A tube amplifier 01 HI-FI

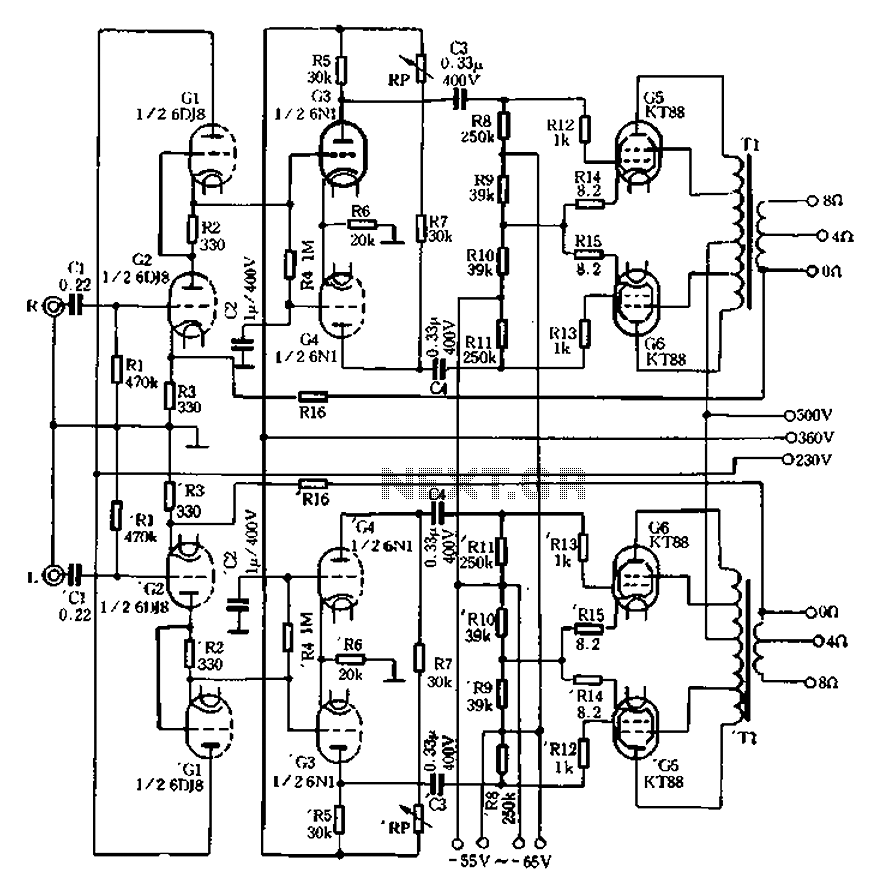

Due to the use of high-quality materials and advanced technology, the output transformer of the machine achieves a frequency response ranging from 10Hz (0.8dB) to 50Hz (1dB), enhancing overall performance. The aircraft power supply voltage section, illustrated in Figure 1-42, consists of three rectifier bridges made from four 1N4007 diodes. Resistors R1 and R2, along with capacitors C1, C2, C3, and C4, are configured to prevent uneven overvoltage caused by partial pressure. The design incorporates high-voltage electrical delay control using normally open contact groups. Resistor R3 is utilized as a power resistor; due to the voltage levels (500V, 360V, and 140V) present between the relay K1 output and the transistor VT1, R3 is implemented to reduce the voltage requirement for the VT1 tube, with R3 set to 60V (40mA). Resistor R4 is rated at 82kΩ, while capacitor C6 is 10µF, which is employed to minimize output grain. Diodes VD13 to VD15 form a regulator circuit, stabilizing the voltage to approximately 360V. Transistors VT1 and VT2 are configured in a Darlington arrangement to enhance voltage regulation. Capacitors C7 and C9 serve as filters for high-frequency noise, while R3, R5, and R6 share power distribution, with R5 set to 1.5kΩ and R6 to 82kΩ. The transistors VT1 and VT2 are high-voltage power transistors (2SC3306), and VT3 is a power transistor (2SC3743).

The circuit described operates within a power supply system designed for aircraft applications, where reliability and performance are critical. The output transformer’s frequency response is particularly notable for its low distortion across the specified range, which is essential for audio and signal integrity in high-fidelity applications. The rectifier bridges, constructed from 1N4007 diodes, are robust components capable of handling high reverse voltages, ensuring that the system can operate under various load conditions without failure.

The configuration of resistors and capacitors plays a vital role in maintaining voltage stability and preventing overshoot during transient conditions. The use of a Darlington pair (VT1 and VT2) provides a high current gain, allowing the circuit to drive loads more effectively while maintaining a stable output voltage. The choice of high-voltage transistors (2SC3306 and 2SC3743) indicates that the circuit is designed to handle significant power levels, making it suitable for demanding applications.

The filtering capacitors (C7 and C9) are strategically placed to mitigate high-frequency noise that could interfere with the performance of the power supply. This noise filtering is crucial in sensitive electronic environments, such as those found in aircraft systems, where electromagnetic interference can adversely affect operation.

Overall, the circuit exemplifies advanced engineering practices, utilizing high-quality components and thoughtful design to achieve a reliable and efficient power supply solution for aviation applications.As a result of high quality materials and advanced technology, the machine output transformer frequency response can reach 10Hz (a 0.8dB) ~ 50Hz (a ldB), to improve the overall index basis. Aircraft power supply voltage section shown in Figure 1-42 in each group, three rectifier bridges are constituted by the four 1N4007, Rl ,. R2 is Cl, C2. C3 and C4 are resistors, two capacitors connected in series in order to prevent Because a partial pressure caused by uneven overvoltage.

Following is used to achieve high-voltage electrical delay control, the machine uses its normally open contact groups. R3 is power resistors, since the relay Kl output between the output and the VT1 have 500v - 360V-140V pressure, so affixed R3 to reduce the requirements for VT1 tube, R3 take 60V (40mA a R4 taken 82kn C6 take lO fiF.

It used to reduce grain output .VD13 ~ VD15 crossing the regulator diode, electrical voltage to around 360V o VT1, VT2 connected in Darlington form, to get a better voltage regulation review C7 and C9 filter high frequency wave capacitors, and R3 taken o.lrdrFpR5 like to share power, R5 taken 1.5kfl.R6 take 82kfl + C7 with R4 a C 5.VT1, VT2 uses high-voltage power transistor 2SC3306, VT3 as the power transistor 2SC3743

The circuit described operates within a power supply system designed for aircraft applications, where reliability and performance are critical. The output transformer’s frequency response is particularly notable for its low distortion across the specified range, which is essential for audio and signal integrity in high-fidelity applications. The rectifier bridges, constructed from 1N4007 diodes, are robust components capable of handling high reverse voltages, ensuring that the system can operate under various load conditions without failure.

The configuration of resistors and capacitors plays a vital role in maintaining voltage stability and preventing overshoot during transient conditions. The use of a Darlington pair (VT1 and VT2) provides a high current gain, allowing the circuit to drive loads more effectively while maintaining a stable output voltage. The choice of high-voltage transistors (2SC3306 and 2SC3743) indicates that the circuit is designed to handle significant power levels, making it suitable for demanding applications.

The filtering capacitors (C7 and C9) are strategically placed to mitigate high-frequency noise that could interfere with the performance of the power supply. This noise filtering is crucial in sensitive electronic environments, such as those found in aircraft systems, where electromagnetic interference can adversely affect operation.

Overall, the circuit exemplifies advanced engineering practices, utilizing high-quality components and thoughtful design to achieve a reliable and efficient power supply solution for aviation applications.As a result of high quality materials and advanced technology, the machine output transformer frequency response can reach 10Hz (a 0.8dB) ~ 50Hz (a ldB), to improve the overall index basis. Aircraft power supply voltage section shown in Figure 1-42 in each group, three rectifier bridges are constituted by the four 1N4007, Rl ,. R2 is Cl, C2. C3 and C4 are resistors, two capacitors connected in series in order to prevent Because a partial pressure caused by uneven overvoltage.

Following is used to achieve high-voltage electrical delay control, the machine uses its normally open contact groups. R3 is power resistors, since the relay Kl output between the output and the VT1 have 500v - 360V-140V pressure, so affixed R3 to reduce the requirements for VT1 tube, R3 take 60V (40mA a R4 taken 82kn C6 take lO fiF.

It used to reduce grain output .VD13 ~ VD15 crossing the regulator diode, electrical voltage to around 360V o VT1, VT2 connected in Darlington form, to get a better voltage regulation review C7 and C9 filter high frequency wave capacitors, and R3 taken o.lrdrFpR5 like to share power, R5 taken 1.5kfl.R6 take 82kfl + C7 with R4 a C 5.VT1, VT2 uses high-voltage power transistor 2SC3306, VT3 as the power transistor 2SC3743