switching ac loads triac

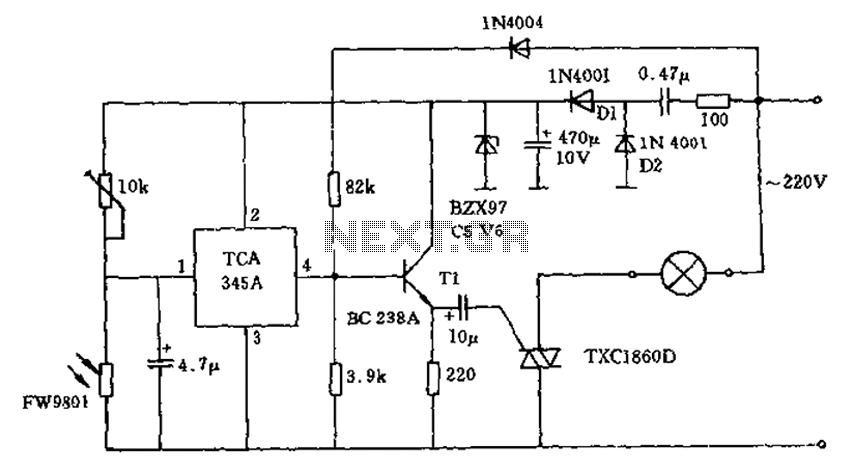

A circuit is needed to control a couple of large AC solenoid valves and several single-phase AC motors. The line voltage is 132VAC, with the solenoids drawing 1A and the motors drawing 13A and 27A when operating. The goal is to accomplish this using triacs, which are more cost-effective than relays. The intention is to simplify the design by eliminating the need for snubber circuits and other protective components like MOVs. The loads will be driven by 5V logic from a PIC microcontroller, which is compatible with many models designed for switching high inductance loads, typically accepting input voltages from 3 to 32 VDC without requiring additional current limiting resistors. It is important to consider electrical code compliance when working with line voltage and motors connected to the grid, including motor overload protection, which may be required in certain jurisdictions for a 1hp single-phase setup. Although contactors and motor overload devices are available, they can be relatively inexpensive, often costing only a few tens of dollars, and provide a robust solution. Proper wire sizing, fuses, or breakers rated for the load are essential for safety. While overload devices are generally underutilized in small homeowner-operated devices, a thermal-type motor overload protection controller can be obtained for approximately $35, offering a means to disconnect and preventing damage to motors. Adhering to electrical codes is crucial for safety, even in DIY projects. The user has experience with Automation Direct products but seeks a smaller solution, as the PCB designed to replace a PLC is compact and cost-efficient. The remaining challenge is the size of the contactor, prompting the consideration of triacs, which occupy less space and could potentially be mounted directly onto the PCB. PCB mount relays may also be a viable option to reduce cost and size.

To implement a circuit that controls large AC solenoid valves and single-phase AC motors using triacs, the following schematic components and considerations should be taken into account:

1. **Power Supply**: The circuit will operate at a line voltage of 132VAC. Ensure the power supply can handle the total current draw from the solenoids and motors, which can peak at 27A during operation.

2. **Triac Selection**: Choose triacs rated for higher than the maximum load current. For instance, a triac rated for at least 40A would provide a safety margin. Snubberless triacs can be advantageous as they reduce the need for external snubber circuits.

3. **Microcontroller Interface**: The PIC microcontroller will output control signals at 5V logic levels. Opto-isolators can be used to interface the microcontroller with the triacs, providing electrical isolation and protecting the microcontroller from high voltage spikes.

4. **Protection Components**: Although the intention is to avoid complex protection schemes, include necessary components such as fuses rated for the load current and MOVs for transient voltage suppression. Consider including a thermal overload relay for the motors to prevent damage from overheating.

5. **PCB Design**: Design the PCB to accommodate the triacs and other components. Ensure that traces are sufficiently wide to handle the load current, and consider thermal management to dissipate heat generated by the triacs during operation.

6. **Relay Options**: If triacs do not meet size or performance needs, explore PCB mount relays that can switch AC loads. These relays should also be rated appropriately for the load current and voltage.

7. **Compliance with Electrical Codes**: Ensure that the design adheres to local electrical codes, especially concerning safety features like overload protection and proper disconnect means for the motors.

8. **Testing and Validation**: After assembling the circuit, conduct thorough testing to ensure reliable operation under load conditions. Monitor temperature rise in components to ensure safe operation.

By following these guidelines, a compact and efficient circuit can be designed to control AC solenoid valves and motors using triacs, while also adhering to safety standards and electrical codes.A circuit to turn on/off a couple of big AC solenoid valves and a couple of 1ph ac motors. my line v is 132VAC and the solenoids measure 1A and the motors measure 13A and 27A once running. does anyone know how to do this with triacs they are much cheaper than relays. I have found much info on "snubberless", "alternistors", etc. I just want to make this as easy and simple as possible and this seems to eliminate the sizing and selection of "snubber circuit" and other protection components like MOV. I ultimately need to drive these loads from 5V logic from a pic microcontroller. They are premade and many models are specifically built for switching high inductance loads. The typical input is 3 -32 VDC and no additional current limiting resistor is needed. There are also some electrical code issues to consider when working with line voltage and motors, if you are connected to the grid.

Also, in case of a problem, you might be interested in motor overload protection. I am not sure if it would be code required at 1hp single phase in your jurisdiction. and buying a contactor and motor overload. You will be able to get away with spending only a few tens of dollars, and will have a durable solution. The contactors there cost not much more than a triac. Use the correct size of wire for the load and distance it is from the power source and use fuses or breakers that are rated for the size of load you are running.

Overload devices are great but rarely used on small home owner operated devices. a full thermal type motor overload protection controller costs about the same as a standard 1 hp motor. they used too. but now you can get one for $35 with a "means to disconnect. " Depending on your application, that might be nice insurance to avoid burning out a $110 motor. Just a heads up, just in case. Code is not just for it`s own sake. It is logical rules for safety. Those safety rules are still in play, even in a homeowner project. I always follow the code, even if I don`t need to get inspected. thanks everyone for replying, and i am familiar with automation direct. that is what i am using right now. the problem is the size. I have the pcb to replace a plc, and it is a fraction of the cost and size for my project. now that that is done, the contactor is the largest component left and I want it to be smaller, thereby leading me to "triacs" which seem very small in comparison and I could put it right on to the pcb.

maybe a pcb mount relay is the way to go here to save cost and size 🔗 External reference

To implement a circuit that controls large AC solenoid valves and single-phase AC motors using triacs, the following schematic components and considerations should be taken into account:

1. **Power Supply**: The circuit will operate at a line voltage of 132VAC. Ensure the power supply can handle the total current draw from the solenoids and motors, which can peak at 27A during operation.

2. **Triac Selection**: Choose triacs rated for higher than the maximum load current. For instance, a triac rated for at least 40A would provide a safety margin. Snubberless triacs can be advantageous as they reduce the need for external snubber circuits.

3. **Microcontroller Interface**: The PIC microcontroller will output control signals at 5V logic levels. Opto-isolators can be used to interface the microcontroller with the triacs, providing electrical isolation and protecting the microcontroller from high voltage spikes.

4. **Protection Components**: Although the intention is to avoid complex protection schemes, include necessary components such as fuses rated for the load current and MOVs for transient voltage suppression. Consider including a thermal overload relay for the motors to prevent damage from overheating.

5. **PCB Design**: Design the PCB to accommodate the triacs and other components. Ensure that traces are sufficiently wide to handle the load current, and consider thermal management to dissipate heat generated by the triacs during operation.

6. **Relay Options**: If triacs do not meet size or performance needs, explore PCB mount relays that can switch AC loads. These relays should also be rated appropriately for the load current and voltage.

7. **Compliance with Electrical Codes**: Ensure that the design adheres to local electrical codes, especially concerning safety features like overload protection and proper disconnect means for the motors.

8. **Testing and Validation**: After assembling the circuit, conduct thorough testing to ensure reliable operation under load conditions. Monitor temperature rise in components to ensure safe operation.

By following these guidelines, a compact and efficient circuit can be designed to control AC solenoid valves and motors using triacs, while also adhering to safety standards and electrical codes.A circuit to turn on/off a couple of big AC solenoid valves and a couple of 1ph ac motors. my line v is 132VAC and the solenoids measure 1A and the motors measure 13A and 27A once running. does anyone know how to do this with triacs they are much cheaper than relays. I have found much info on "snubberless", "alternistors", etc. I just want to make this as easy and simple as possible and this seems to eliminate the sizing and selection of "snubber circuit" and other protection components like MOV. I ultimately need to drive these loads from 5V logic from a pic microcontroller. They are premade and many models are specifically built for switching high inductance loads. The typical input is 3 -32 VDC and no additional current limiting resistor is needed. There are also some electrical code issues to consider when working with line voltage and motors, if you are connected to the grid.

Also, in case of a problem, you might be interested in motor overload protection. I am not sure if it would be code required at 1hp single phase in your jurisdiction. and buying a contactor and motor overload. You will be able to get away with spending only a few tens of dollars, and will have a durable solution. The contactors there cost not much more than a triac. Use the correct size of wire for the load and distance it is from the power source and use fuses or breakers that are rated for the size of load you are running.

Overload devices are great but rarely used on small home owner operated devices. a full thermal type motor overload protection controller costs about the same as a standard 1 hp motor. they used too. but now you can get one for $35 with a "means to disconnect. " Depending on your application, that might be nice insurance to avoid burning out a $110 motor. Just a heads up, just in case. Code is not just for it`s own sake. It is logical rules for safety. Those safety rules are still in play, even in a homeowner project. I always follow the code, even if I don`t need to get inspected. thanks everyone for replying, and i am familiar with automation direct. that is what i am using right now. the problem is the size. I have the pcb to replace a plc, and it is a fraction of the cost and size for my project. now that that is done, the contactor is the largest component left and I want it to be smaller, thereby leading me to "triacs" which seem very small in comparison and I could put it right on to the pcb.

maybe a pcb mount relay is the way to go here to save cost and size 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713