MiniVol PGA2320 Volume Control

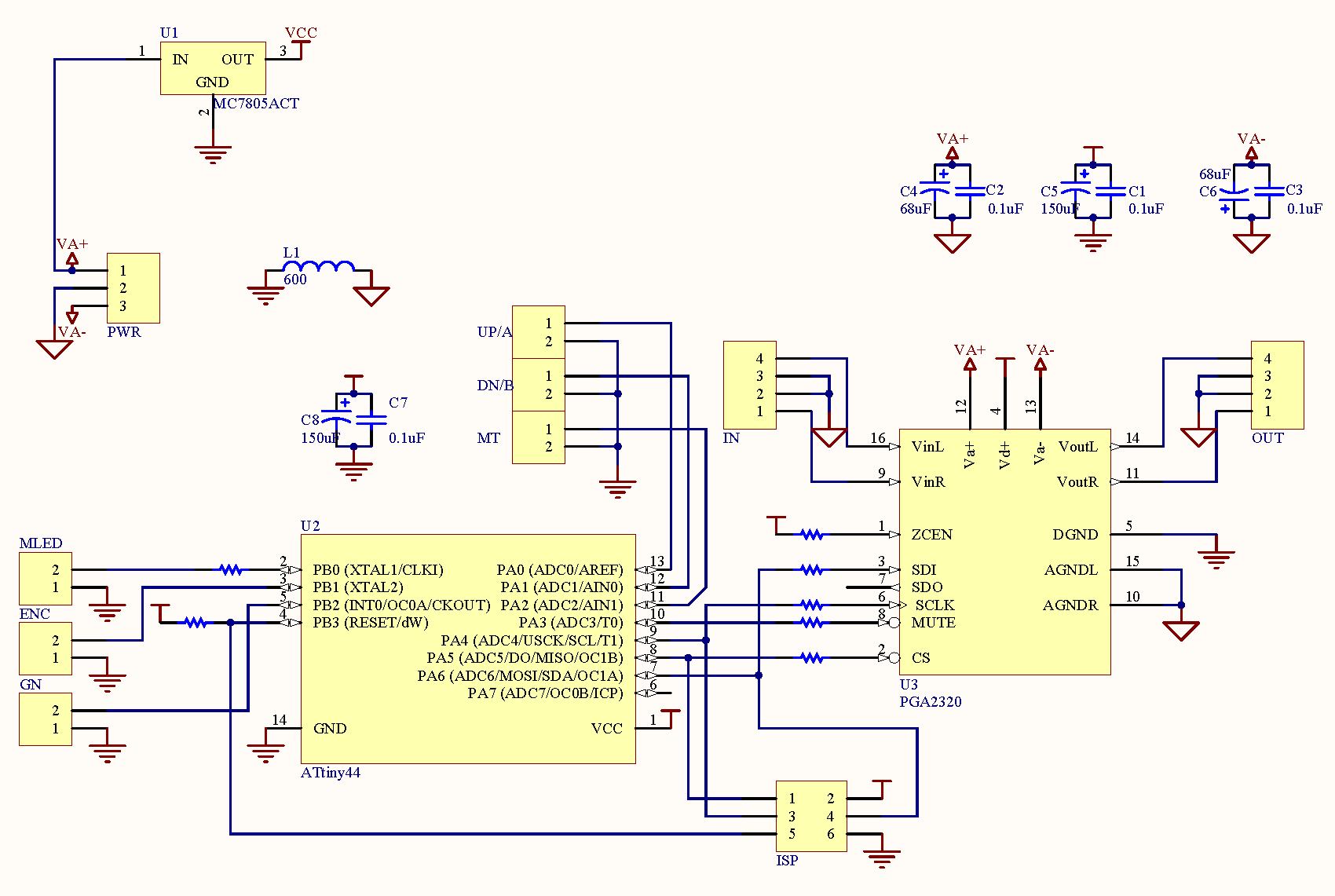

MiniVol is a straightforward volume control board utilizing the TI PGA2320 volume control IC, which operates over a range of -95.5 dB to +31.5 dB. It employs a small Atmel AVR microcontroller to manage the PGA2320 and allows users to choose between up/down pushbuttons or a rotary encoder for the interface. The microcontroller's EEPROM stores the current setting across power cycles. A jumper limits the control to 0 dB gain, adhering to the KISS principle. An external ±15V power supply is necessary, such as the MiniPow. The design features a dual-layer PCB and firmware available for DIY use. The PCB is compact and modular, ideal for DIY amplifier or preamplifier projects, serving as an affordable and high-quality alternative to potentiometers or stepped attenuators. For balanced configurations, two boards can be used (refer to build notes for details). SMD components dominate the design due to the PGA2320's availability in the SO-16 package and size constraints. The total parts cost, excluding the PCB, is approximately $25. If demand is sufficient, there may be plans to offer boards and preprogrammed microcontrollers for sale. MiniVol requires a minimum ±15V regulated supply, which is further regulated to 5V for the digital control section using an onboard 78L05. An external 5V supply can be utilized by connecting to ground and Vcc at the U1 position. Decoupling is achieved with a 150 µF electrolytic capacitor in parallel with a 100nF X7R ceramic capacitor for each chip on the digital supply, and 68 µF electrolytic capacitors in parallel with 100nF X7R ceramics for the ± analog supplies. This decoupled supply feeds the PGA2320, with the source signal connected directly to its inputs. No buffering is provided, but the PGA2320 can be driven by a source with a 600 Ω or lower output impedance. An Atmel ATtiny24/44/84 microcontroller provides digital control through six user interface pins. Two pins are dedicated for UP/DOWN pushbutton input or a rotary encoder, and a third pin is allocated for a mute button. Two jumper inputs are available: ENC determines the type of user interface, while GN caps the PGA2320 gain at 0 dB. All inputs utilize the AVR's internal pull-ups. An output pin, MLED, drives a mute LED when the system is muted. An ISP connector is linked to the AVR's SPI port for programming. The SPI port also connects to the PGA2320 through 10K Ω resistors. The PCB layout prioritizes the separation of digital and analog sections, maintaining small current loops for both signal types. Two unbroken ground planes are implemented per the PGA2320 datasheet, connected at a single point using a ferrite chip, located beneath the 5V regulator's feed trace from V+ to maintain a small loop and minimize interference with the analog section. Signal traces are kept short and distanced from digital signals, despite the microcontroller being in sleep mode most of the time. Two mounting holes are included. A parts table lists components for the MiniVol, allowing substitutions at the builder's discretion. The firmware is designed to be robust, serving as a foundation for future projects. It is interrupt-driven, utilizing timers. At startup, the previous state is retrieved from EEPROM, and the device enters a main loop awaiting events. The core of the firmware is a scan interrupt that samples inputs every 1 ms. After debouncing, detected changes are queued for processing by the main loop. A timer delays approximately 1 second before writing the current state to EEPROM, resetting if changes occur before expiration, thus conserving EEPROM write cycles. The interrupt also places the device in sleep mode, which can be awakened by pin change interrupts. For balanced configurations, two boards are required: one fully populated as the controller and the other as a partially populated slave board. Certain components (C7, C8, R2, U2, ISP, switch, MLED, and configuration headers) should be omitted from the slave board. A socket replaces U2, and the boards are stacked with the master board on top. Stiff leads or header pins extend U2 pins to connect to the socket on the slave board. Specific U2 pins (7, 8, 9, 10) must be connected, ensuring no other U2 pins are connected between boards. The slave board's digital controls will then follow the master board's operation.MiniVol is my effort at a very simple volume control board based on the excellent TI PGA2320 volume control IC, which offers impressive specs and can operate over a range of -95. 5dB to +31. 5dB. It utilises a small Atmel AVR microcontroller to control the PGA2320, and gives the builder the option of using either up/down pushbuttons or a rotary enco

der as the user interface. The microcontroller`s EEPROM is used to store the current setting between power cycles. Since the PGA2320 offers up to 31. 5dB of gain, a jumper is provided to limit the control to 0dB. No additional functionality is provided, honouring the KISS principle. An external ±15V power supply is required, such as my MiniPow. A dual-layer PCB design and firmware are available and free for DIY use. The PCB was designed to be small and modular, perfectly suited to a DIY amp or preamp project as an inexpensive and excellent-sounding alternative to a potentiometer or stepped attenuator. With two boards it can be used for a balanced configuration fairly easily (see build notes for details).

SMD components are used almost exclusively, since the PGA2320 is available only in the SO-16 pacakage, and because size was a major design parameter. Parts cost without the PCB is about $25. If there is sufficient demand, I might consider offering boards and preprogrammed microcontrollers for sale.

MiniVol requires at a minimum a ±15V regulated supply, which is further regulated by an onboard 78L05 to 5V for the digital control section. An external 5V supply could be used if desired, by tapping ground and Vcc at the U1 position. Onboard decoupling consists of 150 µF electrolytic in parallel with 100nF X7R ceramic for each chip on the digital supply, and 68 µF electrolyic in parallel with 100nF X7R ceramic for the ± analog supplies.

This decoupled supply feeds the PGA2320, which has the source signal connected directly to its inputs. No buffering is provided onboard, though the PGA2320 should be driven by a source with 600 © or lower output impedance.

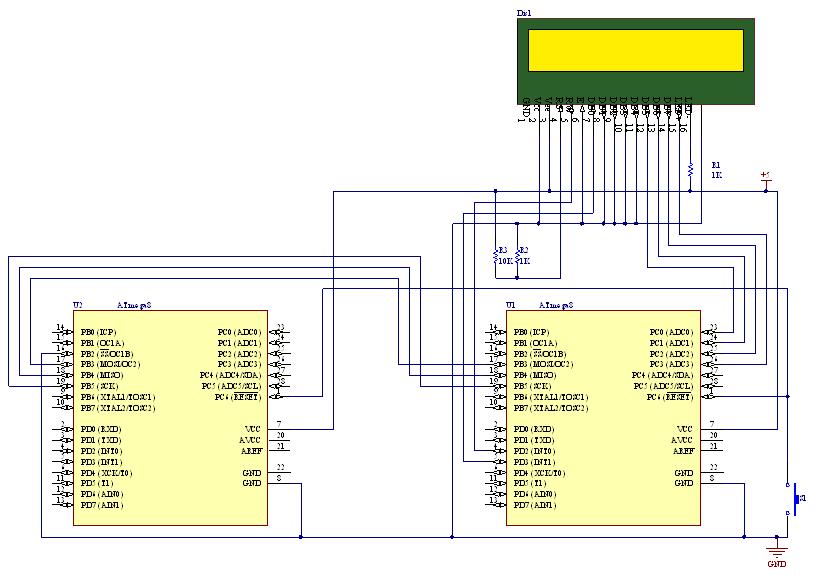

An Atmel ATtiny24/44/84 provides digital control to the system, through six user interface pins. For input, two pins are exposed to provide for either UP/DOWN pushbutton input or a rotary encoder and a third pin provides for a mute button. Two `jumper` inputs are provided as well: ENC selects whether an encoder or pushbuttons are in use, GN selects whether the PGA2320 should be capped at 0dB gain.

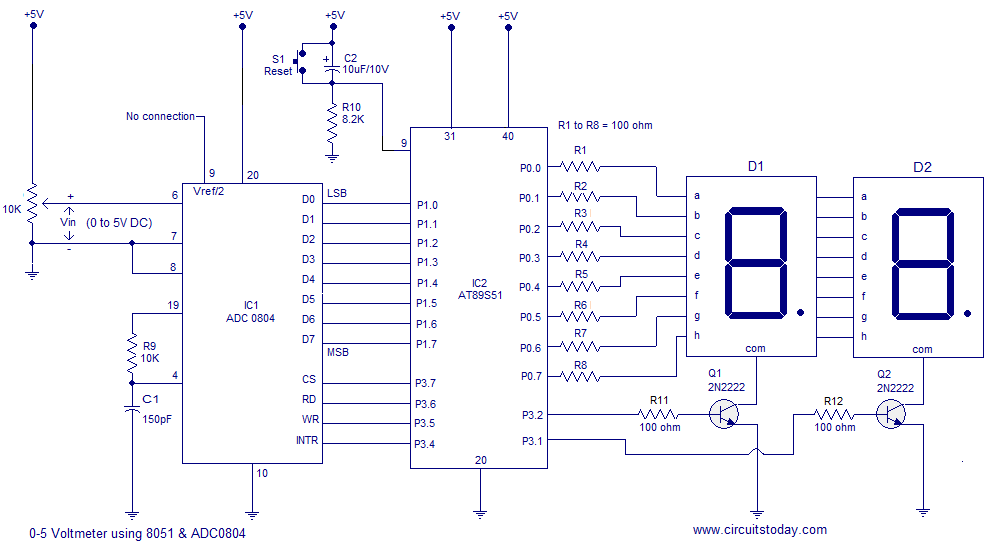

All inputs utilise the AVR`s internal pull-ups. MLED provides an output to drive a mute LED when the system is muted. An ISP connector is connected directly to the AVR`s SPI port to facilitate programming. The SPI port is also connected to the PGA2320 through 10K © resistors. In the image, blue areas are copper in the bottom layer, red areas are copper in the top layer, purple areas have copper in both layers, white areas are the top layer silkscreen. The main goal of the PCB layout was to separate the digital and analog sections as much as possible, and to keep both types of signals` current loops as small as possible.

I believe both of these goals were achieved. Two unbroken ground planes are used per the PGA2320 datasheet, and connected at a single point with a ferrite chip; this point is directly below the 5V regulator`s feed trace from V+ to keep the loop small and out of the way of the analog section. Signal-carrying traces are short and kept away from any digital signals - despite the fact that the microcontroller will be in sleep mode almost all the time.

Two mounting holes are provided. The table below lists parts for the MiniVol. Substitutions may be made at the builder`s discretion; most values and part numbers are not critical. Detailed descriptions and substitutes are below the table. The firmware is a rather over-the-top design. I am intending to use this basic model as a basis for several much larger projects, so I figured I may as well start here.

It is largely interrupt driven, using timers. At startup, previous state is loaded from EEPROM and the device enters the main loop, which simply waits for an event to be dispatched, and processes them when they arrive. The core of the firmware is the scan interrupt, which runs every 1ms and samples the relevant inputs.

After debounce, if changes are detected, the appropriate event is placed into a queue for processing by the main loop. A timer is started that will delay approx 1s and then write the current state to EEPROM. The timer is reset if any changes happen before it expires. This serves to save EEPROM write cycles. This interrupt also places the device in sleep mode when it is triggered. It`s awakened again by a pin change interrupt on the input pins. For balanced configuration, two boards are needed. One board should be fully populated and serves as the controller. The other, slave board must be partially populated. The following parts should be omitted: C7, C8, R2, U2, and the ISP, switch, MLED, and configuration headers.

Install a socket in place of U2. You should then stack the boards, with the master board on top. Use stiff leads or header pins to extend the pins of U2 and connect them to the socket on the slave board below. The following U2 pins must be connected: 7, 8, 9, 10. Do not connect any other U2 pins between boards. The digital controls of the slave board are now connected to the master board, and it should follow the master board exactly.

🔗 External reference

der as the user interface. The microcontroller`s EEPROM is used to store the current setting between power cycles. Since the PGA2320 offers up to 31. 5dB of gain, a jumper is provided to limit the control to 0dB. No additional functionality is provided, honouring the KISS principle. An external ±15V power supply is required, such as my MiniPow. A dual-layer PCB design and firmware are available and free for DIY use. The PCB was designed to be small and modular, perfectly suited to a DIY amp or preamp project as an inexpensive and excellent-sounding alternative to a potentiometer or stepped attenuator. With two boards it can be used for a balanced configuration fairly easily (see build notes for details).

SMD components are used almost exclusively, since the PGA2320 is available only in the SO-16 pacakage, and because size was a major design parameter. Parts cost without the PCB is about $25. If there is sufficient demand, I might consider offering boards and preprogrammed microcontrollers for sale.

MiniVol requires at a minimum a ±15V regulated supply, which is further regulated by an onboard 78L05 to 5V for the digital control section. An external 5V supply could be used if desired, by tapping ground and Vcc at the U1 position. Onboard decoupling consists of 150 µF electrolytic in parallel with 100nF X7R ceramic for each chip on the digital supply, and 68 µF electrolyic in parallel with 100nF X7R ceramic for the ± analog supplies.

This decoupled supply feeds the PGA2320, which has the source signal connected directly to its inputs. No buffering is provided onboard, though the PGA2320 should be driven by a source with 600 © or lower output impedance.

An Atmel ATtiny24/44/84 provides digital control to the system, through six user interface pins. For input, two pins are exposed to provide for either UP/DOWN pushbutton input or a rotary encoder and a third pin provides for a mute button. Two `jumper` inputs are provided as well: ENC selects whether an encoder or pushbuttons are in use, GN selects whether the PGA2320 should be capped at 0dB gain.

All inputs utilise the AVR`s internal pull-ups. MLED provides an output to drive a mute LED when the system is muted. An ISP connector is connected directly to the AVR`s SPI port to facilitate programming. The SPI port is also connected to the PGA2320 through 10K © resistors. In the image, blue areas are copper in the bottom layer, red areas are copper in the top layer, purple areas have copper in both layers, white areas are the top layer silkscreen. The main goal of the PCB layout was to separate the digital and analog sections as much as possible, and to keep both types of signals` current loops as small as possible.

I believe both of these goals were achieved. Two unbroken ground planes are used per the PGA2320 datasheet, and connected at a single point with a ferrite chip; this point is directly below the 5V regulator`s feed trace from V+ to keep the loop small and out of the way of the analog section. Signal-carrying traces are short and kept away from any digital signals - despite the fact that the microcontroller will be in sleep mode almost all the time.

Two mounting holes are provided. The table below lists parts for the MiniVol. Substitutions may be made at the builder`s discretion; most values and part numbers are not critical. Detailed descriptions and substitutes are below the table. The firmware is a rather over-the-top design. I am intending to use this basic model as a basis for several much larger projects, so I figured I may as well start here.

It is largely interrupt driven, using timers. At startup, previous state is loaded from EEPROM and the device enters the main loop, which simply waits for an event to be dispatched, and processes them when they arrive. The core of the firmware is the scan interrupt, which runs every 1ms and samples the relevant inputs.

After debounce, if changes are detected, the appropriate event is placed into a queue for processing by the main loop. A timer is started that will delay approx 1s and then write the current state to EEPROM. The timer is reset if any changes happen before it expires. This serves to save EEPROM write cycles. This interrupt also places the device in sleep mode when it is triggered. It`s awakened again by a pin change interrupt on the input pins. For balanced configuration, two boards are needed. One board should be fully populated and serves as the controller. The other, slave board must be partially populated. The following parts should be omitted: C7, C8, R2, U2, and the ISP, switch, MLED, and configuration headers.

Install a socket in place of U2. You should then stack the boards, with the master board on top. Use stiff leads or header pins to extend the pins of U2 and connect them to the socket on the slave board below. The following U2 pins must be connected: 7, 8, 9, 10. Do not connect any other U2 pins between boards. The digital controls of the slave board are now connected to the master board, and it should follow the master board exactly.

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713