fluorescent lamp project

Compact Fluorescent Lamps (CFL) are affordable, widely available, and easy to find. However, these lamps often do not last as long as their warranty period. Typically, the electronic components fail while the lamp itself remains functional, making it suitable for repurposing in projects. When a CFL fails to operate, it can be converted into a battery-powered camping lamp. To begin, use a saw to cut the non-functional light bulb along the sonic weld area, as indicated by the red line in the accompanying figure. This process separates the fluorescent lamp from the electronic circuit, which is generally mounted on a small round printed circuit board populated with surface mount components. Although diagnosing and repairing the lamp is possible with a similar functioning bulb and some patience, it may not be practical unless it serves as a learning experience. After cutting, the lamp can be secured with several 4-40 screws, using the plastic ring on the metal side of an empty coffee can or another suitable enclosure. The newly assembled driver circuit, battery, and possibly a battery charger can be housed within this container. Suitable battery types for this project include rechargeable options such as Nickel Cadmium (NiCd), Nickel Metal Hydride (NiMH), Lithium Ion (Li-Ion), or sealed lead-acid batteries, with variations in their charger circuits. The driver circuit utilized in this project is a single transistor blocking oscillator. Blocking oscillators are efficient for driving fluorescent loads because the phosphor continues to glow for a period after each excitation pulse. The operating frequency, which influences brightness and circuit efficiency, is primarily determined by the resistor R2 and capacitor C2. Adjusting the values of R2 or C2 modifies both the frequency and brightness of the bulb. Audio or ferrite core transformers can handle higher frequencies more effectively than standard power transformers. To ensure longevity, it is important to monitor the maximum bulb current, which should typically not exceed 10-12 Watts for smaller lamp tubes. The usual ionization voltages for these tubes range from 60-80 Volts. If necessary, the capacitor C3 can be adjusted to limit the tube current according to the specific lamp in use. Higher instantaneous current is permissible due to the pulse drive nature of the circuit. The output voltage is significantly influenced by the transformer turns ratio. While a transformer from a tube or transistor radio can be used for simplicity, a custom coil wound from an old transformer’s lamination or a ferrite toroid core transformer is also effective. The transformer for this blocking oscillator has a turns ratio of 20:1, but a small power transformer rated for 120 Vac to 12 Vac can also be utilized. A complete eight-piece parts kit, excluding the battery and lamp, is available for $25, which includes shipping and an appropriate transformer. A seven-piece parts kit, excluding the battery, lamp, and transformer, is priced at $15 and also includes shipping. All parts are guaranteed to work, whether new or recycled.

Parts and materials:

- B1: Battery, 12 Volt

- C1: Capacitor, 0.1 µF, 25V, Film or Disc

- C2: Capacitor, 0.01 µF, 25V, Film or Disc

- C3: Capacitor, 0.1 µF, 25V, Disc

- D1: Diode, 1N914

- Q1: Transistor, 2N2102, NPN, HS Switch

- R1: Resistor, 12K, 5%, 1/4W, CC

- R2: Resistor, 10K, 5%, 1/4W, CC

- TR1: Transformer, Output or Power, 120Vac/12Vac

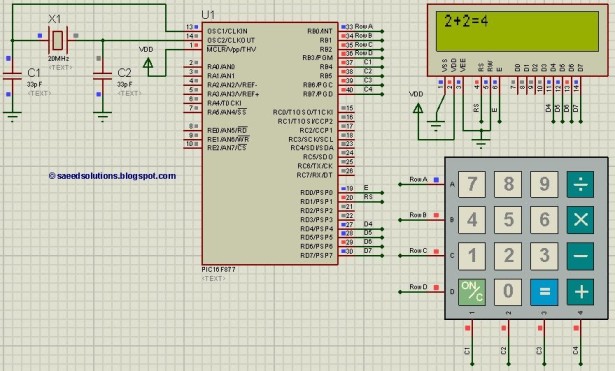

The schematic for this circuit will illustrate the arrangement of these components, showing how the battery connects to the driver circuit, which then drives the fluorescent lamp. The blocking oscillator configuration will be highlighted, demonstrating the relationship between the transistor, capacitors, and the transformer. The circuit's design ensures efficient operation and adaptability for various battery types, making it suitable for portable applications such as camping lamps.Compact Fluorescent Lamps [CFL] are low in price, plentiful and easy to find. Unfortunately, the current crop of these lamps seldom lasts as long as their warranty. Usually only the electronics fail and the lamp part of the bulb assembly are still very useable to provide the necessary part for this project. So next time one of those new technology bulbs refused to function convert it to a battery powered camping lamp. Using a saw cut the defunct light bulb apart along the sonic weld area, indicated by the red line in Figure 1. The object of the cutting is to separate and remove the fluorescent lamp from the rest of the circuit.

The electronic circuit is usually on a small round printed circuit board that is loaded with surface mount components. It is possible to diagnose the cause of the failure and repair the lamp. To do this another identical bulb and sufficient patience is a requirement but unless it is a learning project, it is more trouble than what it is worth.

After the cut is completed, mount the lamp with a few 4-40 screws, using the plastic ring on the metal side of an empty coffee can or some other suitable box. The newly built driver circuit, battery and maybe the battery charger can be housed inside that container.

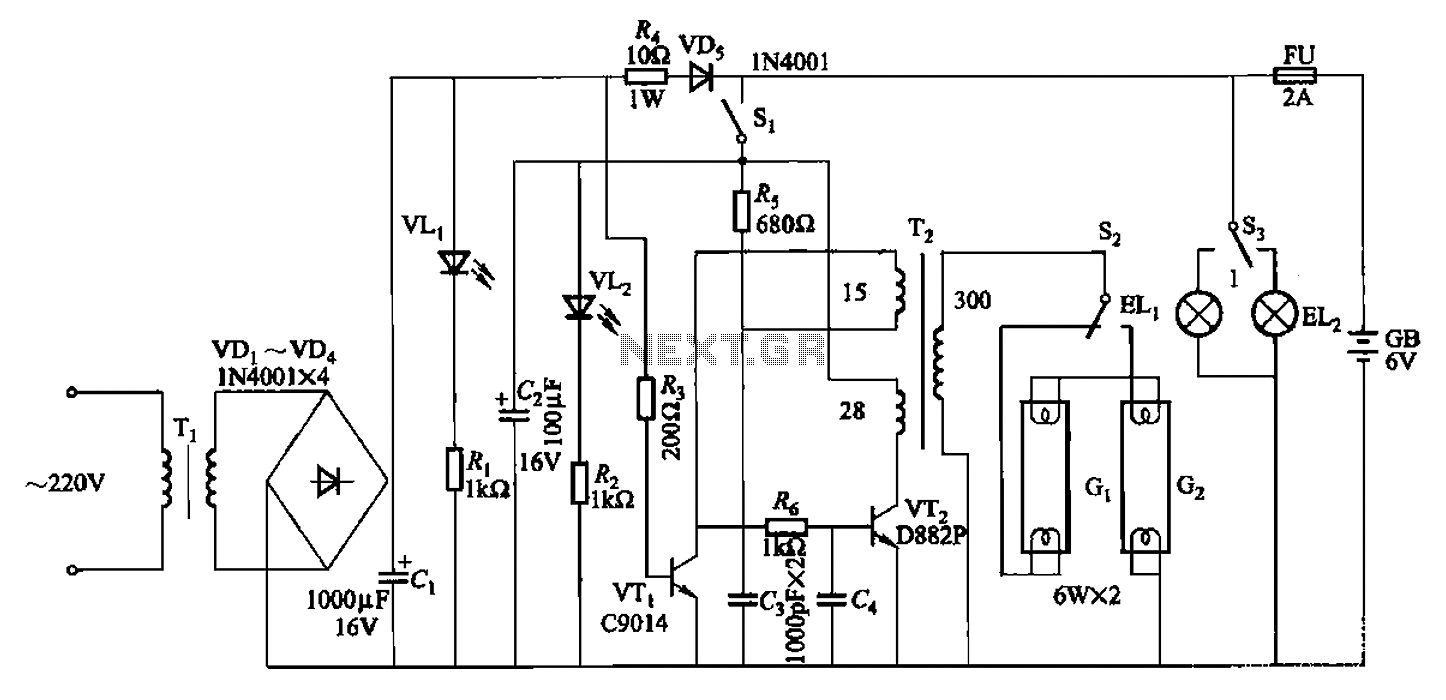

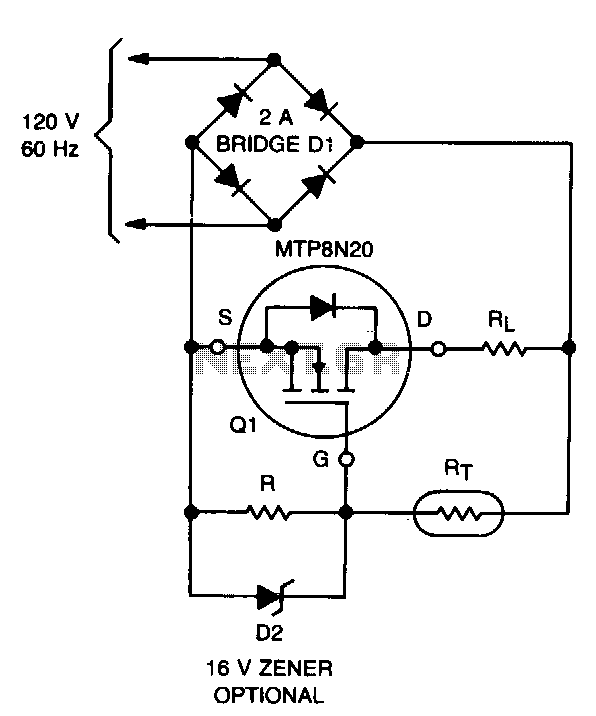

The battery for this project can be some rechargeable type. NiCd (Nickel Cadmium), NiMHd (Nickel Metal Hydride), Li-Ion (Lithium Ion) or sealed lead acid batteries will work properly, only their charger circuit differs. The driver circuit used here is a single transistor, blocking oscillator - Figure 2. Blocking oscillators are nearly ideal to drive fluorescent load because the phosphor glows a relatively long time after each excitation pulse.

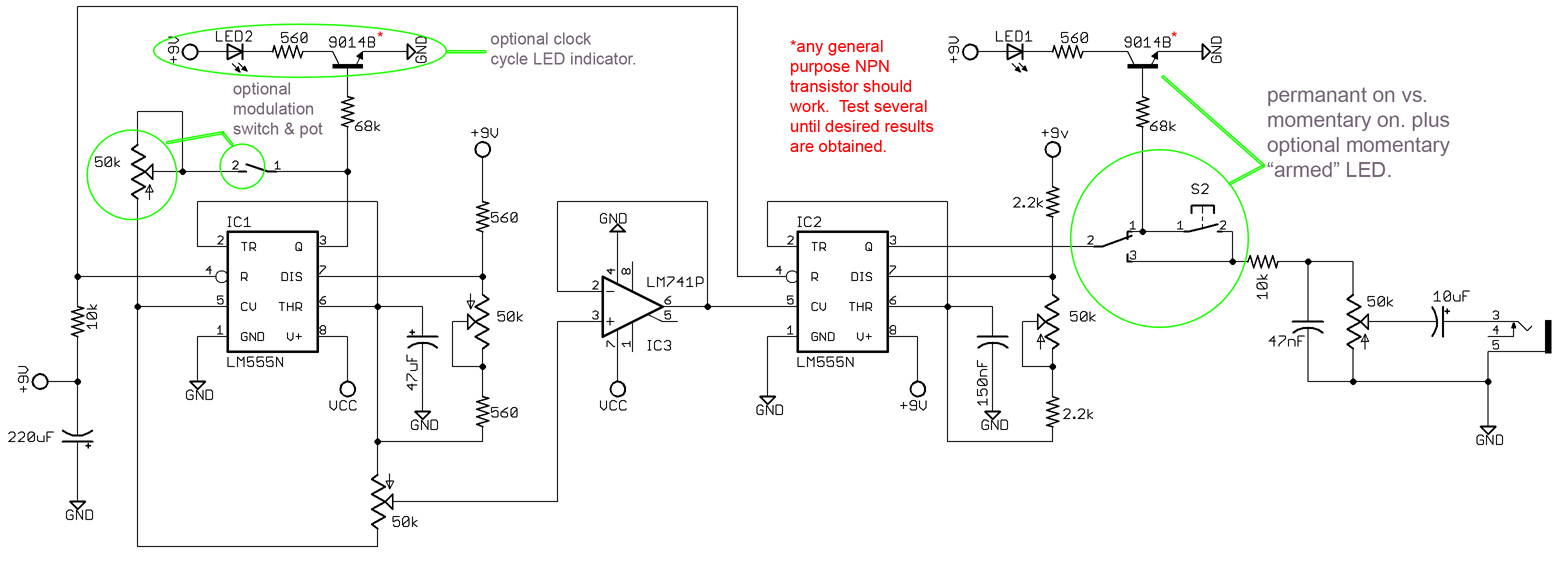

The higher the frequency - within reason - the brighter the bulb and the higher the circuit efficiency will be. Operating frequency is set mostly by R2, C2 - Figure 3. Changing the value of the R2 resistor or the C2 capacitor adjusts the frequency and the brightness. Audio or ferrite core transformers are able to work on higher frequencies efficiently than power transformers.

The maximum bulb current should be observed to keep lamp life long. On smaller lamp tubes 10-12 Watts is a reasonable maximum dissipation value. Usual tube ionization voltages are in the 60-80 Volt range. Adjust the value of C3 capacitor if necessary to the lamp on hand to limit the tube current. With pulse drive, higher instantaneous current is permitted. The available voltage depends highly on the transformer turns ratio. For simplicity, an output transformer from a tube or transistor radio can be used, but a custom-made coil wound using an old transformer`s lamination or a ferrite toroid core transformer would work just fine. The transformer for this blocking oscillator had a turn ratio of 20:1 but a 120 Vac/12 Vac small power transformer can also be used.

The complete eight-piece parts kit without the battery and the lamp is available for this circuit for $25 that includes shipping and a suitable transformer. A seven-piece parts kit without the battery, lamp and transformer that includes shipping is $15. Parts are new or recycled. All guaranteed to work. Order here. Parts and materials: B1 - Battery, 12 Volt C1 - Capacitor, 0. 1 uF, 25V, Film or Disc C2 - Capacitor, 0. 01 uF, 25V, Film or Disc C3 - Capacitor, 0. 1 uF, 25V, Disc D1 - Diode, 1N914 Q1 - Transistor, 2N2102, NPN, HS Switch R1 - Resistor, 12K, 5%, 1/4W, CC R2 - Resistor, 10K, 5%, 1/4W, CC TR1 - Transformer, Output or Power 120Vac/12Vac

🔗 External reference

Parts and materials:

- B1: Battery, 12 Volt

- C1: Capacitor, 0.1 µF, 25V, Film or Disc

- C2: Capacitor, 0.01 µF, 25V, Film or Disc

- C3: Capacitor, 0.1 µF, 25V, Disc

- D1: Diode, 1N914

- Q1: Transistor, 2N2102, NPN, HS Switch

- R1: Resistor, 12K, 5%, 1/4W, CC

- R2: Resistor, 10K, 5%, 1/4W, CC

- TR1: Transformer, Output or Power, 120Vac/12Vac

The schematic for this circuit will illustrate the arrangement of these components, showing how the battery connects to the driver circuit, which then drives the fluorescent lamp. The blocking oscillator configuration will be highlighted, demonstrating the relationship between the transistor, capacitors, and the transformer. The circuit's design ensures efficient operation and adaptability for various battery types, making it suitable for portable applications such as camping lamps.Compact Fluorescent Lamps [CFL] are low in price, plentiful and easy to find. Unfortunately, the current crop of these lamps seldom lasts as long as their warranty. Usually only the electronics fail and the lamp part of the bulb assembly are still very useable to provide the necessary part for this project. So next time one of those new technology bulbs refused to function convert it to a battery powered camping lamp. Using a saw cut the defunct light bulb apart along the sonic weld area, indicated by the red line in Figure 1. The object of the cutting is to separate and remove the fluorescent lamp from the rest of the circuit.

The electronic circuit is usually on a small round printed circuit board that is loaded with surface mount components. It is possible to diagnose the cause of the failure and repair the lamp. To do this another identical bulb and sufficient patience is a requirement but unless it is a learning project, it is more trouble than what it is worth.

After the cut is completed, mount the lamp with a few 4-40 screws, using the plastic ring on the metal side of an empty coffee can or some other suitable box. The newly built driver circuit, battery and maybe the battery charger can be housed inside that container.

The battery for this project can be some rechargeable type. NiCd (Nickel Cadmium), NiMHd (Nickel Metal Hydride), Li-Ion (Lithium Ion) or sealed lead acid batteries will work properly, only their charger circuit differs. The driver circuit used here is a single transistor, blocking oscillator - Figure 2. Blocking oscillators are nearly ideal to drive fluorescent load because the phosphor glows a relatively long time after each excitation pulse.

The higher the frequency - within reason - the brighter the bulb and the higher the circuit efficiency will be. Operating frequency is set mostly by R2, C2 - Figure 3. Changing the value of the R2 resistor or the C2 capacitor adjusts the frequency and the brightness. Audio or ferrite core transformers are able to work on higher frequencies efficiently than power transformers.

The maximum bulb current should be observed to keep lamp life long. On smaller lamp tubes 10-12 Watts is a reasonable maximum dissipation value. Usual tube ionization voltages are in the 60-80 Volt range. Adjust the value of C3 capacitor if necessary to the lamp on hand to limit the tube current. With pulse drive, higher instantaneous current is permitted. The available voltage depends highly on the transformer turns ratio. For simplicity, an output transformer from a tube or transistor radio can be used, but a custom-made coil wound using an old transformer`s lamination or a ferrite toroid core transformer would work just fine. The transformer for this blocking oscillator had a turn ratio of 20:1 but a 120 Vac/12 Vac small power transformer can also be used.

The complete eight-piece parts kit without the battery and the lamp is available for this circuit for $25 that includes shipping and a suitable transformer. A seven-piece parts kit without the battery, lamp and transformer that includes shipping is $15. Parts are new or recycled. All guaranteed to work. Order here. Parts and materials: B1 - Battery, 12 Volt C1 - Capacitor, 0. 1 uF, 25V, Film or Disc C2 - Capacitor, 0. 01 uF, 25V, Film or Disc C3 - Capacitor, 0. 1 uF, 25V, Disc D1 - Diode, 1N914 Q1 - Transistor, 2N2102, NPN, HS Switch R1 - Resistor, 12K, 5%, 1/4W, CC R2 - Resistor, 10K, 5%, 1/4W, CC TR1 - Transformer, Output or Power 120Vac/12Vac

🔗 External reference