Piezoelectric Sound

A piezoelectric sounder (self-drive type) consists solely of a piezoelectric diaphragm with a feedback electrode and is utilized in conjunction with an external drive circuit. The drive circuit for both types of sounders is a simple configuration comprising one transistor and three resistors. When a DC voltage V is applied to the drive circuit, the oscillation conditions are met near the resonant frequency, causing the piezoelectric diaphragm to oscillate and produce sound. Each product has a standard drive circuit, details of which are available in the catalog. Unlike an electromagnetic buzzer, which operates through a current flowing in a built-in electromagnet coil, a piezoelectric sound component is activated by a voltage applied to piezoelectric ceramic, resulting in significantly lower current consumption compared to an electromagnetic buzzer. The current consumption (excluding the peripheral circuit) of a piezoelectric sounder (external drive type) can be calculated using a theoretical equation. When the charging and discharging times of the sounder are much shorter than the input signal's period, the average current flowing into the sounder during a half period can be determined using the provided equation. The average current for each part number is listed in a corresponding table. As long as the product is used within the specified maximum input voltage range, electrical polarity does not need to be considered. A piezoelectric sounder (external drive type) is designed to produce sound at a stable sound pressure when driven at the specified frequency, but it can also generate sound at other frequencies. This allows for the production of not only single tones but also melodies and complex sounds, making it suitable for applications such as operational confirmation sounds, alarms, and pseudo sounds. However, sound pressure levels may diminish at certain drive frequencies depending on the frequency characteristics of each product, necessitating evaluation before use. For instance, if a piezoelectric sounder designed to operate at 4 kHz is driven at 2 kHz, it is essential to adjust the duty ratio of the input voltage to increase sound pressure. For example, changing the duty ratio from 50% to 25% can raise the sound pressure by approximately 10 dB for the PKM13EPYH4002-B0 sounder. This increase in sound pressure is contingent upon the specific frequency characteristics of the piezoelectric sounder.

A piezoelectric sounder, particularly the self-drive type, operates based on the principle of piezoelectricity, where mechanical stress applied to piezoelectric materials generates an electrical charge. In this configuration, the piezoelectric diaphragm is the primary element that vibrates to produce sound waves. The feedback electrode enhances the efficiency of the oscillation by providing a mechanism for the diaphragm to self-excite, amplifying the sound output.

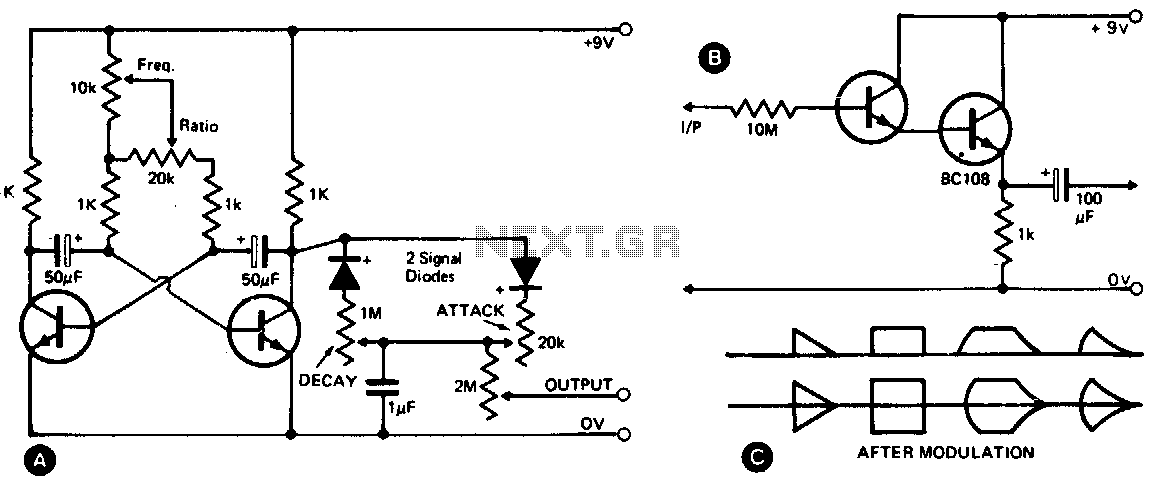

The external drive circuit typically consists of a transistor that acts as a switch, controlling the current flow through the piezoelectric diaphragm. The three resistors in the circuit help set the biasing conditions and determine the oscillation frequency. The simplicity of this design allows for easy integration into various electronic systems.

When designing applications that utilize piezoelectric sounders, it is crucial to consider the resonant frequency of the diaphragm, as this frequency will yield the highest sound pressure output. The ability of the sounder to operate effectively at various frequencies allows for versatility in application, including alert signals, notifications, and musical tones.

The adjustment of the duty cycle is an important technique for managing sound pressure levels without altering the voltage supply. By varying the duty cycle—essentially the proportion of time the signal is on versus off—the average power delivered to the sounder can be increased, thus enhancing the perceived loudness. This method is particularly useful in battery-operated devices where power conservation is essential.

In summary, the piezoelectric sounder (external drive type) is a highly efficient component suitable for a wide range of audio applications. Its low current consumption, versatility in frequency response, and the ability to manipulate sound pressure through duty cycle adjustments make it a preferred choice in modern electronic designs. Proper evaluation of the sound pressure characteristics across different frequencies is recommended to optimize performance in specific applications.In contrast, a piezoelectric sounder (self drive type) consists of only a piezoelectric diaphragm with a feedback electrode. It is used in combination with an external drive circuit. The drive circuit for both of the above is a simple circuit consisting of one transistor and three resistors.

When a DC voltage V is applied to the drive circuit, the oscillation conditions in the circuit are satisfied in the vicinity of the resonant frequency. As a result, the piezoelectric diaphragm is driven at the oscillation frequency, causing it to emit a sound. Regarding the drive circuit for a piezoelectric sounder (self drive type), we set a standard circuit for each product.

For details, please refer to our catalog. In contrast to an electromagnetic buzzer which is driven by a current flowing through a built-in electromagnet coil, a piezoelectric sound component is driven by a voltage applied to piezoelectric ceramic. Consequently, it features much lower current consumption than that of an electromagnetic buzzer. The current consumption (excluding that of the peripheral circuit) by a piezoelectric sounder (external drive type) can be calculated simply from the theoretical equation below.

When the charging and discharging times of a piezoelectric sounder (external drive type) are significantly smaller than the length of one period of the input signal, the average value of the current which flows into the piezoelectric sounder (external drive type) during a half period can be calculated from the following equation. The average value of the current flowing through the piezoelectric sounder (external excited type), calculated using the above equation for each part No.

, is shown in the table below. Provided that you use the product within the range of the maximum input voltage specified for each product, there is no need to take account of the electrical polarity. Is there any problem with using a Piezoelectric Sounder (External Drive Type) at a frequency other than that used to obtain the specified sound pressure level A piezoelectric sounder (external drive type) is designed to produce sound at a stable sound pressure when it is driven at the frequency used to obtain the specified sound pressure, however it will also produce sound at other frequencies as well.

Consequently, it can produce not only a single sound but also melodies and other complex sounds, enabling it to be used in such applications as operation confirmation sounds, alarms, melodies, and pseudo sounds. However, there are cases in which the sound pressure level becomes very small depending upon the drive frequency, although this will also depend upon the frequency characteristics of sound pressure level of each product, so check and evaluate the product before using it.

Can a Piezoelectric Sounder (External Drive Type) intended to be driven at 4 kHz in order to obtain the specified sound pressure level is driven at 2 kHz, and the sound pressure increased as well A piezoelectric sounder (external drive type) is a voltage-driven type. In order to increase the sound pressure, it is necessary to raise the input voltage. However, generally it is not easy to increase the input voltage to the drive circuit. Accordingly, the sound pressure can be raised by changing the duty ratio of the input voltage without changing the input voltage.

(Regarding the duty ratio, refer to Fig. 1. ) When a piezoelectric sounder intended to be driven at 4 kHz in order to obtain the specified sound pressure is to be driven at 2 kHz, change the duty ratio of the input signal from 50% to 25%. Taking our piezoelectric sounder PKM13EPYH4002-B0 as an example, this will cause the sound pressure to rise by approximately 10 dB.

(Refer to Fig. 2 and Fig. 3. ) This result depends upon the frequency characteristics of sound pressure level of the piezoelectric sounder, so the value of the increase in sound pressure will differ according to the type of 🔗 External reference

A piezoelectric sounder, particularly the self-drive type, operates based on the principle of piezoelectricity, where mechanical stress applied to piezoelectric materials generates an electrical charge. In this configuration, the piezoelectric diaphragm is the primary element that vibrates to produce sound waves. The feedback electrode enhances the efficiency of the oscillation by providing a mechanism for the diaphragm to self-excite, amplifying the sound output.

The external drive circuit typically consists of a transistor that acts as a switch, controlling the current flow through the piezoelectric diaphragm. The three resistors in the circuit help set the biasing conditions and determine the oscillation frequency. The simplicity of this design allows for easy integration into various electronic systems.

When designing applications that utilize piezoelectric sounders, it is crucial to consider the resonant frequency of the diaphragm, as this frequency will yield the highest sound pressure output. The ability of the sounder to operate effectively at various frequencies allows for versatility in application, including alert signals, notifications, and musical tones.

The adjustment of the duty cycle is an important technique for managing sound pressure levels without altering the voltage supply. By varying the duty cycle—essentially the proportion of time the signal is on versus off—the average power delivered to the sounder can be increased, thus enhancing the perceived loudness. This method is particularly useful in battery-operated devices where power conservation is essential.

In summary, the piezoelectric sounder (external drive type) is a highly efficient component suitable for a wide range of audio applications. Its low current consumption, versatility in frequency response, and the ability to manipulate sound pressure through duty cycle adjustments make it a preferred choice in modern electronic designs. Proper evaluation of the sound pressure characteristics across different frequencies is recommended to optimize performance in specific applications.In contrast, a piezoelectric sounder (self drive type) consists of only a piezoelectric diaphragm with a feedback electrode. It is used in combination with an external drive circuit. The drive circuit for both of the above is a simple circuit consisting of one transistor and three resistors.

When a DC voltage V is applied to the drive circuit, the oscillation conditions in the circuit are satisfied in the vicinity of the resonant frequency. As a result, the piezoelectric diaphragm is driven at the oscillation frequency, causing it to emit a sound. Regarding the drive circuit for a piezoelectric sounder (self drive type), we set a standard circuit for each product.

For details, please refer to our catalog. In contrast to an electromagnetic buzzer which is driven by a current flowing through a built-in electromagnet coil, a piezoelectric sound component is driven by a voltage applied to piezoelectric ceramic. Consequently, it features much lower current consumption than that of an electromagnetic buzzer. The current consumption (excluding that of the peripheral circuit) by a piezoelectric sounder (external drive type) can be calculated simply from the theoretical equation below.

When the charging and discharging times of a piezoelectric sounder (external drive type) are significantly smaller than the length of one period of the input signal, the average value of the current which flows into the piezoelectric sounder (external drive type) during a half period can be calculated from the following equation. The average value of the current flowing through the piezoelectric sounder (external excited type), calculated using the above equation for each part No.

, is shown in the table below. Provided that you use the product within the range of the maximum input voltage specified for each product, there is no need to take account of the electrical polarity. Is there any problem with using a Piezoelectric Sounder (External Drive Type) at a frequency other than that used to obtain the specified sound pressure level A piezoelectric sounder (external drive type) is designed to produce sound at a stable sound pressure when it is driven at the frequency used to obtain the specified sound pressure, however it will also produce sound at other frequencies as well.

Consequently, it can produce not only a single sound but also melodies and other complex sounds, enabling it to be used in such applications as operation confirmation sounds, alarms, melodies, and pseudo sounds. However, there are cases in which the sound pressure level becomes very small depending upon the drive frequency, although this will also depend upon the frequency characteristics of sound pressure level of each product, so check and evaluate the product before using it.

Can a Piezoelectric Sounder (External Drive Type) intended to be driven at 4 kHz in order to obtain the specified sound pressure level is driven at 2 kHz, and the sound pressure increased as well A piezoelectric sounder (external drive type) is a voltage-driven type. In order to increase the sound pressure, it is necessary to raise the input voltage. However, generally it is not easy to increase the input voltage to the drive circuit. Accordingly, the sound pressure can be raised by changing the duty ratio of the input voltage without changing the input voltage.

(Regarding the duty ratio, refer to Fig. 1. ) When a piezoelectric sounder intended to be driven at 4 kHz in order to obtain the specified sound pressure is to be driven at 2 kHz, change the duty ratio of the input signal from 50% to 25%. Taking our piezoelectric sounder PKM13EPYH4002-B0 as an example, this will cause the sound pressure to rise by approximately 10 dB.

(Refer to Fig. 2 and Fig. 3. ) This result depends upon the frequency characteristics of sound pressure level of the piezoelectric sounder, so the value of the increase in sound pressure will differ according to the type of 🔗 External reference