High Voltage Electrolytic Capacitor Reformer

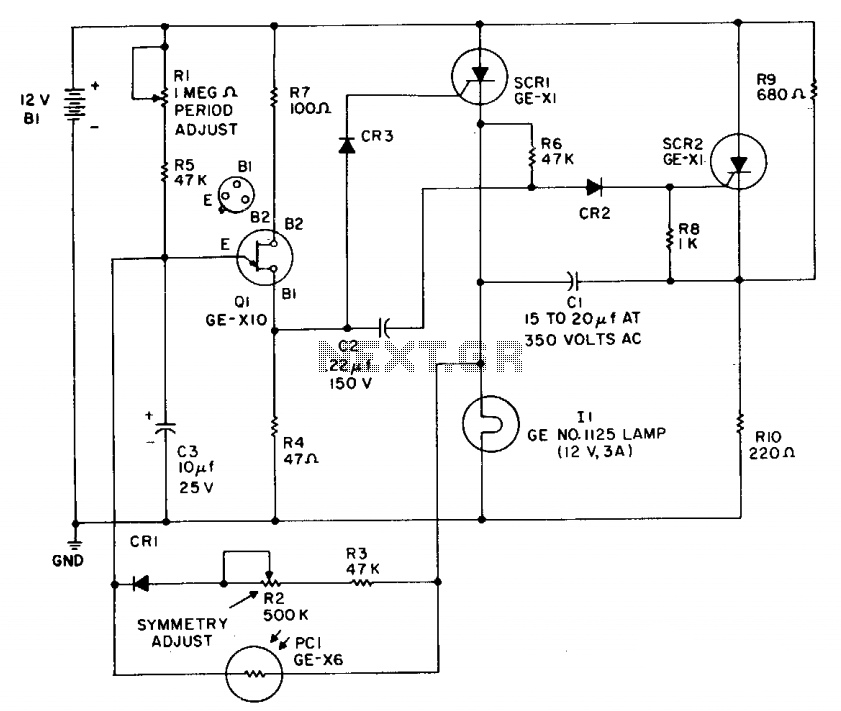

High voltage electrolytic capacitors in valve equipment can deteriorate if the equipment is unused for an extended period. This deterioration manifests as reduced capacitance and significantly increased leakage current. In some instances, the capacitor may become nearly short-circuited. Using equipment with such capacitors can lead to high current draw, potentially causing overheating and explosion of the capacitors. This situation can also damage the mains transformer and rectifier valve. The unit is designed to pass a controlled low current through the capacitor, allowing the internal chemical composition to reform gradually without the risk of overheating. Two output voltages are available: the 240V setting is for reforming 275V capacitors, while the 320V setting is suitable for 350V and higher components. The unit is also beneficial in the early stages of testing and repairing valve equipment. This unit operates from a mains supply of 220-240V at 50/60Hz and is not suitable for 110-120V supplies, commonly used in the USA and some other countries. Suggestions for creating a 120V version are provided at the end of the article. The unit connects directly to the mains and generates potentially lethal voltages. It is essential to prevent use by young children or individuals unaware of the dangers, and the unit must be clearly labeled with appropriate warnings. It is advised that the unit not be permanently fitted with a mains plug to avoid accidental connection to the mains. The unit is intended for workshop use by knowledgeable individuals familiar with high voltages. This project is not suitable for beginners. The mains supply voltage (220-240V AC) is half-wave rectified by diode D1 and smoothed by capacitor C1. Resistor R1 limits the initial inrush current to C1 and must be a wirewound component. Resistor R2 gradually discharges C1 and any connected capacitors when the mains supply is turned off, taking approximately 15 seconds for C1 alone, with longer times for additional capacitors. The voltage is regulated by diodes D2, D3, and D4, with D4 short-circuited by switch SW1 in the 240V setting. Resistor R3 serves as the current limiting component and will generate heat. The zener diodes are rated at 5W. Resistor R4 is included in the negative output rail to allow for output current monitoring without interrupting the circuit. A meter can be connected periodically to observe the current, rather than dedicating a meter for the entire reforming process. A voltmeter connected across R4 will indicate 0-3.5V for 0-35mA output current, with the voltage reading multiplied by ten to determine current in milliamps. R4 may be replaced with a suitable DC milliammeter mounted in the case. R3 limits the current through the capacitor to a safe threshold. If the capacitor leakage current is high, the output voltage will be low due to the voltage drop across R3. The zener diode chain prevents the voltage from exceeding the rated capacitor voltage when leakage is lower. The circuit is constructed on plain matrix board; Veroboard should not be used due to insufficient track spacing for the high voltages involved. Although a printed circuit board could be designed, it is unnecessary for this simple design. A suggested circuit board layout is provided, although variations may be made to accommodate the components and case used. Components should not be packed too closely together, as R3 will generate heat and should be mounted slightly above the surface.The high voltage electrolytic capacitors in valve equipment tend to deteriorate if the equipment is not used for an extended period. This deterioration takes the form of reduced capacitance and greatly increased leakage current. In some cases, the capacitor will become virtually short circuit. If an item of equipment with capacitors in this state was used, the high current drawn could cause the capacitors to overheat and possibly explode. This can also cause damage to the mains transformer and rectifier valve. This unit is designed to pass a controlled low current through the capacitor, allowing the internal chemical composition to reform gradually without the risk of overheating. Two output voltages are available. The 240V setting is intended for reforming 275V capacitors, while the 320V setting may be used for 350V and higher components.

The unit is also very useful in the early stages of testing and repairing valve equipment. This use is detailed elsewhere on this web site, and will not be repeated here. This unit is designed for operation from a mains supply of 220-240V 50/60Hz. The design is not suitable for operation from a 110-120V supply (as used in the USA and some other countries). However suggestions from a visitor to this page, for producing a 120V version, is given at the end of the article.

This unit is connected directly to the mains and produces potentially lethal voltages. Do not allow this unit to be used by young children or persons who are not aware of the dangers. The unit must be prominently labelled with appropriate warnings. It is recommended that this unit is not permanently fitted with a mains plug, so that it cannot be inadvertently connected to the mains. The unit is intended to be used in a workshop situation, by someone who knows what he or she is doing.

Anyone who is familiar with working on valve equipment should be used to dealing with high voltages and therefore able to treat this unit with due respect. This project is definitely not suitable for beginners. The mains supply voltage (220-240V AC) is half wave rectified by D1 and smoothed by C1. R1 is a surge-limiting component, intended to limit the initial inrush current to C1. R1 must be a wirewound component. R2 will gradually discharge C1 and any capacitors that are connected to the output of the unit when the mains supply is switched off.

This will take about 15 seconds with C1 alone, and much longer with additional capacitors connected. The voltage is then regulated by D2, D3 and D4. Note that D4 is short-circuited by SW1 on the 240V setting. R3 is the current limiting component, and will run warm. The zener diodes are rated at 5W. R4 is added in the negative output rail to allow the output current to be monitored without breaking the circuit. This allows a meter to be connected periodically to monitor the current, rather than committing a meter for the whole reforming process.

A voltmeter connected across this resistor will indicate 0 - 3. 5V for 0 - 35mA output current. Thus, the voltage reading should be multiplied by ten to obtain the current in milliamps. R4 could be replaced with a suitable DC milliammeter fitted to the case. R3 will limit the current through the capacitor to a safe limit. If the capacitor leakage current is high, the output voltage will be low due to the voltage drop in R3. The zener diode chain prevents the voltage rising above the rated capacitor voltage when the leakage is lower.

The circuit is constructed on plain matrix board. Do not use Veroboard, as the spacing between the tracks is insufficient for the high voltages involved. A printed circuit board could be designed, but it is not really necessary for a simple design like this.

A suggested circuit board layout is shown, although this may be varied to suit the components and case used. Do not pack the components too close together. R3 will get warm, and should be mounted a little above the surf 🔗 External reference

The unit is also very useful in the early stages of testing and repairing valve equipment. This use is detailed elsewhere on this web site, and will not be repeated here. This unit is designed for operation from a mains supply of 220-240V 50/60Hz. The design is not suitable for operation from a 110-120V supply (as used in the USA and some other countries). However suggestions from a visitor to this page, for producing a 120V version, is given at the end of the article.

This unit is connected directly to the mains and produces potentially lethal voltages. Do not allow this unit to be used by young children or persons who are not aware of the dangers. The unit must be prominently labelled with appropriate warnings. It is recommended that this unit is not permanently fitted with a mains plug, so that it cannot be inadvertently connected to the mains. The unit is intended to be used in a workshop situation, by someone who knows what he or she is doing.

Anyone who is familiar with working on valve equipment should be used to dealing with high voltages and therefore able to treat this unit with due respect. This project is definitely not suitable for beginners. The mains supply voltage (220-240V AC) is half wave rectified by D1 and smoothed by C1. R1 is a surge-limiting component, intended to limit the initial inrush current to C1. R1 must be a wirewound component. R2 will gradually discharge C1 and any capacitors that are connected to the output of the unit when the mains supply is switched off.

This will take about 15 seconds with C1 alone, and much longer with additional capacitors connected. The voltage is then regulated by D2, D3 and D4. Note that D4 is short-circuited by SW1 on the 240V setting. R3 is the current limiting component, and will run warm. The zener diodes are rated at 5W. R4 is added in the negative output rail to allow the output current to be monitored without breaking the circuit. This allows a meter to be connected periodically to monitor the current, rather than committing a meter for the whole reforming process.

A voltmeter connected across this resistor will indicate 0 - 3. 5V for 0 - 35mA output current. Thus, the voltage reading should be multiplied by ten to obtain the current in milliamps. R4 could be replaced with a suitable DC milliammeter fitted to the case. R3 will limit the current through the capacitor to a safe limit. If the capacitor leakage current is high, the output voltage will be low due to the voltage drop in R3. The zener diode chain prevents the voltage rising above the rated capacitor voltage when the leakage is lower.

The circuit is constructed on plain matrix board. Do not use Veroboard, as the spacing between the tracks is insufficient for the high voltages involved. A printed circuit board could be designed, but it is not really necessary for a simple design like this.

A suggested circuit board layout is shown, although this may be varied to suit the components and case used. Do not pack the components too close together. R3 will get warm, and should be mounted a little above the surf 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713