Handy Pen Torch Circuit

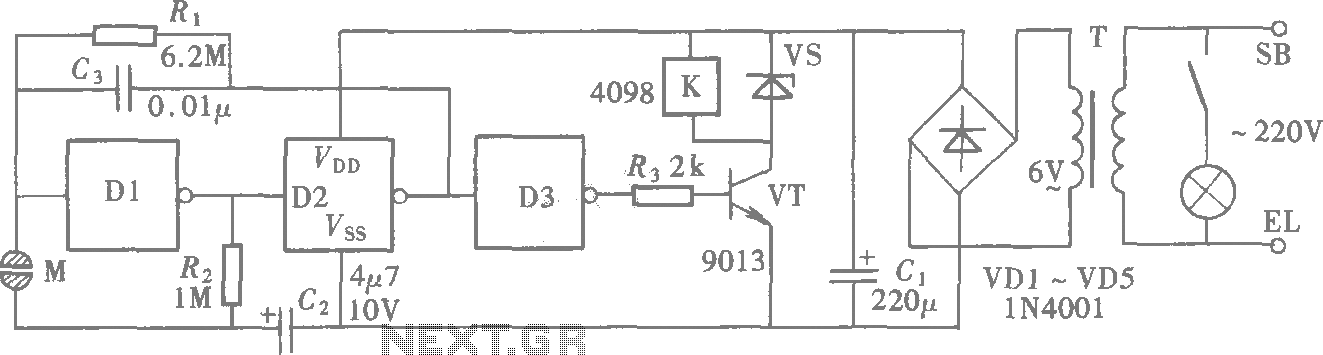

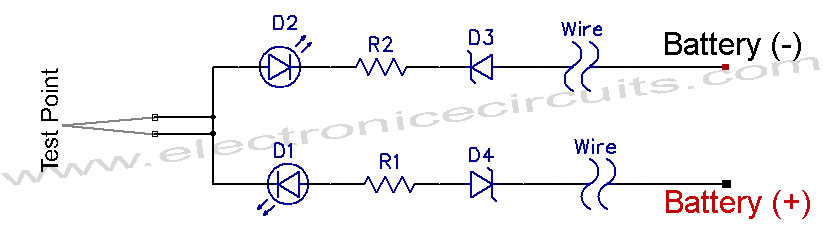

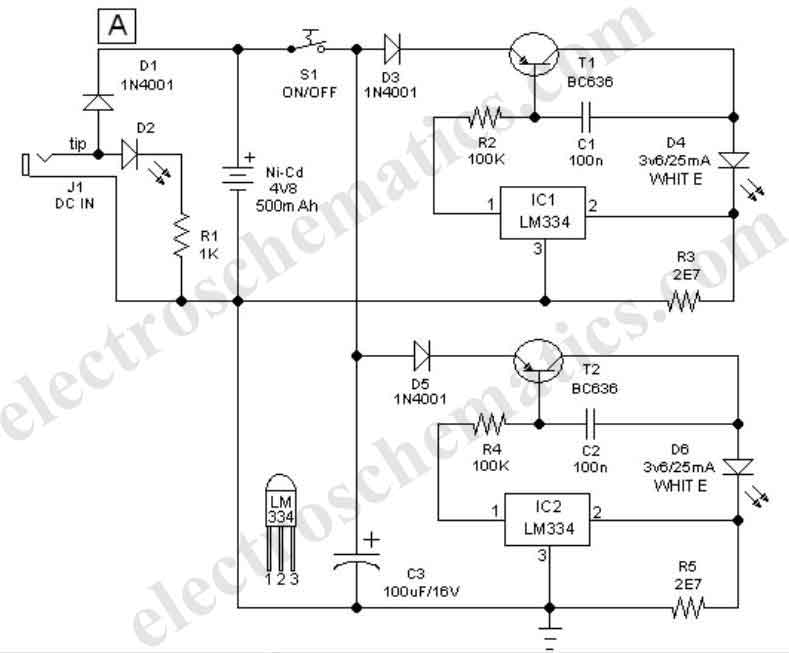

This easy-to-construct handy pen torch electronic circuit has a low component count and utilizes two power white LEDs for illumination. A low voltage (4.8V DC) supply is derived from a built-in rechargeable Ni-Cd battery pack and is converted into two independent constant current sources using two precision adjustable shunt regulator chips (LM334, IC1 and IC2). Approximately 25 mA at 3.6 volt DC is available at the output of these ICs. This regulated DC supply drives the two power white LEDs (D4 and D6). Resistors (R3 and R5) limit the output current and consequently the light output of IC1 and IC2, respectively. Diode (D1) serves as an input polarity guard and prevents reverse current flow. Capacitor (C1) acts as a buffer for circuit stabilization. After successful construction, preferably on a small piece of general-purpose PCB, the entire circuit should be enclosed in a suitable and attractive pen torch cabinet. If necessary, suitable holes should be drilled in the cabinet to attach the DC socket, on/off switch, and input indicator. In the prototype, a commonly available 4.8 volt/500mAh Ni-Cd battery pack (used in cordless telephones) is employed. A simple yet reliable AC mains powered battery charger circuit for the handy pen torch is also included. This charger circuit is based around transistor (T1, BC636), powered by a 12V/350mA step-down transformer and associated components (D1, D2, and C1). The unregulated 12V DC from the input power converter circuit, which includes the step-down transformer (TRF), rectifier diodes (D1, D2), and filter capacitor (C1), is fed to T1 through a current-limiting resistor (R1). The grounded base PNP transistor (T1) functions as a constant current generator. With a 22-ohm resistor for R1, the charging current available at the output of the charger is approximately 50 mA. A red LED (D3) provides a fixed voltage reference to the base of T1, assisted by resistor (R2). During the charging process, diode (D1) in the main circuit prevents reverse current flow from the battery pack when the charging input supply is absent. After constructing the pen torch circuit, the assembled unit should be fitted inside a small plastic enclosure for safety and convenience.

The circuit design for the handy pen torch is characterized by its simplicity and efficiency, making it an ideal project for electronics enthusiasts. The use of two LM334 precision adjustable shunt regulators allows for accurate current control, ensuring that the power white LEDs emit a consistent brightness without risk of damage due to overcurrent. The choice of a 4.8V Ni-Cd battery pack ensures that the system remains portable and rechargeable, catering to the need for a compact light source.

The inclusion of a constant current charger circuit demonstrates a thoughtful approach to battery management. The BC636 transistor efficiently regulates the charging process, maintaining an optimal current level to prolong battery life. The use of a step-down transformer, along with rectifier diodes and a filter capacitor, forms a reliable power supply for the charger, ensuring stable performance.

The design also emphasizes safety with the implementation of a diode to prevent reverse current flow during charging, protecting the battery from potential damage. The overall construction of the circuit on a general-purpose PCB facilitates ease of assembly and troubleshooting.

In summary, this handy pen torch circuit is a practical and effective solution for portable lighting needs, combining low component count with robust performance features. The final product, once housed in a protective enclosure, is not only functional but also visually appealing, making it suitable for various applications.This easy to construct Handy pen torch electronic circuit and low component count, uses two power white LEDs for lighting. Low volt (4. 8V dc) supply available from the built in rechargeable Ni-Cd battery pack is first converted into two channel (independent) constant current sources by two pieces of the renowned precision adjustable shunt regul

ator chip LM334 (IC1 and IC2). Around 25 mA at 3. 6 volt dc is available at the output of these ICs. This regulated dc supply is used to drive two power white LEDs D4 and D6. Resistors R3 and R5 limlits the output current (and hence the light output) of IC1 and IC2 circuits respectively. Diode D1 works as an input polarity guard cum reverse current flow preventer. Capacitor C1 is a simple buffer for circuit stabilization. After succesful construction, preferably on a small piece of general purpose PCB, enclose the whole circuit in a suitable and attractive pen torch cabinet.

If necessary, drill suitable holes in the cabinet to attatch the dc socket, on/off switch and the input indicator etc. In prototype, commonly available 4. 8 volt/500mah Ni-Cd battery pack (for cordless telephones) is used. One very simple but reliable ac mains powered battery charger circuit for the handy pen torch is also included here.

Basically the pen torch circuit is a constant current charger wired around Transistor T1 (BC636), powered by a 12v/350mA step down transformer and associated componentsD1, D2 and C1. Unregulated 12 volt dc available from the input power convereter circuit, comprising step down transformer(TRF), rectifier diodes (D1, D2) and filter capacitor (C1), is fed to T1 through a current limiting resistor R1.

Grounded base PNP transistor T1 here works as a constant current generator. With 22 ohm resistor for R1, the charging current available at the output of the charger is near 50 mA. Red LED (D3) provides a fixed voltage reference to the base of T1, with the help of resistor R2. (During charging process, Diode D1 in the main circuit prevent reverse current flow from the battery pack when charging input supply is absent.

) After construction of the pen torch circuit, fit the assembled unit inside a small plastic enclosure for safety and convenience. Pen Torch Electronic Circuit Schematic If necessary, drill suitable holes in the cabinet to attatch the dc socket, on/off available 4.

8 volt/500mah Ni-Cd battery pack (for cordless telephones) is Name: Tridev Kripa Total articles written: 54. Visit the author website 🔗 External reference

The circuit design for the handy pen torch is characterized by its simplicity and efficiency, making it an ideal project for electronics enthusiasts. The use of two LM334 precision adjustable shunt regulators allows for accurate current control, ensuring that the power white LEDs emit a consistent brightness without risk of damage due to overcurrent. The choice of a 4.8V Ni-Cd battery pack ensures that the system remains portable and rechargeable, catering to the need for a compact light source.

The inclusion of a constant current charger circuit demonstrates a thoughtful approach to battery management. The BC636 transistor efficiently regulates the charging process, maintaining an optimal current level to prolong battery life. The use of a step-down transformer, along with rectifier diodes and a filter capacitor, forms a reliable power supply for the charger, ensuring stable performance.

The design also emphasizes safety with the implementation of a diode to prevent reverse current flow during charging, protecting the battery from potential damage. The overall construction of the circuit on a general-purpose PCB facilitates ease of assembly and troubleshooting.

In summary, this handy pen torch circuit is a practical and effective solution for portable lighting needs, combining low component count with robust performance features. The final product, once housed in a protective enclosure, is not only functional but also visually appealing, making it suitable for various applications.This easy to construct Handy pen torch electronic circuit and low component count, uses two power white LEDs for lighting. Low volt (4. 8V dc) supply available from the built in rechargeable Ni-Cd battery pack is first converted into two channel (independent) constant current sources by two pieces of the renowned precision adjustable shunt regul

ator chip LM334 (IC1 and IC2). Around 25 mA at 3. 6 volt dc is available at the output of these ICs. This regulated dc supply is used to drive two power white LEDs D4 and D6. Resistors R3 and R5 limlits the output current (and hence the light output) of IC1 and IC2 circuits respectively. Diode D1 works as an input polarity guard cum reverse current flow preventer. Capacitor C1 is a simple buffer for circuit stabilization. After succesful construction, preferably on a small piece of general purpose PCB, enclose the whole circuit in a suitable and attractive pen torch cabinet.

If necessary, drill suitable holes in the cabinet to attatch the dc socket, on/off switch and the input indicator etc. In prototype, commonly available 4. 8 volt/500mah Ni-Cd battery pack (for cordless telephones) is used. One very simple but reliable ac mains powered battery charger circuit for the handy pen torch is also included here.

Basically the pen torch circuit is a constant current charger wired around Transistor T1 (BC636), powered by a 12v/350mA step down transformer and associated componentsD1, D2 and C1. Unregulated 12 volt dc available from the input power convereter circuit, comprising step down transformer(TRF), rectifier diodes (D1, D2) and filter capacitor (C1), is fed to T1 through a current limiting resistor R1.

Grounded base PNP transistor T1 here works as a constant current generator. With 22 ohm resistor for R1, the charging current available at the output of the charger is near 50 mA. Red LED (D3) provides a fixed voltage reference to the base of T1, with the help of resistor R2. (During charging process, Diode D1 in the main circuit prevent reverse current flow from the battery pack when charging input supply is absent.

) After construction of the pen torch circuit, fit the assembled unit inside a small plastic enclosure for safety and convenience. Pen Torch Electronic Circuit Schematic If necessary, drill suitable holes in the cabinet to attatch the dc socket, on/off available 4.

8 volt/500mah Ni-Cd battery pack (for cordless telephones) is Name: Tridev Kripa Total articles written: 54. Visit the author website 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713