Thyristor Tester

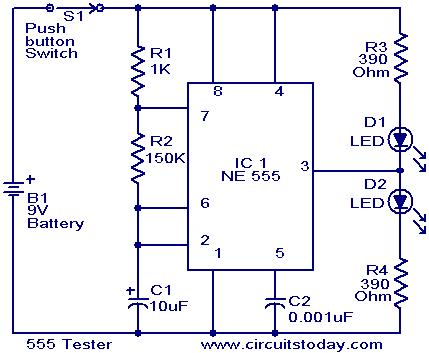

The circuit diagram represents a useful tool for quickly testing various types of thyristors, including silicon-controlled rectifiers (SCRs) and triacs. For triacs, all four quadrants are assessed using switch S3, while testing a standard thyristor requires the adjustment of a positive power supply and trigger current via switch S1. Resistors R1 and R2 are selected to provide a current of approximately 28 mA, which is typically sufficient for most thyristors. The holding current, determined by resistor R3, is set at 125 mA, ensuring adequate conduction after triggering. The circuit includes a red low-current LED (D1) and a green low-current LED (D2) to indicate the conducting quadrant of the thyristor. Testing is initiated with switch S2, and the circuit can be reset using switch S4 after testing. Connector K1 features three short wires with insulated crocodile clips, facilitating connections to various thyristors. Proper connections are crucial: for a triac, MT1/A1 connects to ground, the gate connects to S2, and MT2/A2 connects to R3; for a standard thyristor, the anode connects to R3, the cathode connects to ground, and the gate connects to S2. If necessary, the trigger current can be adjusted by changing the values of resistors R1 and R3. Additionally, a variable power supply can be used to modify the trigger current, with caution to ensure resistor dissipation limits are not exceeded.

The thyristor testing circuit is designed with versatility and user-friendliness in mind. The inclusion of switch S3 allows for comprehensive testing of triacs across all quadrants, which is essential for applications where bidirectional control is required. The configuration of the circuit with S1 for standard thyristors ensures that the user can easily switch between different types of thyristors without complex adjustments.

Resistors R1 and R2 are critical components that set the testing current, and their values must be carefully calculated to ensure that 28 mA is achieved without exceeding the power ratings of the resistors. The choice of a holding current of 125 mA via R3 provides a reliable operational threshold for maintaining conduction in the thyristor post-triggering, which is vital for applications that require stable operation after initial activation.

The use of two LEDs (D1 and D2) not only provides visual feedback but also enhances the circuit's usability by allowing quick identification of the conducting state. This feature is particularly useful in educational settings or during troubleshooting processes, where rapid assessment is necessary.

The circuit's reset functionality via S4 ensures that tests can be conducted repeatedly without manual disconnection and reconnection of the components, enhancing efficiency. The crocodile clips on connector K1 offer a practical solution for connecting various thyristors, simplifying the testing process while minimizing the risk of incorrect connections.

In cases where specific testing conditions are required, the ability to modify the trigger current by adjusting R1 and R3 or using a variable power supply adds a layer of adaptability to the circuit. This flexibility is especially beneficial for advanced users who may need to test thyristors under varying conditions to evaluate performance or troubleshoot issues effectively. Careful attention must be paid to resistor ratings to prevent overheating, particularly when using higher currents or variable supplies. Overall, this thyristor testing circuit is a well-thought-out design that caters to both basic and advanced testing needs in electronic applications.The circuit in the diagram is a very handy tool for rapidly checking all kinds of thyristor (SCR, triac, ). In case of a triac, all four quadrants are tested, which is done with S3, while in case of a standard thyristor, a positive power supply and trigger current need to be set, which is done with S1.

The value of resistors R1 and R2 is chosen to obtain a current of about 28 mA, which is more than sufficient for most thyristors. The hold current is determined by R3, and is 125 mA, which is more than adequate to keep the thyristor in conduction after it has been triggered. Since D1 is a red, low-current LED, and D2 a green, low-current LED, it can be seen in a wink in which quadrant the thyristor conducts.

Testing is started with S2, and the circuit is reset with S4 after the test has been concluded. Three short lengths of circuit wire terminated into insulated crocodile clips on connector K1 will be found very convenient for linking any kind of thyristor to the circuit. Mind correct connections, though: in the case of a triac, MT1/A1 is linked to earth, the gate to S2 and MT2/A2 to R3; in the case of a standard thyristor, the anode is linked to R3, the cathode to earth, and the gate to S2.

If, in a rare case the trigger current needs to be altered, this can be done by changing the value of resistors R1 R3 as appropriate. The trigger current may also be made variable by the use of a variable power supply. If that is done, make sure that the dissipation in the resistors is not exceeded. 🔗 External reference

The thyristor testing circuit is designed with versatility and user-friendliness in mind. The inclusion of switch S3 allows for comprehensive testing of triacs across all quadrants, which is essential for applications where bidirectional control is required. The configuration of the circuit with S1 for standard thyristors ensures that the user can easily switch between different types of thyristors without complex adjustments.

Resistors R1 and R2 are critical components that set the testing current, and their values must be carefully calculated to ensure that 28 mA is achieved without exceeding the power ratings of the resistors. The choice of a holding current of 125 mA via R3 provides a reliable operational threshold for maintaining conduction in the thyristor post-triggering, which is vital for applications that require stable operation after initial activation.

The use of two LEDs (D1 and D2) not only provides visual feedback but also enhances the circuit's usability by allowing quick identification of the conducting state. This feature is particularly useful in educational settings or during troubleshooting processes, where rapid assessment is necessary.

The circuit's reset functionality via S4 ensures that tests can be conducted repeatedly without manual disconnection and reconnection of the components, enhancing efficiency. The crocodile clips on connector K1 offer a practical solution for connecting various thyristors, simplifying the testing process while minimizing the risk of incorrect connections.

In cases where specific testing conditions are required, the ability to modify the trigger current by adjusting R1 and R3 or using a variable power supply adds a layer of adaptability to the circuit. This flexibility is especially beneficial for advanced users who may need to test thyristors under varying conditions to evaluate performance or troubleshoot issues effectively. Careful attention must be paid to resistor ratings to prevent overheating, particularly when using higher currents or variable supplies. Overall, this thyristor testing circuit is a well-thought-out design that caters to both basic and advanced testing needs in electronic applications.The circuit in the diagram is a very handy tool for rapidly checking all kinds of thyristor (SCR, triac, ). In case of a triac, all four quadrants are tested, which is done with S3, while in case of a standard thyristor, a positive power supply and trigger current need to be set, which is done with S1.

The value of resistors R1 and R2 is chosen to obtain a current of about 28 mA, which is more than sufficient for most thyristors. The hold current is determined by R3, and is 125 mA, which is more than adequate to keep the thyristor in conduction after it has been triggered. Since D1 is a red, low-current LED, and D2 a green, low-current LED, it can be seen in a wink in which quadrant the thyristor conducts.

Testing is started with S2, and the circuit is reset with S4 after the test has been concluded. Three short lengths of circuit wire terminated into insulated crocodile clips on connector K1 will be found very convenient for linking any kind of thyristor to the circuit. Mind correct connections, though: in the case of a triac, MT1/A1 is linked to earth, the gate to S2 and MT2/A2 to R3; in the case of a standard thyristor, the anode is linked to R3, the cathode to earth, and the gate to S2.

If, in a rare case the trigger current needs to be altered, this can be done by changing the value of resistors R1 R3 as appropriate. The trigger current may also be made variable by the use of a variable power supply. If that is done, make sure that the dissipation in the resistors is not exceeded. 🔗 External reference