Credit card sized ethernet arduino controller

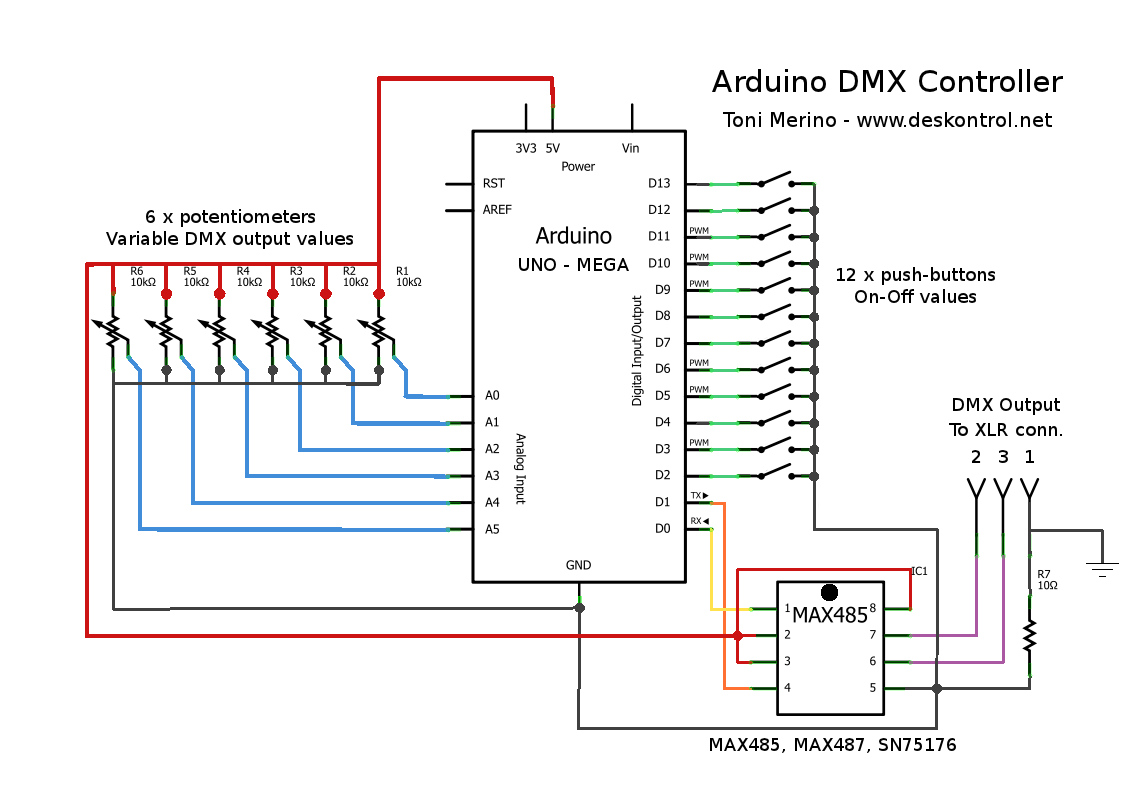

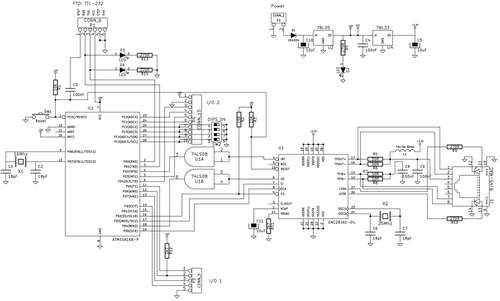

The Arduino is a user-friendly and versatile controller platform suitable for various projects. Recently, an Ethernet shield was purchased for the Arduino to enable remote control of projects, which proved to be highly effective. This led to the idea of creating a cost-effective, dedicated remote controller in a compact size, akin to a credit card. The project involves developing a simple Arduino-compatible controller with embedded Ethernet and additional I/O lines for applications such as a remote thermometer, fridge controller, and humidity sensor. The software was primarily developed by a collaborator, but the focus here is on constructing the controller board. A 4-position DIP switch allows for modification of programmed functions. A limitation of the standard Arduino Ethernet library is the fixed IP address in the code; however, the DIP switch enables the selection of a block of addresses, allowing up to 16 boards to be configured easily. Detailed instructions for etching the board are available in a related write-up. The design incorporates a surface mount IC (74HC08), which is straightforward to solder. The PDF layout provided is essential for accurate toner transfer and should be printed at full size for best results. An update has corrected the pin spacing issue of the Ethernet jack in the layout. The soldering process involves tinning the pads, placing the IC correctly, and carefully soldering each pin while ensuring proper alignment. After soldering the 74HC08, surface mount capacitors are to be attached using a similar method. A sample project demonstrates the functionality of the controller, utilizing a DS1820 chip connected to the I/O pins.

The project involves designing a compact Arduino-compatible controller that integrates Ethernet connectivity and additional input/output capabilities. This controller can be utilized for various remote monitoring applications. The incorporation of a 4-position DIP switch allows users to easily change the IP address configuration without modifying the software. This feature is particularly advantageous for deploying multiple sensors, as it simplifies the setup process across different devices.

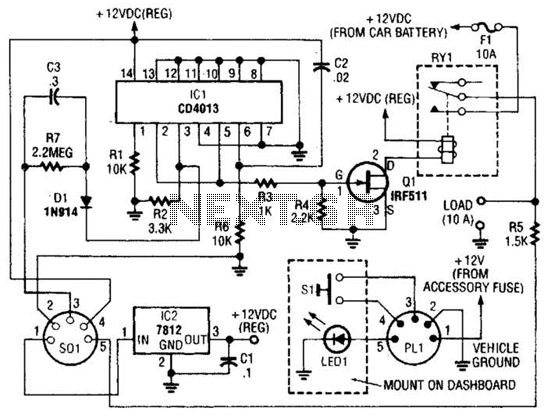

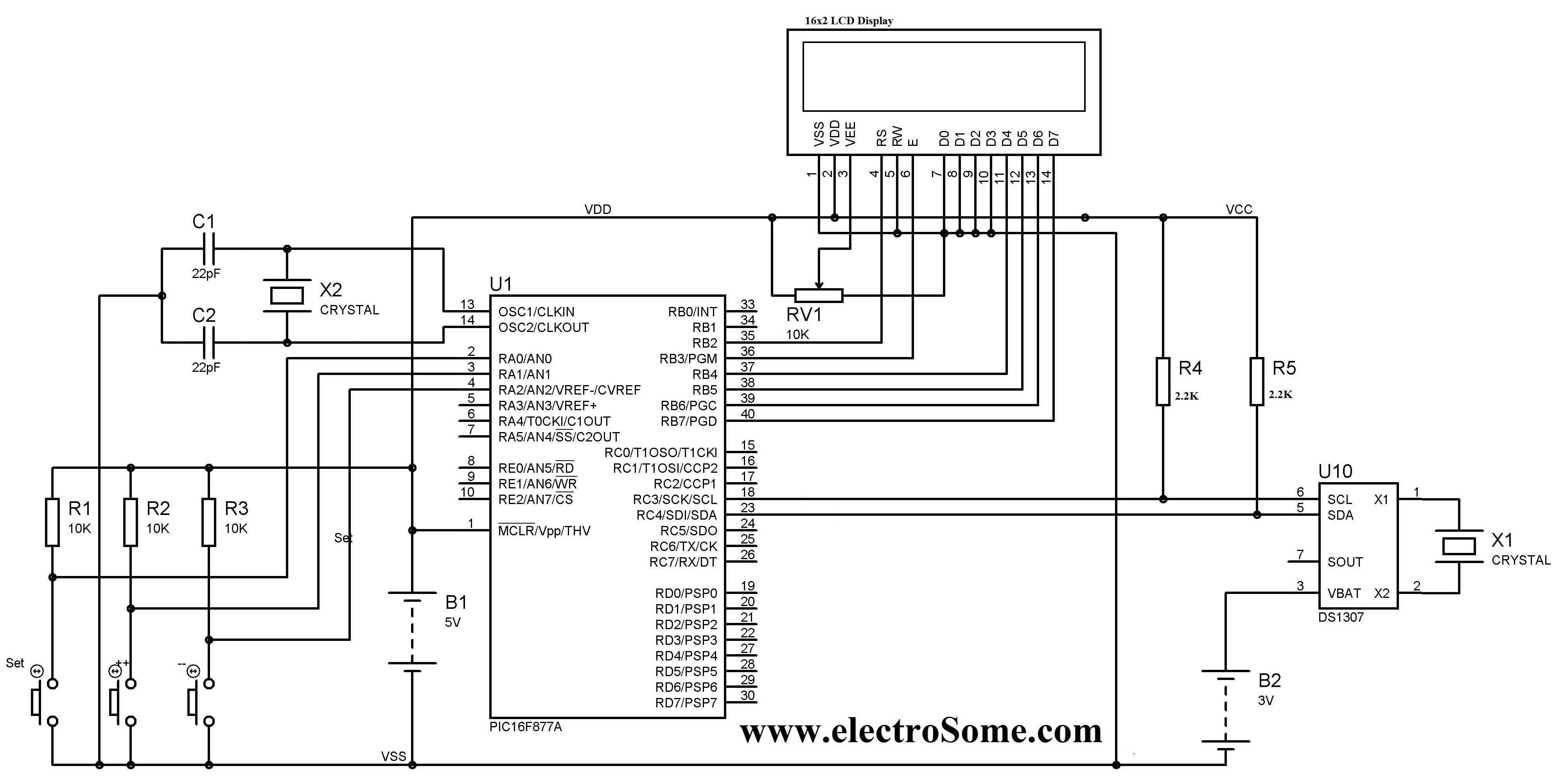

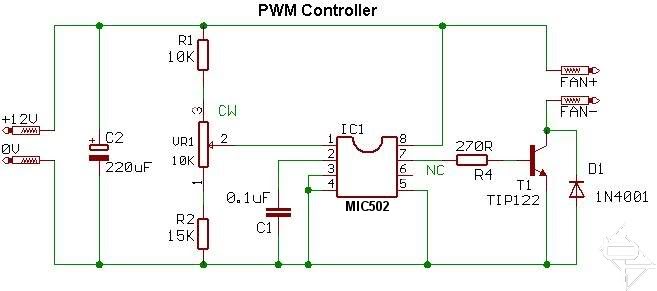

In terms of hardware, the circuit includes a microcontroller, the 74HC08 logic gate IC, and surface mount capacitors. The choice of a surface mount IC allows for a more compact design, making it feasible to fit the entire circuit onto a PCB the size of a credit card. The soldering process for surface mount components, while initially daunting, is manageable with the right techniques. Tinning the pads before placement enhances the soldering process, ensuring a secure connection.

The project also emphasizes the importance of careful alignment and soldering techniques to avoid common pitfalls such as cold solder joints or short circuits. A magnifying lamp can be beneficial for inspecting the soldered connections, ensuring that each pin is correctly soldered without bridging.

For programming, the use of an FTDI-TTL cable facilitates easy code downloading to the microcontroller, enabling quick iterations and testing of the controller's functionality. The provided sample project serves as a practical demonstration of the controller's capabilities, showcasing how to connect a DS1820 temperature sensor and read data through the Ethernet interface.

Overall, this project not only illustrates the process of creating a custom Arduino-compatible controller but also highlights the versatility and accessibility of Arduino as a platform for developing innovative remote monitoring solutions.I love the Arduino as a simple and accessible controller platform for many varied projects. A few months ago, a purchased an Ethernet shield for my Arduino controller to work on some projects with a mate of mine it was a massive hit for the first time, I could control my projects remotely using simple software. That got me thinking The Arduino costs about $30AUD, and the Ethernet board cost about $30AUD as well. That is a lot of money Could I make a simple, dedicated remote controller for much cheaper Why Yes I could. Could I make it the size of a credit card Why Yes I could! This project is my simple Arduino compatible controller that has embedded Ethernet, and the capacity to drive some extra I/O lines for projects, such as a Remote thermometer, a Remotely accessible Fridge controller, and a Remote Humidity sensor.

I have to say from the start that I didn`t write all of the software, my mate Mikal did that but this instructable is about making your own controller board! There is also a 4 position DIP switch that can be used to allow programmed functions to be modified. A failing of the standard Arduino Ethernet library is that the IP address for the board has to be set in code.

Using the DIP switch, a block of addresses can be selected from as required. You can make 16 boards, and have each board automatically select a different address based on the switch setting. This is *really* handy when you have deployed 10 sensors around the house. All you need to do is set a switch and then they are configured. I wrote detailed instructions in my Arduino Wordclock writeup that you can follow to etch your own board.

Check out for details. One thing with this layout - I had to use a surface mount IC (a 74HC08) Please do not be too scared by the surface mount technology it is extremely simple to solder as we will see in the next step. Remember download the PDF file as the master not the PNG picture the PNG is just there so that you can see what it will look like it is almost certainly not to scale!

If you print the PDF full size (without scaling) then it is the exact correct size for Toner Transfer. *Upate* I just made another controller and realised that the pin spacing on the Ethernet jack was slightly off .

It has been fixed in the attached PDF layout. Continue by tinning the pads where the IC will be mounted just apply a little bit of solder, not a great mound. Once the pads of the PCB have been tinned, get the part, place it onto the tinned pads, double check it is oriented correctly The PCB has a dot where pin 1 should be make sure that the part is facing that direction.

Then using a fine tipped soldering iron, touch one pad on a corner of the chip to heat it. Let the solder melt, and then let it cool. Look closely at the part to verify that it is still oriented correctly, and aligned with all the pads. Then solder the opposite corner. Now, under a decent light, using a magnifying lamp, spend a minute double checking that the device is sitting correctly on the pads if it isn`t, just re-heat a pin, and fix it up.

Once you are happy that the alignment is correct, heat the rest of the pads to melt the solder and connect the device. If necessary, add just a tiny bit of solder. Again double check that your work is neat and clean If you end up shorting pins together, don`t panic just use a little bit of Solder Wick to remove the excess solder.

Once you have the 74HC08 soldered, pat yourself on the back, and go and show your fine work to a significant person in your life! You did it! You can now solder Surface Mount parts! A whole new world awaits you! Next solder down the surface mount capacitors on the back of the board they are *simple*, just use a similar process to what youhave already used and do not be afraid to add a little bit of solder to keep the joints neat.

Finally spend a couple of minutes under a strong light double checking your work If I had a dollar for every stupid time I forgot to solder a pin, and spent a night debugging something silly I would be able to spend the rest of my life writing Instructables projects . Sadly . Anyway, where was I Ahhh. Attached is a sample project in this case, it is the trivial web server example from the Arduino library it uses a DS1820 chip connected to Pin 2 of I/O 1.

Use a FTDI-TTL cable to download the code you can get one of the cables from They only cost $20, and I can guarantee that every project you make in the future will have that magic 6 pin interface . 🔗 External reference

The project involves designing a compact Arduino-compatible controller that integrates Ethernet connectivity and additional input/output capabilities. This controller can be utilized for various remote monitoring applications. The incorporation of a 4-position DIP switch allows users to easily change the IP address configuration without modifying the software. This feature is particularly advantageous for deploying multiple sensors, as it simplifies the setup process across different devices.

In terms of hardware, the circuit includes a microcontroller, the 74HC08 logic gate IC, and surface mount capacitors. The choice of a surface mount IC allows for a more compact design, making it feasible to fit the entire circuit onto a PCB the size of a credit card. The soldering process for surface mount components, while initially daunting, is manageable with the right techniques. Tinning the pads before placement enhances the soldering process, ensuring a secure connection.

The project also emphasizes the importance of careful alignment and soldering techniques to avoid common pitfalls such as cold solder joints or short circuits. A magnifying lamp can be beneficial for inspecting the soldered connections, ensuring that each pin is correctly soldered without bridging.

For programming, the use of an FTDI-TTL cable facilitates easy code downloading to the microcontroller, enabling quick iterations and testing of the controller's functionality. The provided sample project serves as a practical demonstration of the controller's capabilities, showcasing how to connect a DS1820 temperature sensor and read data through the Ethernet interface.

Overall, this project not only illustrates the process of creating a custom Arduino-compatible controller but also highlights the versatility and accessibility of Arduino as a platform for developing innovative remote monitoring solutions.I love the Arduino as a simple and accessible controller platform for many varied projects. A few months ago, a purchased an Ethernet shield for my Arduino controller to work on some projects with a mate of mine it was a massive hit for the first time, I could control my projects remotely using simple software. That got me thinking The Arduino costs about $30AUD, and the Ethernet board cost about $30AUD as well. That is a lot of money Could I make a simple, dedicated remote controller for much cheaper Why Yes I could. Could I make it the size of a credit card Why Yes I could! This project is my simple Arduino compatible controller that has embedded Ethernet, and the capacity to drive some extra I/O lines for projects, such as a Remote thermometer, a Remotely accessible Fridge controller, and a Remote Humidity sensor.

I have to say from the start that I didn`t write all of the software, my mate Mikal did that but this instructable is about making your own controller board! There is also a 4 position DIP switch that can be used to allow programmed functions to be modified. A failing of the standard Arduino Ethernet library is that the IP address for the board has to be set in code.

Using the DIP switch, a block of addresses can be selected from as required. You can make 16 boards, and have each board automatically select a different address based on the switch setting. This is *really* handy when you have deployed 10 sensors around the house. All you need to do is set a switch and then they are configured. I wrote detailed instructions in my Arduino Wordclock writeup that you can follow to etch your own board.

Check out for details. One thing with this layout - I had to use a surface mount IC (a 74HC08) Please do not be too scared by the surface mount technology it is extremely simple to solder as we will see in the next step. Remember download the PDF file as the master not the PNG picture the PNG is just there so that you can see what it will look like it is almost certainly not to scale!

If you print the PDF full size (without scaling) then it is the exact correct size for Toner Transfer. *Upate* I just made another controller and realised that the pin spacing on the Ethernet jack was slightly off .

It has been fixed in the attached PDF layout. Continue by tinning the pads where the IC will be mounted just apply a little bit of solder, not a great mound. Once the pads of the PCB have been tinned, get the part, place it onto the tinned pads, double check it is oriented correctly The PCB has a dot where pin 1 should be make sure that the part is facing that direction.

Then using a fine tipped soldering iron, touch one pad on a corner of the chip to heat it. Let the solder melt, and then let it cool. Look closely at the part to verify that it is still oriented correctly, and aligned with all the pads. Then solder the opposite corner. Now, under a decent light, using a magnifying lamp, spend a minute double checking that the device is sitting correctly on the pads if it isn`t, just re-heat a pin, and fix it up.

Once you are happy that the alignment is correct, heat the rest of the pads to melt the solder and connect the device. If necessary, add just a tiny bit of solder. Again double check that your work is neat and clean If you end up shorting pins together, don`t panic just use a little bit of Solder Wick to remove the excess solder.

Once you have the 74HC08 soldered, pat yourself on the back, and go and show your fine work to a significant person in your life! You did it! You can now solder Surface Mount parts! A whole new world awaits you! Next solder down the surface mount capacitors on the back of the board they are *simple*, just use a similar process to what youhave already used and do not be afraid to add a little bit of solder to keep the joints neat.

Finally spend a couple of minutes under a strong light double checking your work If I had a dollar for every stupid time I forgot to solder a pin, and spent a night debugging something silly I would be able to spend the rest of my life writing Instructables projects . Sadly . Anyway, where was I Ahhh. Attached is a sample project in this case, it is the trivial web server example from the Arduino library it uses a DS1820 chip connected to Pin 2 of I/O 1.

Use a FTDI-TTL cable to download the code you can get one of the cables from They only cost $20, and I can guarantee that every project you make in the future will have that magic 6 pin interface . 🔗 External reference