Speed-Limit Alert

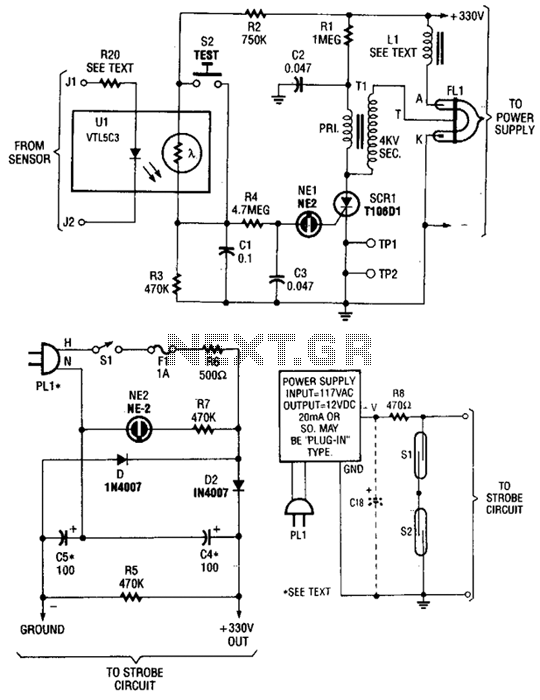

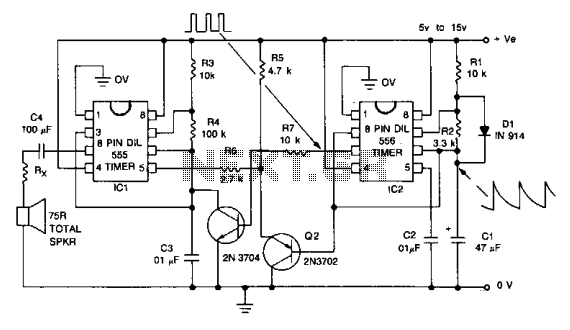

IC1 serves as a differential amplifier for the electromagnetic pulses produced by the engine's spark plugs, which are detected by sensor coil L1. IC2A amplifies these pulses further, while inverters IC2B to IC2F provide clean pulse squaring. The monostable multivibrator IC3A functions as a frequency discriminator, with pin 6 going high when the speed limit, determined by R11, is reached. IC3B, along with transistors and associated components, manages the timing for the signaling mechanism, which includes LED D5 and piezo sounder BZ1. D3 introduces a small amount of hysteresis. D1 is used during setup to monitor the spark plugs' emissions, aiding in the optimal placement of the device on or near the dashboard. After setup, D1 and R9 may be removed or turned off to conserve battery power. During the initial operation, R8 must be adjusted for optimal performance, typically achieving the best results when its value is between 10K and 20K ohms. The final adjustment can be made with the assistance of another person. While driving, the helper should adjust trimmer R11 until the beeper and LED D5 activate at the desired speed. Reducing the vehicle's speed should stop the beeping. L1 can be a 10mH small inductor typically found in a compact rectangular plastic casing. For increased sensitivity, a specialized coil can be constructed by winding 130 to 150 turns of 0.2 mm enameled wire around a 5 cm diameter form (such as a can). After winding, the coil should be removed from the form and secured with insulating tape to create a standalone coil. To test the circuit, temporarily disconnect C2 from pin 6 of IC1 and connect a signal generator output across C2 and ground. Set the generator frequency to approximately 100Hz and adjust R11 until beeping and LED D5 activation are observed. Reducing the frequency to 99 or 98Hz should result in the cessation of beeping and flashing.

The circuit described utilizes a combination of integrated circuits and passive components to effectively monitor engine speed through electromagnetic pulses generated by the spark plugs. The differential amplifier IC1 is critical for interpreting the weak signals from the sensor coil L1, allowing for the detection of engine activity. The subsequent amplification by IC2A ensures that the signals are strong enough for further processing. The inverters IC2B to IC2F serve to square the pulse signals, which is essential for accurate timing and triggering in the subsequent stages of the circuit.

The use of a monostable multivibrator, IC3A, as a frequency discriminator is a key feature, allowing the circuit to respond to specific frequency thresholds set by R11. This design choice enables the system to activate signaling components only when the vehicle reaches a predetermined speed, providing a practical application for speed monitoring.

The timing control provided by IC3B, along with the transistors and other components, ensures that the signaling mechanism operates effectively, generating audible and visual alerts through the piezo sounder BZ1 and LED D5. The inclusion of hysteresis through D3 allows for stable operation, preventing false triggering due to noise or fluctuations in the signal.

The setup procedure involving D1 is designed to facilitate optimal placement of the device, ensuring that it can accurately monitor the spark plug emissions. The ability to remove or disable D1 and R9 after setup enhances the circuit's efficiency and battery life.

The adjustment of R8 during initial operation is crucial for calibrating the sensitivity of the circuit, allowing it to respond appropriately to the engine's operational characteristics. The suggested range for R8 ensures that the circuit can accommodate variations in engine performance.

For those seeking enhanced sensitivity, the option to construct a custom coil provides flexibility in the design, enabling users to tailor the sensor's response to their specific needs. The detailed testing procedure with the signal generator offers a straightforward method for fine-tuning the circuit's performance, ensuring reliable operation when integrated into a vehicle.IC1 forms a differential amplifier for the electromagnetic pulses generated by the engine sparking-plugs, picked-up by sensor coil L1. IC2A further amplifies the pulses and IC2B to IC2F inverters provide clean pulse squaring. The monostable multivibrator IC3A is used as a frequency discriminator, its pin 6 going firmly high when speed limit (settl

ed by R11) is reached. IC3B, the transistors and associate components provide timings for the signaling part, formed by LED D5 and piezo sounder BZ1. D3 introduces a small amount of hysteresis. D1 is necessary at set-up to monitor the sparking-plugs emission, thus allowing to find easily the best placement for the device on the dashboard or close to it.

After the setting is done, D1 & R9 can be omitted or switched-off, with battery savings. During the preceding operation R8 must be adjusted for better results. The best setting of this trimmer is usually obtained when its value lies between 10 and 20K. The final simplest setting can be made with the help of a second person. Drive the vehicle and reach the speed needed. The helper must adjust the trimmer R11 until the device operates the beeper and D5. Reducing vehicle`s speed the beep must stop. L1 can be a 10mH small inductor usually sold in the form of a tiny rectangular plastic box. If you need an higher sensitivity you can build a special coil, winding 130 to 150 turns of 0. 2 mm. enameled wire on a 5 cm. diameter former (e. g. a can). Extract the coil from the former and tape it with insulating tape making thus a stand-alone coil. Temporarily disconnect C2 from IC1 pin 6. Connect the generator output across C2 and Ground. Set the generator frequency to e. g. 100Hz and trim R11 until you will hear the beeps and LED D5 will start flashing. Reducing the frequency to 99 or 98 Hz, beeping and flashing must stop. 🔗 External reference

The circuit described utilizes a combination of integrated circuits and passive components to effectively monitor engine speed through electromagnetic pulses generated by the spark plugs. The differential amplifier IC1 is critical for interpreting the weak signals from the sensor coil L1, allowing for the detection of engine activity. The subsequent amplification by IC2A ensures that the signals are strong enough for further processing. The inverters IC2B to IC2F serve to square the pulse signals, which is essential for accurate timing and triggering in the subsequent stages of the circuit.

The use of a monostable multivibrator, IC3A, as a frequency discriminator is a key feature, allowing the circuit to respond to specific frequency thresholds set by R11. This design choice enables the system to activate signaling components only when the vehicle reaches a predetermined speed, providing a practical application for speed monitoring.

The timing control provided by IC3B, along with the transistors and other components, ensures that the signaling mechanism operates effectively, generating audible and visual alerts through the piezo sounder BZ1 and LED D5. The inclusion of hysteresis through D3 allows for stable operation, preventing false triggering due to noise or fluctuations in the signal.

The setup procedure involving D1 is designed to facilitate optimal placement of the device, ensuring that it can accurately monitor the spark plug emissions. The ability to remove or disable D1 and R9 after setup enhances the circuit's efficiency and battery life.

The adjustment of R8 during initial operation is crucial for calibrating the sensitivity of the circuit, allowing it to respond appropriately to the engine's operational characteristics. The suggested range for R8 ensures that the circuit can accommodate variations in engine performance.

For those seeking enhanced sensitivity, the option to construct a custom coil provides flexibility in the design, enabling users to tailor the sensor's response to their specific needs. The detailed testing procedure with the signal generator offers a straightforward method for fine-tuning the circuit's performance, ensuring reliable operation when integrated into a vehicle.IC1 forms a differential amplifier for the electromagnetic pulses generated by the engine sparking-plugs, picked-up by sensor coil L1. IC2A further amplifies the pulses and IC2B to IC2F inverters provide clean pulse squaring. The monostable multivibrator IC3A is used as a frequency discriminator, its pin 6 going firmly high when speed limit (settl

ed by R11) is reached. IC3B, the transistors and associate components provide timings for the signaling part, formed by LED D5 and piezo sounder BZ1. D3 introduces a small amount of hysteresis. D1 is necessary at set-up to monitor the sparking-plugs emission, thus allowing to find easily the best placement for the device on the dashboard or close to it.

After the setting is done, D1 & R9 can be omitted or switched-off, with battery savings. During the preceding operation R8 must be adjusted for better results. The best setting of this trimmer is usually obtained when its value lies between 10 and 20K. The final simplest setting can be made with the help of a second person. Drive the vehicle and reach the speed needed. The helper must adjust the trimmer R11 until the device operates the beeper and D5. Reducing vehicle`s speed the beep must stop. L1 can be a 10mH small inductor usually sold in the form of a tiny rectangular plastic box. If you need an higher sensitivity you can build a special coil, winding 130 to 150 turns of 0. 2 mm. enameled wire on a 5 cm. diameter former (e. g. a can). Extract the coil from the former and tape it with insulating tape making thus a stand-alone coil. Temporarily disconnect C2 from IC1 pin 6. Connect the generator output across C2 and Ground. Set the generator frequency to e. g. 100Hz and trim R11 until you will hear the beeps and LED D5 will start flashing. Reducing the frequency to 99 or 98 Hz, beeping and flashing must stop. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713