Voltage regulator or resistors to change voltages for motors

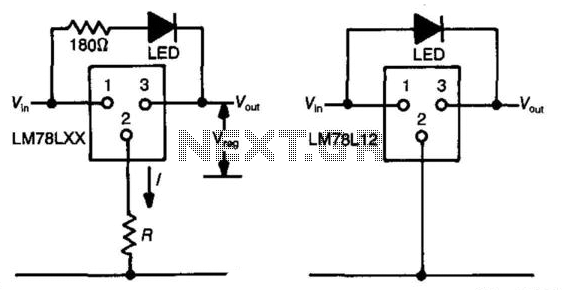

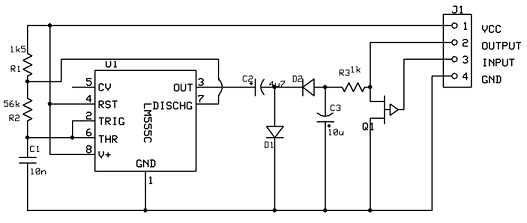

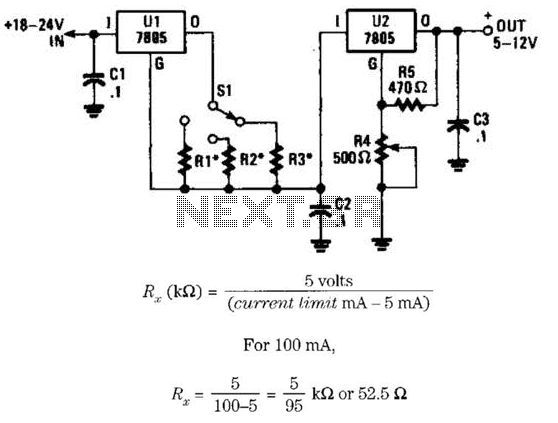

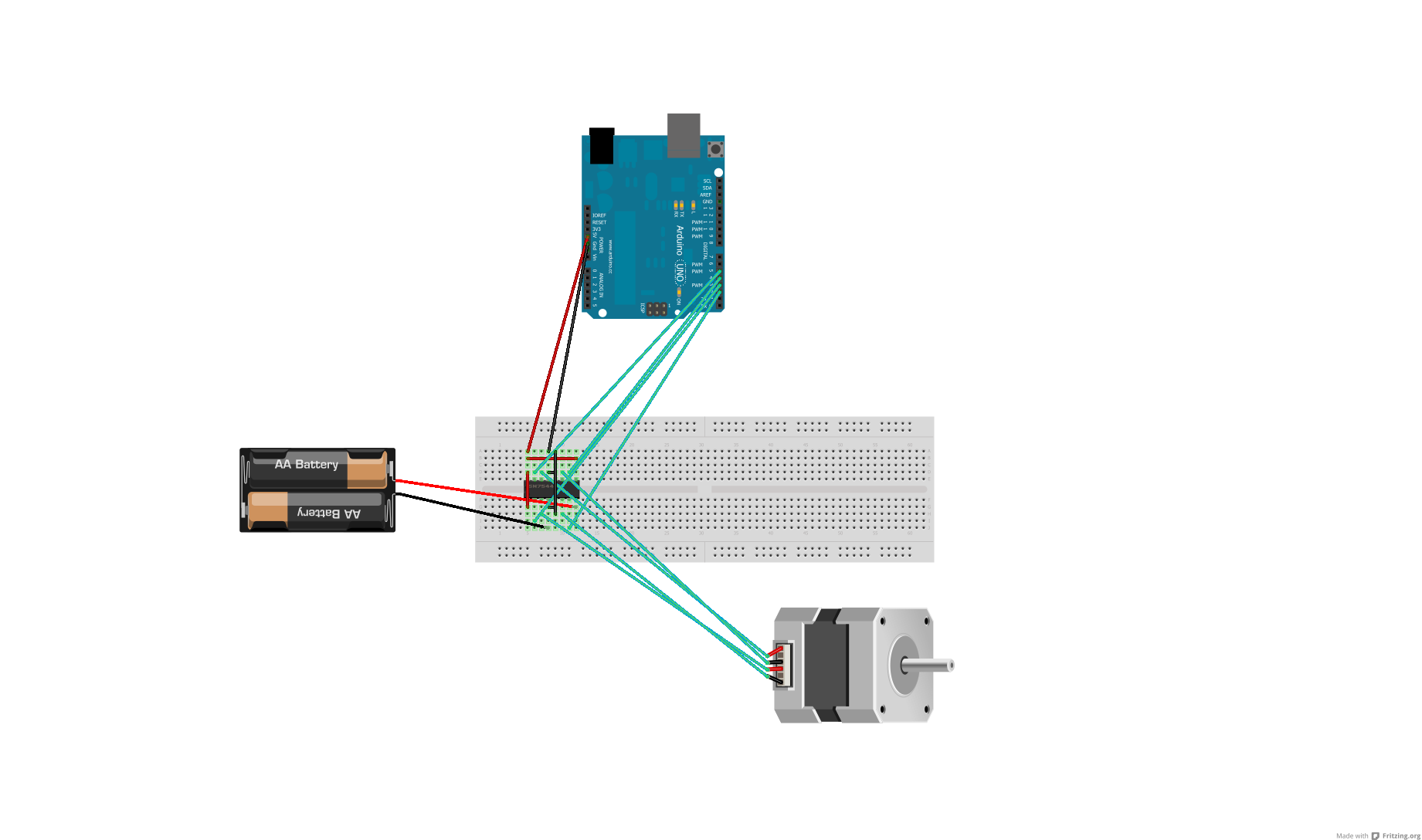

After conducting some research, it was found that voltage can be adjusted using either a voltage regulator chip or resistors. Several scenarios require reducing the voltage for motors, prompting a question about the appropriate method for each application. An H-Bridge is used to drive a bipolar stepper motor rated at 3.1V, and there is a need to change the stepper motor's speed. It is unclear whether the H-Bridge in this circuit reduces the voltage as necessary to adjust the motor's speed or if it simply allows for rotation in either direction at a constant speed. Additionally, a 7.2V DC motor is driven with PWM output. The power and ground of the PWM are expected to be wired to the motor's 7.2V power supply, while the signal wire connects to one of the Arduino's ports. This motor also requires speed adjustment. Although the intention is to use resistors for all voltage adjustments, it has been noted that resistors may not be suitable if the connected device, such as a motor that needs to change speeds, is involved. For the stepper motor, the inputs should be wired to an H-Bridge using a 3V power supply (2 AA cells in series). While a separate power supply for the stepper motor is planned to simplify the setup, a question arises about using a resistor to drop 9V to 7.2V to supply power to an H-Bridge connected to the stepper motor if both were powered by the same source (6 AA cells). For the 7.2V DC motor, an H-Bridge could be used to pulse 7.2V to the power and ground of the PWM, while the signal wire would control the motor's speed. The suitability of using resistors to drop 9V to 7.2V and pulse the signal wire for speed control is uncertain, particularly regarding the issue of resistors dropping varying amounts of voltage based on motor load. There is also consideration of using several 12V golf cart batteries with the 7.2V DC motor and a 12V air compressor, although concerns about the amperage exceeding the appliances' capacity exist. The goal is to reduce reliance on AA/9V batteries, which have become costly. A diagram exists for the 7.2V motors and 12V air compressor, but the method to drop the voltage to 7.2V remains unclear. The LM317 adjustable voltage regulator was considered, but it can only handle currents up to 1.5A, while the planned motor has a stall torque of 3.6A. The motor is not a servo but is connected to a 3-wire motor controller that uses a standard PWM signal to drive the motor. The plan is to connect the 7.2V power supply to the power and ground of the motor controller and link the motor controller's signal wire to an Arduino port.

In this circuit design, voltage regulation is a critical aspect, particularly when dealing with motors that require variable speeds. The use of an H-Bridge is appropriate for controlling the bipolar stepper motor, as it allows for bidirectional control and speed modulation through PWM signals. The H-Bridge can effectively manage the voltage supplied to the motor, ensuring that it operates within its rated specifications.

For the bipolar stepper motor rated at 3.1V, it is essential to ensure that the H-Bridge is supplied with an appropriate voltage that can be modulated to achieve the desired performance. The power supply for the H-Bridge should be selected based on the stepper motor's requirements, and it may be beneficial to use a dedicated power source to avoid any fluctuations that could affect performance.

The 7.2V DC motor, driven by PWM, requires careful consideration of the connections to ensure proper functionality. The PWM signal should be connected to the appropriate input on the motor controller, and the power supply must be capable of delivering sufficient current to meet the motor's stall requirements. Given the stall torque of 3.6A, it is crucial to select a power supply that can handle this load, as the LM317 voltage regulator would be inadequate for this application.

In scenarios where voltage needs to be dropped, using resistors is generally not advisable for motors that require speed control due to their load-dependent voltage drop characteristics. Instead, a more reliable method, such as using a buck converter or a more robust voltage regulator capable of handling higher currents, should be considered. This would ensure consistent voltage delivery regardless of load variations.

When integrating the 12V golf cart batteries into the system, it is vital to ensure that the motor controller and motors are rated for the input voltage. The concern regarding the amperage output of the batteries exceeding the motor's capacity can be mitigated by incorporating appropriate current limiting measures within the circuit design.

Overall, careful planning of the power supply, voltage regulation, and motor control strategy is essential for the successful implementation of this motor control application. Properly selecting components and understanding the operational requirements will lead to a more efficient and effective circuit design.After doing a little research I found out that I can change voltage by either using a voltage regulator chip or resistors. I have a couple different scenarios in which I`ll have to drop the voltage for my motors and I was wondering which method to use for each application.

I`m using an H-Bridge to drive a bipolar stepper motor rated at 3. 1V. I nee d the stepper motor`s speed to change. Does the H-Bridge in this circuit drop the voltages as necessary to change the motors speed or is it simply able to rotate in either direction at a constant speed Driving a 7. 2V DC motor with a PWM output ( ). I believe I`m supposed to wire up the power and ground of the PWM to the motor`s 7. 2V power supply and wire the signal wire to one of the Arduino`s ports. This motor would also have to change speed. Although I`d like to use resistors for all of my voltage drops/increases I believe I read somewhere that it cant be used if the appliance its connected to has to change voltages (ex.

a motor that needs to change speeds. ) Stepper Motor - Wire the inputs to an H bridge with a 3v power supply. (2 AA cells in series) Although I`m planning on giving the stepper motor a seperate power supply to simply things, if I were to run it off the same power source (6 AA cells) as the Arduino, can I use a resistor to drop 9v to 7. 2v and than supply that power to an H-bridge Which would than be connected to the stepper motor. 7. 2V DC Motor - Use an h-bridge to pulse 7. 2V to the power and ground of the PWM and pulse the signal wire to control the motors speed Or can I use resistors to drop 9v to 7.

2v and than simply pulse the signal wire to control the speed I`m not sure if the problem with the resistors dropping varying amounts of voltage depending on the motor`s load would persist in this scenario. (Kind of similar to the stepper motor scenario except I`m pulsing the motor through a PWM motor controller instead of an H-bridge.

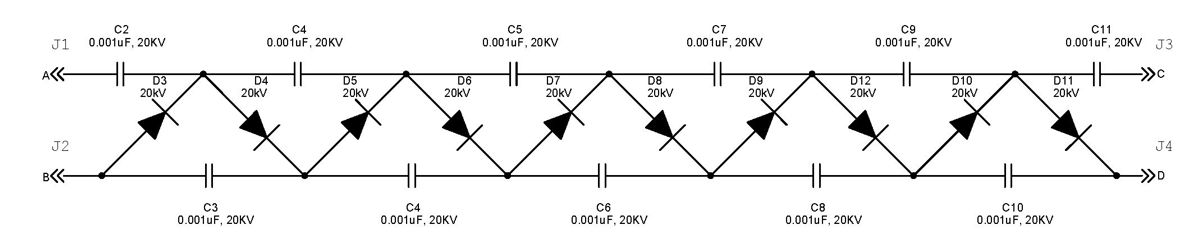

) I actually have several 12v golf cart batteries which can be found here. If I were to use this, it would be with the 7. 2V DC Motor and 12V Air Compressor. (The Stepper Motor is going on a moving vehicle which is way too weak to carry the battery. ) I was thinking about using these batteries but I thought the amperes it gives out would far exceed what any of my appliances can handle. It`d be awesome if I can use this though! I`m constantly going through AA/9v batteries and its been getting quite expensive. This is the diagram for the 7. 2V motors and 12V air compressor. The batteries shown there is actually a ~12V car battery. I`m still trying to figure out how I`m supposed to drop the voltage to 7. 2. I looked at the LM317 adjustable voltage regulator but it can only handle current up to 1. 5A and the motor I`m planning on using has a stall torque of 3. 6A. The motor I`m using is NOT a servo but it`s connected to a 3-wire motor controller ( which uses a standard PWM signal to drive the motor.

My plan is to connect the 7. 2V power supply to the power and ground of the motor controller and to connect the motor controller`s signal wire to one of the Arduino`s ports. 🔗 External reference

In this circuit design, voltage regulation is a critical aspect, particularly when dealing with motors that require variable speeds. The use of an H-Bridge is appropriate for controlling the bipolar stepper motor, as it allows for bidirectional control and speed modulation through PWM signals. The H-Bridge can effectively manage the voltage supplied to the motor, ensuring that it operates within its rated specifications.

For the bipolar stepper motor rated at 3.1V, it is essential to ensure that the H-Bridge is supplied with an appropriate voltage that can be modulated to achieve the desired performance. The power supply for the H-Bridge should be selected based on the stepper motor's requirements, and it may be beneficial to use a dedicated power source to avoid any fluctuations that could affect performance.

The 7.2V DC motor, driven by PWM, requires careful consideration of the connections to ensure proper functionality. The PWM signal should be connected to the appropriate input on the motor controller, and the power supply must be capable of delivering sufficient current to meet the motor's stall requirements. Given the stall torque of 3.6A, it is crucial to select a power supply that can handle this load, as the LM317 voltage regulator would be inadequate for this application.

In scenarios where voltage needs to be dropped, using resistors is generally not advisable for motors that require speed control due to their load-dependent voltage drop characteristics. Instead, a more reliable method, such as using a buck converter or a more robust voltage regulator capable of handling higher currents, should be considered. This would ensure consistent voltage delivery regardless of load variations.

When integrating the 12V golf cart batteries into the system, it is vital to ensure that the motor controller and motors are rated for the input voltage. The concern regarding the amperage output of the batteries exceeding the motor's capacity can be mitigated by incorporating appropriate current limiting measures within the circuit design.

Overall, careful planning of the power supply, voltage regulation, and motor control strategy is essential for the successful implementation of this motor control application. Properly selecting components and understanding the operational requirements will lead to a more efficient and effective circuit design.After doing a little research I found out that I can change voltage by either using a voltage regulator chip or resistors. I have a couple different scenarios in which I`ll have to drop the voltage for my motors and I was wondering which method to use for each application.

I`m using an H-Bridge to drive a bipolar stepper motor rated at 3. 1V. I nee d the stepper motor`s speed to change. Does the H-Bridge in this circuit drop the voltages as necessary to change the motors speed or is it simply able to rotate in either direction at a constant speed Driving a 7. 2V DC motor with a PWM output ( ). I believe I`m supposed to wire up the power and ground of the PWM to the motor`s 7. 2V power supply and wire the signal wire to one of the Arduino`s ports. This motor would also have to change speed. Although I`d like to use resistors for all of my voltage drops/increases I believe I read somewhere that it cant be used if the appliance its connected to has to change voltages (ex.

a motor that needs to change speeds. ) Stepper Motor - Wire the inputs to an H bridge with a 3v power supply. (2 AA cells in series) Although I`m planning on giving the stepper motor a seperate power supply to simply things, if I were to run it off the same power source (6 AA cells) as the Arduino, can I use a resistor to drop 9v to 7. 2v and than supply that power to an H-bridge Which would than be connected to the stepper motor. 7. 2V DC Motor - Use an h-bridge to pulse 7. 2V to the power and ground of the PWM and pulse the signal wire to control the motors speed Or can I use resistors to drop 9v to 7.

2v and than simply pulse the signal wire to control the speed I`m not sure if the problem with the resistors dropping varying amounts of voltage depending on the motor`s load would persist in this scenario. (Kind of similar to the stepper motor scenario except I`m pulsing the motor through a PWM motor controller instead of an H-bridge.

) I actually have several 12v golf cart batteries which can be found here. If I were to use this, it would be with the 7. 2V DC Motor and 12V Air Compressor. (The Stepper Motor is going on a moving vehicle which is way too weak to carry the battery. ) I was thinking about using these batteries but I thought the amperes it gives out would far exceed what any of my appliances can handle. It`d be awesome if I can use this though! I`m constantly going through AA/9v batteries and its been getting quite expensive. This is the diagram for the 7. 2V motors and 12V air compressor. The batteries shown there is actually a ~12V car battery. I`m still trying to figure out how I`m supposed to drop the voltage to 7. 2. I looked at the LM317 adjustable voltage regulator but it can only handle current up to 1. 5A and the motor I`m planning on using has a stall torque of 3. 6A. The motor I`m using is NOT a servo but it`s connected to a 3-wire motor controller ( which uses a standard PWM signal to drive the motor.

My plan is to connect the 7. 2V power supply to the power and ground of the motor controller and to connect the motor controller`s signal wire to one of the Arduino`s ports. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713