sequential led bar graph circuit

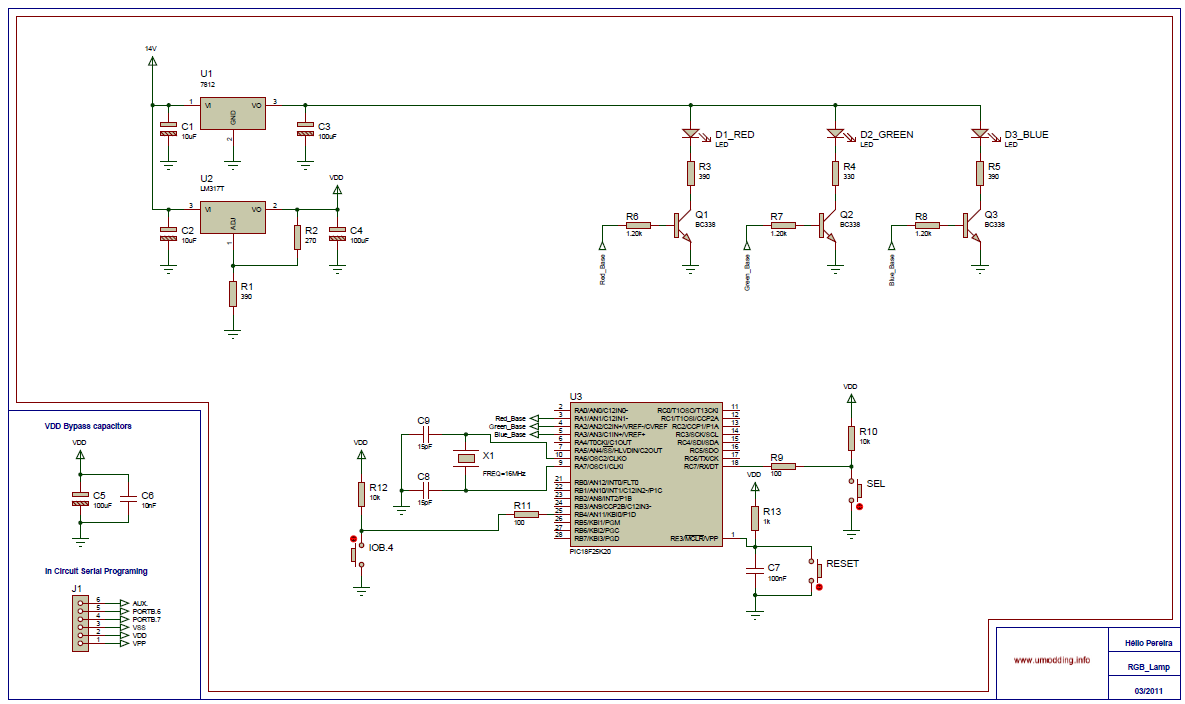

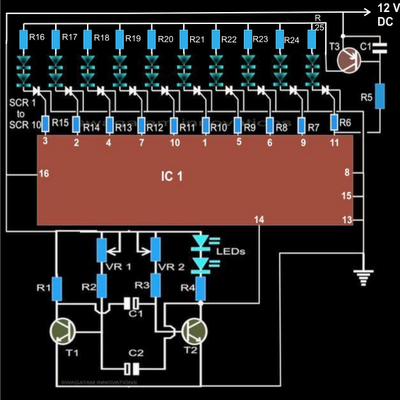

The article explains a straightforward method for creating an incremental LED bar graph using the IC 4017, which has specifications that may not fully align with current requirements. It discusses how to modify the IC for these operations. The method involves constructing an array of LEDs that sequentially illuminate, forming a bar graph. The circuit employs the standard IC 4017 to implement the LED light sequence. The primary component of this sequential LED driver circuit is the widely used Johnson's Decade Counter IC 4017. Typically, the IC functions by sequentially activating its outputs from 1 to 11 in response to a clock signal applied at pin #14. The outputs turn high in sequence, causing the previous output to turn low immediately as the high state moves through the assigned pinouts. When LEDs are connected to these outputs, the resulting effect is that a dot of light appears to jump from the start to the finish, repeatedly cycling through the sequence. However, the visual effect is not particularly captivating since only one LED or lamp illuminates at any given moment during the sequence, which does not create a very striking display. The sequencing capability of the IC is a complex function that is difficult to replicate with a single IC, and this aspect should be recognized. To enhance the visual appeal while maintaining the sequencing feature, one approach is to prevent the previously lit LEDs from turning off during the sequencing process. This means that as the sequence begins, the LEDs will light up one after another to form a continuous illuminated bar until the entire array is lit. Once the sequence concludes, the entire bar will turn off, and the cycle will restart. To achieve this, a latching arrangement is necessary to keep the LEDs illuminated while the sequencing logic goes low. An SCR (Silicon Controlled Rectifier) is one device capable of latching its output when its gate is triggered. This function is suitable for DC power supplies, making it appropriate for this application. In the circuit diagram, all output pinouts of the IC are connected to the gates of corresponding SCRs, with the LEDs connected across the positive supply and the anodes of the SCRs. As the IC outputs generate shifting pulses, the SCRs activate sequentially, illuminating the LEDs and latching the lights in an increasing order until the last LED is lit. Afterward, the entire array turns off. The switch-off function for the LED chain is managed by a PNP transistor (T3), which remains on as long as the output at pin #11 is low. Pin #11, being the last output in the sequence, stays low until the sequence is complete, at which point it goes high. When pin #11 becomes high, it inhibits the base of T3 from conducting, cutting power to the LEDs and the SCRs. This breaks the SCR latching, turning off the entire array and restarting the sequence from LED 1 at pin #3. An astable multivibrator can be used to generate the clock signals, and a common transistor type of AMV is utilized here, which is simple to build and configure. A capacitor at the base of T3 is included to ensure the transistor switches off after a delay, allowing the last LED at pin #11 to fully illuminate before the entire bar turns off.

The circuit design for the incremental LED bar graph involves several critical components and connections. The IC 4017 serves as the primary control unit, with its outputs connected to the gates of SCRs that manage the LED illumination. Each SCR corresponds to an LED, allowing it to latch on when triggered by the IC output. The configuration ensures that once a SCR is activated, the associated LED remains lit, creating a visual effect of a growing bar graph as each successive LED lights up in sequence.

To implement the timing and sequencing, a clock signal is generated by the astable multivibrator, which can be constructed using a simple transistor-based circuit. The frequency of the clock can be adjusted by varying the resistor and capacitor values in the multivibrator circuit, allowing for control over the speed of the LED sequence.

The PNP transistor (T3) plays a crucial role in managing the overall operation of the LED array. Its operation is dependent on the state of pin #11 of the IC 4017, which ensures that the entire LED array is powered only when the sequence is complete. The inclusion of a capacitor at the base of T3 allows for a brief delay, ensuring that the last LED has sufficient time to illuminate fully before the entire array shuts off, enhancing the visual appeal of the display.

This design not only showcases the capabilities of the IC 4017 in controlling LED sequences but also highlights the effectiveness of using SCRs for latching and maintaining illumination, resulting in a more engaging and visually dynamic LED bar graph display.The article describes a simple method of making an incremental LED bar graph by using the IC 4017, which is rather equipped with specifications not suiting the present functions. Let`s learn how we can mod the IC for the operations. Here we study an easy method of making an array of LEDs chase to develop into a sequential LED bar graph.

The LED s start from one of the 10 pin outs of the IC and go on switching one after the other until all the LEDs are lit forming an incrementing bar graph. The circuit uses the ordinary IC 4017 for implementing this interesting LED light sequence. The main component of this sequential LED driver circuit is the popular Johnson`s Decade Counter IC 4017.

As we all know, the normal functioning of the IC involves sequential shifting of its outputs 1 to 11, in response to a clock signal applied at its pin #14. The outputs become high in sequence such that the previous output becomes low immediately as the high position leaps through the assigned pi-outs.

If LEDs are connected to the outputs, the above sequence would produce an effect of an illuminated dot jumping from start to finish and repeating the sequence. Though the effect looks interesting, fails to bewitch the folks simply because the illuminations produced are very low.

This is because, only one LED or lamp glows at any instant while sequencing, not enough to make the system very eye-catching. However the sequencing factor of the IC cannot be ignored as it`s one complex function that cannot be achieved a single IC and the chip must be credited for this attribute.

So, what can we do to improve the above feature such that the engaged lights become more attractive and the sequencing feature is also exploited at the same time One idea would be to stop the former LEDs in the sequence from shutting down while the array is sequencing. It means now as the illuminating sequence begins, the LEDs light up one after the other to form an illuminated bar, until the whole array is lit up.

Once the whole sequence ends, the entire bar is shut off and the cycle repeats all over again. To keep the LEDs hold their illuminations even with the sequencing logic going low, we would require some kind latching arrangement with the LEDs for implementing the trick. As we all know an SCR is one device which latches up its output pin outs when its gate is triggered. The function is available only with DC supplies though, and here the circuit being operated with a DC, becomes perfectly suitable for the above application.

Referring to the figure we see that all the output pin outs of the IC are configured to the gates of the corresponding SCRs, and the LED are connected across the positive and the anodes of the scr. When the IC outputs start generating the shifting pulses, the SCRs close one after the other, illuminating the LEDs in sequence and latch the illuminations in the incrementing order until the last LED is lit.

After this the whole array switches OFF. The switch-off feature of the LED chain is implemented by T3 and is introduced exactly for this function. T3 being a PNP transistor, remains switched ON as long as the output at pin #11 is low. Pin #11 being the last pin out in the whole sequence remains at logic low until the sequence concludes over it, making it also go high.

As soon as pin #11 becomes high, the base of T3 is inhibited from conduction, switching off the power to the LEDs and the SCR. The SCR latch breaks, shutting off the whole array and the sequence gets initiated again from LED 1 at pin #3.

Any astable multivibrator may be used for sourcing the clocks. Here we have used the common transistor type of AMV, which is perhaps the most simple to build and configure. The capacitor at the base of T3 is placed so that the transistor switches after a while, and allows the last LED at pin #11 to light up completely before the whole bar gets shut off.

🔗 External reference

The circuit design for the incremental LED bar graph involves several critical components and connections. The IC 4017 serves as the primary control unit, with its outputs connected to the gates of SCRs that manage the LED illumination. Each SCR corresponds to an LED, allowing it to latch on when triggered by the IC output. The configuration ensures that once a SCR is activated, the associated LED remains lit, creating a visual effect of a growing bar graph as each successive LED lights up in sequence.

To implement the timing and sequencing, a clock signal is generated by the astable multivibrator, which can be constructed using a simple transistor-based circuit. The frequency of the clock can be adjusted by varying the resistor and capacitor values in the multivibrator circuit, allowing for control over the speed of the LED sequence.

The PNP transistor (T3) plays a crucial role in managing the overall operation of the LED array. Its operation is dependent on the state of pin #11 of the IC 4017, which ensures that the entire LED array is powered only when the sequence is complete. The inclusion of a capacitor at the base of T3 allows for a brief delay, ensuring that the last LED has sufficient time to illuminate fully before the entire array shuts off, enhancing the visual appeal of the display.

This design not only showcases the capabilities of the IC 4017 in controlling LED sequences but also highlights the effectiveness of using SCRs for latching and maintaining illumination, resulting in a more engaging and visually dynamic LED bar graph display.The article describes a simple method of making an incremental LED bar graph by using the IC 4017, which is rather equipped with specifications not suiting the present functions. Let`s learn how we can mod the IC for the operations. Here we study an easy method of making an array of LEDs chase to develop into a sequential LED bar graph.

The LED s start from one of the 10 pin outs of the IC and go on switching one after the other until all the LEDs are lit forming an incrementing bar graph. The circuit uses the ordinary IC 4017 for implementing this interesting LED light sequence. The main component of this sequential LED driver circuit is the popular Johnson`s Decade Counter IC 4017.

As we all know, the normal functioning of the IC involves sequential shifting of its outputs 1 to 11, in response to a clock signal applied at its pin #14. The outputs become high in sequence such that the previous output becomes low immediately as the high position leaps through the assigned pi-outs.

If LEDs are connected to the outputs, the above sequence would produce an effect of an illuminated dot jumping from start to finish and repeating the sequence. Though the effect looks interesting, fails to bewitch the folks simply because the illuminations produced are very low.

This is because, only one LED or lamp glows at any instant while sequencing, not enough to make the system very eye-catching. However the sequencing factor of the IC cannot be ignored as it`s one complex function that cannot be achieved a single IC and the chip must be credited for this attribute.

So, what can we do to improve the above feature such that the engaged lights become more attractive and the sequencing feature is also exploited at the same time One idea would be to stop the former LEDs in the sequence from shutting down while the array is sequencing. It means now as the illuminating sequence begins, the LEDs light up one after the other to form an illuminated bar, until the whole array is lit up.

Once the whole sequence ends, the entire bar is shut off and the cycle repeats all over again. To keep the LEDs hold their illuminations even with the sequencing logic going low, we would require some kind latching arrangement with the LEDs for implementing the trick. As we all know an SCR is one device which latches up its output pin outs when its gate is triggered. The function is available only with DC supplies though, and here the circuit being operated with a DC, becomes perfectly suitable for the above application.

Referring to the figure we see that all the output pin outs of the IC are configured to the gates of the corresponding SCRs, and the LED are connected across the positive and the anodes of the scr. When the IC outputs start generating the shifting pulses, the SCRs close one after the other, illuminating the LEDs in sequence and latch the illuminations in the incrementing order until the last LED is lit.

After this the whole array switches OFF. The switch-off feature of the LED chain is implemented by T3 and is introduced exactly for this function. T3 being a PNP transistor, remains switched ON as long as the output at pin #11 is low. Pin #11 being the last pin out in the whole sequence remains at logic low until the sequence concludes over it, making it also go high.

As soon as pin #11 becomes high, the base of T3 is inhibited from conduction, switching off the power to the LEDs and the SCR. The SCR latch breaks, shutting off the whole array and the sequence gets initiated again from LED 1 at pin #3.

Any astable multivibrator may be used for sourcing the clocks. Here we have used the common transistor type of AMV, which is perhaps the most simple to build and configure. The capacitor at the base of T3 is placed so that the transistor switches after a while, and allows the last LED at pin #11 to light up completely before the whole bar gets shut off.

🔗 External reference