Winds from the 555 programmed

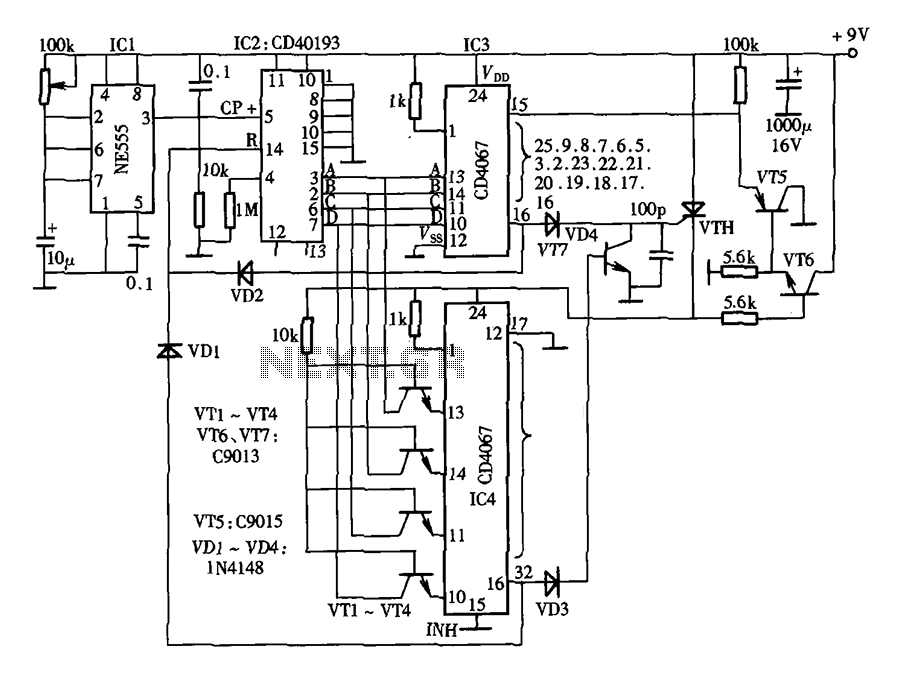

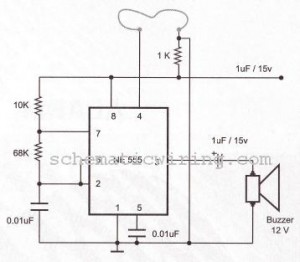

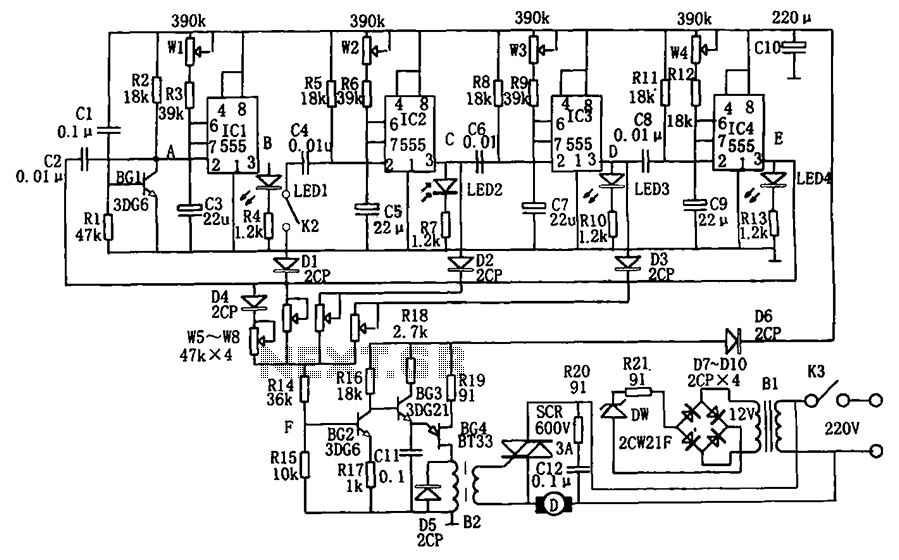

The circuit depicted in the figure is a wind speed programmable circuit. It includes a step-down rectifier circuit, a multi-stage cycle timing circuit, a phase shift control circuit, and a thyristor control circuit. The buck rectifier provides a DC voltage to the controller. The multi-level timing loop is centered around a 555 timer integrated circuit (IC). Upon powering on, the startup circuit composed of R1, C1, and BG1 generates a negative pulse applied to the trigger terminal of IC1 (555), initiating the delay circuit formed by IC1, W1, R3, and C3, which produces a high output. The corresponding delay time, td1, is approximately 1.1 (Rw1 + R3) C3, with parameters indicating a timing range of about 0.6 to 10 seconds. During this time, C3 charges, and when the voltage across C3 reaches 2/3 of VDD, IC1 resets, resulting in a low output from pin 3 of IC1. This low output is then fed through R5 to the trigger pin of IC2, causing its timing circuit to transition from high to low output. The states of IC3 and IC4 change similarly. When the output from pin 3 of IC4 transitions from high to low (indicating the expiration of the delay), this feedback is sent to the trigger terminal of IC1, repeating the process to sequentially activate LEDs ED1, LED2, LED3, and LED4, with only one LED lit at any given time. The phase shift control circuit comprises components BG2 to BG4. The outputs from cycle timer IC2, IC3, and IC4 are routed through W5, W7, and W8 to the control circuit, allowing adjustments to t2, t3, and t4 periods, which correspond to the voltage values applied to each BG2. With the minimum resistance setting on the potentiometer, BG2 receives the maximum input voltage, resulting in the motor voltage being close to 220V, thereby achieving maximum fan wind speed. Conversely, with maximum resistance on each potentiometer, the fan wind speed reaches its minimum. By tuning potentiometers W5 to W8 to different positions, the varying periods create differences in motor speed, simulating a natural wind effect. Adjustments to W1 to W4 allow for control over the duration of the wind speed changes.

The wind speed programmable circuit operates by integrating several critical components to achieve precise control over fan speed. The step-down rectifier serves as the initial stage, converting AC voltage to a stable DC voltage, which is essential for the subsequent control circuits. The core timing mechanism utilizes the 555 timer IC, which is renowned for its versatility in generating precise time delays and oscillations. The configuration of resistors and capacitors surrounding the 555 timer determines the timing intervals, allowing for a customizable range of wind speeds.

The multi-stage cycle timing circuit employs a series of 555 timers (IC1, IC2, IC3, and IC4), each configured in a monostable mode to create a cascading effect. As each timer completes its set delay, it triggers the next stage, leading to a sequential activation of the output devices. This design ensures that the fan operates in a rhythmic pattern, mimicking natural wind variations, which can enhance comfort in various applications.

The phase shift control circuit, consisting of BG2 to BG4, provides additional modulation of the output voltage to the fan motor. By adjusting the potentiometers (W5, W7, and W8), the user can influence the duration of the voltage application to each phase, thereby controlling the speed and behavior of the fan motor. This capability allows for fine-tuning of the wind speed to suit specific environmental conditions or user preferences.

Overall, the design of this wind speed programmable circuit emphasizes flexibility and user control, making it suitable for applications where variable air movement is desired. The integration of timing circuits with phase control enhances the functionality, providing a sophisticated solution for managing fan speeds in various settings. As shown in FIG wind speed programmable circuit. The circuit consists of step-down rectifier circuit, a multi-stage cycle timing circuit, phase shift control circuit, thyristor control circuit. Wherein the circuit is a buck rectifier provides a DC voltage across the controller.Multi-level loop by the timing circuit 555 as the core component of the four single stable circuit. Just power on, the start-up circuit R1, C1 and BG1 composition generates a negative pulse applied to IC1 (555) of the trigger terminal ( feet), so that the delay circuit consists of IC1, W1, R3, C3 composed happen set, the output high.

Corresponding to the delay time td1 1.1 (Rw1 + R3) C3, illustrated parameters corresponding time is about 0.6 to 10 seconds. In the meantime, C3 is charged when the voltage on C3 charge to make IC1 foot to reach 2/3VDD when, IC1 reset occurs, a low level output by C4 3 feet, after R5 differential added to IC2 feet, IC2 corresponding timing circuit occurs due feet set, output high to low.

IC3, IC4 state change of the same. When the output from the IC4 3 feet high into low (delay expires) when it is fed back to the trigger terminal of IC1 feet, repeat the process in order to achieve multi-heap Fan thin 5 Mi Van braid barium meal Bru joint of bones intestinal worm ED1, LED2, LED3, LED4 sequentially lit, and at any one time only one light.Phase shift control circuit consists of BG2 ~ BG4 composition. Cycle timer IC2, IC3, IC4 output through W5, W7, W8 applied to the control circuit, adjusting W5, W7, W8, may be changed accordingly t2, t3, t4 period applied to each voltage value BG2.

When the minimum potentiometer resistance, that is applied to the BG2 maximum input voltage, this time near both ends of the motor voltage of 220V, the fan has a maximum wind speed; maximum when the resistance of each potentiometer, the corresponding minimum fan wind speed. When each potentiometer W5 ~ W8 tune in a different location, because each level is inconsistent period, the motor speed operation, to achieve a similar effect of natural wind.

Adjust W1 ~ W4, for different lengths of time can be controlled to achieve the rate of change of wind speed rhythm to adjust.

The wind speed programmable circuit operates by integrating several critical components to achieve precise control over fan speed. The step-down rectifier serves as the initial stage, converting AC voltage to a stable DC voltage, which is essential for the subsequent control circuits. The core timing mechanism utilizes the 555 timer IC, which is renowned for its versatility in generating precise time delays and oscillations. The configuration of resistors and capacitors surrounding the 555 timer determines the timing intervals, allowing for a customizable range of wind speeds.

The multi-stage cycle timing circuit employs a series of 555 timers (IC1, IC2, IC3, and IC4), each configured in a monostable mode to create a cascading effect. As each timer completes its set delay, it triggers the next stage, leading to a sequential activation of the output devices. This design ensures that the fan operates in a rhythmic pattern, mimicking natural wind variations, which can enhance comfort in various applications.

The phase shift control circuit, consisting of BG2 to BG4, provides additional modulation of the output voltage to the fan motor. By adjusting the potentiometers (W5, W7, and W8), the user can influence the duration of the voltage application to each phase, thereby controlling the speed and behavior of the fan motor. This capability allows for fine-tuning of the wind speed to suit specific environmental conditions or user preferences.

Overall, the design of this wind speed programmable circuit emphasizes flexibility and user control, making it suitable for applications where variable air movement is desired. The integration of timing circuits with phase control enhances the functionality, providing a sophisticated solution for managing fan speeds in various settings. As shown in FIG wind speed programmable circuit. The circuit consists of step-down rectifier circuit, a multi-stage cycle timing circuit, phase shift control circuit, thyristor control circuit. Wherein the circuit is a buck rectifier provides a DC voltage across the controller.Multi-level loop by the timing circuit 555 as the core component of the four single stable circuit. Just power on, the start-up circuit R1, C1 and BG1 composition generates a negative pulse applied to IC1 (555) of the trigger terminal ( feet), so that the delay circuit consists of IC1, W1, R3, C3 composed happen set, the output high.

Corresponding to the delay time td1 1.1 (Rw1 + R3) C3, illustrated parameters corresponding time is about 0.6 to 10 seconds. In the meantime, C3 is charged when the voltage on C3 charge to make IC1 foot to reach 2/3VDD when, IC1 reset occurs, a low level output by C4 3 feet, after R5 differential added to IC2 feet, IC2 corresponding timing circuit occurs due feet set, output high to low.

IC3, IC4 state change of the same. When the output from the IC4 3 feet high into low (delay expires) when it is fed back to the trigger terminal of IC1 feet, repeat the process in order to achieve multi-heap Fan thin 5 Mi Van braid barium meal Bru joint of bones intestinal worm ED1, LED2, LED3, LED4 sequentially lit, and at any one time only one light.Phase shift control circuit consists of BG2 ~ BG4 composition. Cycle timer IC2, IC3, IC4 output through W5, W7, W8 applied to the control circuit, adjusting W5, W7, W8, may be changed accordingly t2, t3, t4 period applied to each voltage value BG2.

When the minimum potentiometer resistance, that is applied to the BG2 maximum input voltage, this time near both ends of the motor voltage of 220V, the fan has a maximum wind speed; maximum when the resistance of each potentiometer, the corresponding minimum fan wind speed. When each potentiometer W5 ~ W8 tune in a different location, because each level is inconsistent period, the motor speed operation, to achieve a similar effect of natural wind.

Adjust W1 ~ W4, for different lengths of time can be controlled to achieve the rate of change of wind speed rhythm to adjust.