Baseball

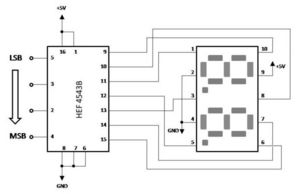

The objective of this project was to create an interactive baseball game inspired by pinball mechanics. The game features a solenoid-powered bat and a pitching mechanism that employs a motor and lever arm arrangement. Both components are controlled by buttons, allowing two players to compete against each other. The game includes targets for scoring singles, doubles, triples, and home runs, utilizing a simple photodiode-phototransistor circuit to detect the ball. LEDs illuminate each base, and a scoreboard consists of two seven-segment displays along with LEDs indicating outs. The design mimics a slanted surface similar to a pinball machine, where the ball rolls down, and players attempt to hit it back up into the scoring zones. These scoring areas are equipped with dampening backstops and milled grooves to direct the ball into a designated hole containing a sensor. If the ball does not land in any scoring zone, it rolls back toward the bat and into an out hole, minimizing the number of holes and sensors required. Rails along the playfield prevent the ball from exiting the designated area. Beneath the playfield, an inclined board channels the ball back to the pitching mechanism. The housing features sides for mounting the bat button and preventing the ball from escaping the recess. An acrylic sheet serves as the rear wall, with cutouts for pitching and scoreboard display. The bat, crafted from wood using a band saw and sanded to finish, has two drilled holes: one for anchoring and another for attaching an actuator. A spring-return solenoid powered by two 9.6V rechargeable batteries in series actuates the bat. The user interface consists of a standard push button located on the right side of the game, similar to traditional pinball buttons. To enhance the baseball experience, a system is implemented to allow the user to swing only once per pitched ball. For pitching, an RS385 motor and scooping arm are utilized. The motor is connected to a 9.6V battery from the kit. Upon activation, the arm rotates upward until it makes contact with a static bar. A lever switch attached to this bar sends a pulse to the PIC microcontroller, indicating that a pitch has been thrown. The ball's momentum propels it out of the scoop and onto the playfield via a curved ramp. The motor is also connected to a push button, enabling another player to pitch, thus enhancing interactivity. The arm, bar, and ramp are fabricated from scrap sheet metal sourced from the machine shop. An infrared optical sensor detects the ball as it passes through a hole. The transistor receives a steady stream of infrared radiation until the ball obstructs the beam, sending a pulse to the PIC to register an out, single, double, triple, or home run. To power the solenoid and motor, external power is required, which is supplied by the 9.6V rechargeable batteries found in the lab kits. The first battery is permanently connected to the pitching motor, while the second battery is wired in series with the first and connected to the solenoid via an RSB52 relay. When the PIC sends a high pulse to activate the coil, the user can engage the solenoid using the bat button. The PIC generates a 0.5-second pulse, slightly longer than needed for pitching the ball. This pulse is triggered when the pitching arm contacts the lever switch on the stopping bar at the back of the game. Ideally, pressing the pitch button raises the arm, activates the switch, and pitches the ball. The relay activates, allowing the player to complete the circuit for the solenoid with the bat button. Once the half-second delay concludes, the relay closes.

The circuit design for this interactive baseball game integrates various components to ensure smooth operation and responsiveness during gameplay. The core elements include the PIC microcontroller, which serves as the central processing unit, managing inputs from the buttons, sensors, and switches. The solenoid is controlled through a relay, allowing for high-current switching without directly interfacing with the microcontroller. This design choice enhances reliability and protects the PIC from potential damage due to high current draw.

The photodiode-phototransistor circuit is critical for ball detection, providing real-time feedback to the microcontroller regarding the ball's position on the playfield. The infrared sensor continuously monitors for obstructions, allowing the game to register scores accurately. The use of LEDs for bases and the scoreboard provides clear visual feedback to players, enhancing the gaming experience.

The mechanical components, including the pitching arm and the bat, are designed for durability and functionality. The spring-return mechanism in the solenoid ensures that the bat returns to its resting position quickly, allowing for rapid successive swings. The motor's design, coupled with the lever switch, guarantees precise control over the pitching process, enhancing the overall interactivity of the game.

The housing and structural elements are carefully designed to prevent the ball from leaving the play area while facilitating smooth ball movement back to the pitching mechanism. The integration of scrap materials in the construction process demonstrates an efficient use of resources while maintaining structural integrity.

Overall, this interactive baseball game combines mechanical and electronic components to create an engaging user experience, blending the excitement of baseball with the dynamic nature of pinball. The thoughtful design and implementation of each system contribute to a cohesive and enjoyable game for players of all ages.The goal of this project was to make an interactive baseball game inspired by pinball. There is a solenoid-powered bat and a pitching mechanism that utilizes a motor and lever arm setup. Both of these are controlled by buttons so that two people can play against each other. The game has targets for a single, double, triple, and home run, with a si mple photodiode-phototransistor circuit to sense the ball. There are LEDs to light up each base as well as a scoreboard containing two seven-segment displays and LEDs for outs. The general concept is to have a slanted surface similar to a pinball machine. The ball will roll down and the user will try to hit it back up into a single, double, triple or homerun.

These "hits" have dampening backstops and milled down grooves to channel the ball into a hole where a sensor is placed. If none of these are hit then the ball rolls back down towards the bat and into an out hole. This was done to limit the number of holes and sensor we would need to create. There are rails along the play field so the ball will not fly off. Underneath, there is a recess, which is an oppositely slanted board to channel the ball back to the pitching apparatus.

The housing has sides to mount the bat button and keep the ball from sliding out of the recess. A acrylic sheet was used to wrap around the back as the rear wall. Holes were cut to allow pitching and scoreboard display. The Bat was fashioned out of wood on the band saw and sanded to a finish. Two holes were drilled: one to act as an anchoring pivot point and the other to be attached to an actuator. A Spring Return Solenoid, run on two 9. 6V rechargeable batteries in series, was used to actuate the bat. The user interface was a simple push button usually stocked in the lab. This button was located on the right side of the game similar to where pinball buttons are located. In order to make the game more like baseball we set up a system to only allow the user to swing once per pitched ball.

To learn more about this look below to Bat Relay. To actuate the ball up to a position to be "pitched" a RS385 motor and scooping arm were used. The motor was hooked up to a 9. 6V battery found in the kits. Once activated the arm turns upwards until hitting a static bar. Attached to the bar is a lever switch which sends a pulse to the PIC telling it that a pitch has been thrown. The momentum of the ball would shoot it out of the scoop where a curved ramp would project it onto the play field.

The motor is attached to a simple push button so another player can pitch creating a more interactive game. The arm, bar and ramp were made out of scrap sheet metal found in the machine shop. An IR optical sensor was used to detect the ball falling through a hole. The transistor will be receive a large amount of infrared radiation constantly, until a ball falls through.

The obstruction will send a pulse to the PIC and either an out, single, double, triple or homerun will be executed. In order to power our solenoid and motor we needed external power. We used the 9. 6V rechargeable batteries found in the lab kits. The first battery is permanently connected to the pitching motor as well as in series with the second battery.

The two batteries in series are connected to the solenoid via a RSB52 relay. When the PIC sends a high pulse to activate the coil the user can then activate the solenoid with the bat button. The PIC only sends a. 5 second pulse, which is a little more time then is needed to pitch the ball. The PIC is activated to send this pulse when the pitching arm hits the lever switch located on the stopping bar in the back of the game (See pitching above).

Ideally, when the pitch button is activated it will turn the arm upwards and both activate the switch and pitch the ball. The relay will come on allowing the player to complete the loop on the solenoid with the bat button. Once the half second delay ends the relay close 🔗 External reference

The circuit design for this interactive baseball game integrates various components to ensure smooth operation and responsiveness during gameplay. The core elements include the PIC microcontroller, which serves as the central processing unit, managing inputs from the buttons, sensors, and switches. The solenoid is controlled through a relay, allowing for high-current switching without directly interfacing with the microcontroller. This design choice enhances reliability and protects the PIC from potential damage due to high current draw.

The photodiode-phototransistor circuit is critical for ball detection, providing real-time feedback to the microcontroller regarding the ball's position on the playfield. The infrared sensor continuously monitors for obstructions, allowing the game to register scores accurately. The use of LEDs for bases and the scoreboard provides clear visual feedback to players, enhancing the gaming experience.

The mechanical components, including the pitching arm and the bat, are designed for durability and functionality. The spring-return mechanism in the solenoid ensures that the bat returns to its resting position quickly, allowing for rapid successive swings. The motor's design, coupled with the lever switch, guarantees precise control over the pitching process, enhancing the overall interactivity of the game.

The housing and structural elements are carefully designed to prevent the ball from leaving the play area while facilitating smooth ball movement back to the pitching mechanism. The integration of scrap materials in the construction process demonstrates an efficient use of resources while maintaining structural integrity.

Overall, this interactive baseball game combines mechanical and electronic components to create an engaging user experience, blending the excitement of baseball with the dynamic nature of pinball. The thoughtful design and implementation of each system contribute to a cohesive and enjoyable game for players of all ages.The goal of this project was to make an interactive baseball game inspired by pinball. There is a solenoid-powered bat and a pitching mechanism that utilizes a motor and lever arm setup. Both of these are controlled by buttons so that two people can play against each other. The game has targets for a single, double, triple, and home run, with a si mple photodiode-phototransistor circuit to sense the ball. There are LEDs to light up each base as well as a scoreboard containing two seven-segment displays and LEDs for outs. The general concept is to have a slanted surface similar to a pinball machine. The ball will roll down and the user will try to hit it back up into a single, double, triple or homerun.

These "hits" have dampening backstops and milled down grooves to channel the ball into a hole where a sensor is placed. If none of these are hit then the ball rolls back down towards the bat and into an out hole. This was done to limit the number of holes and sensor we would need to create. There are rails along the play field so the ball will not fly off. Underneath, there is a recess, which is an oppositely slanted board to channel the ball back to the pitching apparatus.

The housing has sides to mount the bat button and keep the ball from sliding out of the recess. A acrylic sheet was used to wrap around the back as the rear wall. Holes were cut to allow pitching and scoreboard display. The Bat was fashioned out of wood on the band saw and sanded to a finish. Two holes were drilled: one to act as an anchoring pivot point and the other to be attached to an actuator. A Spring Return Solenoid, run on two 9. 6V rechargeable batteries in series, was used to actuate the bat. The user interface was a simple push button usually stocked in the lab. This button was located on the right side of the game similar to where pinball buttons are located. In order to make the game more like baseball we set up a system to only allow the user to swing once per pitched ball.

To learn more about this look below to Bat Relay. To actuate the ball up to a position to be "pitched" a RS385 motor and scooping arm were used. The motor was hooked up to a 9. 6V battery found in the kits. Once activated the arm turns upwards until hitting a static bar. Attached to the bar is a lever switch which sends a pulse to the PIC telling it that a pitch has been thrown. The momentum of the ball would shoot it out of the scoop where a curved ramp would project it onto the play field.

The motor is attached to a simple push button so another player can pitch creating a more interactive game. The arm, bar and ramp were made out of scrap sheet metal found in the machine shop. An IR optical sensor was used to detect the ball falling through a hole. The transistor will be receive a large amount of infrared radiation constantly, until a ball falls through.

The obstruction will send a pulse to the PIC and either an out, single, double, triple or homerun will be executed. In order to power our solenoid and motor we needed external power. We used the 9. 6V rechargeable batteries found in the lab kits. The first battery is permanently connected to the pitching motor as well as in series with the second battery.

The two batteries in series are connected to the solenoid via a RSB52 relay. When the PIC sends a high pulse to activate the coil the user can then activate the solenoid with the bat button. The PIC only sends a. 5 second pulse, which is a little more time then is needed to pitch the ball. The PIC is activated to send this pulse when the pitching arm hits the lever switch located on the stopping bar in the back of the game (See pitching above).

Ideally, when the pitch button is activated it will turn the arm upwards and both activate the switch and pitch the ball. The relay will come on allowing the player to complete the loop on the solenoid with the bat button. Once the half second delay ends the relay close 🔗 External reference