and legal consequences. ### Requirements for RoHS Compliance 1. Restricted Substances: The RoHS Directive currently restricts the use of six substances in electronics: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs). 2. Exemptions: Certain exemptions exist for specific applications or industries, allowing limited use of restricted substances where alternatives are not technically feasible. 3. Supplier Declarations: Manufacturers must obtain Declarations of RoHS compliance from their component suppliers to ensure transparency in the supply chain. ### Compliance Testing X-ray Fluorescence (XRF) and Energy Dispersive X-ray Fluorescence (EDXRF) are common techniques used to test products for RoHS compliance. These methods analyze the elemental composition of materials to detect banned substances. ### Design Strategies for RoHS Compliance - Material Selection: Opt for RoHS-compliant materials at the design stage to simplify compliance. - Design for Environment (DfE): Implement design practices that minimize the use of hazardous substances and facilitate recycling at the end of the product's life cycle. - Supply Chain Management: Ensure clear communication with suppliers regarding RoHS compliance and maintain proper documentation. By integrating RoHS considerations into the design process, engineers can create environmentally friendly products that align with global regulatory standards. This proactive approach not only benefits the environment but also enhances market acceptability and sustainability practices within the electronics industry.4.2 RoHS Compliance

Manufacturers of electronic devices face stringent regulations that require compliance with directives such as the Restriction of Hazardous Substances (RoHS). RoHS compliance restricts the use of hazardous materials in electrical and electronic equipment, ensuring the protection of human health and the environment. Let's delve into the key aspects of RoHS compliance in electronics design. ### RoHS Directive Background The RoHS Directive originated in the European Union and aims to limit the use of certain hazardous substances like lead, mercury, cadmium, and others in electronic products. Compliance with RoHS is a legal requirement for products sold in the EU and often influences global manufacturing practices due to market demands. ### Importance of RoHS Compliance Ensuring RoHS compliance is crucial for electronic device manufacturers to access European markets and meet international environmental standards. Non-compliance can result in heavy fines, product recalls, damage to brand reputation, and legal consequences. ### Requirements for RoHS Compliance 1. Restricted Substances: The RoHS Directive currently restricts the use of six substances in electronics: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs). 2. Exemptions: Certain exemptions exist for specific applications or industries, allowing limited use of restricted substances where alternatives are not technically feasible. 3. Supplier Declarations: Manufacturers must obtain Declarations of RoHS compliance from their component suppliers to ensure transparency in the supply chain. ### Compliance Testing X-ray Fluorescence (XRF) and Energy Dispersive X-ray Fluorescence (EDXRF) are common techniques used to test products for RoHS compliance. These methods analyze the elemental composition of materials to detect banned substances. ### Design Strategies for RoHS Compliance - Material Selection: Opt for RoHS-compliant materials at the design stage to simplify compliance. - Design for Environment (DfE): Implement design practices that minimize the use of hazardous substances and facilitate recycling at the end of the product's life cycle. - Supply Chain Management: Ensure clear communication with suppliers regarding RoHS compliance and maintain proper documentation. By integrating RoHS considerations into the design process, engineers can create environmentally friendly products that align with global regulatory standards. This proactive approach not only benefits the environment but also enhances market acceptability and sustainability practices within the electronics industry.5. Consumer Electronics Case Study

Consumer Electronics Case Study

In the realm of enclosure design for consumer electronics, a vital consideration is ensuring the balance between aesthetics, functionality, and practicality. Let's delve into a case study that illustrates the intricate interplay of various factors in the design process. #### Understanding User Interaction Dynamics Consumer electronics, such as smartphones, exemplify the fusion of cutting-edge technology with sleek design. In the journey of creating the ideal smartphone enclosure, engineers must meticulously study user interaction dynamics. Factors like button placement, screen accessibility, and overall ergonomics profoundly influence the design. #### Material Selection for Durability and Aesthetics The choice of materials plays a pivotal role in the durability and aesthetics of electronic enclosures. In our case study, engineers opt for premium-grade aluminum alloys due to their lightweight nature, robustness, and ability to facilitate intricate design details. The material must also undergo rigorous testing to ensure it withstands daily wear and tear. #### Heat Dissipation and Thermal Management Efficient heat dissipation is paramount in consumer electronics to prevent overheating and ensure optimal device performance. Our case study incorporates innovative thermal management solutions, such as heat pipes and strategically placed ventilation systems, to enhance heat dissipation while maintaining a slim profile. #### Seamless Integration of Components In the pursuit of a sleek and streamlined design, the seamless integration of components is a top priority. Precision engineering and meticulous layout planning are crucial to maximize internal space utilization without compromising on functionality. This includes accommodating batteries, circuit boards, and speakers within the confined enclosure space. #### Design for Manufacturing (DFM) Considerations Manufacturability is a key aspect that influences the design process. Our case study emphasizes Design for Manufacturing (DFM) principles to streamline production processes and minimize material waste. The enclosure design must strike a balance between complexity and simplicity to enable cost-effective mass production without compromising on quality. #### User-Centric Design Iterations Iterative design plays a crucial role in refining the consumer electronics enclosure to meet user preferences and market demands. Feedback from focus groups, usability tests, and market trends guide the iterative design process, ensuring that the final product not only meets technical specifications but also resonates with the target audience. By delving into this consumer electronics case study, we gain valuable insights into the intricate craftsmanship and engineering excellence required to create functional, aesthetically pleasing, and user-centric electronic enclosures. This real-world example underscores the fusion of art and science in the realm of enclosure design for consumer electronics.Consumer Electronics Case Study

In the realm of enclosure design for consumer electronics, a vital consideration is ensuring the balance between aesthetics, functionality, and practicality. Let's delve into a case study that illustrates the intricate interplay of various factors in the design process. #### Understanding User Interaction Dynamics Consumer electronics, such as smartphones, exemplify the fusion of cutting-edge technology with sleek design. In the journey of creating the ideal smartphone enclosure, engineers must meticulously study user interaction dynamics. Factors like button placement, screen accessibility, and overall ergonomics profoundly influence the design. #### Material Selection for Durability and Aesthetics The choice of materials plays a pivotal role in the durability and aesthetics of electronic enclosures. In our case study, engineers opt for premium-grade aluminum alloys due to their lightweight nature, robustness, and ability to facilitate intricate design details. The material must also undergo rigorous testing to ensure it withstands daily wear and tear. #### Heat Dissipation and Thermal Management Efficient heat dissipation is paramount in consumer electronics to prevent overheating and ensure optimal device performance. Our case study incorporates innovative thermal management solutions, such as heat pipes and strategically placed ventilation systems, to enhance heat dissipation while maintaining a slim profile. #### Seamless Integration of Components In the pursuit of a sleek and streamlined design, the seamless integration of components is a top priority. Precision engineering and meticulous layout planning are crucial to maximize internal space utilization without compromising on functionality. This includes accommodating batteries, circuit boards, and speakers within the confined enclosure space. #### Design for Manufacturing (DFM) Considerations Manufacturability is a key aspect that influences the design process. Our case study emphasizes Design for Manufacturing (DFM) principles to streamline production processes and minimize material waste. The enclosure design must strike a balance between complexity and simplicity to enable cost-effective mass production without compromising on quality. #### User-Centric Design Iterations Iterative design plays a crucial role in refining the consumer electronics enclosure to meet user preferences and market demands. Feedback from focus groups, usability tests, and market trends guide the iterative design process, ensuring that the final product not only meets technical specifications but also resonates with the target audience. By delving into this consumer electronics case study, we gain valuable insights into the intricate craftsmanship and engineering excellence required to create functional, aesthetically pleasing, and user-centric electronic enclosures. This real-world example underscores the fusion of art and science in the realm of enclosure design for consumer electronics.5.3 Medical Device Housing

In the realm of medical devices, housing plays a crucial role in ensuring both the functionality and safety of the equipment. The design of the enclosure for medical devices is a sophisticated task that demands meticulous attention to detail. Factors such as material selection, electromagnetic compatibility, sterilization requirements, and patient safety standards must all be carefully considered during the design process. ###Material Selection

The choice of materials for medical device housing is critical to the overall performance and durability of the equipment. Factors like biocompatibility, strength, impact resistance, and sterilizability are paramount. Common materials used in medical device enclosures include medical-grade plastics, stainless steel, aluminum, and titanium. Each material offers unique properties that cater to specific requirements of the medical device. ###Electromagnetic Compatibility (EMC)

In the medical field, electromagnetic interference (EMI) can significantly impact the performance of electronic devices. Therefore, medical device enclosures must adhere to stringent EMC standards to ensure proper functioning and reliability. Shielding materials, grounding techniques, and appropriate design practices are essential to mitigate the effects of EMI on sensitive medical equipment. ###Sterilization Requirements

Medical devices must undergo rigorous sterilization processes to maintain a sterile environment during usage. The housing design should facilitate easy cleaning and sterilization procedures without compromising the integrity of the device. Factors such as smooth surfaces, ingress protection ratings, and material compatibility with sterilization methods play a vital role in ensuring the effectiveness of sterilization processes. ###Patient Safety Standards

Ensuring the safety of patients is paramount in medical device design. The housing should be ergonomically designed to enhance user comfort and reduce the risk of user-related errors. Clear labeling, intuitive interfaces, and proper ventilation are crucial aspects of medical device housing that contribute to overall patient safety. By integrating these considerations into the design of medical device housing, engineers and designers can develop products that meet the high standards of the medical industry while prioritizing user safety and device performance. The intricate interplay between material science, electromagnetics, sterilization techniques, and safety standards culminates in the creation of robust and reliable medical devices that improve patient outcomes and healthcare practices.5.3 Medical Device Housing

In the realm of medical devices, housing plays a crucial role in ensuring both the functionality and safety of the equipment. The design of the enclosure for medical devices is a sophisticated task that demands meticulous attention to detail. Factors such as material selection, electromagnetic compatibility, sterilization requirements, and patient safety standards must all be carefully considered during the design process. ###Material Selection

The choice of materials for medical device housing is critical to the overall performance and durability of the equipment. Factors like biocompatibility, strength, impact resistance, and sterilizability are paramount. Common materials used in medical device enclosures include medical-grade plastics, stainless steel, aluminum, and titanium. Each material offers unique properties that cater to specific requirements of the medical device. ###Electromagnetic Compatibility (EMC)

In the medical field, electromagnetic interference (EMI) can significantly impact the performance of electronic devices. Therefore, medical device enclosures must adhere to stringent EMC standards to ensure proper functioning and reliability. Shielding materials, grounding techniques, and appropriate design practices are essential to mitigate the effects of EMI on sensitive medical equipment. ###Sterilization Requirements

Medical devices must undergo rigorous sterilization processes to maintain a sterile environment during usage. The housing design should facilitate easy cleaning and sterilization procedures without compromising the integrity of the device. Factors such as smooth surfaces, ingress protection ratings, and material compatibility with sterilization methods play a vital role in ensuring the effectiveness of sterilization processes. ###Patient Safety Standards

Ensuring the safety of patients is paramount in medical device design. The housing should be ergonomically designed to enhance user comfort and reduce the risk of user-related errors. Clear labeling, intuitive interfaces, and proper ventilation are crucial aspects of medical device housing that contribute to overall patient safety. By integrating these considerations into the design of medical device housing, engineers and designers can develop products that meet the high standards of the medical industry while prioritizing user safety and device performance. The intricate interplay between material science, electromagnetics, sterilization techniques, and safety standards culminates in the creation of robust and reliable medical devices that improve patient outcomes and healthcare practices.6. Smart Enclosures with IoT Integration

Smart Enclosures with IoT Integration

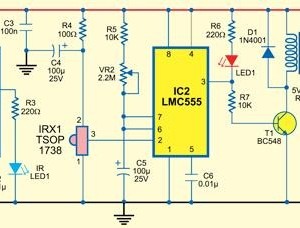

In the realm of enclosure design, integrating IoT capabilities with enclosures has revolutionized the way we interact with and monitor various systems. Smart enclosures leverage IoT technologies to enable remote monitoring, control, and data collection. This subsection delves into the intricate details of designing and implementing smart enclosures with IoT integration for advanced applications. Smart enclosures with IoT integration combine traditional enclosure design principles with cutting-edge sensors, actuators, and communication modules. By seamlessly integrating IoT components into enclosures, engineers can create intelligent systems that offer enhanced functionality, efficiency, and connectivity. ###Sensors and Data Acquisition:

Central to smart enclosures is the deployment of sensors for capturing environmental parameters, such as temperature, humidity, pressure, and light intensity. These sensors play a crucial role in monitoring the enclosure's surroundings and collecting real-time data. The acquired data is then processed and transmitted using IoT protocols to enable remote access and analysis. ###Actuators and Control Systems:

In addition to sensors, smart enclosures incorporate actuators to enable responsive control over enclosed systems. Actuators allow for automated adjustments based on sensor data, enhancing the enclosure's adaptability and functionality. By integrating actuators controlled through IoT platforms, engineers can remotely manage various aspects of the enclosure's operation. ###Communication Protocols:

IoT integration in enclosures relies on efficient communication protocols to facilitate seamless data transfer between the enclosure and external devices or cloud platforms. Common protocols such as MQTT, CoAP, and HTTP are utilized to establish stable connections and ensure secure data exchange. Choosing the appropriate communication protocol is essential for reliable IoT operation within the enclosure ecosystem. ###Energy Management:

Efficient energy management is paramount for sustainable operation of smart enclosures. Implementing power-efficient components, energy harvesting techniques, and optimized power management systems ensures long-term functionality without frequent maintenance. IoT-enabled energy monitoring and control mechanisms contribute to maintaining the enclosure's energy balance and longevity. ###Data Analytics and Visualization:

The data collected from smart enclosures holds valuable insights that can be leveraged through advanced analytics and visualization tools. By employing machine learning algorithms, predictive analytics, and interactive dashboards, engineers can extract actionable information from the data streams generated by IoT-enabled enclosures. Visualizing essential metrics and trends enhances decision-making and system optimization. ###Security and Privacy Considerations:

Securing IoT-integrated enclosures against cyber threats and unauthorized access is critical for maintaining data integrity and operational safety. Implementing robust encryption methods, access controls, and intrusion detection systems safeguards sensitive information transmitted within the enclosure network. Prioritizing security measures ensures the reliability and resilience of smart enclosures in the face of evolving cyber risks. --- Within the realm of enclosure design, the integration of IoT technologies opens up a realm of possibilities for creating intelligent and adaptive systems. By incorporating sensors, actuators, communication protocols, energy management strategies, data analytics, and security measures, engineers can craft smart enclosures that redefine the capabilities of traditional enclosures. The synergy between enclosure design principles and IoT innovation paves the way for enhanced efficiency, functionality, and connectivity in diverse applications.Smart Enclosures with IoT Integration

In the realm of enclosure design, integrating IoT capabilities with enclosures has revolutionized the way we interact with and monitor various systems. Smart enclosures leverage IoT technologies to enable remote monitoring, control, and data collection. This subsection delves into the intricate details of designing and implementing smart enclosures with IoT integration for advanced applications. Smart enclosures with IoT integration combine traditional enclosure design principles with cutting-edge sensors, actuators, and communication modules. By seamlessly integrating IoT components into enclosures, engineers can create intelligent systems that offer enhanced functionality, efficiency, and connectivity. ###Sensors and Data Acquisition:

Central to smart enclosures is the deployment of sensors for capturing environmental parameters, such as temperature, humidity, pressure, and light intensity. These sensors play a crucial role in monitoring the enclosure's surroundings and collecting real-time data. The acquired data is then processed and transmitted using IoT protocols to enable remote access and analysis. ###Actuators and Control Systems:

In addition to sensors, smart enclosures incorporate actuators to enable responsive control over enclosed systems. Actuators allow for automated adjustments based on sensor data, enhancing the enclosure's adaptability and functionality. By integrating actuators controlled through IoT platforms, engineers can remotely manage various aspects of the enclosure's operation. ###Communication Protocols:

IoT integration in enclosures relies on efficient communication protocols to facilitate seamless data transfer between the enclosure and external devices or cloud platforms. Common protocols such as MQTT, CoAP, and HTTP are utilized to establish stable connections and ensure secure data exchange. Choosing the appropriate communication protocol is essential for reliable IoT operation within the enclosure ecosystem. ###Energy Management:

Efficient energy management is paramount for sustainable operation of smart enclosures. Implementing power-efficient components, energy harvesting techniques, and optimized power management systems ensures long-term functionality without frequent maintenance. IoT-enabled energy monitoring and control mechanisms contribute to maintaining the enclosure's energy balance and longevity. ###Data Analytics and Visualization:

The data collected from smart enclosures holds valuable insights that can be leveraged through advanced analytics and visualization tools. By employing machine learning algorithms, predictive analytics, and interactive dashboards, engineers can extract actionable information from the data streams generated by IoT-enabled enclosures. Visualizing essential metrics and trends enhances decision-making and system optimization. ###Security and Privacy Considerations:

Securing IoT-integrated enclosures against cyber threats and unauthorized access is critical for maintaining data integrity and operational safety. Implementing robust encryption methods, access controls, and intrusion detection systems safeguards sensitive information transmitted within the enclosure network. Prioritizing security measures ensures the reliability and resilience of smart enclosures in the face of evolving cyber risks. --- Within the realm of enclosure design, the integration of IoT technologies opens up a realm of possibilities for creating intelligent and adaptive systems. By incorporating sensors, actuators, communication protocols, energy management strategies, data analytics, and security measures, engineers can craft smart enclosures that redefine the capabilities of traditional enclosures. The synergy between enclosure design principles and IoT innovation paves the way for enhanced efficiency, functionality, and connectivity in diverse applications.6.2 Sustainable Materials and Recycling

In the realm of enclosure design, considering sustainable materials and recycling practices is paramount for both environmental responsibility and cost-effectiveness. By opting for eco-friendly materials and implementing efficient recycling strategies, engineers and manufacturers can significantly reduce the impact of electronic products on the environment. ### Sustainable Materials Selection One fundamental aspect of sustainable enclosure design is the careful selection of materials. Choosing biodegradable, recyclable, or renewable resources can substantially minimize the carbon footprint of the product. Materials such as bamboo, recycled plastics, and bio-based polymers offer viable alternatives to traditional, non-renewable options. The advanced properties of these materials, including durability and thermal conductivity, make them increasingly popular choices in modern engineering. ### Recycling Strategies Implementing effective recycling strategies is another pivotal factor in sustainable enclosure design. Designing products with disassembly and material separation in mind facilitates the recycling process. By ensuring that components are easily separable and identifiable, manufacturers can streamline the recycling of materials such as metals, plastics, and electronic components. Additionally, incorporating standardized labeling for recyclable parts can further enhance the efficiency of recycling operations. ### Environmental Impact Considerations When assessing the environmental impact of enclosure materials, life cycle analysis plays a crucial role. Understanding the environmental footprint of materials from extraction to disposal enables engineers to make informed decisions regarding material selection and design optimization. This comprehensive approach considers factors such as energy consumption, emissions, and resource depletion, providing a holistic view of the environmental implications of enclosure design choices. ### Practical Applications In real-world applications, sustainable enclosure design principles are increasingly being adopted across various industries. From consumer electronics to industrial machinery, the integration of eco-friendly materials and recycling practices is reshaping product development strategies. By incorporating sustainable design principles early in the development process, companies can create innovative products that align with environmental regulations and consumer preferences.6.2 Sustainable Materials and Recycling