LDR Pole Light Switch

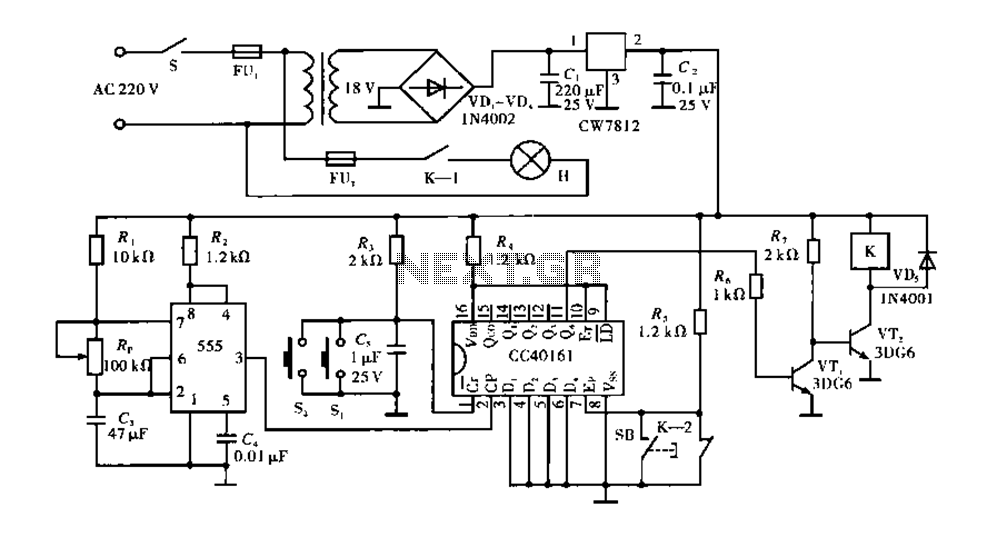

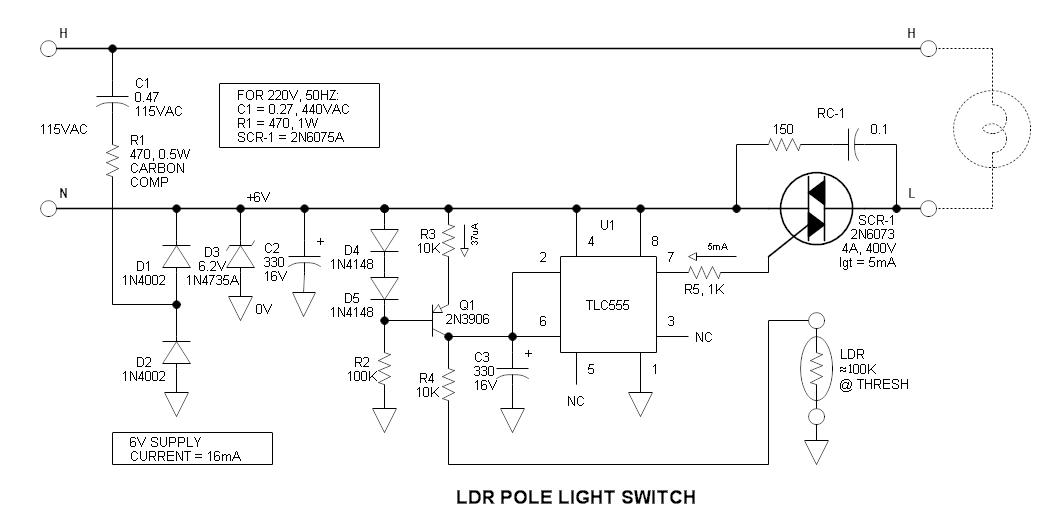

The vintage pole light, which is 62 years old, has traditionally been controlled by a timer, leading to ongoing frustration due to the need for adjustments with changing seasons. After accidentally knocking it over, an update was deemed necessary. The circuit incorporates a light-dependent resistor (LDR), a TLC555 configured as a Schmitt trigger, and a TRIAC power switch. The entire assembly fits neatly within the steel pole light tube, with the LDR protruding through a hole on the side. The project was enjoyable and practical. The power supply is a capacitor-limited charge pump type, regulated at 6.2V by a zener diode. To ensure safety, the return conductor was identified to prevent the electronics, including the LDR, from floating on the hot lead. Most testing was conducted using an isolation transformer for safety. Resistor R1 must handle high peak power transient current upon power application, so a carbon composition, ceramic composition, or wire-wound resistor is advisable. The maximum DC current available is 16mA, while the actual load is approximately 6mA. The application operates at 115V, 60Hz, with components indicated for 230VAC on the schematic. In this circuit, +6V serves as the power return lead, and 0V is the common for the electronic circuit. The LDR utilized is a TO-5 package, suitable for passing through a hole and secured with silicone rubber. The Clairex CL703M19 LDR is no longer available, but the DigiKey PDV-P8103-ND is a potential alternative, albeit with possible adjustments needed for bias current to set the threshold. The TLC555 functions as a voltage threshold detection device with hysteresis. Pin 7 drives the TRIAC gate directly through its open collector output, representing an unconventional application. The CMOS version was chosen to minimize power supply load, as a bipolar 555 resulted in doubled power supply ripple voltage to about 0.5VP-P. Due to the considerable hysteresis of the 555, concerns arose that the ON and OFF thresholds would be excessively apart. To mitigate this, the LDR is biased by a current source, with Q1 configured as a current source to maintain collector current irrespective of collector voltage, effectively increasing the gain of the LDR. The current is adjustable via the emitter resistor (R3), which drops approximately 0.37V. The logic TRIAC is notable for being triggered by either positive or negative gate current, regardless of voltage blocking polarity. For enhanced sensitivity, negative gate current was utilized. The chosen TRIAC has a gate current sensitivity (Igt) of 1.5mA, below the maximum specification of 5mA. However, gate overdrive of 5mA is recommended to ensure reliable operation at low winter temperatures. A Quencharc RC-1 is connected across the TRIAC to manage turn-off voltage transients. The decision to retain the vintage incandescent lamp is based on aesthetic considerations, with plans to transition to LED technology only when its color balance aligns with that of incandescent lighting.

The circuit described integrates several components to form a reliable and efficient lighting control system. The light-dependent resistor (LDR) serves as the primary sensor, detecting ambient light levels to determine when to activate the lighting. The TLC555 timer, configured as a Schmitt trigger, enhances the sensitivity and stability of the light detection process, ensuring that fluctuations in light do not cause erratic switching of the TRIAC. The TRIAC acts as a power switch, allowing for the control of high voltage and current loads with low power control signals. The careful selection of components, such as the LDR and the specific type of TRIAC, demonstrates an understanding of the unique requirements of controlling an incandescent light source while also considering future upgrades to LED technology.

The circuit's design emphasizes safety through the use of an isolation transformer during testing and careful routing of conductors to prevent floating grounds. The use of a current source to bias the LDR not only increases its sensitivity but also stabilizes its performance across varying conditions. The implementation of a Quencharc RC-1 across the TRIAC is crucial for suppressing voltage spikes, which could otherwise damage the circuit or lead to unreliable operation. This comprehensive approach to circuit design ensures that the lighting control system remains functional and safe while accommodating the aesthetic preferences of vintage lighting.My vintage (62 year old) pole light has always been controlled by a timer ”a source of continual frustration due the requirement of readjustment for the ever-changing seasons. However, after knocking it over (I backed my car into it ), I decided it was time for an update. The circuit consists of a light dependent resistor (LDR), TLC555 (applied as Schmitt trigger), and a TRIAC power switch. The complete assembly neatly fits inside the steel pole light tube and the LDR peeks out through a hole in the side. This was really a fun project, and useful to boot. The power supply is the typical capacitor limited charge pump type that is zener regulated at 6. 2V. Due to the lack of isolation, I was careful to identify the return conductor so that the electronics (including the LDR) would not be floating on the hot lead.

For safety, most of the testing was done using an isolation transformer. R1 must absorb a high peak power transient current when power is applied, so a carbon comp, ceramic comp, or wire wound resistor is recommended. Maximum DC current available is 16mA. Actual load is about 6mA. My application was 115V, 60hZ. For 230VAC, the components are indicated on the schematic. In this circuit, +6V is the power return lead, and 0V is the electronic circuit common ”to visualize this, one must screw his head on backwards The light dependent resistor (CdS photocell) that I used was in the TO-5 package that is well adapted for poking through a hole and is held in place with silicone rubber.

The Clairex CL703M19 LDR that I used is no longer available and I have been unable to locate the specs. The DigiKey PDV-P8103-ND appears to be a reasonable choice, but may require bias current tweaking to set the threshold.

A TLC 555 was used as a voltage threshold detecting device with hysteresis. Pin 7 drives the TRIAC gate directly via its open collector output. This is a rather unconventional application. The CMOS version is used to minimize power supply load ”I tried a bipolar 555 and it worked, but the power supply ripple voltage doubled to about 0. 5VP-P. Because the 555 has so much hysteresis, I feared that the ON & OFF thresholds would be too far apart.

To help reduce the hysteresis, the LDR is biased by a current source. Q1 is wired as a current source ”its collector current does not vary with collector voltage. This technique essentially increases the gain of the LDR. The current is set via adjusting the emitter resistor (R3) ”it drops about 0. 37V. The logic TRIAC is an interesting device. It can be triggered by either a positive or negative gate current regardless of voltage blocking polarity. For maximum sensitivity, I used negative gate current. The device I used had an actual Igt (gate current sensitivity) of 1. 5mA that is well below the 5mA Max specification. However, gate overdrive (5mA in my case) is recommended to assure that it fires at low winter temperatures.

Quencharc RC-1 is connected across the TRIAC to help control turn-off voltage transients. For the time being, I am sticking with the vintage incandescent lamp ”it is a matter of aesthetics. I will upgrade to LED technology only when its color balance matches incandescent. 🔗 External reference

The circuit described integrates several components to form a reliable and efficient lighting control system. The light-dependent resistor (LDR) serves as the primary sensor, detecting ambient light levels to determine when to activate the lighting. The TLC555 timer, configured as a Schmitt trigger, enhances the sensitivity and stability of the light detection process, ensuring that fluctuations in light do not cause erratic switching of the TRIAC. The TRIAC acts as a power switch, allowing for the control of high voltage and current loads with low power control signals. The careful selection of components, such as the LDR and the specific type of TRIAC, demonstrates an understanding of the unique requirements of controlling an incandescent light source while also considering future upgrades to LED technology.

The circuit's design emphasizes safety through the use of an isolation transformer during testing and careful routing of conductors to prevent floating grounds. The use of a current source to bias the LDR not only increases its sensitivity but also stabilizes its performance across varying conditions. The implementation of a Quencharc RC-1 across the TRIAC is crucial for suppressing voltage spikes, which could otherwise damage the circuit or lead to unreliable operation. This comprehensive approach to circuit design ensures that the lighting control system remains functional and safe while accommodating the aesthetic preferences of vintage lighting.My vintage (62 year old) pole light has always been controlled by a timer ”a source of continual frustration due the requirement of readjustment for the ever-changing seasons. However, after knocking it over (I backed my car into it ), I decided it was time for an update. The circuit consists of a light dependent resistor (LDR), TLC555 (applied as Schmitt trigger), and a TRIAC power switch. The complete assembly neatly fits inside the steel pole light tube and the LDR peeks out through a hole in the side. This was really a fun project, and useful to boot. The power supply is the typical capacitor limited charge pump type that is zener regulated at 6. 2V. Due to the lack of isolation, I was careful to identify the return conductor so that the electronics (including the LDR) would not be floating on the hot lead.

For safety, most of the testing was done using an isolation transformer. R1 must absorb a high peak power transient current when power is applied, so a carbon comp, ceramic comp, or wire wound resistor is recommended. Maximum DC current available is 16mA. Actual load is about 6mA. My application was 115V, 60hZ. For 230VAC, the components are indicated on the schematic. In this circuit, +6V is the power return lead, and 0V is the electronic circuit common ”to visualize this, one must screw his head on backwards The light dependent resistor (CdS photocell) that I used was in the TO-5 package that is well adapted for poking through a hole and is held in place with silicone rubber.

The Clairex CL703M19 LDR that I used is no longer available and I have been unable to locate the specs. The DigiKey PDV-P8103-ND appears to be a reasonable choice, but may require bias current tweaking to set the threshold.

A TLC 555 was used as a voltage threshold detecting device with hysteresis. Pin 7 drives the TRIAC gate directly via its open collector output. This is a rather unconventional application. The CMOS version is used to minimize power supply load ”I tried a bipolar 555 and it worked, but the power supply ripple voltage doubled to about 0. 5VP-P. Because the 555 has so much hysteresis, I feared that the ON & OFF thresholds would be too far apart.

To help reduce the hysteresis, the LDR is biased by a current source. Q1 is wired as a current source ”its collector current does not vary with collector voltage. This technique essentially increases the gain of the LDR. The current is set via adjusting the emitter resistor (R3) ”it drops about 0. 37V. The logic TRIAC is an interesting device. It can be triggered by either a positive or negative gate current regardless of voltage blocking polarity. For maximum sensitivity, I used negative gate current. The device I used had an actual Igt (gate current sensitivity) of 1. 5mA that is well below the 5mA Max specification. However, gate overdrive (5mA in my case) is recommended to assure that it fires at low winter temperatures.

Quencharc RC-1 is connected across the TRIAC to help control turn-off voltage transients. For the time being, I am sticking with the vintage incandescent lamp ”it is a matter of aesthetics. I will upgrade to LED technology only when its color balance matches incandescent. 🔗 External reference