GenesisRadio Transceivers

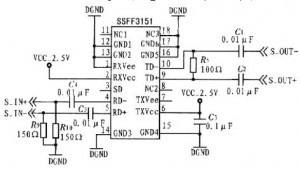

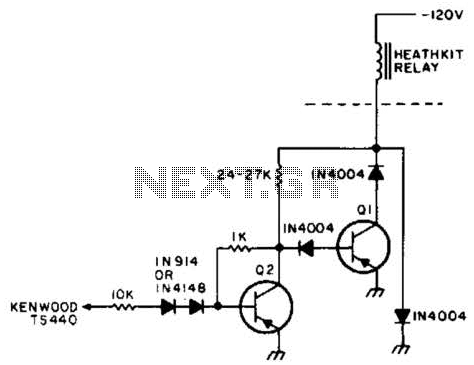

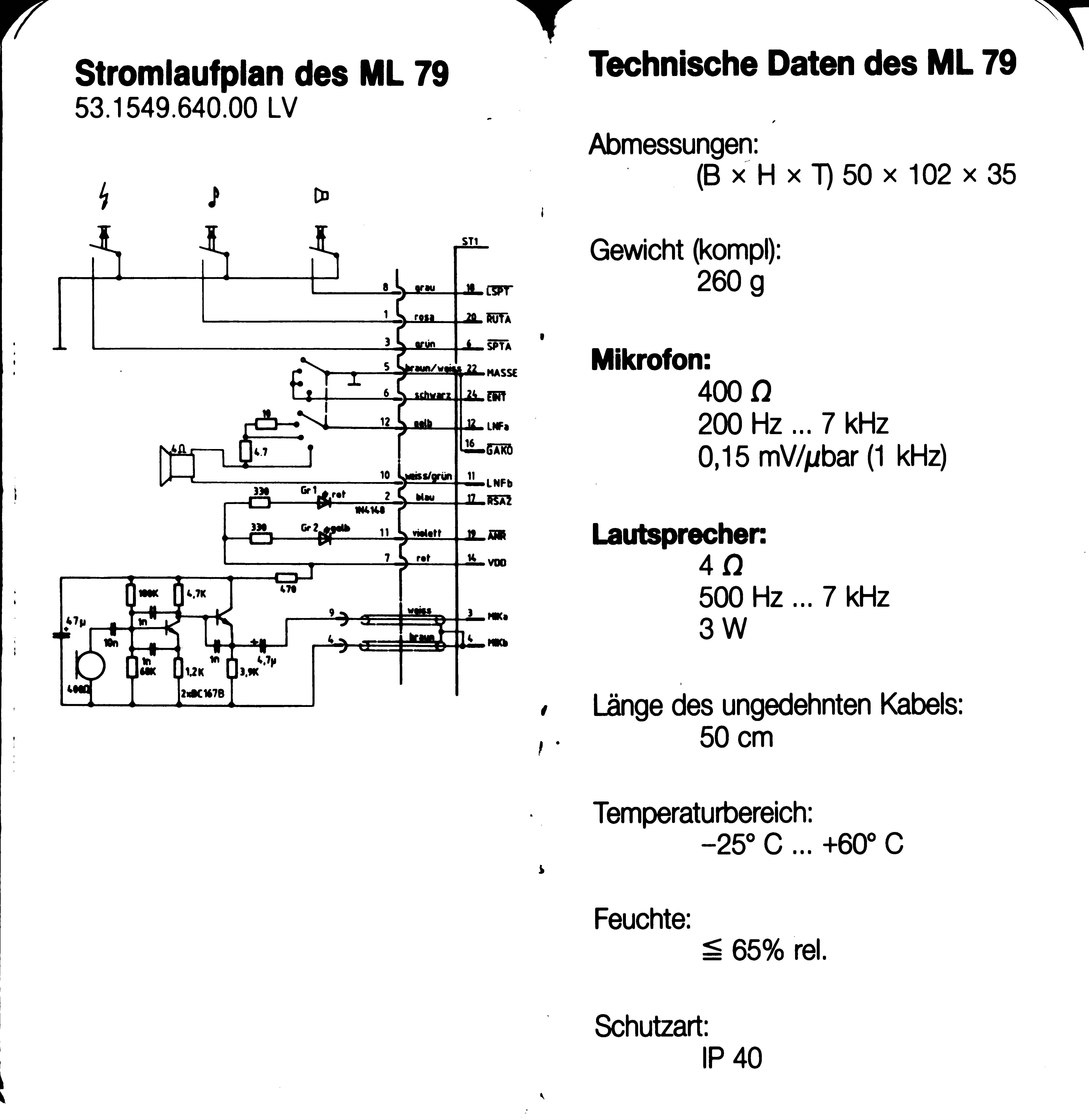

Later, the same pivot table will be utilized to list the parts for each of the eight phases in the build, organizing them into phase-specific bags of parts. The initial observation is that there are slight inconsistencies between the well-illustrated online assembly pictorials (with associated instructions) and the Word Document of the Assembly Manual. For instance, Phase 1 requires 21 diodes plus one zener diode, which are referenced in the online documentation but not in the Word document. The customary practice of breaking the schematic down by phase may not be effective for this kit. However, all components are present, albeit spread out. The key takeaway is to thoroughly review all versions of the instructions (Word, online, and BOM) for each phase before commencing construction. Familiarity with the schematics is essential to track components from the schematic to the PCB and vice versa. The documentation provided online includes four schematic snippets that appear to be snapshots of development or intended for general use in follow-on kits. Unfortunately, this has made it challenging to correlate the schematics with the PCB, as the identifiers (e.g., "R9," "C53," "L4," etc.) of most components in the schematics do not match those on the silkscreen. Reverse engineering the PCB back to the schematic is possible, but it is a complex task. A request has been made to GenesisRadio for a complete schematic that aligns component identifiers with the PCB silkscreen, which would facilitate troubleshooting. Upon encountering a new kit and design, a "virtual build" approach is taken, virtually placing components onto an image of the board, stage by stage. This method ensures a comprehensive understanding of the circuits and aids in creating enhanced documentation for the kit and its construction. This is particularly valuable for the G40 due to potential ambiguities arising from schematic segmentation and inconsistent component identification. The goal of this stage is to provide the 5 Volt power rail for the CMOS ICs, as well as to power the RX and TX LEDs and the 12 Volt input point. It is crucial to ensure that the external power supply is at the correct voltage (12-13.8 Vdc) and capable of delivering 2 to 3 Amps, as a faulty or underrated power supply is a common issue. This stage features two areas on the board designated for providing the 5 V power supply and the RX and TX LEDs, as well as several diodes (one zener and 21 regular diodes) distributed throughout the board. Parts of this stage are represented across two schematics: "Genesis G* RX/TX PC Control + CW Monitor Design" and "Monoband HF SDR Transceiver Genesis G40."

The construction of the circuit requires careful attention to detail, particularly during the assembly of the power supply stage. The 5 Volt rail is critical for the operation of CMOS ICs, which are sensitive to voltage variations. The use of a zener diode in conjunction with the regular diodes ensures voltage regulation and protection against reverse polarity, which can damage the sensitive components. The specification for the external power supply emphasizes the need for a robust source capable of maintaining stable voltage under load, which is essential for the reliable operation of the entire system.

In the assembly process, it is important to cross-reference the components with both the online and Word documentation to ensure all necessary parts are accounted for. The discrepancies in component identifiers between the schematics and the PCB silkscreen can lead to confusion; therefore, a meticulous approach is recommended. The virtual build method serves as an effective strategy to visualize the assembly process, allowing for identification of potential issues before physical assembly begins.

Overall, thorough preparation and understanding of the circuit design, along with careful assembly practices, will contribute significantly to the successful completion of the project. The integration of feedback from the assembly process and the request for improved documentation will enhance future iterations of the kit and support more efficient troubleshooting and assembly for users.Later, I will use the same pivot table to list the parts out by each of the 8 phases in the build, organizing them into phase-specific bags O` parts. First thing I notice is that there are some slight disconnects between the liberally illustrated, online assembly pictorials (with associated instructions) and the Word Document of the Assembly Manual.

For example, Phase 1 calls for 21 diodes plus a zener diode. These are referenced in the online docs, but not in the word document. My customary practice of breaking the schematic out by phase is likely not going to work for me with this kit. Still, everything is all there; just spread out a bit. Lesson to be taken away from this is to thoroughly review the instructions (all versions: Word, on-line, and BOM) for each phase before beginning construction in that phase.

You want to know what you are doing with each component and where on the board! Before going into a build, I always like to familiarize myself with the schematics and make sure I can track from the schematic to the PCB and vice versa. The documentation provided on the website ( Word Document ) has 4 bits of schematic which are apparently snapshots of development as the design progressed (or intended for general purpose use in the follow-on kits).

Unfortunately, at least for me, this made it quite difficult to track from the schematic to the PC and back, since the identifiers (e. g. , "R9", "C53", "L4", etc. ) of most of the components in the schematics did not match with the identifiers on the silk-screen. Of course, one could always reverse engineer the PCB back to the schematic by essentially repeating the schematic-to-pcb mapping process in reverse.

I am not up to that task and have asked GenesisRadio if it might be possible to publish a complete schematic that agrees on component identifiers with the pcb silkscreen. This would make any required troubleshooting (not that I expect to need any) infinitely easier. When I encounter a new kit and a new design, I like to go through a "virtual build" - virtually placing components onto an image of the board, stage-by-stage.

This forces me to devote the time and effort to really understand the circuit(s) and also provides materials for use in enhanced documentation of the kit and its construction. This turns out to be particularly valueable in the case of the G40 because there are potential ambiguities brought about by the schematic segmentation and inconsistent component identification mentioned above.

The purpose of this stage is to provide the 5 Volt power rail for the CMOS ICs (as well as provide for Power and TX LEDs and the 12 Volt input point. Make sure your external power supply has the correct volatge (12-13. 8 Vdc) and it should be capable of producing 2 to 3 Amps. A faulty or underrated power supply is a very common problem. This stage had two areas of the board which were populated to provide the 5 V power supply and the LEDs for RX and TX.

In addition, there were some diodes that were populated throughout the board (1 zener and 21 regular diodes). Parts of this stage are spread across two of the schematics: "Genesis G* RX/TX PC Control + CW Monitor Design" and "Monoband HF SDR Transceiver Genesis G40".

🔗 External reference

The construction of the circuit requires careful attention to detail, particularly during the assembly of the power supply stage. The 5 Volt rail is critical for the operation of CMOS ICs, which are sensitive to voltage variations. The use of a zener diode in conjunction with the regular diodes ensures voltage regulation and protection against reverse polarity, which can damage the sensitive components. The specification for the external power supply emphasizes the need for a robust source capable of maintaining stable voltage under load, which is essential for the reliable operation of the entire system.

In the assembly process, it is important to cross-reference the components with both the online and Word documentation to ensure all necessary parts are accounted for. The discrepancies in component identifiers between the schematics and the PCB silkscreen can lead to confusion; therefore, a meticulous approach is recommended. The virtual build method serves as an effective strategy to visualize the assembly process, allowing for identification of potential issues before physical assembly begins.

Overall, thorough preparation and understanding of the circuit design, along with careful assembly practices, will contribute significantly to the successful completion of the project. The integration of feedback from the assembly process and the request for improved documentation will enhance future iterations of the kit and support more efficient troubleshooting and assembly for users.Later, I will use the same pivot table to list the parts out by each of the 8 phases in the build, organizing them into phase-specific bags O` parts. First thing I notice is that there are some slight disconnects between the liberally illustrated, online assembly pictorials (with associated instructions) and the Word Document of the Assembly Manual.

For example, Phase 1 calls for 21 diodes plus a zener diode. These are referenced in the online docs, but not in the word document. My customary practice of breaking the schematic out by phase is likely not going to work for me with this kit. Still, everything is all there; just spread out a bit. Lesson to be taken away from this is to thoroughly review the instructions (all versions: Word, on-line, and BOM) for each phase before beginning construction in that phase.

You want to know what you are doing with each component and where on the board! Before going into a build, I always like to familiarize myself with the schematics and make sure I can track from the schematic to the PCB and vice versa. The documentation provided on the website ( Word Document ) has 4 bits of schematic which are apparently snapshots of development as the design progressed (or intended for general purpose use in the follow-on kits).

Unfortunately, at least for me, this made it quite difficult to track from the schematic to the PC and back, since the identifiers (e. g. , "R9", "C53", "L4", etc. ) of most of the components in the schematics did not match with the identifiers on the silk-screen. Of course, one could always reverse engineer the PCB back to the schematic by essentially repeating the schematic-to-pcb mapping process in reverse.

I am not up to that task and have asked GenesisRadio if it might be possible to publish a complete schematic that agrees on component identifiers with the pcb silkscreen. This would make any required troubleshooting (not that I expect to need any) infinitely easier. When I encounter a new kit and a new design, I like to go through a "virtual build" - virtually placing components onto an image of the board, stage-by-stage.

This forces me to devote the time and effort to really understand the circuit(s) and also provides materials for use in enhanced documentation of the kit and its construction. This turns out to be particularly valueable in the case of the G40 because there are potential ambiguities brought about by the schematic segmentation and inconsistent component identification mentioned above.

The purpose of this stage is to provide the 5 Volt power rail for the CMOS ICs (as well as provide for Power and TX LEDs and the 12 Volt input point. Make sure your external power supply has the correct volatge (12-13. 8 Vdc) and it should be capable of producing 2 to 3 Amps. A faulty or underrated power supply is a very common problem. This stage had two areas of the board which were populated to provide the 5 V power supply and the LEDs for RX and TX.

In addition, there were some diodes that were populated throughout the board (1 zener and 21 regular diodes). Parts of this stage are spread across two of the schematics: "Genesis G* RX/TX PC Control + CW Monitor Design" and "Monoband HF SDR Transceiver Genesis G40".

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713