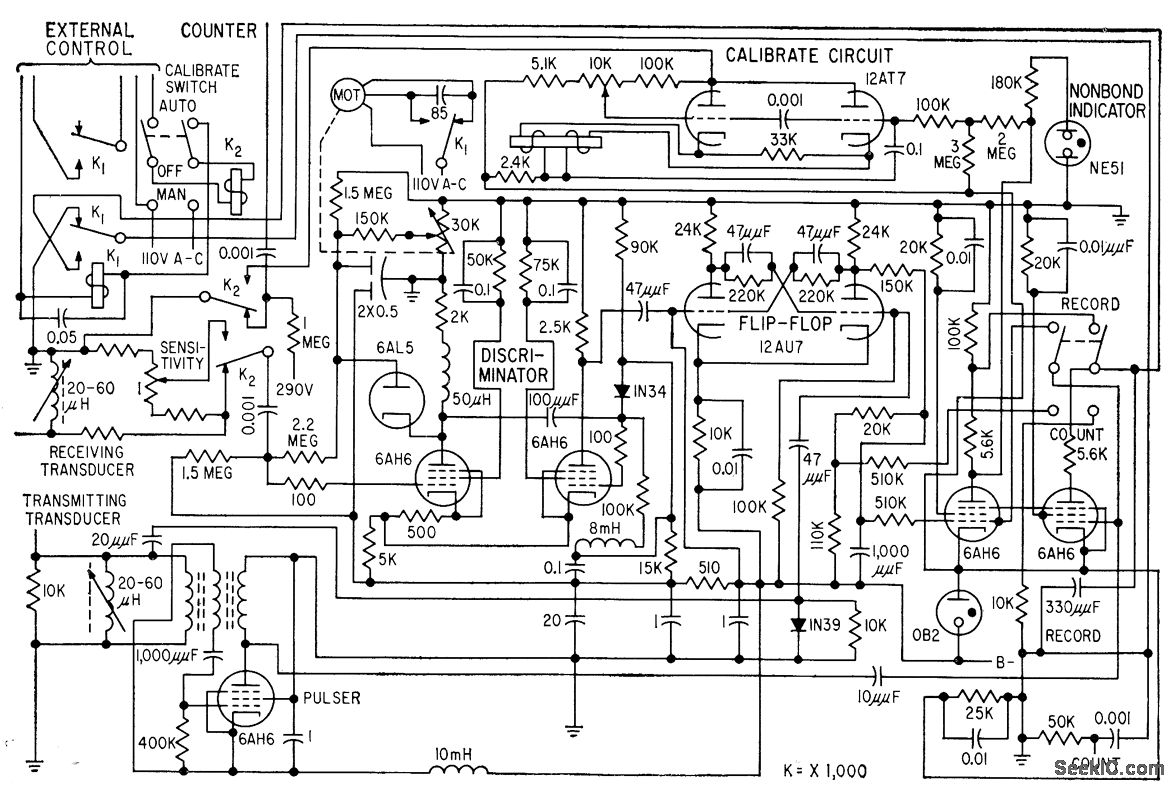

900 KC FLAW DETECTOR

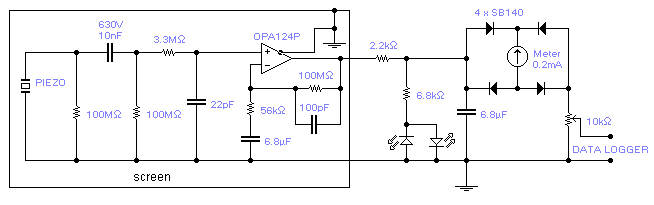

The attenuation of ultrasonic pulses transmitted through a test piece indicates the presence and extent of internal defects, such as non-bonds between aluminum cladding and a uranium core. The test piece and transducers are submerged in water to ensure effective coupling for a 900-kc ultrasonic wave generated by a barium titanate transducer from the pulser. A motor adjusts the discriminator threshold to match the signal received from the attenuator.

The ultrasonic testing setup described involves the use of a barium titanate transducer, which is known for its piezoelectric properties, allowing it to convert electrical energy into ultrasonic waves effectively. The transducer emits ultrasonic pulses at a frequency of 900 kHz, which are transmitted through the test piece. The water medium serves as a coupling agent, enhancing the transmission of ultrasonic waves by minimizing acoustic impedance mismatch between the transducer and the test piece.

As the ultrasonic waves propagate through the test piece, they encounter various internal structures and defects. When these waves meet a defect, such as a non-bond between the aluminum cladding and the uranium core, they are attenuated or reflected, depending on the nature of the defect. The attenuation of these pulses is critical for determining the size and extent of internal flaws.

The received signals are processed by an attenuator, which reduces the amplitude of the incoming signals to a manageable level. A motor-driven discriminator then adjusts its threshold to match the amplitude of the signals received from the attenuator. This threshold adjustment is essential for accurately distinguishing between valid signals and noise, ensuring that only relevant data regarding potential defects is analyzed.

In summary, this ultrasonic testing method provides a non-destructive approach to inspect the integrity of materials used in critical applications, such as nuclear reactors, by identifying internal flaws that could compromise safety and performance.Attenuation of ultrasonic pulses boomed through test piece reveals presence and extent of internal defects, such as nonbonds between aluminum cladding and uranium core. Test piece and transducers are submerged in water to provide good coupling for 900-kc ultrasonic wave from barium titanate transducer of pulser.

Motor sets discriminator threshold to equal signal received from attenuator. -J. D. Ross and R. W. Leep, Ultrasonic Pulses Detect Reactor-Slug Flaws, Electronics, 31:25, p 59-61. 🔗 External reference

The ultrasonic testing setup described involves the use of a barium titanate transducer, which is known for its piezoelectric properties, allowing it to convert electrical energy into ultrasonic waves effectively. The transducer emits ultrasonic pulses at a frequency of 900 kHz, which are transmitted through the test piece. The water medium serves as a coupling agent, enhancing the transmission of ultrasonic waves by minimizing acoustic impedance mismatch between the transducer and the test piece.

As the ultrasonic waves propagate through the test piece, they encounter various internal structures and defects. When these waves meet a defect, such as a non-bond between the aluminum cladding and the uranium core, they are attenuated or reflected, depending on the nature of the defect. The attenuation of these pulses is critical for determining the size and extent of internal flaws.

The received signals are processed by an attenuator, which reduces the amplitude of the incoming signals to a manageable level. A motor-driven discriminator then adjusts its threshold to match the amplitude of the signals received from the attenuator. This threshold adjustment is essential for accurately distinguishing between valid signals and noise, ensuring that only relevant data regarding potential defects is analyzed.

In summary, this ultrasonic testing method provides a non-destructive approach to inspect the integrity of materials used in critical applications, such as nuclear reactors, by identifying internal flaws that could compromise safety and performance.Attenuation of ultrasonic pulses boomed through test piece reveals presence and extent of internal defects, such as nonbonds between aluminum cladding and uranium core. Test piece and transducers are submerged in water to provide good coupling for 900-kc ultrasonic wave from barium titanate transducer of pulser.

Motor sets discriminator threshold to equal signal received from attenuator. -J. D. Ross and R. W. Leep, Ultrasonic Pulses Detect Reactor-Slug Flaws, Electronics, 31:25, p 59-61. 🔗 External reference