Broken Charger-connection Alert

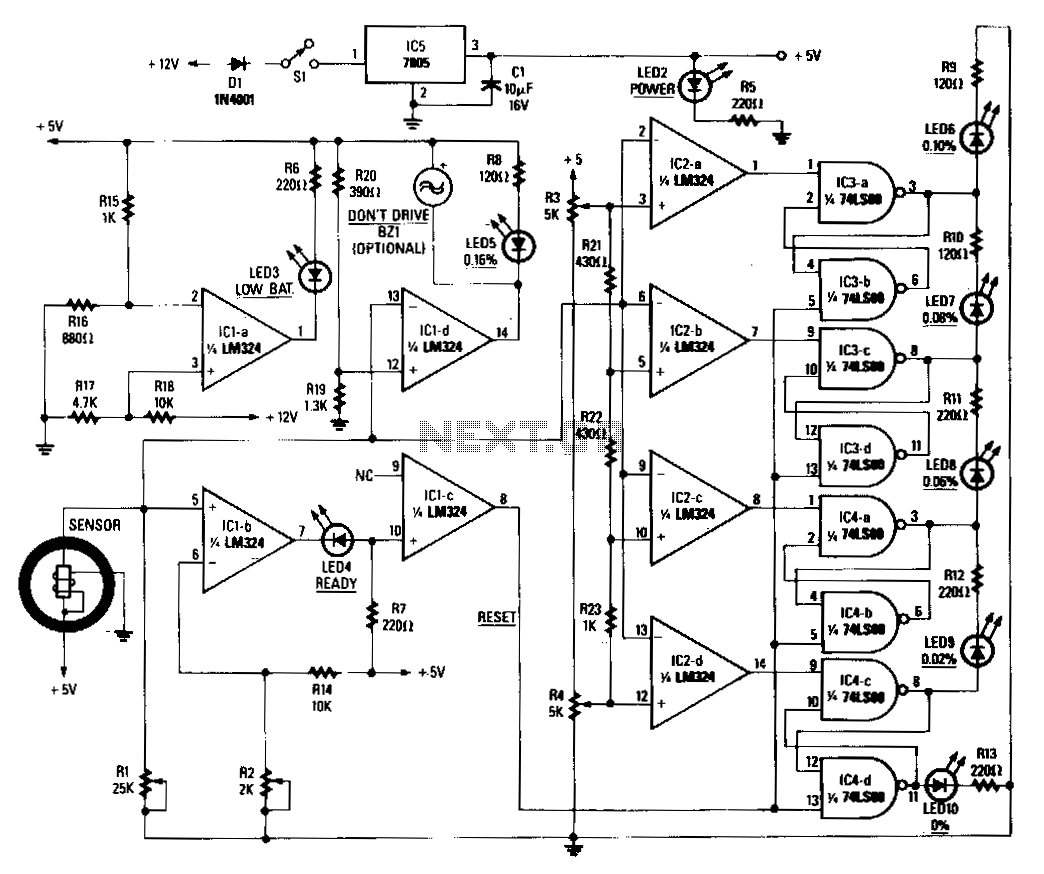

The above circuit can be useful to detect if the load of any battery charger or plug-in adaptor supply is not properly connected. The load can be a set of batteries to be charged or any other type of battery or low dc voltage operated device. More: The circuit can safely operate over a 3 to 15V range and 1A max. current, provided the supply voltage is about one volt higher than the voltage required by the load. Circuit operation: The circuit is inserted between the supply and the load, therefore

The circuit described functions as a load detection mechanism for battery chargers and plug-in adapters. Its primary purpose is to ensure that the load, which could be a set of batteries or any low DC voltage device, is properly connected to the power supply. This is crucial for preventing damage to both the power source and the load due to incorrect connections.

The circuit operates within a voltage range of 3 to 15 volts and can handle a maximum current of 1 ampere. It is important to note that the supply voltage must be at least one volt higher than the voltage required by the load to ensure proper functionality. This voltage differential is necessary for the circuit to effectively detect the presence of the load.

In terms of operation, the circuit is placed in series between the power supply and the load. This configuration allows it to monitor the current flow to the load. If the load is disconnected or improperly connected, the circuit will detect a drop in current flow. This change can be indicated through various means, such as an LED indicator or a relay that can trigger an alarm or a shutdown mechanism.

The design of the circuit may incorporate components such as resistors, transistors, and diodes to manage the detection process. A resistor can be used to limit the current flowing through the circuit, while a transistor can act as a switch to control the indicator or relay based on the detected current level. Diodes may be included to protect the circuit from reverse polarity or voltage spikes.

Overall, this load detection circuit is a valuable tool for ensuring the safe and effective operation of battery chargers and similar devices, providing an essential safeguard against improper connections.The above circuit can be useful to detect if the load of any battery charger or plug-in adaptor supply is not properly connected. The load can be a set of batteries to be charged or any other type of battery or low dc voltage operated device.

The circuit can safely operate over a 3 to 15V range and 1A max. current, provided the supply voltage is about one volt higher than the voltage required by the load. Circuit operation: The circuit is inserted between the supply and the load, therefore 🔗 External reference

The circuit described functions as a load detection mechanism for battery chargers and plug-in adapters. Its primary purpose is to ensure that the load, which could be a set of batteries or any low DC voltage device, is properly connected to the power supply. This is crucial for preventing damage to both the power source and the load due to incorrect connections.

The circuit operates within a voltage range of 3 to 15 volts and can handle a maximum current of 1 ampere. It is important to note that the supply voltage must be at least one volt higher than the voltage required by the load to ensure proper functionality. This voltage differential is necessary for the circuit to effectively detect the presence of the load.

In terms of operation, the circuit is placed in series between the power supply and the load. This configuration allows it to monitor the current flow to the load. If the load is disconnected or improperly connected, the circuit will detect a drop in current flow. This change can be indicated through various means, such as an LED indicator or a relay that can trigger an alarm or a shutdown mechanism.

The design of the circuit may incorporate components such as resistors, transistors, and diodes to manage the detection process. A resistor can be used to limit the current flowing through the circuit, while a transistor can act as a switch to control the indicator or relay based on the detected current level. Diodes may be included to protect the circuit from reverse polarity or voltage spikes.

Overall, this load detection circuit is a valuable tool for ensuring the safe and effective operation of battery chargers and similar devices, providing an essential safeguard against improper connections.The above circuit can be useful to detect if the load of any battery charger or plug-in adaptor supply is not properly connected. The load can be a set of batteries to be charged or any other type of battery or low dc voltage operated device.

The circuit can safely operate over a 3 to 15V range and 1A max. current, provided the supply voltage is about one volt higher than the voltage required by the load. Circuit operation: The circuit is inserted between the supply and the load, therefore 🔗 External reference