Simple Capacitive Touch Sensor

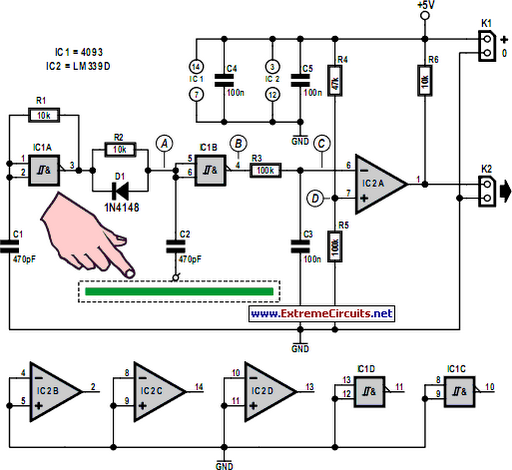

Capacitive touch sensors operate based on the electrical capacitance of the human body. When a finger approaches the sensor, it establishes a capacitance to Earth ranging from 30 to 100 pF. This phenomenon can be utilized for proximity detection and touch-controlled switching. Capacitive switches offer distinct advantages over other types of touch switches, such as those relying on 50 Hz or 60 Hz detection or resistance detection, though they are often more complex to implement. Manufacturers like Microchip have previously developed specialized integrated circuits (ICs) for this purpose. Nevertheless, it is feasible to create a reliable capacitive detector or switch using a limited number of standard components. This design detects changes in the pulse width of the signal when the contact is touched. In the schematic, the following stages can be identified from left to right: a square-wave generator operating at 300 kHz, utilizing a Schmitt trigger IC (CD4093); an RC network with a fly-back diode, followed by a Schmitt trigger/contact plate with an isolation capacitor of 470 pF; and an RC network that converts the pulse width change into a voltage. This voltage measures approximately 2.9-3.2 V when the plate is touched and 2.6 V when it is not. An LM339 comparator is employed to compare the voltage at point C with a reference voltage (D), which is set to about 2.8 V using a potential divider. The circuit output remains active as long as the contact plate is touched. To clarify the circuit operation, signals at various points are illustrated, with a dotted line representing the signal when the plate is touched and a solid line when it is not. The reference voltage at D must be calibrated via potential divider R4/R5 (by adjusting R4's value). The required reference voltage is highly dependent on the contact plate's surface area, typically a few square centimeters. Larger surfaces increase capacitance, resulting in a higher voltage at C when the plate is not touched, necessitating the reference voltage at D to be closer to 3.4 V for larger areas, such as the entire metal enclosure of a device. The circuit requires a connection to Earth for higher frequency operation (300 kHz) and does not function in battery-powered systems without such a connection. In many systems lacking a direct Earth connection, sufficient parasitic capacitance to mains Earth may be present. In certain scenarios, an additional capacitor may be required between the mains Earth and the circuit's ground, which must comply with safety regulations and be rated for over 3-4 kV (i.e., a Class Y capacitor). The output signal can be utilized in various ways to activate systems, and incorporating an additional Schmitt trigger at the output is advisable, particularly when connecting to a digital input.

Capacitive touch sensors leverage the inherent capacitance created by human contact to facilitate user interaction with electronic devices. The operational principle hinges on detecting variations in capacitance induced by the presence of a finger, which significantly alters the electrical characteristics of the sensor circuit. The design outlined employs a square-wave generator, specifically utilizing a CD4093 Schmitt trigger, to produce a stable 300 kHz signal. This frequency is crucial for maintaining sensitivity to changes in capacitance.

The RC network, consisting of resistors and capacitors, plays a vital role in shaping the response of the circuit. The inclusion of a fly-back diode protects against voltage spikes, ensuring the integrity of the circuit components. The isolation capacitor (470 pF) further enhances the stability of the measurements by isolating the sensor from noise and interference.

The conversion of pulse width changes into a voltage signal is a critical step, allowing the circuit to translate physical touch into an electrical signal that can be processed. The LM339 comparator is employed to compare this voltage against a predetermined reference voltage, which is adjustable based on the capacitance characteristics of the contact plate. The output from the comparator can trigger subsequent electronic actions, such as activating a relay or interfacing with microcontrollers.

The design considerations also emphasize safety, particularly when integrating capacitive touch sensors into devices that may be connected to mains power. The requirement for a Class Y capacitor ensures compliance with electrical safety standards, protecting users from potential electric shock hazards.

Overall, this capacitive touch sensor design exemplifies an effective approach to human-device interaction, balancing sensitivity, reliability, and safety within electronic systems.Capacitive touch sensors are based on the electrical capacitance of the human body. When, for example, a finger comes close to the sensor, it creates a capacitance to Earth with a value of 30 to 100 pF. This effect can be used for proximity detection and touch-controlled switching. Capacitive switches have clear advantages compared to other types of touch switches (for example 50 Hz or 60 Hz detection or resistance detection), but are often more complex to implement. Manufacturers such as Microchip have in the past designed specialist ICs for this purpose. However, it is still possible to design a reliable capacitive detector and/or switch using only a limited number of standard components.

In this design we detect the change in the pulsewidth of the signal when the contact is touched. In Figure 1 the following stages can be recognised, from left to right:- a square-wave generator with a frequency of 300 kHz, using a Schmitt trigger IC (CD4093); - an RC network with a fly-back diode, followed by a Schmitt trigger/contact plate with an isolation capacitor of 470 pF; - an RC network that converts the change in pulsewidth into a voltage. This voltage is about 2. 9-3. 2 V when the plate is touched (and 2. 6 V when it isn`t touched); - an LM339 comparator is used to compare the voltage at point C with a reference voltage (D).

The latter is set to about 2. 8 V using a potential divider. As long as the contact plate is touched the output of the circuit will be active. To make the operation of the circuit clearer we have shown the signals at various points in Figure 2. The dotted line represents the signal when the plate is touched, the solid line when it isn`t touched.

The reference voltage at D has to be set up once via potential divider R4/R5 (change the value of R4). The required value is strongly dependent on the surface area of the contact plate (this is usually a few square centimeters).

Larger surfaces increase the capacitance and the voltage at C will therefore be greater when the plate isn`t touched. The reference voltage at D should then be set closer to 3. 4 V. The touch sensor can therefore also be made to work with larger areas (such as the complete metal enclosure of a device).

The circuit only works when a connection for higher frequencies (300 kHz) is made to Earth in some way. The circuit therefore doesn`t work in battery-powered systems without a connection to Earth. In many systems without a direct connection to Earth there is sufficient parasitic capacitance to the mains Earth.

In some cases it will be necessary to add an extra capacitor between the mains Earth and the Ground of the circuit. To comply with safety regulations this capacitor should be rated for>3-4 kV (i. e. a Class Y capacitor). The output signal can be used in various ways to switch on systems. The addition of an extra Schmitt trigger to the output is recommended in many cases, especially if the output connects to a digital input.

🔗 External reference

Capacitive touch sensors leverage the inherent capacitance created by human contact to facilitate user interaction with electronic devices. The operational principle hinges on detecting variations in capacitance induced by the presence of a finger, which significantly alters the electrical characteristics of the sensor circuit. The design outlined employs a square-wave generator, specifically utilizing a CD4093 Schmitt trigger, to produce a stable 300 kHz signal. This frequency is crucial for maintaining sensitivity to changes in capacitance.

The RC network, consisting of resistors and capacitors, plays a vital role in shaping the response of the circuit. The inclusion of a fly-back diode protects against voltage spikes, ensuring the integrity of the circuit components. The isolation capacitor (470 pF) further enhances the stability of the measurements by isolating the sensor from noise and interference.

The conversion of pulse width changes into a voltage signal is a critical step, allowing the circuit to translate physical touch into an electrical signal that can be processed. The LM339 comparator is employed to compare this voltage against a predetermined reference voltage, which is adjustable based on the capacitance characteristics of the contact plate. The output from the comparator can trigger subsequent electronic actions, such as activating a relay or interfacing with microcontrollers.

The design considerations also emphasize safety, particularly when integrating capacitive touch sensors into devices that may be connected to mains power. The requirement for a Class Y capacitor ensures compliance with electrical safety standards, protecting users from potential electric shock hazards.

Overall, this capacitive touch sensor design exemplifies an effective approach to human-device interaction, balancing sensitivity, reliability, and safety within electronic systems.Capacitive touch sensors are based on the electrical capacitance of the human body. When, for example, a finger comes close to the sensor, it creates a capacitance to Earth with a value of 30 to 100 pF. This effect can be used for proximity detection and touch-controlled switching. Capacitive switches have clear advantages compared to other types of touch switches (for example 50 Hz or 60 Hz detection or resistance detection), but are often more complex to implement. Manufacturers such as Microchip have in the past designed specialist ICs for this purpose. However, it is still possible to design a reliable capacitive detector and/or switch using only a limited number of standard components.

In this design we detect the change in the pulsewidth of the signal when the contact is touched. In Figure 1 the following stages can be recognised, from left to right:- a square-wave generator with a frequency of 300 kHz, using a Schmitt trigger IC (CD4093); - an RC network with a fly-back diode, followed by a Schmitt trigger/contact plate with an isolation capacitor of 470 pF; - an RC network that converts the change in pulsewidth into a voltage. This voltage is about 2. 9-3. 2 V when the plate is touched (and 2. 6 V when it isn`t touched); - an LM339 comparator is used to compare the voltage at point C with a reference voltage (D).

The latter is set to about 2. 8 V using a potential divider. As long as the contact plate is touched the output of the circuit will be active. To make the operation of the circuit clearer we have shown the signals at various points in Figure 2. The dotted line represents the signal when the plate is touched, the solid line when it isn`t touched.

The reference voltage at D has to be set up once via potential divider R4/R5 (change the value of R4). The required value is strongly dependent on the surface area of the contact plate (this is usually a few square centimeters).

Larger surfaces increase the capacitance and the voltage at C will therefore be greater when the plate isn`t touched. The reference voltage at D should then be set closer to 3. 4 V. The touch sensor can therefore also be made to work with larger areas (such as the complete metal enclosure of a device).

The circuit only works when a connection for higher frequencies (300 kHz) is made to Earth in some way. The circuit therefore doesn`t work in battery-powered systems without a connection to Earth. In many systems without a direct connection to Earth there is sufficient parasitic capacitance to the mains Earth.

In some cases it will be necessary to add an extra capacitor between the mains Earth and the Ground of the circuit. To comply with safety regulations this capacitor should be rated for>3-4 kV (i. e. a Class Y capacitor). The output signal can be used in various ways to switch on systems. The addition of an extra Schmitt trigger to the output is recommended in many cases, especially if the output connects to a digital input.

🔗 External reference