Make this Fancy LED Tail Ring Light Circuit for your Car

The following article outlines a sophisticated LED sequencing and diverging ring light that can serve as a tail brake light in vehicles. This circuit concept was proposed by a dedicated reader, Mr. Bobby. The design aims to create a circular tail light that illuminates rings in sequence from the center outward as the brake is engaged, lighting one ring at a time until all LEDs are activated. After all rings are lit, the LEDs will flash twice before remaining illuminated continuously. The core of the circuit is IC1, a serial shift register, which controls the illumination of the LEDs connected to pinouts #3, #4, #5, #6, #10, #11, #12, and #13 in a sequential manner. This sequence is maintained as clock pulses are applied to pin #8 of the IC. The LEDs connected to pinouts #3, #4, #5, #6, and #10 are arranged in a circular fashion, creating a visually appealing effect as they light up from the innermost ring to the outermost. The sequence continues until it reaches pin #10. The necessary positive supply for the LEDs is provided through transistor T1, which remains activated due to the low logic at pin #13 of IC1. The LEDs should be wired in a circular configuration across the collectors of T1 and T2/T3/T4/T5 to form the corresponding rings.

The circuit design features a serial shift register (IC1), which is pivotal for controlling the LED sequencing. The shift register operates by receiving clock pulses at pin #8, which triggers the output pins sequentially. Each activated output pin corresponds to an LED that is part of the circular arrangement. The LEDs are driven by transistors (T1, T2, T3, T4, T5), which act as switches, allowing current to flow through the LEDs when activated. The arrangement of the LEDs in a circular pattern enhances the visual effect of the light sequence, creating a dynamic and engaging display as the brake is applied.

The design can be further refined by incorporating additional features such as adjustable LED brightness, using PWM (Pulse Width Modulation) techniques, to enhance visibility during different lighting conditions. Additionally, integrating a microcontroller could allow for customizable lighting patterns and sequences, providing greater flexibility and functionality. The power supply for the circuit should be carefully considered to ensure it meets the voltage and current requirements of the LEDs while maintaining efficiency and reliability.

In summary, this LED sequencing diverging ring light circuit offers a creative solution for automotive lighting, combining aesthetics with functionality. The careful arrangement of components and thoughtful design choices contribute to an effective and visually striking tail light system.The following article describes a fancy LED sequencing/diverging ring type light which can be used as a tail brake light in cars. The circuit idea was requested by one of the avid readers of this blog, Mr. Bobby. lets learn more. Could this circuit be adapted to create a round tail light that lights rings in sequence from the center out as the bra

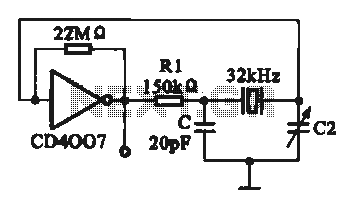

ke is pressed, one ring at a time until all the LEDs are lit and then flash all the LEDs twice and keep all LEDs lit solid after If not, could you design a circuit that would I would be willing to pay for your time. IC1 which is a "serial shift resistor" forms the heart of the entire circuit, the main function of this IC is to illuminate the LEDs connected to pin outs #3-4-5-6-10-11-12-13 in a sequence, keeping the sequence latched and illuminated as it proceeds.

This happens in response to each clock pulse applied at pin#8 of the IC. The LEDs which aretriggeredby the pin#3-4-5-6 and 10 are arranged as rings such that it illuminates from inner most ring first toward the outermost ring, producing an interesting and visually rich effect. In response to the above clocks, the sequence proceeds creating the desired diverging illumination effects, until it reaches pin#10.

The LEDs receive the required positive supply through T1 which stays triggered due to the low logic at pin#13 of IC1 The LEDs which needs to be connected across the collectors of T1 and T2/T3/T4/T5 may be wired up in the following manner. The arrangement should be designed in a circular manner to form the corresponding RINGs. 🔗 External reference

The circuit design features a serial shift register (IC1), which is pivotal for controlling the LED sequencing. The shift register operates by receiving clock pulses at pin #8, which triggers the output pins sequentially. Each activated output pin corresponds to an LED that is part of the circular arrangement. The LEDs are driven by transistors (T1, T2, T3, T4, T5), which act as switches, allowing current to flow through the LEDs when activated. The arrangement of the LEDs in a circular pattern enhances the visual effect of the light sequence, creating a dynamic and engaging display as the brake is applied.

The design can be further refined by incorporating additional features such as adjustable LED brightness, using PWM (Pulse Width Modulation) techniques, to enhance visibility during different lighting conditions. Additionally, integrating a microcontroller could allow for customizable lighting patterns and sequences, providing greater flexibility and functionality. The power supply for the circuit should be carefully considered to ensure it meets the voltage and current requirements of the LEDs while maintaining efficiency and reliability.

In summary, this LED sequencing diverging ring light circuit offers a creative solution for automotive lighting, combining aesthetics with functionality. The careful arrangement of components and thoughtful design choices contribute to an effective and visually striking tail light system.The following article describes a fancy LED sequencing/diverging ring type light which can be used as a tail brake light in cars. The circuit idea was requested by one of the avid readers of this blog, Mr. Bobby. lets learn more. Could this circuit be adapted to create a round tail light that lights rings in sequence from the center out as the bra

ke is pressed, one ring at a time until all the LEDs are lit and then flash all the LEDs twice and keep all LEDs lit solid after If not, could you design a circuit that would I would be willing to pay for your time. IC1 which is a "serial shift resistor" forms the heart of the entire circuit, the main function of this IC is to illuminate the LEDs connected to pin outs #3-4-5-6-10-11-12-13 in a sequence, keeping the sequence latched and illuminated as it proceeds.

This happens in response to each clock pulse applied at pin#8 of the IC. The LEDs which aretriggeredby the pin#3-4-5-6 and 10 are arranged as rings such that it illuminates from inner most ring first toward the outermost ring, producing an interesting and visually rich effect. In response to the above clocks, the sequence proceeds creating the desired diverging illumination effects, until it reaches pin#10.

The LEDs receive the required positive supply through T1 which stays triggered due to the low logic at pin#13 of IC1 The LEDs which needs to be connected across the collectors of T1 and T2/T3/T4/T5 may be wired up in the following manner. The arrangement should be designed in a circular manner to form the corresponding RINGs. 🔗 External reference