geiger counter circuit

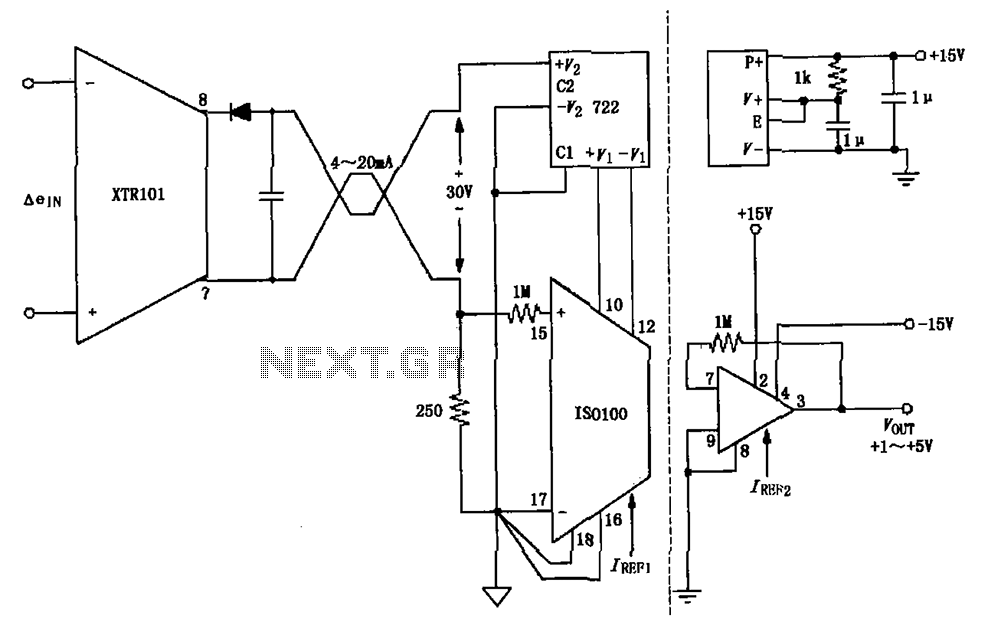

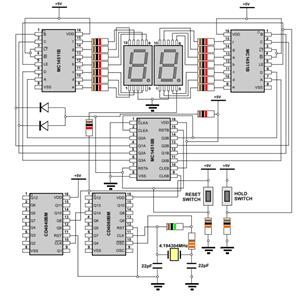

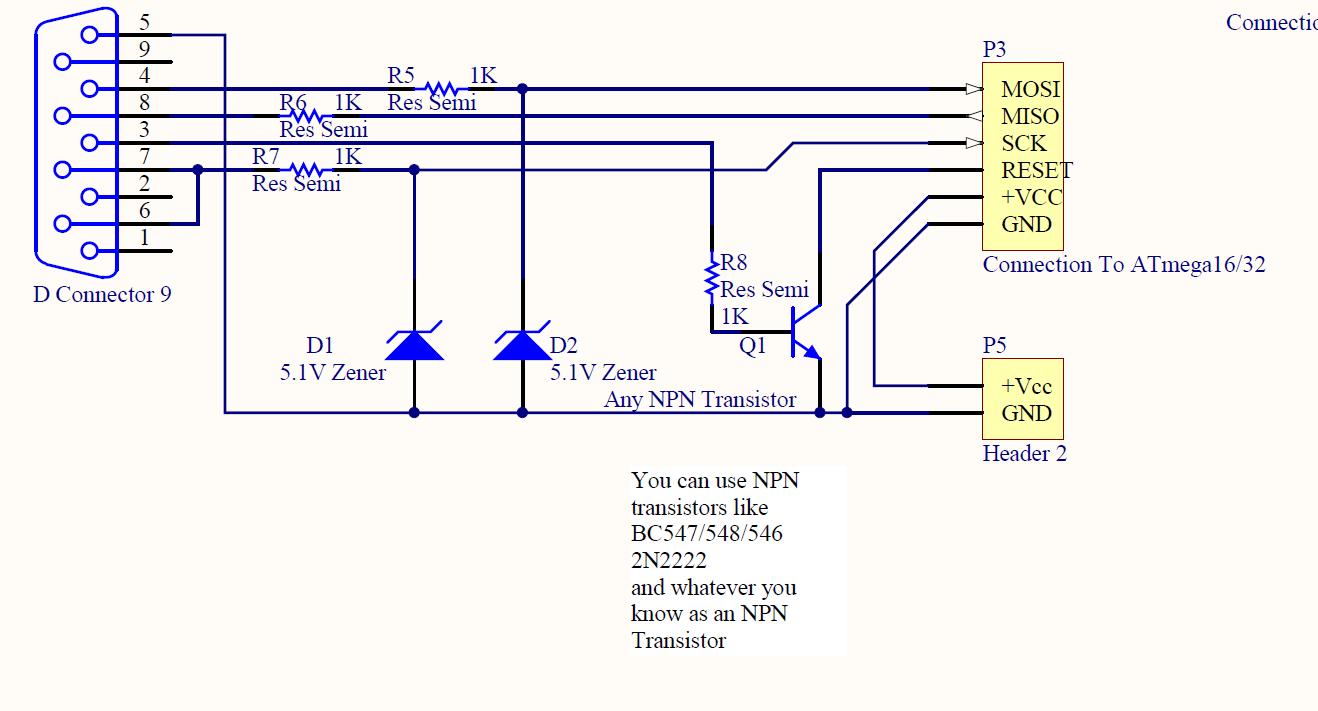

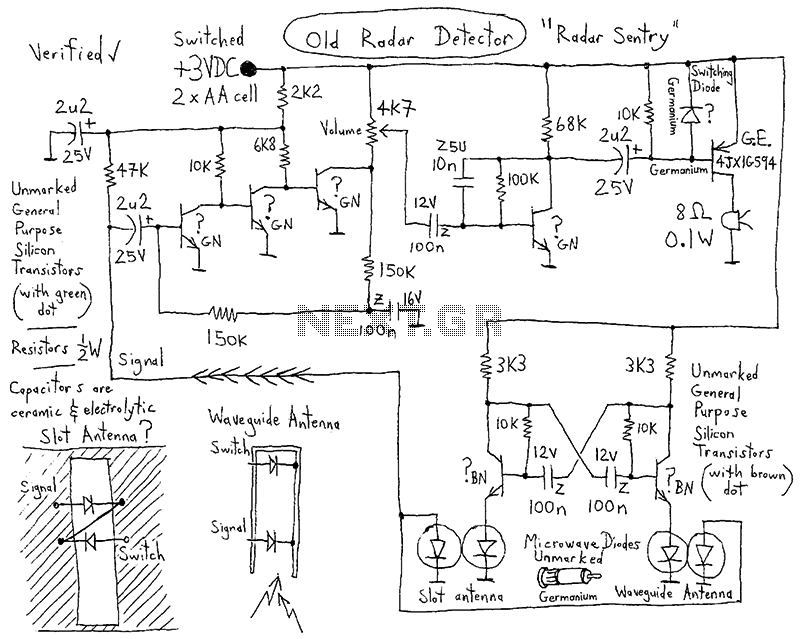

A CI-22BG tube and a CI-3BG tube were purchased for a total of 16G. Due to the lack of radioactive materials for testing the Geiger counter, a piece of radioactive Fiesta dinnerware was ordered from eBay. Red Fiestaware historically contained uranium oxide in its glaze, making it sufficiently radioactive to be detected by a Geiger counter. The Geiger tubes require a high voltage of 400V to operate. Additionally, a microcontroller is needed to count the events, and an LCD display is desired for output visualization. A buzzer is also a necessary component for the Geiger counter. A USB port has been included since a microcontroller is being utilized, allowing the device to be powered either by USB or an external voltage source. The circuit in the upper left corner, adapted from a Stack Exchange answer, manages the selection of the appropriate power supply. It will utilize USB power when connected; otherwise, it will switch to the external power supply. IC1 is a step-up converter designed to increase the supply voltage to 7V or pass it through if the input is already above 7V. This enables the device to operate with an external voltage as low as 2V. IC3 is a 5V low dropout regulator that converts 7V to 5V for the microcontroller. Centrally located is the high voltage supply, which produces 400V from a 7V input, operating in a closed loop with the microcontroller adjusting the duty cycle to maintain stable output voltage. Typically, a Geiger tube allows only a small leakage current, but when ionizing radiation interacts with the tube, some of the gas inside becomes ionized, permitting a higher current to flow. A 4.7M anode resistor (R10) limits this current to a safe level. The resulting current raises the voltage at the base of transistor T4, turning it on and pulling the detect line low. The microcontroller then registers an interrupt on the pin change, counting one event. The high voltage supply schematic includes R18, R19, and C13 for feedback to the microcontroller, while R9 and C5 filter the output, and R10 serves as the anode resistor for the Geiger tubes. To enable operation with USB, the input voltage is set at 5V, which must be elevated to 400V. Unlike many Geiger counter high voltage supplies that utilize transformers, this design avoids them due to their size, weight, and cost. Initial tests on a breadboard with a boost DC/DC converter running in discontinuous mode showed that it could achieve a voltage of 444V from a 5V input, which is sufficient for powering a Geiger tube. Although higher voltages were possible, they exceeded the breakdown voltage of the SF16 diodes (400V) and approached the upper limit of the Geiger tubes (450V). With improved PCB layout, the output voltage could potentially exceed 500V. Testing the high voltage supply with a 5V input voltage revealed that the circuit utilized SF16 diodes, which have a breakdown voltage of 400V but appear to handle slightly more. The MOSFET used is FQN1N50C. Various transistors and diodes were tested, with on-resistance and switching speed being crucial parameters for the MOSFETs. The only high voltage BJT available, MSP44, did not function as intended. Due to the discontinuous mode operation of the boost converter, the reverse recovery time of the diode is critical for minimizing leakage. The 1N4007 diodes performed poorly in this application.

The design of the Geiger counter circuit integrates various components to achieve the desired functionality of radiation detection and event counting. The use of high-voltage Geiger tubes necessitates a reliable high voltage supply, which is achieved through a boost converter that can elevate the input voltage to the required levels. The microcontroller plays a central role in managing the power supply selection, processing the detection events, and controlling the output display through the LCD. The inclusion of a USB port enhances the versatility of the device, allowing for convenient power options. The feedback mechanism with resistors and capacitors ensures that the voltage levels remain stable and within operational limits, while the anode resistor safeguards the Geiger tube from excessive current. The careful selection of components, including the high voltage diodes and MOSFETs, demonstrates a commitment to optimizing performance while maintaining safety and efficiency. Furthermore, the avoidance of bulky transformers in favor of a compact boost converter design reflects a modern approach to circuit design, prioritizing both functionality and practicality. This comprehensive approach results in a Geiger counter capable of effectively detecting radiation while providing accurate event counting and user-friendly operation.I bought one CI-22BG tube and one CI-3BG tube for total of 16G. Because I didn`t have anything radioactive to test my Geiger counter, I also ordered a piece of radioactive Fiesta dinnerware from ebay. Red Fiestware used to have uranium oxide in its glaze that was radioactive enough to be detected with a Geiger counter.

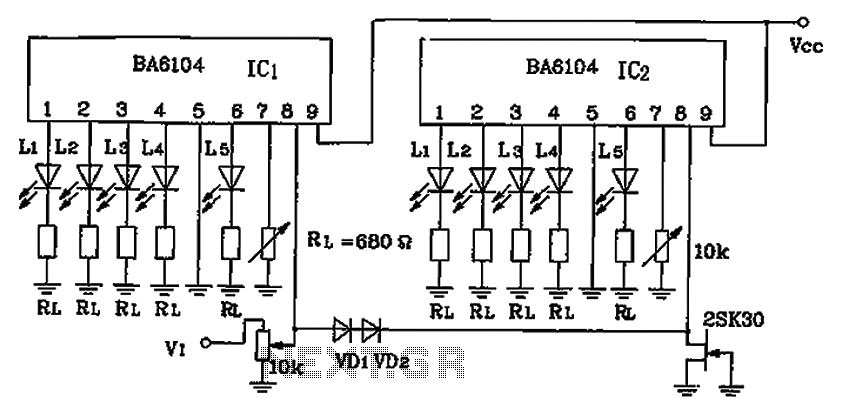

Geiger tube needs a high voltage, my tubes need 400V, to function. We need also a microcontroller to count the events and maybe a LCD to display the output. Also no Geiger counter is complete without a buzzer. I decided to also have USB port now that I included a microcontroller. The device can be powered by USB or external voltage source. Circuit on the upper left corner, which was copied from this Stack Exchange answer, is responsible for choosing the right power supply. It will use USB if it`s connected, otherwise it`ll connect the external power supply. IC1 is step up converter that will increase supply voltage to 7V, or pass it through if it`s already over 7V.

This will allow the device to work with even 2V external voltage. IC3 is 5V low dropout regulator, that will regulate 7V to 5V for microcontroller. At the center there`s the high voltage supply that will output 400V from 7V input. It runs in a closed loop with microcontroller adjusting the duty cycle to get a stable output voltage. Normally Geiger tube will pass only a small leakage current, but when ionizing radiation hits the Geiger tube some of the gas inside the tube is ionized which will allow higher current through the tube, 4.

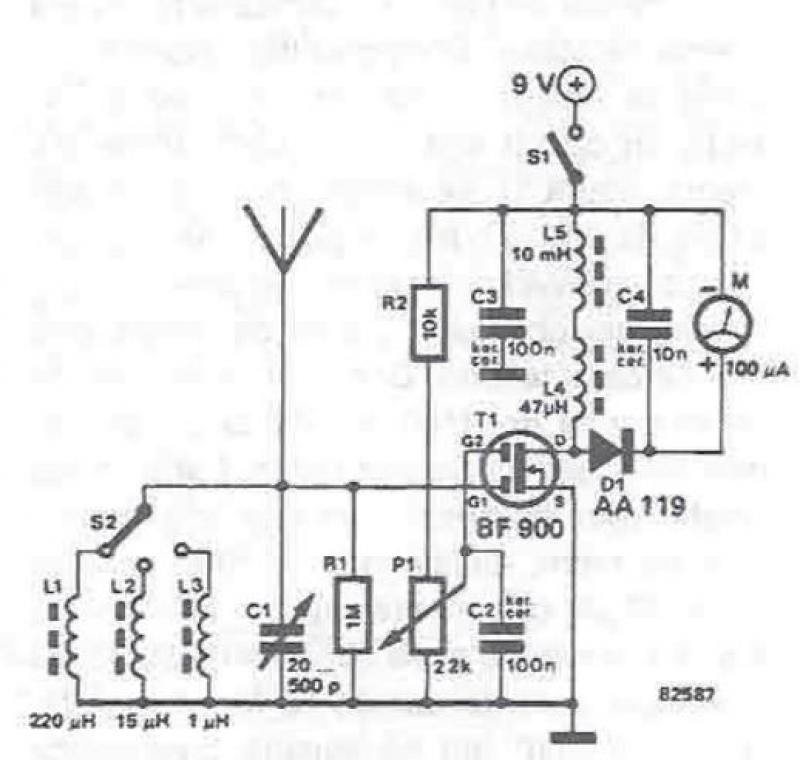

7M anode resistor R10 limits this current to a safe value. This current will raise voltage at the base of T4 turning it on which pulls the detect net low. Then the microcontroller interrupts at the pin change and counts one event. High voltage supply schematic. R18, R19 and C13 are for feedback to microcontroller. R9 and C5 are used to filter the output and R10 is Geiger tubes anode resistor. Because I wanted the device to work with USB the input voltage is 5V and this needs to be raised to 400V. Many other Geiger counter high voltage supplies use some topology that includes a transformer, but because transformers are big, heavy and expensive I didn`t want to use them.

At first I wondered if ordinary boost DC/DC converter running in discontinuous mode would give high enough voltage gain, so I made some test on a breadboard and with right components I managed to get 444V from 5V input voltage, which is more than enough to drive a Geiger tube. It could have gone to even higher voltages, but I was already over the SF16 diodes 400V breakdown voltage and 450V was upper limit of Geiger tubes working voltage.

With a better layout on the PCB output voltage can reach over 500V. Testing HV supply with 5V input voltage. This circuit uses SF16 diode, which should have a breakdown voltage of 400V, but looks like it can handle a little bit more. Mosfet is FQN1N50C. I tested several different transistors and diodes. For mosfets, on resistance and switching speed were most important parameters. I didn`t manage to get the only high voltage BJT I had, MSP44, to work at all. Because boost converter works in discontinuous mode, reverse recovery time of diode is important to minimize leakage.

1N4007 diodes were garbage at this 🔗 External reference

The design of the Geiger counter circuit integrates various components to achieve the desired functionality of radiation detection and event counting. The use of high-voltage Geiger tubes necessitates a reliable high voltage supply, which is achieved through a boost converter that can elevate the input voltage to the required levels. The microcontroller plays a central role in managing the power supply selection, processing the detection events, and controlling the output display through the LCD. The inclusion of a USB port enhances the versatility of the device, allowing for convenient power options. The feedback mechanism with resistors and capacitors ensures that the voltage levels remain stable and within operational limits, while the anode resistor safeguards the Geiger tube from excessive current. The careful selection of components, including the high voltage diodes and MOSFETs, demonstrates a commitment to optimizing performance while maintaining safety and efficiency. Furthermore, the avoidance of bulky transformers in favor of a compact boost converter design reflects a modern approach to circuit design, prioritizing both functionality and practicality. This comprehensive approach results in a Geiger counter capable of effectively detecting radiation while providing accurate event counting and user-friendly operation.I bought one CI-22BG tube and one CI-3BG tube for total of 16G. Because I didn`t have anything radioactive to test my Geiger counter, I also ordered a piece of radioactive Fiesta dinnerware from ebay. Red Fiestware used to have uranium oxide in its glaze that was radioactive enough to be detected with a Geiger counter.

Geiger tube needs a high voltage, my tubes need 400V, to function. We need also a microcontroller to count the events and maybe a LCD to display the output. Also no Geiger counter is complete without a buzzer. I decided to also have USB port now that I included a microcontroller. The device can be powered by USB or external voltage source. Circuit on the upper left corner, which was copied from this Stack Exchange answer, is responsible for choosing the right power supply. It will use USB if it`s connected, otherwise it`ll connect the external power supply. IC1 is step up converter that will increase supply voltage to 7V, or pass it through if it`s already over 7V.

This will allow the device to work with even 2V external voltage. IC3 is 5V low dropout regulator, that will regulate 7V to 5V for microcontroller. At the center there`s the high voltage supply that will output 400V from 7V input. It runs in a closed loop with microcontroller adjusting the duty cycle to get a stable output voltage. Normally Geiger tube will pass only a small leakage current, but when ionizing radiation hits the Geiger tube some of the gas inside the tube is ionized which will allow higher current through the tube, 4.

7M anode resistor R10 limits this current to a safe value. This current will raise voltage at the base of T4 turning it on which pulls the detect net low. Then the microcontroller interrupts at the pin change and counts one event. High voltage supply schematic. R18, R19 and C13 are for feedback to microcontroller. R9 and C5 are used to filter the output and R10 is Geiger tubes anode resistor. Because I wanted the device to work with USB the input voltage is 5V and this needs to be raised to 400V. Many other Geiger counter high voltage supplies use some topology that includes a transformer, but because transformers are big, heavy and expensive I didn`t want to use them.

At first I wondered if ordinary boost DC/DC converter running in discontinuous mode would give high enough voltage gain, so I made some test on a breadboard and with right components I managed to get 444V from 5V input voltage, which is more than enough to drive a Geiger tube. It could have gone to even higher voltages, but I was already over the SF16 diodes 400V breakdown voltage and 450V was upper limit of Geiger tubes working voltage.

With a better layout on the PCB output voltage can reach over 500V. Testing HV supply with 5V input voltage. This circuit uses SF16 diode, which should have a breakdown voltage of 400V, but looks like it can handle a little bit more. Mosfet is FQN1N50C. I tested several different transistors and diodes. For mosfets, on resistance and switching speed were most important parameters. I didn`t manage to get the only high voltage BJT I had, MSP44, to work at all. Because boost converter works in discontinuous mode, reverse recovery time of diode is important to minimize leakage.

1N4007 diodes were garbage at this 🔗 External reference