how to design h bridge circuit for

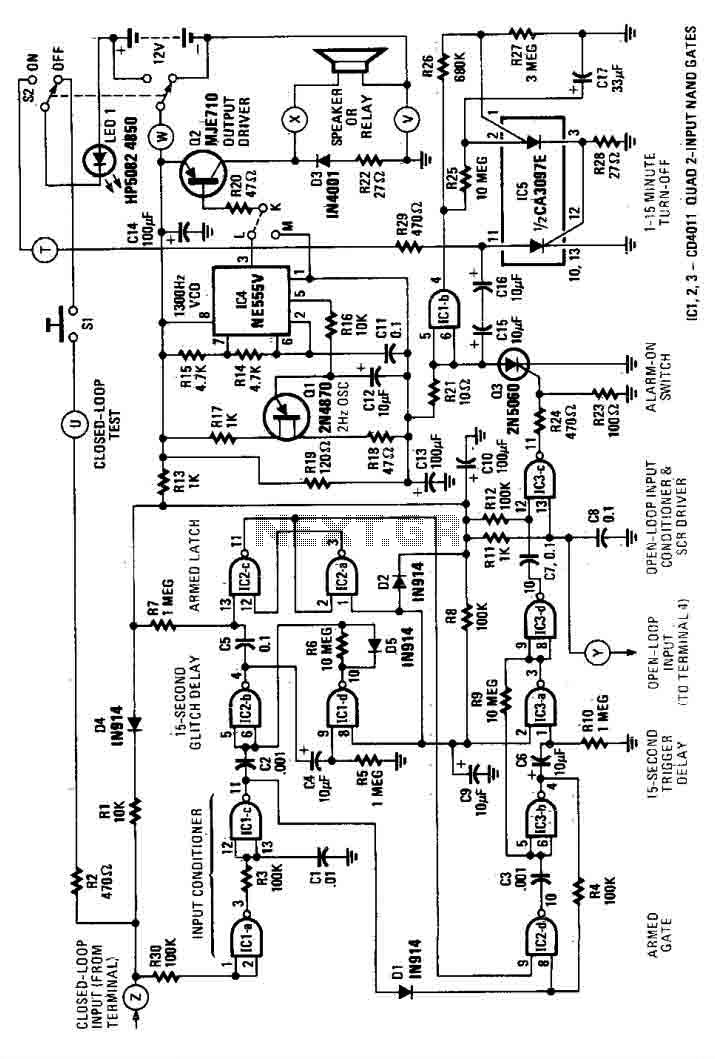

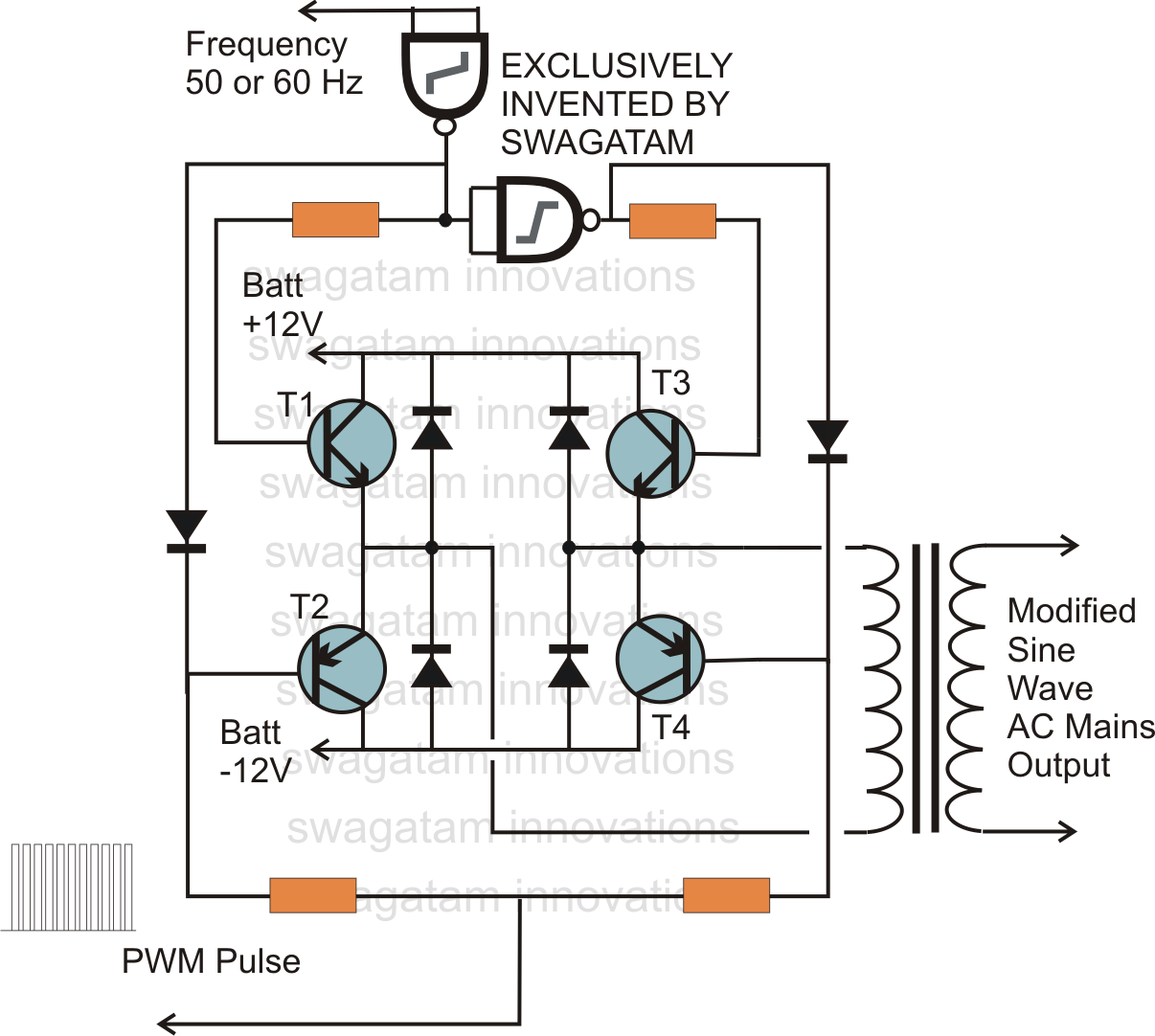

In electronics, an H-bridge circuit refers to a configuration consisting of four individual switching devices, such as transistors or MOSFETs, which can be controlled by external discrete signals from the respective stages of the control circuit. During operation, the complementary pairs from each arm of the bridge switch together, meaning that the NPN device from the left arm and the PNP device from the right arm conduct simultaneously in response to an external applied signal. This arrangement generates a push-pull effect in the connected transformer winding of the inverter, which in turn produces a complete AC cycle at the output of the transformer. The unique arrangement of the devices allows for driving them through two individual signal sources: one determines the switching rate of the output, while the other controls the RMS value of the output from the transformer. Transistors T2 and T4 are fed with PWM pulses that switch ON together; however, when T1 is conducting, T2 remains OFF, and similarly, when T3 conducts, T4 stays OFF. The two diodes from the respective NAND gates manage this operation, allowing only the relevant transistors to perform the PWM switching. Consequently, the NPN transistors are responsible for generating regular 50 or 60 Hz pulses, while the PNP transistors break the square waves according to the PWM sections.

The H-bridge circuit is a crucial component in applications requiring bidirectional control of motors and other inductive loads. The four switches are typically arranged in a bridge topology, where two switches connect to the positive supply voltage and two connect to the ground. This configuration allows for the reversal of current through the load by selectively turning on the appropriate switches.

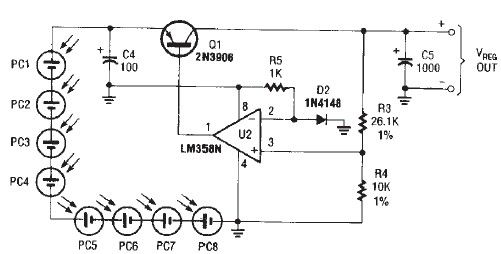

When designing an H-bridge, careful consideration must be given to the switching devices used, as they must handle the load current and voltage levels. MOSFETs are often preferred for their high efficiency and fast switching capabilities. Additionally, gate drivers may be employed to ensure that the transistors are turned on and off efficiently, minimizing switching losses and heat generation.

The control logic for the H-bridge can be implemented using microcontrollers or dedicated driver ICs, which provide the necessary PWM signals to modulate the output voltage and control the speed of the connected motor. The PWM frequency must be chosen based on the application requirements, balancing responsiveness and efficiency.

Protection features, such as diodes for flyback protection, should be incorporated to safeguard the circuit from voltage spikes generated by inductive loads. Furthermore, incorporating feedback mechanisms can enhance performance by allowing real-time adjustments to the PWM signals based on the load conditions.

In summary, the H-bridge circuit is a versatile and efficient solution for controlling the direction and speed of motors, making it an essential component in various electronic applications, including robotics, automotive systems, and industrial automation.In electronics H-bridge circuit refers to a configuration consisting of four individual switching devices like transistors or mosfets, such that these can be switched through external discrete signals from respective stages of the involved control circuit. While switching, the complementary pairs from each of the arms switch together, meaningthe NPN device from the left arm and the PNP

device from the right arm of the bridge conduct together in response to an external applied signal. The arrangement generates a push pull effect in the connected transformer winding of the inverter which in turn generates a required one full cycle of AC at the output of the transformer. The special arrangement of the devices make it possible for driving the devices through two individual signal sources, one which decides the switching rate of the output while the other decides the RMS value of the output from the transformer.

Transistors T2 and T4 ae fed with the PWM pulses which switch ON together, however when T1 is conducting, T2 should remain shut OFF and similarly when T3 conducts T4 should remain OFF, the two diodes from the respective NAND gates takes care of the issue and allow only the relevant transistors to carry out the PWM switching. Thus the NPN transistors are responsible for producing the regular 50 or 60 Hz pulses while the PNP transistors are responsible for breaking the square waves as per the PWM sections.

🔗 External reference

The H-bridge circuit is a crucial component in applications requiring bidirectional control of motors and other inductive loads. The four switches are typically arranged in a bridge topology, where two switches connect to the positive supply voltage and two connect to the ground. This configuration allows for the reversal of current through the load by selectively turning on the appropriate switches.

When designing an H-bridge, careful consideration must be given to the switching devices used, as they must handle the load current and voltage levels. MOSFETs are often preferred for their high efficiency and fast switching capabilities. Additionally, gate drivers may be employed to ensure that the transistors are turned on and off efficiently, minimizing switching losses and heat generation.

The control logic for the H-bridge can be implemented using microcontrollers or dedicated driver ICs, which provide the necessary PWM signals to modulate the output voltage and control the speed of the connected motor. The PWM frequency must be chosen based on the application requirements, balancing responsiveness and efficiency.

Protection features, such as diodes for flyback protection, should be incorporated to safeguard the circuit from voltage spikes generated by inductive loads. Furthermore, incorporating feedback mechanisms can enhance performance by allowing real-time adjustments to the PWM signals based on the load conditions.

In summary, the H-bridge circuit is a versatile and efficient solution for controlling the direction and speed of motors, making it an essential component in various electronic applications, including robotics, automotive systems, and industrial automation.In electronics H-bridge circuit refers to a configuration consisting of four individual switching devices like transistors or mosfets, such that these can be switched through external discrete signals from respective stages of the involved control circuit. While switching, the complementary pairs from each of the arms switch together, meaningthe NPN device from the left arm and the PNP

device from the right arm of the bridge conduct together in response to an external applied signal. The arrangement generates a push pull effect in the connected transformer winding of the inverter which in turn generates a required one full cycle of AC at the output of the transformer. The special arrangement of the devices make it possible for driving the devices through two individual signal sources, one which decides the switching rate of the output while the other decides the RMS value of the output from the transformer.

Transistors T2 and T4 ae fed with the PWM pulses which switch ON together, however when T1 is conducting, T2 should remain shut OFF and similarly when T3 conducts T4 should remain OFF, the two diodes from the respective NAND gates takes care of the issue and allow only the relevant transistors to carry out the PWM switching. Thus the NPN transistors are responsible for producing the regular 50 or 60 Hz pulses while the PNP transistors are responsible for breaking the square waves as per the PWM sections.

🔗 External reference