Resistivity

1. Definition and Units of Resistivity

Definition and Units of Resistivity

Resistivity, denoted by the Greek letter Ï (rho), is an intrinsic property of a material that quantifies how strongly it opposes the flow of electric current. Unlike resistance, which depends on the geometry of the conductor, resistivity is a fundamental characteristic of the material itself. It is defined as the resistance per unit length per unit cross-sectional area.

Mathematical Definition

The resistivity Ï of a material is derived from Ohm's law and the geometry of the conductor. For a uniform conductor of length L, cross-sectional area A, and resistance R, resistivity is given by:

This equation shows that resistivity is independent of the conductor's dimensions, making it a material-specific property. The derivation begins with the microscopic form of Ohm's law, where the current density J is related to the electric field E by:

Here, σ is the conductivity, the inverse of resistivity (σ = 1/Ï). Integrating this over the conductor's volume yields the macroscopic resistance R.

Units of Resistivity

In the International System of Units (SI), resistivity is measured in ohm-meters (Ω·m). This unit arises from the dimensional analysis of the defining equation:

In practical applications, especially for highly resistive materials, units such as ohm-centimeters (Ω·cm) or microhm-meters (μΩ·m) are also used. For example, the resistivity of copper is approximately 1.68 × 10−8 Ω·m, while that of silicon is around 2.3 × 103 Ω·m.

Temperature Dependence

Resistivity is temperature-dependent, particularly in metals and semiconductors. For metals, resistivity increases with temperature due to enhanced phonon scattering, described by:

where Ï0 is the resistivity at reference temperature T0, and α is the temperature coefficient of resistivity. In semiconductors, resistivity decreases with temperature because of increased charge carrier concentration.

Practical Relevance

Resistivity is critical in material selection for electrical and electronic applications. High-resistivity materials (e.g., ceramics) are used as insulators, while low-resistivity materials (e.g., copper, aluminum) are preferred for conductors. In semiconductor engineering, controlled resistivity is achieved through doping to tailor device performance.

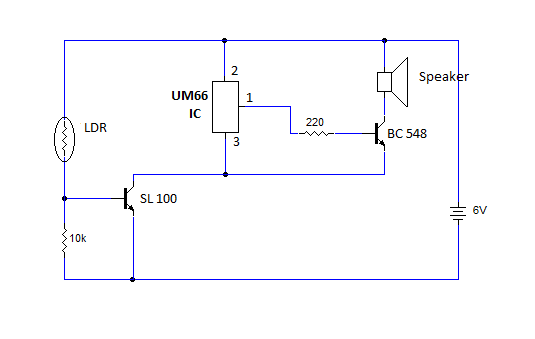

For instance, the resistivity of silicon can be precisely adjusted by introducing dopants like phosphorus (n-type) or boron (p-type), enabling the fabrication of transistors and integrated circuits with desired electrical characteristics.

Relationship Between Resistivity, Resistance, and Conductivity

The fundamental relationship between resistivity (Ï), resistance (R), and conductivity (σ) is governed by the material properties and geometric dimensions of a conductor. These parameters are interconnected through both microscopic and macroscopic physical principles.

Resistivity and Resistance

The resistance R of a uniform conductor is directly proportional to its resistivity Ï and length L, and inversely proportional to its cross-sectional area A:

This equation arises from the Drude model of electron transport, where resistivity quantifies how strongly a material opposes the flow of electric current. For non-uniform geometries, integration over the conductor's dimensions is required.

Conductivity as the Inverse of Resistivity

Conductivity σ is the reciprocal of resistivity, representing a material's ability to conduct electric current:

In terms of resistance, conductivity can be expressed as:

This reciprocal relationship highlights that materials with high resistivity (e.g., insulators) have low conductivity, while conductors exhibit the opposite behavior.

Temperature Dependence and Material Variations

For most metals, resistivity increases with temperature due to enhanced phonon-electron scattering:

where Ï0 is the resistivity at reference temperature T0, and α is the temperature coefficient of resistivity. In semiconductors, the behavior is more complex due to carrier concentration changes with temperature.

Practical Implications in Engineering

Understanding these relationships is critical for:

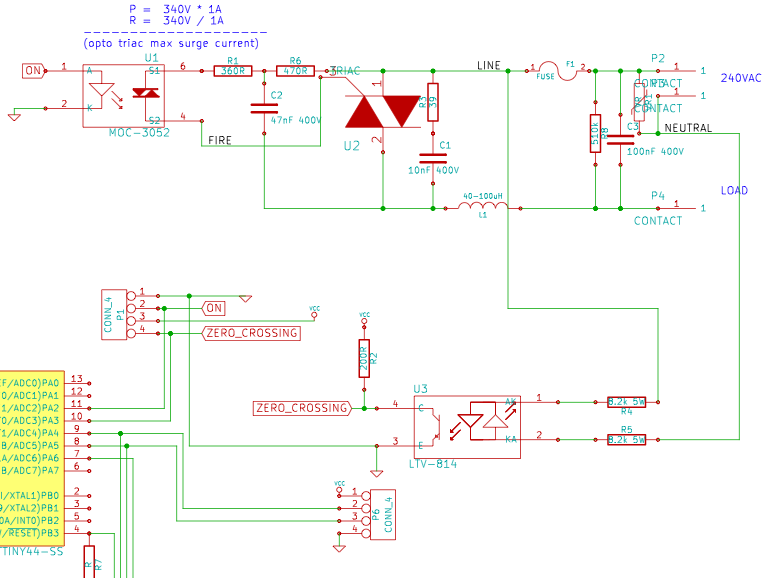

- Circuit design: Selecting materials with appropriate resistivity for resistors, traces, and interconnects.

- Power systems: Minimizing resistive losses in transmission lines by using high-conductivity materials like copper.

- Semiconductor devices: Engineering doping profiles to achieve desired conductivity in transistors and diodes.

Anisotropic Materials and Tensor Formulation

In anisotropic materials (e.g., graphite, some ceramics), resistivity and conductivity become second-rank tensors:

where E is the electric field vector and J is the current density vector. The tensor components account for directional variations in electron mobility.

For isotropic materials, these tensors reduce to scalar quantities, simplifying to the standard Ohm's Law formulation.

1.3 Factors Affecting Resistivity

The resistivity (Ï) of a material is not an intrinsic constant but varies based on several physical and environmental factors. Understanding these dependencies is critical for material selection in engineering applications, semiconductor design, and cryogenic systems.

Temperature Dependence

In conductors, resistivity increases with temperature due to enhanced lattice vibrations (phonons), which scatter conduction electrons more effectively. The linear approximation for metals near room temperature is:

where Ï0 is the reference resistivity at temperature T0, and α is the temperature coefficient of resistivity. For pure copper at 20°C, α ≈ 0.00393 K-1.

In semiconductors, resistivity decreases exponentially with temperature as more charge carriers are thermally excited across the band gap:

Impurity Concentration

Adding impurities to a host material introduces localized scattering centers. Matthiessen's rule approximates the total resistivity as:

In doped silicon, resistivity can be precisely controlled from 10-3 Ω·m to 103 Ω·m by varying dopant concentration (typically 1014 to 1020 atoms/cm3).

Mechanical Strain

Applied stress alters interatomic distances, modifying electron mobility. The piezoresistive effect in silicon is quantified by:

where πij are piezoresistive coefficients (up to 90×10-11 Pa-1 in n-type Si) and σij is the stress tensor. This effect enables MEMS strain sensors with gauge factors exceeding 100.

Crystalline Structure

Resistivity exhibits anisotropy in non-cubic crystals. Graphite demonstrates in-plane resistivity of ~5×10-6 Ω·m versus ~3×10-4 Ω·m along the c-axis due to π-orbital overlap variations. Single-crystal silicon shows 30% resistivity variation between <100> and <111> directions.

Magnetic Fields

In strong magnetic fields (B), materials exhibit magnetoresistance. For non-magnetic metals, the Kohler rule governs the transverse magnetoresistance:

Colossal magnetoresistance (CMR) materials like La1-xSrxMnO3 show resistivity changes exceeding 105% in 1-10T fields near their Curie temperature.

Frequency Effects

At high frequencies (>1GHz), the skin depth (δ) causes current to concentrate near conductor surfaces, effectively increasing resistance:

For copper at 10GHz, δ ≈ 0.66 μm, necessitating surface treatments or hollow conductors in RF applications.

2. Resistivity in Conductors

2.1 Resistivity in Conductors

Resistivity, denoted by Ï, is an intrinsic property of a material that quantifies its opposition to the flow of electric current. In conductors, resistivity arises primarily due to electron scattering mechanisms, including lattice vibrations (phonons), impurities, and defects. The Drude model provides a classical framework for understanding resistivity, while quantum mechanical corrections refine this picture.

Microscopic Origins of Resistivity

At the microscopic level, resistivity in conductors is governed by electron scattering events. The mean free path λ of electrons—the average distance traveled between collisions—determines the material's resistance. The resistivity can be expressed as:

where m is the electron mass, n is the charge carrier density, e is the electron charge, and Ï„ is the mean free time between collisions. This relation highlights that higher carrier densities (e.g., in metals like copper) result in lower resistivity.

Temperature Dependence

In pure metals, resistivity increases linearly with temperature due to enhanced phonon-electron scattering. Mathematically, this is described by:

where Ïâ‚€ is the resistivity at reference temperature Tâ‚€, and α is the temperature coefficient of resistivity. For copper, α ≈ 0.00393 °Câ»Â¹, making it highly predictable for engineering applications.

Matthiessen’s Rule

In real conductors, resistivity contributions from impurities and lattice vibrations are additive. Matthiessen’s Rule states:

This principle explains why alloying metals (e.g., nichrome) increases resistivity—impurity scattering dominates even at room temperature.

Practical Implications

- Power transmission lines: Aluminum (low Ï, lightweight) is preferred despite higher resistivity than copper due to cost and weight trade-offs.

- Integrated circuits: Copper interconnects replaced aluminum in sub-180 nm nodes due to lower resistivity, reducing RC delays.

- Cryogenic systems: Superconductors exhibit zero resistivity below critical temperatures, enabling MRI magnets and quantum computing.

Anomalous Resistivity Effects

At nanoscales, surface scattering and grain boundary effects become significant, violating bulk resistivity models. The Fuchs-Sondheimer and Mayadas-Shatzkes models account for these phenomena:

where d is the film thickness and p is the electron surface scattering specularity parameter.

2.2 Resistivity in Semiconductors

Intrinsic Semiconductor Resistivity

The resistivity Ï of an intrinsic semiconductor is governed by the concentration of charge carriers (electrons and holes) and their mobilities. In an undoped semiconductor, the carrier concentrations are equal (n = p = ni), where ni is the intrinsic carrier concentration. The resistivity is given by:

where q is the electron charge, μn and μp are the electron and hole mobilities, respectively. The intrinsic carrier concentration ni is temperature-dependent and follows:

Here, Nc and Nv are the effective density of states in the conduction and valence bands, Eg is the bandgap energy, k is Boltzmann’s constant, and T is the absolute temperature.

Extrinsic Semiconductor Resistivity

Doping introduces additional charge carriers, significantly altering resistivity. For an n-type semiconductor (donor-doped), the electron concentration dominates (n ≈ Nd), and resistivity becomes:

Similarly, for a p-type semiconductor (acceptor-doped), hole concentration dominates (p ≈ Na), leading to:

At high doping levels, carrier mobility decreases due to impurity scattering, complicating the relationship between doping and resistivity.

Temperature Dependence

Semiconductor resistivity exhibits three distinct temperature regimes:

- Low temperature: Freeze-out region where carriers are trapped by dopant atoms, causing resistivity to rise exponentially as temperature decreases.

- Mid temperature: Extrinsic region where most dopants are ionized, and resistivity is relatively stable.

- High temperature: Intrinsic region where thermal excitation across the bandgap dominates, and resistivity decreases exponentially with temperature.

Practical Applications

Understanding resistivity in semiconductors is critical for designing devices such as:

- Diodes and transistors: Controlled doping profiles optimize conductivity and junction behavior.

- Thermistors: Temperature-sensitive resistors leverage the strong temperature dependence of semiconductor resistivity.

- Integrated circuits: Precise doping ensures proper resistivity for interconnects and active regions.

Case Study: Silicon Resistivity

Silicon, the most widely used semiconductor, has an intrinsic resistivity of approximately 2.3 × 103 Ω·cm at room temperature. Doping with phosphorus (n-type) or boron (p-type) can reduce resistivity to as low as 10-3 Ω·cm at high doping concentrations (>1019 cm-3).

2.3 Resistivity in Insulators

Fundamental Behavior of Insulators

Insulators exhibit extremely high resistivity, typically in the range of \(10^8\) to \(10^{16}\) Ω·m, due to their large bandgap (\(>3\) eV). Unlike conductors or semiconductors, insulators have a nearly empty conduction band and a fully occupied valence band at room temperature. The absence of free charge carriers results in minimal current flow even under strong electric fields. The resistivity \(\rho\) of an insulator follows the Arrhenius relation:

where \(E_g\) is the bandgap energy, \(k_B\) is Boltzmann’s constant, and \(T\) is temperature. This exponential dependence explains why insulators maintain high resistivity across a wide temperature range.

Breakdown Mechanisms and Practical Limits

Despite their high resistivity, insulators fail under extreme electric fields due to:

- Dielectric breakdown: Field strengths exceeding \(10^6\)–\(10^8\) V/m generate avalanche ionization.

- Thermal runaway: Joule heating reduces \(\rho\) locally, creating conductive paths.

- Partial discharge: Microscopic voids ionize, eroding material over time.

The breakdown voltage \(V_{bd}\) for a uniform field is derived from:

where \(E_{bd}\) is the material-specific dielectric strength (e.g., 20 MV/m for alumina) and \(d\) is thickness.

Material-Specific Resistivity Trends

Common insulators and their room-temperature resistivity:

| Material | Resistivity (Ω·m) | Bandgap (eV) |

|---|---|---|

| Fused silica | \(10^{16}\) | 8.9 |

| Alumina | \(10^{14}\) | 7.5 |

| PTFE (Teflon) | \(10^{13}\) | 6.0 |

Frequency-Dependent Effects

At high frequencies (\(>1\) MHz), insulators exhibit complex impedance due to:

- Dipole relaxation: Orientational polarization lags behind AC fields, increasing loss tangent (\(\tan \delta\)).

- Space charge effects: Trapped charges modulate local fields, causing dispersion in permittivity.

The frequency-dependent complex resistivity \(\tilde{\rho}(\omega)\) is given by:

where \(\epsilon_r(\omega)\) is the relative permittivity and \(\sigma_0\) is DC conductivity.

Applications in High-Voltage Engineering

Insulators are critical in:

- Power transmission: Porcelain and silicone rubber insulators withstand kV/mm gradients.

- Capacitor dielectrics: Polymer films (e.g., polypropylene) minimize leakage currents.

- Microelectronics: SiOâ‚‚ layers in MOSFETs prevent gate leakage below 1 nm thicknesses.

3. Experimental Methods for Measuring Resistivity

3.1 Experimental Methods for Measuring Resistivity

Four-Point Probe Technique

The four-point probe method is a highly accurate technique for measuring resistivity, particularly in thin films and semiconductor materials. It eliminates lead resistance errors by separating current injection and voltage measurement. Two outer probes supply a known current I, while the inner probes measure the resulting voltage drop V. For a semi-infinite material, resistivity Ï is given by:

where s is the probe spacing. For thin films with thickness t ≪ s, the correction factor yields:

Van der Pauw Method

Van der Pauw's method enables resistivity measurements on arbitrarily shaped samples with uniform thickness, provided contacts are small and positioned at the perimeter. Two sequential measurements are taken:

- Current IAB injected between contacts A and B, voltage VCD measured between C and D

- Current IBC injected between B and C, voltage VDA measured between D and A

The resistivity is calculated using:

where f is a geometric correction factor solved numerically from the transcendental equation.

Bridge Methods

Precision resistance measurements employ bridge circuits:

Wheatstone Bridge

Used for moderate resistances (1 Ω – 1 MΩ), the Wheatstone bridge null-detection method provides high accuracy. The unknown resistance Rx is determined by:

when the bridge is balanced (galvanometer shows zero current).

Kelvin Double Bridge

For low resistances (<1 Ω), the Kelvin bridge eliminates lead and contact resistance errors through a four-terminal configuration. The resistance is calculated via:

where r represents the yoke resistance and Rs is the standard resistor.

Non-Contact Methods

For corrosive or high-temperature materials, non-contact techniques are preferred:

Eddy Current Testing

A time-varying magnetic field induces eddy currents whose penetration depth (skin depth δ) relates to resistivity:

where μ is permeability and f is frequency. Phase and amplitude changes in the detector coil correlate with Ï.

Microwave Reflectometry

At GHz frequencies, the surface impedance Zs of a material relates to its resistivity through:

measured via waveguide or coaxial reflection coefficients.

Temperature-Dependent Measurements

For characterizing superconductors or semiconductors, cryogenic systems with four-probe configurations measure Ï(T) curves. Key considerations include:

- Thermal EMF cancellation through current reversal

- AC excitation to minimize Joule heating

- Guarding techniques for high-resistivity samples

3.2 Mathematical Formulas and Calculations

Fundamental Resistivity Equation

The intrinsic property of a material to oppose electric current is quantified by resistivity (Ï). The fundamental relationship between resistance (R), length (L), and cross-sectional area (A) is:

This linear approximation holds for homogeneous, isotropic materials under steady-state conditions. The unit of resistivity is Ω·m (ohm-meter), though engineering applications often use Ω·cm.

Temperature Dependence

Resistivity varies with temperature according to:

Where:

- Ï0 is reference resistivity at T0 (typically 20°C)

- α is the first-order temperature coefficient (1/K)

- β is the second-order coefficient for precision applications

For conductors, α is positive (resistivity increases with temperature), while semiconductors exhibit negative α values.

Anisotropic Materials

In crystalline or composite materials, resistivity becomes a tensor quantity:

Where E is the electric field and J is the current density. For orthotropic materials, the off-diagonal terms vanish.

Thin Film Resistivity

The sheet resistance Râ–¡ (ohms per square) for thin films is calculated using:

Where t is film thickness. This simplifies integrated circuit design where layer thicknesses are controlled precisely.

Non-Ohmic Materials

For materials exhibiting field-dependent resistivity (e.g., varistors), the general form becomes:

Where nonlinear coefficients σn describe the material's conduction behavior under high fields.

Practical Measurement Considerations

The four-point probe method eliminates contact resistance effects:

Where s is probe spacing. Correction factors must be applied for finite sample sizes and non-collinear probe arrangements.

3.3 Temperature Dependence and Correction Factors

The resistivity of a material is not a static property but varies with temperature due to changes in electron-phonon interactions and charge carrier density. For most conductive materials, this dependence can be approximated by a linear relationship near room temperature:

where Ï0 is the reference resistivity at temperature T0 (typically 20°C), and α is the temperature coefficient of resistivity (TCR), expressed in °C-1. For pure metals, α is typically positive, as increased lattice vibrations impede electron flow.

Microscopic Origins of Temperature Dependence

In metals, resistivity primarily arises from:

- Phonon scattering: Lattice vibrations increase with temperature, creating more obstacles for conduction electrons.

- Impurity scattering: Temperature-independent contribution from defects and impurities.

Matthiessen's Rule combines these effects:

At very low temperatures (<5K), quantum effects dominate, and resistivity follows the Bloch-Grüneisen law:

where ΘD is the Debye temperature.

Semiconductors and Insulators

In intrinsic semiconductors, resistivity decreases exponentially with temperature:

where Eg is the band gap and kB is Boltzmann's constant. Doped semiconductors show more complex behavior, with ionization, extrinsic, and intrinsic conduction regimes.

Practical Correction Factors

For precision measurements, standardized correction factors are applied:

| Material | α (×10-3 °C-1) | Valid Range (°C) |

|---|---|---|

| Copper (annealed) | 3.93 | -50 to 150 |

| Aluminum | 4.29 | -50 to 150 |

| Silicon (intrinsic) | -70 | 20 to 150 |

For extended temperature ranges, higher-order polynomial corrections are used. The IEC 60751 standard provides reference functions for platinum resistance thermometers:

where A, B, and C are empirically determined coefficients.

Cryogenic Considerations

Below 30K, the resistivity of pure metals becomes dominated by impurity scattering and surface effects. The residual resistivity ratio (RRR) is a key quality metric:

High-purity copper for superconducting magnets may have RRR > 100, while standard OFHC copper typically has RRR ≈ 50.

4. Use of Resistivity in Material Selection

4.1 Use of Resistivity in Material Selection

The selection of materials for electrical and electronic applications is heavily influenced by their resistivity, a fundamental property that quantifies how strongly a material opposes the flow of electric current. Resistivity (Ï) is defined as the resistance of a unit cube of the material and is expressed in ohm-meters (Ω·m). The relationship between resistance (R), resistivity, and the physical dimensions of a conductor is given by:

where L is the length and A is the cross-sectional area of the conductor. This equation highlights that resistance is directly proportional to resistivity, making Ï a critical parameter in material selection.

Factors Influencing Resistivity

Resistivity is not an intrinsic constant but varies with several factors:

- Temperature: For most metals, resistivity increases with temperature due to enhanced electron-phonon scattering. The temperature dependence is often approximated by:

$$ \rho(T) = \rho_0 [1 + \alpha (T - T_0)] $$where Ï0 is the resistivity at reference temperature T0, and α is the temperature coefficient of resistivity.

- Impurities and Defects: Alloying or introducing impurities increases resistivity by disrupting the periodic potential of the lattice, scattering conduction electrons.

- Crystal Structure: Anisotropic materials exhibit direction-dependent resistivity, crucial for applications like thin-film electronics.

Material Selection Criteria

Choosing a material based on resistivity involves balancing electrical, thermal, and mechanical properties:

- Conductors (Low Ï): Copper (Ï â‰ˆ 1.68×10−8 Ω·m) and aluminum (Ï â‰ˆ 2.65×10−8 Ω·m) dominate wiring due to their low resistivity, ductility, and cost. Silver, though lower in Ï, is reserved for high-performance applications like RF contacts.

- Resistive Elements (Moderate Ï): Nichrome (80% Ni, 20% Cr; Ï â‰ˆ 1.10×10−6 Ω·m) is used in heating elements due to its high melting point and stability.

- Insulators (High Ï): Polymers like PTFE (Ï > 1016 Ω·m) prevent leakage currents in high-voltage systems.

Case Study: Interconnect Materials in ICs

In integrated circuits, aluminum was historically used for interconnects (Ï â‰ˆ 2.65×10−8 Ω·m). However, as feature sizes shrank below 180 nm, copper (Ï â‰ˆ 1.68×10−8 Ω·m) replaced it due to its 40% lower resistivity, reducing RC delays. The transition required innovations like damascene processing to address copper’s diffusion into silicon.

Emerging Materials

Research focuses on materials with tunable resistivity:

- Graphene: Exceptionally low Ï (~10−8 Ω·m) but challenging to integrate at scale.

- Topological Insulators: Bulk insulators with conductive surfaces, enabling novel spintronic devices.

The resistivity spectrum of common materials spans over 30 orders of magnitude, necessitating precise selection for optimal performance in applications ranging from superconducting magnets to insulation coatings.

4.2 Resistivity in Electronic Components

Fundamental Relationship Between Resistivity and Resistance

The resistivity Ï of a material defines its intrinsic opposition to current flow, independent of geometry. For a uniform conductor, resistance R relates to resistivity through the dimensions of the component:

where L is the length and A is the cross-sectional area. This linear dependence on geometry allows resistivity to serve as a material-specific property, while resistance is a component-level characteristic.

Temperature Dependence and Material Behavior

Resistivity varies with temperature, governed by:

Here, α is the temperature coefficient of resistivity, and Ï0 is the reference resistivity at T0. For conductors like copper, α is positive, leading to increased resistivity with temperature due to enhanced electron-phonon scattering. Semiconductors exhibit negative α as charge carrier density dominates over mobility reduction.

Thin-Film and Bulk Resistivity in IC Fabrication

In integrated circuits, thin-film metals and doped semiconductors exhibit modified resistivity due to:

- Surface scattering: Electron mean free path reduction in thin films (< 100 nm) increases Ï beyond bulk values.

- Grain boundary effects: Polycrystalline films show higher resistivity than single-crystal equivalents.

The Mayadas-Shatzkes model quantifies thin-film resistivity:

where p is surface specularity, λ is bulk mean free path, d is film thickness, αg is grain boundary reflection coefficient, and R is grain boundary reflectivity.

Practical Implications in Component Design

Resistivity considerations directly impact:

- Interconnect RC delay: Higher Ï in advanced node metals (e.g., cobalt vs. copper) affects signal propagation.

- Power dissipation: Material selection for high-current paths balances Ï against thermal and electromigration limits.

- Precision resistors: Alloys like NiCr achieve stable Ï with minimal temperature dependence (α ≈ 10 ppm/°C).

Case Study: Resistivity in PCB Traces

For a 1 oz/ft² copper trace (thickness t = 35 μm), the sheet resistance is:

This enables calculation of total trace resistance by counting squares in the current path. High-frequency designs must account for skin effect, where current crowds near the surface, effectively reducing A and increasing R with frequency.

4.3 Resistivity in Power Transmission

Fundamental Considerations

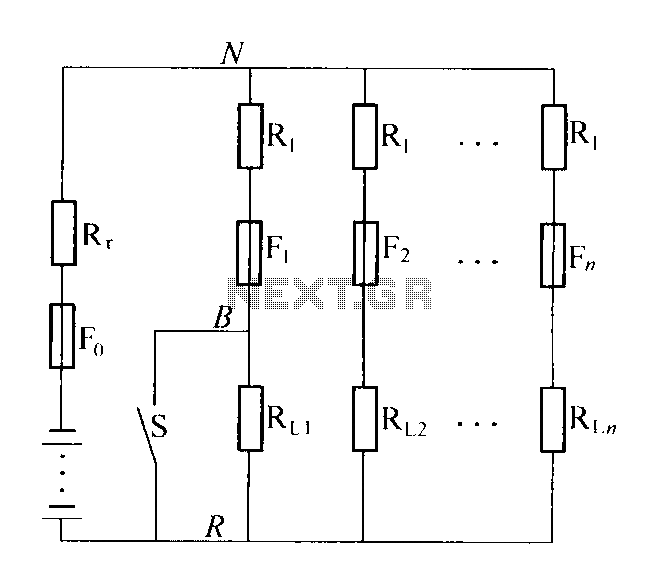

The efficiency of power transmission over long distances is heavily influenced by the resistivity of the conductor material. Resistivity (Ï) determines the power loss (Ploss) due to Joule heating, given by:

where I is the current and R is the resistance of the conductor. The resistance itself depends on resistivity, length (L), and cross-sectional area (A):

For high-power transmission, minimizing Ploss is critical, which necessitates either reducing current or selecting materials with low resistivity.

Material Selection and Trade-offs

Common conductor materials include:

- Copper (Cu): Ï â‰ˆ 1.68 × 10−8 Ω·m — Excellent conductivity but expensive and heavy.

- Aluminum (Al): Ï â‰ˆ 2.82 × 10−8 Ω·m — Lighter and cheaper than copper, but higher resistivity.

- Aluminum Conductor Steel-Reinforced (ACSR): Combines aluminum's conductivity with steel's tensile strength for overhead lines.

The choice involves balancing cost, weight, mechanical strength, and electrical performance.

High-Voltage Transmission and Resistivity

To minimize I2R losses, power grids use high-voltage transmission (V), reducing current for a given power level (P = VI). However, higher voltages introduce insulation challenges and corona discharge losses, which must be weighed against resistive losses.

where cos θ is the power factor. This equation highlights the inverse-square relationship between voltage and resistive losses.

Temperature Dependence and Line Sag

Resistivity increases with temperature (T) for metals, following:

where α is the temperature coefficient. Elevated temperatures also cause thermal expansion, increasing line sag and potentially reducing clearance. This necessitates careful thermal modeling in transmission line design.

Skin Effect at High Frequencies

For AC transmission, current density is non-uniform across the conductor cross-section due to the skin effect, effectively increasing resistance. The skin depth (δ) is given by:

where ω is the angular frequency and μ is the permeability. At power frequencies (50/60 Hz), this effect is minimal for standard conductors but becomes significant for high-frequency harmonics or large-diameter lines.

Superconducting Transmission

Superconductors exhibit zero resistivity below their critical temperature (Tc), enabling lossless power transmission. Practical challenges include cryogenic cooling costs and current density limits. High-temperature superconductors (HTS) like YBCO (Tc ≈ 90 K) offer potential for more feasible implementations.

5. Key Textbooks and Research Papers

5.1 Key Textbooks and Research Papers

- The Handbook Of Electrical Resistivity — Engineering Books — 1.3 Key Applications of Electrical Resistivity. Applications range from industrial processes, electronic circuits, and high-tech materials to environmental and geophysical fields where resistivity plays a role in water contamination studies and mineral exploration. 2. Overview of The Handbook of Electrical Resistivity

- PDF Band Structure and Electrical Conductivity in Semiconductors - PhysLab — band valence band conductivity resistivity mobility unijunction transistor temperature ... \Principles of Electronic Materials and Devices", Boston, McGraw-Hill, (2006), pp. 378-405, 114-122. ... indicated in Figure (3b). The p-n junction is the key compound for numerous semiconductor devices. By combining two p-n junctions, we can form the p-n ...

- PDF 5.1 Resistivity and Conductivity - Springer — 5.1 Resistivity and Conductivity Fig. 1. Fe-Ni-P. Resistance R in Ni75Co5P20 alloy as a function of temperature T [82VARG]. The onset of crystallization appears as a sharp decrease in resistivity. References 82VARG Varga, L., Tompa, K.: Proc. 4th Int. Conf. Rapidly Quenched Met., Sendai, Masumoto,

- Chapter 5 Review - Electrical Engineering Textbooks — 5.3 Resistivity and Resistance. Resistance has units of ohms (), related to volts and amperes by ; The resistance of a cylinder of length and cross-sectional area is where is the resistivity of the material. Values of in Table 5.3.1 show that materials fall into three groups—conductors, semiconductors, and insulators.

- Electronic Devices and Circuits Textbook - studylib.net — Textbook covering semiconductor theory, diodes, transistors, and circuit analysis for college-level engineering students. ... (1-9) where is the resistivity of the material (in .m), l is the length, and a is the cross-sectional area. This can be rewritten as R = l/( a) (1-10) where is the material conductivity (the reciprocal of resistivity ...

- PDF Three-dimensional Electronic Resistivity Mapping of Solid Electrolyte ... — electronic contributions from other parts of the battery circuit. Ex-situ measurements of resistivity at nanometer scales are also lacking. This research seeks to further the understanding of the electronic and structural properties of the SEI and Si active material at the nanoscale through development of a novel experimental approach.

- Electrical Resistivity - an overview | ScienceDirect Topics — To verify the agreement between the experimental data and the Poole-Frenkel theory, we have used Hill's method (Johnsher and Hill, 1978) in which a graph depicts the function lg[jT −4 exp(E i /kT) = f(F 1/2 /T)], where E i is the ionization energy of the Coulomb center, k Boltzmann's constant, and T temperature.If E i = 0.36 eV, points corresponding to conductivities at different ...

- 5 Resistors : The Most Fundamental Component - O'Reilly Media — 5Resistors: The Most Fundamental Component 5.1 Introduction This chapter is about resistors, the most basic electric component. 5.2 Resistor Resistors are the most fundamental and commonly used of … - Selection from Introductory Electrical Engineering With Math Explained in Accessible Language [Book]

- PDF Lab 5.Series and Parallel Resistors - Washington State University — CHAPTER 5. SERIES AND PARALLEL RESISTORS 44 nected between the combined Terminal 1 and the combined Terminal 2. In this case the applied voltage ("pressure" if you will) across each resistor is the same.

- The Resistor Guide: Fundamentals, Types, and Applications — Comprehensive guide on resistors: fundamentals, types, standards, applications, Ohm's Law, Kirchhoff's laws, and more. Ideal for electrical engineering students.

5.2 Online Resources and Tutorials

- The Handbook Of Electrical Resistivity — Engineering Books — 9.2 Online Courses and Tutorials Platforms like Coursera and edX offer courses on material science and electrical engineering that can deepen understanding of resistivity. 9.3 Websites Offering Reliable Scientific Resources Websites such as IEEE Xplore, ResearchGate, and JSTOR provide reputable resources and studies. 10.

- 5.2 Resistivity Notes | PDF - Scribd — 5.2-Resistivity-notes - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Resistivity is a material property that depends on temperature and accounts for how a material's structure affects electron flow. It can be calculated from a material's resistance, length, and cross-sectional area, and is measured in ohm meters. The resistivity of a material increases with ...

- PDF 5.2 Resistance & Resistivity - Save My Exams — 7 A wire of resistivity 1.5 × 10 -8 Ω m has a radius of 0.25 mm and a length that is able to be wound in circles 50 times round a plastic rod of radius 1.25 cm.

- PDF 5.2 Resistance & Resistivity - Save My Exams — Figure 1 shows part of a miniature electronic circuit with two small resistors connected in parallel. The material from which each resistor is made has a resistivity of 2.6 × 10 5 Ω m and both resistors have dimensions of 15 mm by 2.3 mm by 1.3 mm.

- 5.2.4 - Resistivity - QUESTIONS — The document contains 8 questions about electrical resistivity. Question 1 asks about the cross-sectional area and radius of a power cable with a given resistance and material resistivity. Question 2 asks about comparing the resistances of two copper wires with different lengths and diameters. Question 3 asks about the resistance of a cylindrical conductor with different properties than ...

- 20.3 Resistance and Resistivity - College Physics — Summary Explain the concept of resistivity. Use resistivity to calculate the resistance of specified configurations of material. Use the thermal coefficient of resistivity to calculate the change of resistance with temperature.

- Topic 5.2 Formative | PDF | Electrical Resistance And Conductance ... — Topic 5.2 Formative - Free download as PDF File (.pdf), Text File (.txt) or read online for free.

- Resistivity (5.2.5) | DP IB Physics: SL Revision Notes 2016 — FREE Physics revision notes on SI Units. Designed by the teachers at SAVE MY EXAMS for the IB Physics SL.

- Farrow Physics - 5.2b Resistance — THE IB SAYS Essential idea: One of the earliest uses for electricity was to produce light and heat. This technology continues to have a major impact on the lives of people around the world. Understandings: Resistance expressed as R=V/I; Ohm's law Applications and skills: Identifying ohmic /

- PDF Lab 5.Series and Parallel Resistors - Washington State University — To calculate the voltages and currents in simple circuits involving only resistors using the rules for "adding" series and parallel resistors.

5.3 Advanced Topics in Resistivity

- Ohm's law and resistivity | physics-hl | ib | Sparkl — Investigating resistivity in topological insulators involves studying the interplay between topology, symmetry, and electronic structure. These materials challenge conventional notions of resistivity, offering avenues for discovering novel electrical phenomena and developing advanced electronic devices. Comparison Table

- 5.3 Resistivity and Resistance - University of Saskatchewan — where is the resistivity of the material at temperature , is the temperature coefficient of the material, and is the resistivity at , usually taken as . Note also that the temperature coefficient is negative for the semiconductors listed in Table 5.3.1, meaning that their resistivity decreases with increasing temperature. They become better ...

- Chapter 5 Review - Electrical Engineering Textbooks — 5.3 Resistivity and Resistance. Resistance has units of ohms (), related to volts and amperes by ; The resistance of a cylinder of length and cross-sectional area is where is the resistivity of the material. Values of in Table 5.3.1 show that materials fall into three groups—conductors, semiconductors, and insulators.

- 5 Current and Resistance - Introduction to Electricity, Magnetism, and ... — 5.3 Resistivity and Resistance. 5.4 Ohm's Law. 5.5 Electrical Energy and Power. 5.6 Superconductors. Chapter 5 Review. 6 Direct-Current Circuits ... 6.6 Household Wiring and Electrical Safety. Chapter 6 Review. 7 Advanced Circuit Analysis Techniques. 7.1 Mesh Analysis. 7.2 Superposition Theorem. 7.3 Thévenin's Theorem. Chapter 7 Review. 8 ...

- PDF 5.3 Resistivity - flippedaroundphysics.com — 5.3 Resistivity The resistance of a conductor depends on the length, the cross-sectional area and a property of the material called the resistivity (!). Resistivity is a bulk property of the material and is a constant (for a given temperature) for the material. For example, copper has a resistivity of 1.7×10'()* at room temperature. (1)!

- 5.3: Resistivity and Resistance - Physics LibreTexts — The resistivity of a material is a measure of how strongly a material opposes the flow of electrical current. The symbol for resistivity is the lowercase Greek letter rho, \(\rho\), and resistivity is the reciprocal of electrical conductivity: \[\rho = \dfrac{1}{\sigma}.\] The unit of resistivity in SI units is the ohm-meter \((\Omega \cdot m\).

- Resistivity and Resistance - Electrical Engineering Textbooks — View this interactive simulation to see what the effects of the cross-sectional area, the length, and the resistivity of a wire are on the resistance of a conductor. Adjust the variables using slide bars and see if the resistance becomes smaller or larger. Temperature Dependence of Resistivity. Looking back at Table 5.3.1, you will see a column labeled "Temperature Coefficient."

- (PDF) Resistance and Resistivity - Academia.edu — The resistivity of the liquid is 8.5 × 10-5 Ω m. The liquid is poured onto a horizontal surface and quickly sets in the form of a uniform cylindrical disc of radius 25 cm. Calculate the resistance of this disc across its two opposite larger surfaces. You may assume that the resistivity of the material remains constant.

- (PDF) Chapter Resistivity Methods - Academia.edu — For good penetration we must use large enough spacing that sufficient current reaches the target depth; if the latter is 100 m, about one-third of the current will pass below this depth when the spacing is also 100 m. Compared to magnetotellurics, for instance, this places an inherent limitation on the resistivity method.

- Electrical resistivity - Book chapter - IOPscience — Chapter 8 is about the phenomenon of electrical resistivity. This vast and difficult subject is approached here from a perspective that emphasizes the role of the electronic self-energy. Based on the Kubo and generalized Drude formulas, the chapter models the zero-temperature resistivity due to impurity scattering, the contribution of electron ...