Magnetic Circuits

1. Definition and Basic Concepts

1.1 Definition and Basic Concepts

Fundamental Definitions

A magnetic circuit is an analogous concept to an electric circuit, where magnetic flux Φ flows through a closed path of high-permeability materials, such as iron or ferrites, much like electric current flows through conductive paths. The driving force in a magnetic circuit is the magnetomotive force (MMF), denoted as F, which is analogous to electromotive force (EMF) in electric circuits. MMF is generated by current-carrying coils and is given by:

where N is the number of turns in the coil and I is the current. The opposition to magnetic flux is called reluctance (R), analogous to resistance in electric circuits, and is defined as:

where l is the length of the magnetic path, μ is the permeability of the material, and A is the cross-sectional area.

Key Analogies Between Electric and Magnetic Circuits

The behavior of magnetic circuits closely mirrors that of electric circuits, with the following key analogies:

- MMF (F) ↔ EMF (V)

- Magnetic flux (Φ) ↔ Current (I)

- Reluctance (R) ↔ Resistance (R)

- Permeability (μ) ↔ Conductivity (σ)

These analogies allow the application of circuit analysis techniques, such as Kirchhoff’s laws, to magnetic systems.

Magnetic Flux and Flux Density

Magnetic flux Φ is the total magnetic field passing through a given area and is measured in webers (Wb). The flux density (B), measured in teslas (T), is the flux per unit area:

In ferromagnetic materials, B and the magnetic field intensity H are related by the material's permeability:

where μ = μ0μr, with μ0 being the permeability of free space (4π × 10−7 H/m) and μr the relative permeability of the material.

Practical Applications

Magnetic circuits are foundational in the design of transformers, electric motors, inductors, and magnetic sensors. For example, in a transformer, the core is designed to maximize flux linkage while minimizing reluctance to improve efficiency. Similarly, in electric motors, the magnetic circuit ensures optimal torque production by maintaining a high flux density in the air gap.

Nonlinearity and Hysteresis

Unlike electric circuits, magnetic circuits exhibit nonlinear behavior due to the B-H curve of ferromagnetic materials. Saturation occurs when increasing H no longer significantly increases B, limiting the flux density. Additionally, hysteresis introduces energy losses, as the B-H curve follows different paths during magnetization and demagnetization cycles. The area enclosed by the hysteresis loop represents energy dissipated as heat, a critical consideration in AC applications.

1.2 Magnetic Flux and Flux Density

Fundamental Definitions

Magnetic flux, denoted by Φ, quantifies the total magnetic field passing through a given surface. It is a scalar quantity measured in webers (Wb) in the SI system. The differential form of magnetic flux through an infinitesimal area dA is given by the dot product of the magnetic flux density B and the area vector dA:

Integrating over the entire surface S yields the total magnetic flux:

Magnetic Flux Density

Magnetic flux density (B), also called magnetic induction, is a vector field representing the concentration of magnetic flux per unit area. Its SI unit is the tesla (T), where 1 T = 1 Wb/m². In free space, B relates to the magnetic field strength H through the permeability of free space μ₀:

In magnetic materials, the relationship becomes:

where M is the magnetization vector, representing the material's intrinsic dipole moment per unit volume.

Practical Implications

Flux density is critical in designing electromagnetic devices. For example:

- Transformers: Core saturation occurs when B exceeds the material's maximum flux density, leading to nonlinear behavior and losses.

- Electric Motors: Torque production is directly proportional to the rotor's flux density and current.

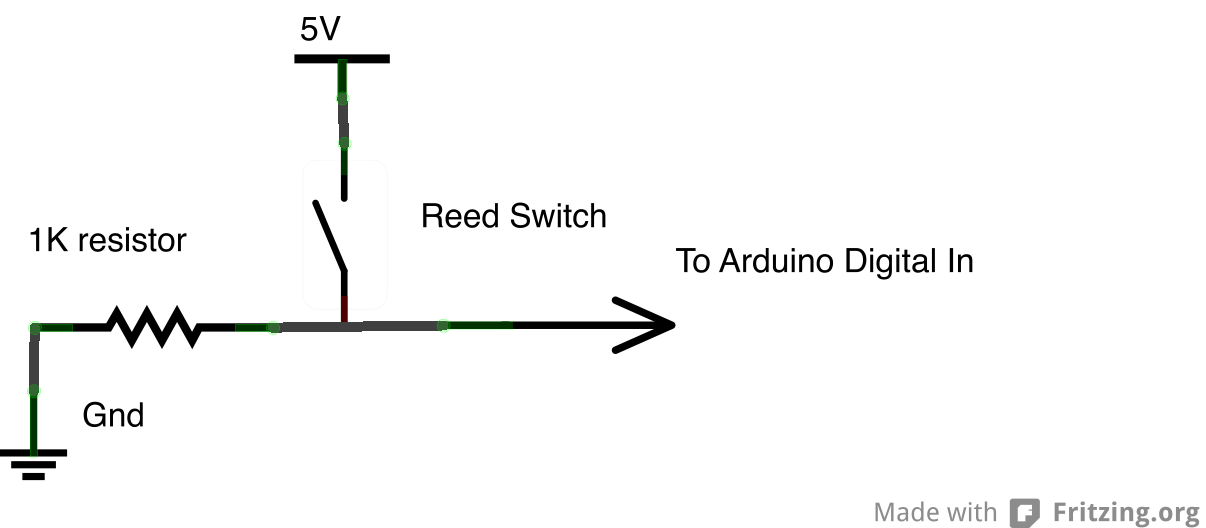

- Magnetic Sensors: Hall-effect sensors measure B to detect position or current.

Gauss’s Law for Magnetism

One of Maxwell’s equations states that magnetic flux through a closed surface is zero, reflecting the absence of magnetic monopoles:

This implies that magnetic field lines form continuous loops, unlike electric field lines originating from charges.

Flux Linkage in Coils

For a coil with N turns, the total flux linkage λ is the product of turns and flux per turn:

This concept underpins Faraday’s law of induction, where a time-varying flux linkage induces an electromotive force (EMF):

Measurement Techniques

Flux density is measured using:

- Hall-effect probes: Output voltage is proportional to B.

- Search coils: Induced voltage integrates to give B.

- Magnetoresistive sensors: Material resistance changes with B.

1.3 Magnetomotive Force (MMF) and Reluctance

Magnetomotive force (MMF) is the magnetic analog of electromotive force (EMF) in electric circuits. It represents the driving force that establishes magnetic flux in a magnetic circuit, analogous to voltage driving current in an electrical circuit. The MMF (F) is defined as the product of the current (I) flowing through a coil and the number of turns (N) in the coil:

Where F is measured in ampere-turns (A·t). Unlike EMF, MMF is not a true force but rather a measure of the magnetic potential difference.

Reluctance and Its Relationship to MMF

Reluctance (R) is the opposition a material offers to the establishment of magnetic flux, analogous to resistance in electrical circuits. It depends on the geometry of the magnetic circuit and the material's permeability (μ). For a uniform cross-section, reluctance is given by:

Where l is the length of the magnetic path, A is the cross-sectional area, and μ is the permeability of the material (μ = μ0μr, with μ0 being the permeability of free space and μr the relative permeability).

Ohm's Law for Magnetic Circuits

The relationship between MMF, flux (Φ), and reluctance mirrors Ohm's Law in electrical circuits:

This shows that magnetic flux is directly proportional to MMF and inversely proportional to reluctance. High-permeability materials (e.g., iron) reduce reluctance, allowing greater flux for a given MMF.

Practical Implications and Applications

In transformer design, minimizing core reluctance is critical for efficient energy transfer. Laminated silicon steel cores are used to reduce eddy currents while maintaining high permeability. Similarly, in electric motors, optimizing the air gap (which has high reluctance) is essential for performance.

For a magnetic circuit with multiple materials in series, total reluctance is the sum of individual reluctances:

For parallel paths, the inverse of total reluctance is the sum of inverse reluctances:

Nonlinearity and Saturation Effects

Unlike electrical resistance, magnetic reluctance is nonlinear due to the B-H curve characteristics of ferromagnetic materials. As flux density increases, permeability drops sharply at saturation, causing reluctance to rise. This limits the practical flux density in magnetic devices.

The complete magnetic circuit equation, accounting for saturation, becomes:

Where H is the magnetic field intensity, which varies nonlinearly with flux density B in ferromagnetic materials.

2. Ferromagnetic, Paramagnetic, and Diamagnetic Materials

2.1 Ferromagnetic, Paramagnetic, and Diamagnetic Materials

The magnetic properties of materials arise from the alignment of electron spins and orbital angular momenta in response to an external magnetic field. These properties are classified into three primary categories: ferromagnetic, paramagnetic, and diamagnetic behavior, each governed by distinct quantum mechanical and thermodynamic principles.

Ferromagnetic Materials

Ferromagnetic materials exhibit strong, spontaneous magnetization even in the absence of an external field due to parallel alignment of atomic magnetic moments. This alignment results from exchange interaction, a quantum mechanical phenomenon where electron spins lower their energy by maintaining parallel orientation. The magnetization M follows the Weiss molecular field theory:

where N is the number of magnetic atoms per unit volume, μ is the magnetic moment, H is the applied field, λ is the molecular field constant, and T is temperature. Below the Curie temperature TC, ferromagnetic materials maintain domains—regions of uniform magnetization separated by Bloch walls.

Practical applications include:

- Permanent magnets (Alnico, NdFeB)

- Transformer cores (grain-oriented Si-steel)

- Magnetic storage media (CoCrPt alloys)

Paramagnetic Materials

Paramagnetic materials weakly align with an external field but lose magnetization when the field is removed. Their susceptibility χ follows Curie's law:

where C is the material-specific Curie constant. The alignment competes with thermal disorder, quantified by the Langevin function for classical moments or Brillouin function for quantum systems. At high fields/low temperatures, paramagnets approach saturation magnetization.

Examples include:

- Rare-earth ions (Gd3+, Dy3+)

- Molecular oxygen (O2)

- Alkali metals above their ordering temperatures

Diamagnetic Materials

Diamagnetic materials generate weak, opposing magnetization to an applied field due to Lenz's law acting on electron orbits. The susceptibility is negative and temperature-independent:

where n is electron density, ⟨r²⟩ is the mean squared orbital radius, and me is electron mass. Superconductors exhibit perfect diamagnetism (Meissner effect) with χ = −1.

Key diamagnetic materials:

- Bismuth (strongest elemental diamagnet)

- Graphite (anisotropic diamagnetism)

- Water (χ ≈ −9×10−6)

Comparative Analysis

The table below contrasts key properties:

| Property | Ferromagnetic | Paramagnetic | Diamagnetic |

|---|---|---|---|

| Susceptibility (χ) | 103–106 | 10−5–10−3 | −10−5–−10−9 |

| Temperature Dependence | Curie-Weiss law | Curie law | None |

| Hysteresis | Present | None | None |

In engineered magnetic circuits, ferromagnetic materials dominate due to their high permeability, while paramagnets find use in cryogenic applications and diamagnets in magnetic shielding.

Hysteresis and B-H Curves

Fundamentals of Hysteresis

Hysteresis in magnetic materials refers to the lagging of magnetic flux density (B) behind the applied magnetic field intensity (H). This phenomenon arises due to the energy dissipation associated with domain wall motion and magnetic dipole alignment. When an alternating magnetic field is applied, the B-H relationship forms a closed loop rather than a single-valued curve, indicating energy loss per cycle.

Mathematical Representation

The hysteresis loop can be characterized mathematically by considering the work done per unit volume during one complete magnetization cycle:

Where W represents the energy loss per cycle per unit volume. For soft magnetic materials, this integral yields a small value, while hard magnetic materials exhibit significantly larger hysteresis losses.

Key Parameters of the B-H Curve

The hysteresis loop reveals several critical material properties:

- Remanence (Br): Residual flux density when H returns to zero

- Coercivity (Hc): Reverse field required to reduce B to zero

- Saturation flux density (Bsat): Maximum achievable flux density

Domain Theory Explanation

At the microscopic level, hysteresis results from the behavior of magnetic domains:

- Initially, domains are randomly oriented (demagnetized state)

- As H increases, favorably oriented domains grow at the expense of others

- At saturation, all domains align with the applied field

- Upon field removal, some alignment persists due to crystal anisotropy

Practical Implications

Hysteresis effects significantly influence the design of electromagnetic devices:

- Transformers: Core materials are selected for minimal hysteresis loss (small loop area)

- Permanent magnets: Require large coercivity to maintain magnetization

- Magnetic storage: Hysteresis enables binary data retention in hard disks

Temperature Dependence

The hysteresis characteristics vary with temperature according to:

Where Tc is the Curie temperature and α is a material-dependent exponent typically ranging from 0.5 to 2.

Measurement Techniques

Modern hysteresis graph measurement systems employ:

- Closed-loop fluxmeters with integrating coils

- Vibrating sample magnetometers (VSM) for small samples

- Epstein frame setups for laminated steel characterization

2.3 Permeability and Saturation

The magnetic permeability (μ) of a material quantifies its ability to support the formation of a magnetic field within itself. It is defined as the ratio of the magnetic flux density (B) to the magnetic field intensity (H):

In free space, the permeability is denoted by μ0 and has a value of approximately 4π × 10−7 H/m. For other materials, permeability is often expressed relative to free space as the relative permeability (μr):

Ferromagnetic materials, such as iron, nickel, and cobalt, exhibit high relative permeability (μr ≫ 1), making them ideal for applications requiring strong magnetic fields. However, their permeability is not constant and varies with H, leading to nonlinear behavior in magnetic circuits.

Nonlinear Permeability and the B-H Curve

The relationship between B and H is nonlinear for ferromagnetic materials, as depicted in the B-H curve. Initially, as H increases, B rises rapidly due to domain alignment. This region is characterized by high permeability. However, as most domains align, the increase in B slows, and the material approaches saturation.

Magnetic Saturation

Saturation occurs when further increases in H produce negligible increases in B. At this point, nearly all magnetic domains are aligned, and the material's permeability drops to near μ0. Operating a magnetic circuit in saturation reduces efficiency and can lead to excessive core losses due to hysteresis and eddy currents.

where Ms is the saturation magnetization, a material-dependent property. For example, pure iron saturates at approximately 2.1 T, while silicon steel saturates around 1.8 T.

Practical Implications

- Transformer Design: Core materials are selected to avoid saturation under normal operating conditions, ensuring linear behavior and minimizing energy losses.

- Inductor Applications: Saturation limits the maximum energy storage capacity, necessitating careful selection of core geometry and material.

- Magnetic Sensors: Saturation effects are exploited in devices like fluxgate magnetometers, where nonlinearity is used to detect external magnetic fields.

Mathematical Modeling of Saturation

To account for saturation in magnetic circuit analysis, empirical models such as the Langevin function or the Fröhlich-Kennelly equation are often used. The Fröhlich-Kennelly relation approximates the B-H curve as:

where μi is the initial permeability and α is a material constant. This model captures the transition from linear to saturated behavior.

This section provides a rigorous, mathematically grounded explanation of permeability and saturation, with clear transitions between concepts and practical applications. The HTML is well-structured, properly closed, and includes an SVG diagram for visual clarity.3. Ohm's Law for Magnetic Circuits

3.1 Ohm's Law for Magnetic Circuits

Magnetic circuits follow an analogous relationship to Ohm's Law in electrical circuits, where magnetomotive force (F), magnetic flux (Φ), and reluctance (R) correspond to voltage (V), current (I), and resistance (R), respectively. The fundamental equation governing magnetic circuits is:

Here, F (magnetomotive force) is the driving force that establishes the magnetic flux, measured in ampere-turns (A·t). The magnetic flux Φ is analogous to current and is measured in webers (Wb), while reluctance R represents opposition to flux and is measured in ampere-turns per weber (A·t/Wb).

Derivation of Magnetic Reluctance

Reluctance depends on the geometry and material properties of the magnetic path. For a uniform cross-section, it is given by:

where:

- l = length of the magnetic path (m)

- A = cross-sectional area (m²)

- μ = permeability of the material (H/m)

Permeability (μ) is a critical parameter, defined as μ = μ0μr, where μ0 is the permeability of free space (4π × 10⁻⁷ H/m) and μr is the relative permeability of the material.

Practical Implications

In real-world applications, magnetic circuits are essential in designing transformers, inductors, and electric motors. For instance, high-permeability materials like silicon steel reduce reluctance, allowing efficient flux linkage in transformer cores. Conversely, air gaps introduce significant reluctance, which can be leveraged in adjustable inductors.

The analogy with Ohm's Law extends to series and parallel magnetic circuits:

- Series reluctance: Rtotal = R1 + R2 + ... + Rn

- Parallel reluctance: 1/Rtotal = 1/R1 + 1/R2 + ... + 1/Rn

Nonlinearity and Hysteresis Effects

Unlike electrical resistance, magnetic reluctance is not constant—it varies with flux density due to the nonlinear B-H curve of ferromagnetic materials. Saturation occurs at high flux densities, where permeability drops, increasing reluctance. Hysteresis losses further complicate energy dissipation in AC applications.

where B is flux density (T) and H is magnetic field strength (A/m). This nonlinearity necessitates iterative or numerical methods for precise circuit analysis.

3.2 Series and Parallel Magnetic Circuits

Magnetic circuits can be analyzed analogously to electric circuits, where magnetomotive force (MMF) replaces voltage, magnetic flux replaces current, and reluctance replaces resistance. The behavior of magnetic circuits in series and parallel configurations follows principles similar to Kirchhoff’s laws but adapted for magnetic quantities.

Series Magnetic Circuits

In a series magnetic circuit, the same magnetic flux Φ flows through all reluctances connected sequentially. The total MMF F is the sum of the MMF drops across each reluctance, analogous to voltage drops in a series electric circuit. For a circuit with n reluctances:

where F = NI (ampere-turns), N is the number of turns, I is the current, and ℛi is the reluctance of the i-th segment. The total reluctance ℛtotal of the series circuit is:

This relationship holds as long as the magnetic material operates within its linear region (i.e., before saturation).

Parallel Magnetic Circuits

In a parallel configuration, the MMF F is the same across all branches, while the total flux Φtotal divides among the parallel reluctances. The equivalent reluctance ℛeq is derived from the harmonic sum of individual reluctances:

The flux in each branch Φi is determined by the ratio of the total MMF to the branch reluctance:

This is analogous to current division in parallel electric circuits.

Practical Considerations

In real-world applications, magnetic circuits often exhibit nonlinearity due to core saturation, hysteresis, and leakage flux. For accurate modeling:

- Core Saturation: At high flux densities, the permeability μ of the material decreases, increasing reluctance nonlinearly.

- Leakage Flux: Not all flux confines itself to the intended path; leakage paths must be accounted for in high-precision designs.

- Fringing Effects: At air gaps, flux lines bulge outward, effectively increasing the cross-sectional area and reducing reluctance.

Example: Series-Parallel Magnetic Circuit

Consider a magnetic core with two parallel limbs, each containing a series air gap. The equivalent reluctance is computed by first combining the series reluctances in each limb and then treating the limbs as parallel branches. For limbs with reluctances ℛ1 and ℛ2, and air gaps ℛg1 and ℛg2:

This approach is widely used in transformer and inductor design, where minimizing reluctance optimizes energy efficiency.

This section provides a rigorous, mathematically grounded explanation of series and parallel magnetic circuits while addressing practical challenges. The equations are derived step-by-step, and real-world considerations are highlighted for advanced readers. The HTML is properly structured with hierarchical headings, mathematical formulas, and well-formed tags.3.3 Air Gaps and Their Effects

Air gaps in magnetic circuits introduce a region of low permeability, significantly altering the circuit's magnetic behavior. The presence of an air gap increases the total reluctance of the magnetic path, reducing the overall magnetic flux for a given magnetomotive force (MMF). The reluctance of the air gap Rg dominates the total reluctance due to its high permeability contrast with ferromagnetic materials.

Reluctance Calculation for Air Gaps

The reluctance of an air gap is given by:

where lg is the length of the air gap, Ag is its cross-sectional area, and μ0 is the permeability of free space (4π × 10−7 H/m). For a magnetic circuit with a ferromagnetic core of reluctance Rc, the total reluctance becomes:

Effect on Flux Density and Inductance

The introduction of an air gap reduces the effective permeability of the magnetic circuit, leading to a lower flux density B for a given MMF. The flux density in the air gap is continuous, but the magnetic field intensity H increases due to the relationship:

In inductors and transformers, air gaps are deliberately introduced to:

- Prevent core saturation by increasing the linear operating range.

- Control inductance by adjusting the gap length.

- Reduce core losses in high-frequency applications.

Fringing Effects

At the edges of an air gap, the magnetic flux lines bulge outward, a phenomenon known as fringing. This increases the effective cross-sectional area of the gap, slightly reducing its reluctance. The fringing factor F is approximated as:

For precise designs, fringing must be accounted for, particularly in sensors and actuators where gap geometry critically influences performance.

Practical Applications

Air gaps are essential in:

- Electric motors and generators to manage flux paths and prevent saturation.

- Magnetic sensors where gap variations translate to measurable changes in inductance or reluctance.

- High-frequency inductors to stabilize inductance against temperature and current variations.

The trade-off between increased reluctance and improved linearity makes air gaps a key design parameter in high-performance magnetic systems.

4. Transformers and Inductors

4.1 Transformers and Inductors

Fundamental Principles

Transformers and inductors rely on Faraday's law of electromagnetic induction, where a time-varying magnetic flux induces an electromotive force (EMF) in a conductor. For an ideal transformer with negligible losses, the voltage ratio between primary (Vp) and secondary (Vs) coils is determined by the turns ratio Np/Ns:

In practical designs, core permeability (μ), hysteresis losses, and eddy currents introduce non-idealities. The magnetomotive force (MMF) is governed by:

where ϕ is the magnetic flux and ℛ is the reluctance of the magnetic circuit.

Transformer Core Materials

High-μ materials like silicon steel, ferrites, or amorphous metals minimize core losses. The core's B-H curve determines saturation flux density (Bsat) and hysteresis loss. For a sinusoidal excitation, core loss per unit volume (Pv) follows Steinmetz's equation:

where kh, ke are material constants, f is frequency, and Bm is peak flux density.

Inductor Design Considerations

Inductors store energy in their magnetic field, with inductance L given by:

where Ac is the core cross-section and lc is the magnetic path length. Air gaps are introduced to prevent saturation, trading off inductance for higher current handling:

Leakage and Parasitic Effects

Non-ideal coupling in transformers results in leakage inductance (Ll), modeled as a series reactance. Capacitive coupling between windings and core losses (Rc) further degrade performance. The equivalent circuit includes:

- Magnetizing inductance (Lm) in parallel with Rc.

- Leakage inductance and winding resistance in series.

High-Frequency Behavior

At high frequencies, skin and proximity effects increase winding resistance, while core losses dominate. Distributed capacitance between turns creates self-resonance, limiting usable bandwidth. The quality factor (Q) of an inductor is:

where Rac accounts for frequency-dependent resistance.

Practical Applications

Power transformers use laminated cores to suppress eddy currents, while RF inductors employ powdered iron or ferrite beads. Flyback converters exploit transformer leakage inductance for energy storage, and coupled inductors enable multi-phase power supplies. Recent advances include planar magnetics for miniaturization and GaN-based high-frequency designs.

4.2 Electromagnets and Actuators

Fundamentals of Electromagnets

An electromagnet consists of a coil wound around a ferromagnetic core, producing a magnetic field when current flows through the coil. The magnetic field strength H is given by Ampère's law:

where N is the number of turns, I is the current, and the integral is taken around the closed path enclosing the current. For a solenoid of length l with uniform field distribution, this simplifies to:

The resulting magnetic flux density B in the core depends on the material's permeability μ:

Force Generation in Electromagnetic Actuators

Electromagnetic actuators convert electrical energy into mechanical motion via the Lorentz force or reluctance force. For a current-carrying conductor in a magnetic field, the Lorentz force is:

In reluctance-based actuators, the force arises from the tendency of the magnetic circuit to minimize reluctance. The force F for a linear actuator can be derived from the rate of change of coenergy W' with position x:

where L is the coil inductance, which varies with the air gap.

Design Considerations

Key parameters in electromagnet design include:

- Magnetic saturation: Core material must be chosen to avoid saturation at operating flux densities

- Coil heating: Current density limited by thermal constraints

- Eddy currents: Laminated cores reduce losses in AC applications

- Leakage flux: Proper magnetic circuit design minimizes flux that doesn't contribute to useful work

Actuator Types and Applications

Common electromagnetic actuator configurations include:

Solenoid Actuators

Linear motion devices where a plunger moves along the axis of a cylindrical coil. Used in valves, relays, and locking mechanisms. The force-displacement characteristic is highly nonlinear due to varying reluctance.

Voice Coil Actuators

Employ a permanent magnet and moving coil arrangement, producing force proportional to current. Applications include disk drive head positioning and precision motion control.

Rotary Actuators

Electromagnetic torque can be generated through various configurations:

- Brushless DC motors: Permanent magnet rotor with electronically commutated stator windings

- Switched reluctance motors: Torque produced by tendency of rotor to align with energized stator poles

- Stepper motors: Precise positioning through sequential stator winding excitation

Dynamic Modeling

The electromechanical system can be described by coupled electrical and mechanical equations:

where R is coil resistance, m is mass, b is damping coefficient, and k is spring constant. For rotary systems, the mechanical equation becomes:

with J as moment of inertia, B as rotational damping, and K as torsional stiffness.

Advanced Materials and Optimization

Recent developments include:

- Amorphous and nanocrystalline alloys: Reduced core losses and improved high-frequency performance

- High-temperature superconductors: Enable extremely strong magnetic fields with minimal losses

- Additive manufacturing: Allows complex magnetic circuit geometries not feasible with traditional methods

Optimization techniques such as finite element analysis (FEA) are routinely used to predict magnetic field distributions and optimize actuator performance before prototyping.

4.3 Magnetic Sensors and Storage Devices

Hall Effect Sensors

The Hall effect is the production of a voltage difference (Hall voltage, VH) across an electrical conductor transverse to an electric current and an applied magnetic field. For a current I flowing through a conductor of thickness d in a magnetic field B, the Hall voltage is given by:

where n is the charge carrier density and e is the electron charge. Modern Hall sensors exploit semiconductor materials (e.g., GaAs, InSb) for high sensitivity, achieving resolutions below 1 μT. Applications include position sensing, current measurement, and brushless DC motor commutation.

Magnetoresistive Sensors

Magnetoresistive (MR) sensors rely on the change in electrical resistance of a material under an applied magnetic field. Key variants include:

- Anisotropic Magnetoresistance (AMR): Resistance varies with the angle between current and magnetization. AMR sensors achieve ~2–5% resistance change and are used in hard drive read heads.

- Giant Magnetoresistance (GMR): Multilayer structures (e.g., Fe/Cr) exhibit resistance changes up to 50%, enabling high-density data storage read heads.

- Tunnel Magnetoresistance (TMR): Magnetic tunnel junctions (MTJs) with MgO barriers achieve >200% resistance ratios, critical for MRAM and high-precision sensors.

Magnetic Storage Principles

Data storage devices encode information via magnetization states. The areal density D (bits/in²) is governed by:

where N is the number of bits and A is the area. Modern hard drives use perpendicular magnetic recording (PMR), where bits are oriented vertically to the platter, enabling densities exceeding 1 Tb/in². The write head’s field Hwrite must exceed the medium’s coercivity Hc:

Spin-Based Memory Technologies

Magnetoresistive RAM (MRAM) stores data via magnetic tunnel junctions (MTJs). A write current generates a spin-transfer torque (STT), flipping the free layer’s magnetization. The tunneling magnetoresistance (TMR) ratio defines read sensitivity:

where RP and RAP are resistances in parallel and antiparallel states. STT-MRAM offers non-volatility, endurance >10¹⁵ cycles, and ns-scale switching.

Emerging Applications

Spintronic sensors integrate MR elements with CMOS for IoT and biomedical devices. Skyrmion-based memory exploits nanoscale magnetic vortices for ultra-low-power storage. Research in all-optical magnetic switching aims to bypass traditional field-driven methods, leveraging femtosecond laser pulses for sub-ps switching.

5. Key Textbooks and Papers

5.1 Key Textbooks and Papers

- PDF Electrical and Electronic Principles and Technology - AIU — Section 1, comprising Chapters 1 to 12, involves essential Basic Electrical and Electronic Engi-neering Principles, with chapters on electrical units and quantities, introduction to electric cir-cuits, resistance variation, chemical effects of elec-tricity, series and parallel networks, capacitors and capacitance, magnetic circuits, electromagnetism, elec-tromagnetic induction, electrical ...

- 5 Electrical and Magnetic Circuits - Electric Power Principles, 2nd ... — 5Electrical and Magnetic Circuits Magnetic circuits offer, as do electric circuits, a way of simplifying the analysis of magnetic field systems, which often can be represented as having a … - Selection from Electric Power Principles, 2nd Edition [Book]

- PDF 6.013 Electromagnetics and Applications, Course Notes — The next four chapters address static and quasistatic systems beginning with Chapter 3, which explores electromagnetics in the context of RLC circuits and devices. Chapter 4 addresses the more general behavior of quasistatic electric and magnetic fields in homogeneous and inhomogeneous media.

- PDF Electric and Magnetic Circuits and Fields - EOLSS — This chapter starts with a brief description of electric circuits, magnetic circuits, electric fields and magnetic fields. In real life, there are many problems which cannot be solved without the combination of the circuit and field approach.

- PDF Electromagnetic Devices and Magnetic Circuits - EOLSS — Summary This chapter introduces magnetic circuit concepts to relatively simple magnetic structures. The objective is to introduce the fundamental notions of electromechanical energy conversion, leading to an understanding of the operation of various electromagnetic devices. The basic principles of energy conversion in electro-magneto-mechanical systems are described, and its usefulness and ...

- Textbook contents | Electromagnetic Field Theory: A Problem Solving ... — Textbook contents: Front-End Matter, Chapter 1: Review of Vector Analysis, Chapter 2: The Electric Field, Chapter 3: Polarization and Conduction, Chapter 4: Electric Field Boundary Value Problems, Chapter 5: The Magnetic Field, Chapter 6: Electromagnetic Induction, Chapter 7: Electrodynamics-Fields and Waves, Chapter 8: Guided Electromagnetic Waves, and Chapter 9: Radiation.

- Electromagnetism and Magnetic Circuits - O'Reilly Media — 5.1 Magnets and Magnetic Fields Magnetism plays an important role in the field of electrical engineering. Construction of almost all electrical gadgets, equipment, and machines are done using the properties of magnetism, like in transformers, electrical rotating machines, i.e., generators and motors, relays, cutouts, electrical bells, etc.

- PDF Electricity and Magnetism - Physica Educator — It features hundreds of new examples, problems, and figures, and contains discussions of real-life applications. The textbook covers all the standard introductory topics, such as electrostatics, mag-netism, circuits, electromagnetic waves, and electric and magnetic fields in matter.

- Introduction to Electricity, Magnetism, and Circuits - Open Textbook — This textbook emphasizes connections between theory and application, making physics concepts interesting and accessible to students while maintaining the mathematical rigour inherent in the subject. Frequent, strong examples focus on how to approach a problem, how to work with the equations, and how to check and generalize the result.

- Readings | Electromagnetic Fields, Forces, and Motion | Electrical ... — This section provides information on assigned readings. The readings are separated into textbook sections and video demonstrations. The textbook sections come from the Zahn and Woodson/Melcher textbooks. The video demonstrations accompany the Haus/Melcher textbook. The Haus/Melcher textbook is used for the first half of the course in addition to the textbook sections listed below.

5.2 Online Resources and Tutorials

- PDF 2.1 Apply voltage source and current source theory to explain circuits ... — Develop essential skills in understanding electronics design and circuit simulation. 2. OUTCOMES Upon satisfactory completion of this course, students will be able to: 2.1 Apply voltage source and current source theory to explain circuits. 2.2 Discuss magnetic flow in practical applications related to electronic circuits.

- Lecture Notes | Electricity and Magnetism - MIT OpenCourseWare — Magnetic Fields. Experiment 5: Magnetic Fields. Hour 2. Charges moving in B Fields. Exam Review. Chapter 8 15 Hour 1. Magnetic Force. Experiment 6: Magnetic Force. Hour 2. Creating B Fields: Biot-Savart. Chapter 9: Sections 9.1 - 9.2 (PDF - 1.9 MB) (PDF - 1.1 MB) 16 Problem Solving Session 5: Magnetic Torque and Moments

- PDF Electrical and Electronic Principles and Technology - AIU — 7.7 Composite series magnetic circuits 87 7.8 Comparison between electrical and magnetic quantities 90 7.9 Hysteresis and hysteresis loss 90 Revision Test 2 93 8 Electromagnetism 94 8.1 Magnetic field due to an electric current 95 8.2 Electromagnets 96 8.3 Force on a current-carrying conductor 98 8.4 Principle of operation of a simple d.c ...

- MTU - EE5200 Home Page - Michigan Technological University — Magnetic Circuits - quick review and introduction of how a transformer works Mutual Inductance - concept handout from EE3120 (refer to Section 2.2 of your text)

- Textbook contents | Electromagnetic Field Theory: A Problem Solving ... — Textbook contents: Front-End Matter, Chapter 1: Review of Vector Analysis, Chapter 2: The Electric Field, Chapter 3: Polarization and Conduction, Chapter 4: Electric Field Boundary Value Problems, Chapter 5: The Magnetic Field, Chapter 6: Electromagnetic Induction, Chapter 7: Electrodynamics-Fields and Waves, Chapter 8: Guided Electromagnetic Waves, and Chapter 9: Radiation.

- PDF Fundamentals of Electrical Circuits - engrcs.com — Circuit Analysis and Design. The content is derived from the author's educational, engineering and management career, and teaching experience. Additionally, the following resources have informed the development of content and format: Katz, R. Contemporary Logic Design. (2005) Pearson. Wakerly, I. Digital Design. (2001) Prentice Hall.

- Chapter 5 Review - Introduction to Electricity, Magnetism, and Circuits — 5.2 Model of Conduction in Metals. The current through a conductor depends mainly on the motion of free electrons. When an electrical field is applied to a conductor, the free electrons in a conductor do not move through a conductor at a constant speed and direction; instead, the motion is almost random due to collisions with atoms and other free electrons.

- Readings | Electromagnetic Fields, Forces, and Motion | Electrical ... — Magnetic circuits, inductance, transformers H/M - 8.6.1 - Surface currents induced in ground plane by overhead conductor Z - 6.2 L9 Magnetic diffusion phenomena H/M - 10.0.1 - Non uniqueness of voltage in an MQS system Z - 6.1 R10 Magnetic diffusion, skin effect Z - 6.4 III. Boundary value EQS and MQS problems: L10

- Lesson Electricity and Magnetic Fields - TeachEngineering.org — Circuits and Magnetic Fields - Students apply the same compass techniques as the previous activity to explore the magnetic field around a current carrying wire. Through the activity, they learn the right hand rule to determine the direction of current flow. Lesson Closure (Conduct this closure after students have completed the accompanying ...

- Circuits on Tinkercad - Tinkercad — Design electronics Place and wire electronic components (even a lemon) to create a virtual circuit from scratch, or use our starter circuits to explore and try things out. No additional hardware required.

5.3 Advanced Topics and Research Areas

- PDF Electromagnetic Devices and Magnetic Circuits - EOLSS — UNESCO - EOLSS SAMPLE CHAPTERS ELECTRICAL ENGINEERING - Vol. I - Electromagnetic Devices and Magnetic Circuits - W.L. Chan and K.K. Li ©Encyclopedia of Life Support Systems (EOLSS) The factor B/H is not constant and it is different at various points on the slope because the slope varies. Therefore the permeability can be defined only at given points on the

- PDF ENGG*3510 Electromechanical Devices - University of Guelph — advanced machines used in industry. As a mechanical engineer, one should have a general understanding on these devices. The course covers magnetic material, permanent magnets, magnetic circuits and related topics such as EMF, MMF, inductance, etc. It also covers transformers, electric machines (motors and

- Top 75 Emerging Research Topics in Electrical Engineering — 4.2 Flexible and Wearable Electronics. a. Stretchable electronics for wearable applications. b. Smart textiles and their integration with electronic components. c. Biocompatible electronics for healthcare monitoring. d. Energy harvesting in wearable devices.

- Textbook contents | Electromagnetic Field Theory: A Problem Solving ... — Textbook contents: Front-End Matter, Chapter 1: Review of Vector Analysis, Chapter 2: The Electric Field, Chapter 3: Polarization and Conduction, Chapter 4: Electric Field Boundary Value Problems, Chapter 5: The Magnetic Field, Chapter 6: Electromagnetic Induction, Chapter 7: Electrodynamics-Fields and Waves, Chapter 8: Guided Electromagnetic Waves, and Chapter 9: Radiation.

- Introduction to Electricity, Magnetism, and Circuits — 7 Advanced Circuit Analysis Techniques. 7.1 Mesh Analysis. 7.2 Superposition Theorem ... 8.3 Motion of a Charged Particle in a Magnetic Field. 8.4 Magnetic Force on a Current-Carrying Conductor. 8.5 Force and Torque on a Current Loop. ... "The Auroral Radar" by Ashton Reimer won first prize in the "Research in Action" category in the ...

- PDF Modeling and Design of Planar Integrated Magnetic Components — Modeling and Design of Planar Integrated Magnetic Components by Shen Wang Dr. Dushan Boroyevich, Co-Chair Dr. W. G. Odendaal, Co-Chair Electrical Engineering (Abstract) Recently planar magnetic technologies have been widely used in power electronics, due to good cooling and ease of fabrication. High frequency operation of magnetic

- Magnetic Circuit Design for Power Electronics - ScienceDirect — As shown in Fig. 16.6, the MMF, F = N·i, is visualized as a force like quantity that pushes a magnetic flux, ϕ, around the magnetic circuit. Magnetic core reluctance, R, in a magnetic circuit is then the counterpart of resistance of an electrical circuit. ϕ = F/R, directly corresponding to Ohm's law. The reluctance opposes the magnetic ...

- Magnetic circuit - Knowledge and References | Taylor & Francis — The magnetic flux Φ in a magnetic circuit is analogous to the electric current I in an electric circuit (Figure 14.3(b)), a closed path being necessary for an electric current. The magnetic flux density B is the flux per unit cross-sectional area (B = Φ/A) and is analogous to the current per unit cross-sectional area of conductor (I/A).

- Electronics | Special Issue : Advancements in Electromagnetic ... - MDPI — The purpose of this Special Issue is to present recent advances in the electronic circuits design, taking into consideration all possible EMI sources as electrostatic discharges (ESD), induced voltages derived by various sources of electromagnetic radiation, etc. Leading researchers from around the globe will be able to discuss their most ...

- Electronics | Special Issue : Advanced Magnetic and Electrical ... - MDPI — For increasing the sensitivity of the sensor, the magnetic field generated by the measurement current passing through the printed circuit board trace is determined through an analytical method and, for comparative analysis, finite elements method simulations are used. The sensor performance is experimentally tested with a demonstrator chip.