Tachometer-and-direction-of-rotation-circuit

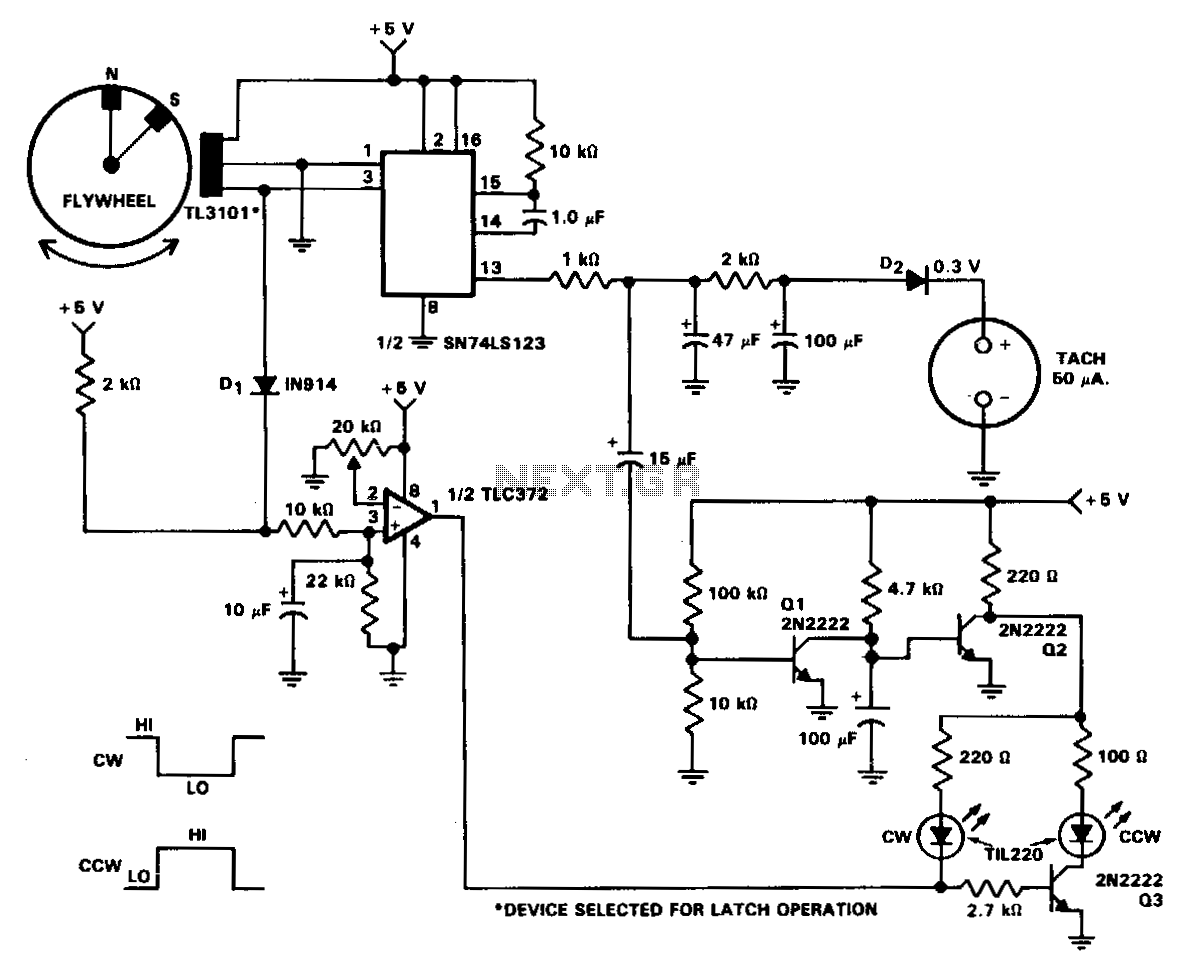

In machine and equipment design, certain applications necessitate the measurement of both shaft speed and direction of rotation. The circuit of a tachometer, which also indicates the direction of rotation, is illustrated. A flywheel is equipped with two magnets embedded in the outer rim, spaced approximately 45 degrees apart. One magnet has its north pole facing outward, while the other magnet has its south pole facing the outer rim of the flywheel. Due to the arrangement of the magnets, a short pulse is generated by the TL3101 in one direction and a longer pulse in the opposite direction. A 0-50 µA meter is employed to monitor the flywheel speed, while LEDs indicate the direction of rotation. The direction-of-rotation circuit consists of three components: a TLC372 device for input conditioning and reference adjustment, two 2N2222 transistors that supply Vee to the two LEDs as required, and two TIL220 LEDs that indicate clockwise (CW) or counterclockwise (CCW) rotation.

The tachometer circuit is an essential component in various applications where precise control and monitoring of rotational speed and direction are critical. The flywheel, which serves as the rotating element, is strategically designed with two magnets positioned at a 45-degree angle to create distinct magnetic fields. This configuration allows for the differentiation of rotational direction based on the duration of the output pulses generated by the TL3101 integrated circuit.

The TL3101 is a precision timing circuit that responds to the magnetic field changes as the flywheel rotates. When the north pole of the first magnet passes the sensor, it generates a short pulse, whereas the south pole of the second magnet generates a longer pulse when it passes. This pulse width modulation effectively indicates the direction of rotation, providing valuable feedback for control systems.

The output from the TL3101 is routed to a TLC372 device, which functions as an input conditioning stage. This stage is crucial for filtering and amplifying the signal, ensuring that it meets the necessary thresholds for further processing. The TLC372 also allows for reference adjustments, which can be fine-tuned to optimize performance based on specific application requirements.

The output from the TLC372 is then fed into two 2N2222 transistors. These transistors act as switches, controlling the application of the Vee supply to the corresponding TIL220 LEDs. The TIL220 LEDs are used to visually indicate the direction of rotation. When the circuit detects a clockwise rotation, one LED illuminates, while the opposite LED lights up for counterclockwise rotation. This visual feedback is essential in applications where operators need to quickly ascertain the direction of movement without relying solely on numerical displays.

In summary, the described tachometer circuit not only measures the speed of the flywheel but also provides a clear indication of the direction of rotation through a well-structured combination of magnetic sensing, signal conditioning, and visual output. This design is particularly valuable in automation, robotics, and other fields where precise rotational control is required.In machine and equipment design. some applications require measurement of both the shaft speed and the direction of rotation. Fig. 56-4 shows the circuit of a tachometer, which also indicates the direction of rotation. The flywheel has two magnets embedded in the outer rim about 45° apart. One magnet has the north pole toward the outside and the other magnet has the south pole toward the outside rim of the flywheel. Because of the magnet spacing, a short on pulse is produced by the TL3101 in one direction and a long on pulse in the other direction. A 0-50 JLA meter is used to monitor the flywheel speed while the LEDs indicate the direction of rotation.

The direction-of-rotation circuit can be divided into three parts: TLC372 device for input conditioning and reference adjustment. Two 2N2222 transistors which apply the Vee to the two LEDs when needed. The two TIL220 LEDs which indicate clockwise (CW) or counterclockwise (CCW) direction of rotation.

The tachometer circuit is an essential component in various applications where precise control and monitoring of rotational speed and direction are critical. The flywheel, which serves as the rotating element, is strategically designed with two magnets positioned at a 45-degree angle to create distinct magnetic fields. This configuration allows for the differentiation of rotational direction based on the duration of the output pulses generated by the TL3101 integrated circuit.

The TL3101 is a precision timing circuit that responds to the magnetic field changes as the flywheel rotates. When the north pole of the first magnet passes the sensor, it generates a short pulse, whereas the south pole of the second magnet generates a longer pulse when it passes. This pulse width modulation effectively indicates the direction of rotation, providing valuable feedback for control systems.

The output from the TL3101 is routed to a TLC372 device, which functions as an input conditioning stage. This stage is crucial for filtering and amplifying the signal, ensuring that it meets the necessary thresholds for further processing. The TLC372 also allows for reference adjustments, which can be fine-tuned to optimize performance based on specific application requirements.

The output from the TLC372 is then fed into two 2N2222 transistors. These transistors act as switches, controlling the application of the Vee supply to the corresponding TIL220 LEDs. The TIL220 LEDs are used to visually indicate the direction of rotation. When the circuit detects a clockwise rotation, one LED illuminates, while the opposite LED lights up for counterclockwise rotation. This visual feedback is essential in applications where operators need to quickly ascertain the direction of movement without relying solely on numerical displays.

In summary, the described tachometer circuit not only measures the speed of the flywheel but also provides a clear indication of the direction of rotation through a well-structured combination of magnetic sensing, signal conditioning, and visual output. This design is particularly valuable in automation, robotics, and other fields where precise rotational control is required.In machine and equipment design. some applications require measurement of both the shaft speed and the direction of rotation. Fig. 56-4 shows the circuit of a tachometer, which also indicates the direction of rotation. The flywheel has two magnets embedded in the outer rim about 45° apart. One magnet has the north pole toward the outside and the other magnet has the south pole toward the outside rim of the flywheel. Because of the magnet spacing, a short on pulse is produced by the TL3101 in one direction and a long on pulse in the other direction. A 0-50 JLA meter is used to monitor the flywheel speed while the LEDs indicate the direction of rotation.

The direction-of-rotation circuit can be divided into three parts: TLC372 device for input conditioning and reference adjustment. Two 2N2222 transistors which apply the Vee to the two LEDs when needed. The two TIL220 LEDs which indicate clockwise (CW) or counterclockwise (CCW) direction of rotation.