pid controller Building a temperature-controlled water bath

There is no prior experience in building controllers, and there is uncertainty about how to begin. A budget constraint of less than 100 euros is present. A power thyristor is already available. The inquiry revolves around the best method to connect a sensor to a heating element. There is a need to construct or program a circuit for this purpose, and a decision must be made regarding whether to create an analog or digital circuit. The necessity of the thyristor is questioned, as an on/off regulation might suffice. Additionally, the ability to define water temperature is required.

To create a temperature control system using a power thyristor, a basic understanding of the components and their interactions is essential. The system will require a temperature sensor, such as a thermistor or a thermocouple, to measure the water temperature. This sensor will provide an analog or digital signal based on the temperature reading.

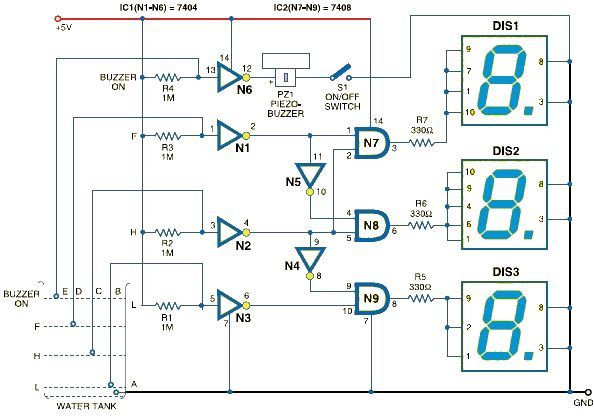

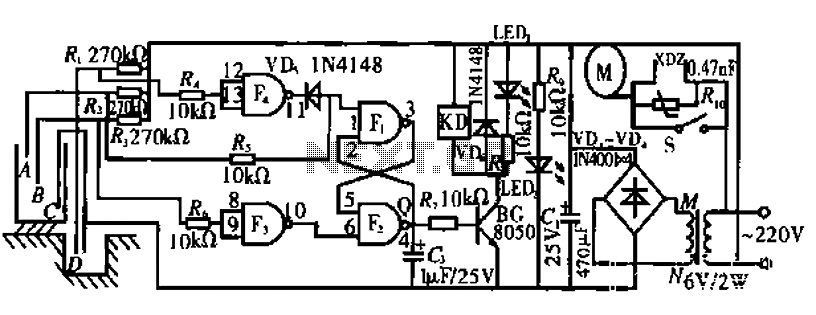

For an analog approach, a thermistor can be used, which varies its resistance with temperature. This resistance change can be converted to a voltage using a voltage divider circuit. The output voltage can then be fed into an operational amplifier configured as a comparator. The comparator will compare the voltage from the thermistor with a set reference voltage, which corresponds to the desired temperature. If the measured temperature falls below the set point, the output of the comparator will trigger the thyristor, allowing current to flow to the heating element. This configuration allows for continuous control of the heating element, adjusting the power as needed to maintain the desired temperature.

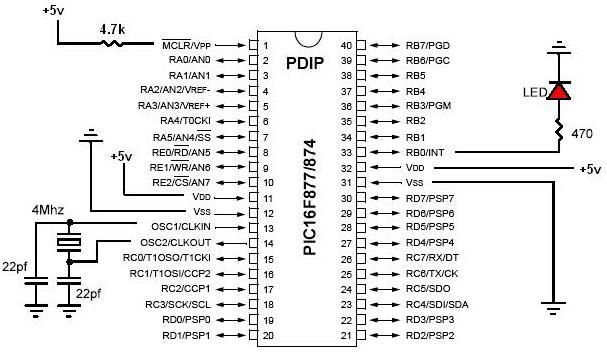

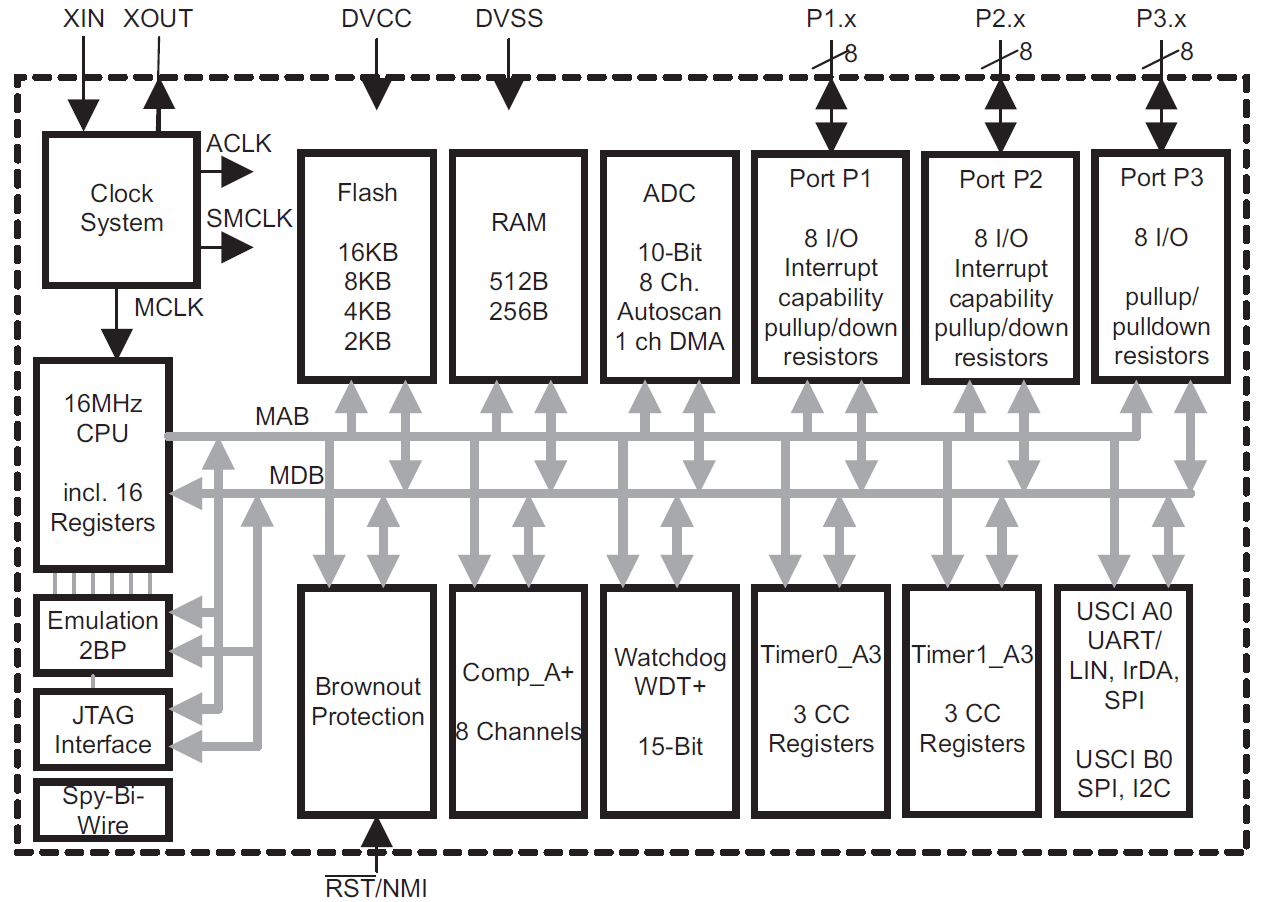

Alternatively, a digital circuit can be implemented using a microcontroller. The temperature sensor can be interfaced with the microcontroller, which will read the temperature data and execute a control algorithm. For example, a simple on/off control can be programmed, where the microcontroller turns the thyristor on when the temperature is below the set point and off when it reaches the desired temperature. This method allows for more flexibility and programmability, enabling the incorporation of features such as hysteresis to prevent rapid cycling of the heating element.

In both scenarios, the thyristor plays a crucial role in controlling the power delivered to the heating element. While an on/off regulation can work without the thyristor, using it allows for better control over the power output, especially in applications requiring precise temperature management. The choice between analog and digital solutions will depend on the complexity desired and the available components.

In summary, the system can be designed using either an analog or digital approach, utilizing a temperature sensor to monitor water temperature and a thyristor to control the heating element, all while staying within budget constraints.I have no experience whatsover with building controllers and have no clue on how to start. I don`t want to spend to much money on the project (< 100 ‚¬) thus money is an issue. The good thing is that I already have a power thyristor. My question is how I can best make the link between the sensor and the h eating element. I of course need to build/program a circuit that does this but do I make an analog or digital circuit I have a thyristor but is this really necessary or should an on/off regulation also work Don`t forget that I also should be able to define the water temperature. 🔗 External reference

To create a temperature control system using a power thyristor, a basic understanding of the components and their interactions is essential. The system will require a temperature sensor, such as a thermistor or a thermocouple, to measure the water temperature. This sensor will provide an analog or digital signal based on the temperature reading.

For an analog approach, a thermistor can be used, which varies its resistance with temperature. This resistance change can be converted to a voltage using a voltage divider circuit. The output voltage can then be fed into an operational amplifier configured as a comparator. The comparator will compare the voltage from the thermistor with a set reference voltage, which corresponds to the desired temperature. If the measured temperature falls below the set point, the output of the comparator will trigger the thyristor, allowing current to flow to the heating element. This configuration allows for continuous control of the heating element, adjusting the power as needed to maintain the desired temperature.

Alternatively, a digital circuit can be implemented using a microcontroller. The temperature sensor can be interfaced with the microcontroller, which will read the temperature data and execute a control algorithm. For example, a simple on/off control can be programmed, where the microcontroller turns the thyristor on when the temperature is below the set point and off when it reaches the desired temperature. This method allows for more flexibility and programmability, enabling the incorporation of features such as hysteresis to prevent rapid cycling of the heating element.

In both scenarios, the thyristor plays a crucial role in controlling the power delivered to the heating element. While an on/off regulation can work without the thyristor, using it allows for better control over the power output, especially in applications requiring precise temperature management. The choice between analog and digital solutions will depend on the complexity desired and the available components.

In summary, the system can be designed using either an analog or digital approach, utilizing a temperature sensor to monitor water temperature and a thyristor to control the heating element, all while staying within budget constraints.I have no experience whatsover with building controllers and have no clue on how to start. I don`t want to spend to much money on the project (< 100 ‚¬) thus money is an issue. The good thing is that I already have a power thyristor. My question is how I can best make the link between the sensor and the h eating element. I of course need to build/program a circuit that does this but do I make an analog or digital circuit I have a thyristor but is this really necessary or should an on/off regulation also work Don`t forget that I also should be able to define the water temperature. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713