LED Bike Light Circuit Project

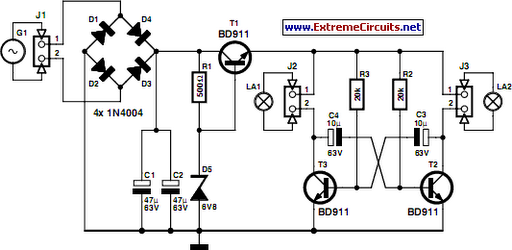

On a mountain bike, a common issue with traditional flashing LED lights from stores is the frequent problem of flat batteries and lights detaching. As an electronics student, a better solution was sought. A front wheel with a built-in dynamo hub was acquired, providing a sine wave output of 30 Vpp (at no load). Using this information, a simple power supply was designed. The transistors employed are of type BD911, which are somewhat oversized for the application, but were readily available at the school. A smaller alternative could also suffice. The power supply is connected to an astable multivibrator that alternately activates the front and rear lights. The frequency of this operation is determined by the RC time constants of resistors R3 and R2 in conjunction with capacitors C3 and C4, respectively. The time can be calculated using the formula: t = R3 * C3 = 20 * 10^3 * 10^(-6) = 0.2 s. A common resistor value of 22k can be used for R2 and R3 without significant impact on performance. A small prototyping board houses six LEDs, each paired with a series voltage dropping resistor. This PCB serves both the front and rear of the bike, utilizing white LEDs for the front and red LEDs for the rear. The main circuit PCB is mounted under the seat for protection and has been operational for over a year. Future revisions could include an on/off switch and the use of SMD components, allowing for closer placement to the front light and improved wiring management. Currently, the dynamo cable extends from the front wheel to the seat, then branches to the front and rear lights.

The circuit design begins with a dynamo hub integrated into the front wheel, which generates alternating current (AC) voltage. This AC voltage is rectified and regulated to supply a stable DC voltage suitable for powering the LED lights. The BD911 transistors serve as switches in the power supply circuit, capable of handling the required load while providing sufficient current to illuminate the LEDs effectively.

The astable multivibrator circuit is crucial for creating a flashing effect. It consists of two resistors (R2 and R3) and two capacitors (C4 and C3), which determine the oscillation frequency. The calculated time period of 0.2 seconds implies a flashing rate that can be visually appealing and attention-grabbing for safety during night rides.

The prototyping board arrangement allows for efficient layout and organization of the LED lights. The use of series resistors with the LEDs ensures that the current flowing through each LED is within safe limits, preventing damage and extending the lifespan of the components. The choice of white LEDs for the front and red LEDs for the rear adheres to standard cycling safety practices, enhancing visibility to others on the road.

Mounting the PCB under the seat protects it from environmental factors such as rain and debris, contributing to the reliability of the system. The suggestion to incorporate an on/off switch would enhance user control, allowing the rider to deactivate the lights when not in use, thereby conserving energy and preventing unnecessary wear on the components.

Considering the use of surface-mount devices (SMD) in future iterations could streamline the design, reduce the circuit footprint, and facilitate easier integration near the front light. This would also simplify the wiring layout, minimizing the distance the dynamo cable must travel and reducing potential points of failure. Overall, this project exemplifies the practical application of electronics in enhancing cycling safety and convenience.On my mountain bike I always used to have one of those well-known flashing LED lights from the high street shop. These often gave me trouble with flat batteries and lights that fell off. As an electronics student I thought: this can be done better . First I bought another front wheel, one which has a dynamo already built in the hub. This supplie d a nice sine wave of 30 Vpp (at no load). With this knowledge I designed a simple power supply. The transistors that are used are type BD911. These are a bit of an over-kill, but there were plenty of these at my school, so that is why I used them. Something a little smaller will also work. The power supply is connected to an astable multi-vibrator. This alternately drives the front light and the rear light. The frequency is determined by the RC time-constant of R3 and C3, and R2 and C4. This time can be calculated with the formula: t = R3G—C3 = 20G—103G—10G—10-6 = 0. 2 s You can use a 22k (common value) for R2 and R3, that doesn`t make much difference. On a small piece of prototyping board are six LEDs with a voltage dropping resistor in series with each pair of LEDs.

Such a PCB is used for both the front and the rear of the bike. Of course, you use white LEDs for the front and red ones for the rear. The PCB with the main circuit is mounted under the seat, where it is safe and has been working for more than a year now. There are a few things I would change for the next revision. An on/off switch would be nice. And if the whole circuit was built with SMD parts it could be mounted near the front light. This would also be more convenient when routing the wiring. Now the cable from the dynamo goes all the way to the seat and from there to the front and rear lights.

🔗 External reference

The circuit design begins with a dynamo hub integrated into the front wheel, which generates alternating current (AC) voltage. This AC voltage is rectified and regulated to supply a stable DC voltage suitable for powering the LED lights. The BD911 transistors serve as switches in the power supply circuit, capable of handling the required load while providing sufficient current to illuminate the LEDs effectively.

The astable multivibrator circuit is crucial for creating a flashing effect. It consists of two resistors (R2 and R3) and two capacitors (C4 and C3), which determine the oscillation frequency. The calculated time period of 0.2 seconds implies a flashing rate that can be visually appealing and attention-grabbing for safety during night rides.

The prototyping board arrangement allows for efficient layout and organization of the LED lights. The use of series resistors with the LEDs ensures that the current flowing through each LED is within safe limits, preventing damage and extending the lifespan of the components. The choice of white LEDs for the front and red LEDs for the rear adheres to standard cycling safety practices, enhancing visibility to others on the road.

Mounting the PCB under the seat protects it from environmental factors such as rain and debris, contributing to the reliability of the system. The suggestion to incorporate an on/off switch would enhance user control, allowing the rider to deactivate the lights when not in use, thereby conserving energy and preventing unnecessary wear on the components.

Considering the use of surface-mount devices (SMD) in future iterations could streamline the design, reduce the circuit footprint, and facilitate easier integration near the front light. This would also simplify the wiring layout, minimizing the distance the dynamo cable must travel and reducing potential points of failure. Overall, this project exemplifies the practical application of electronics in enhancing cycling safety and convenience.On my mountain bike I always used to have one of those well-known flashing LED lights from the high street shop. These often gave me trouble with flat batteries and lights that fell off. As an electronics student I thought: this can be done better . First I bought another front wheel, one which has a dynamo already built in the hub. This supplie d a nice sine wave of 30 Vpp (at no load). With this knowledge I designed a simple power supply. The transistors that are used are type BD911. These are a bit of an over-kill, but there were plenty of these at my school, so that is why I used them. Something a little smaller will also work. The power supply is connected to an astable multi-vibrator. This alternately drives the front light and the rear light. The frequency is determined by the RC time-constant of R3 and C3, and R2 and C4. This time can be calculated with the formula: t = R3G—C3 = 20G—103G—10G—10-6 = 0. 2 s You can use a 22k (common value) for R2 and R3, that doesn`t make much difference. On a small piece of prototyping board are six LEDs with a voltage dropping resistor in series with each pair of LEDs.

Such a PCB is used for both the front and the rear of the bike. Of course, you use white LEDs for the front and red ones for the rear. The PCB with the main circuit is mounted under the seat, where it is safe and has been working for more than a year now. There are a few things I would change for the next revision. An on/off switch would be nice. And if the whole circuit was built with SMD parts it could be mounted near the front light. This would also be more convenient when routing the wiring. Now the cable from the dynamo goes all the way to the seat and from there to the front and rear lights.

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713