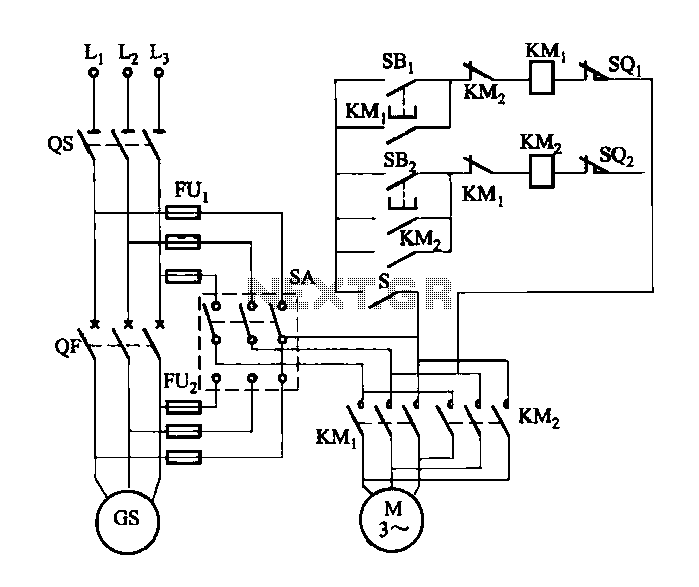

DC arc welding machine load path from one power outage

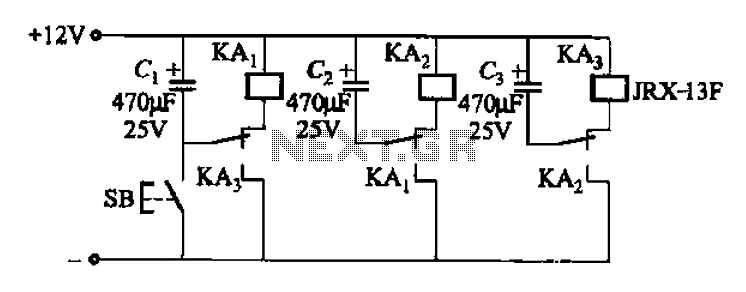

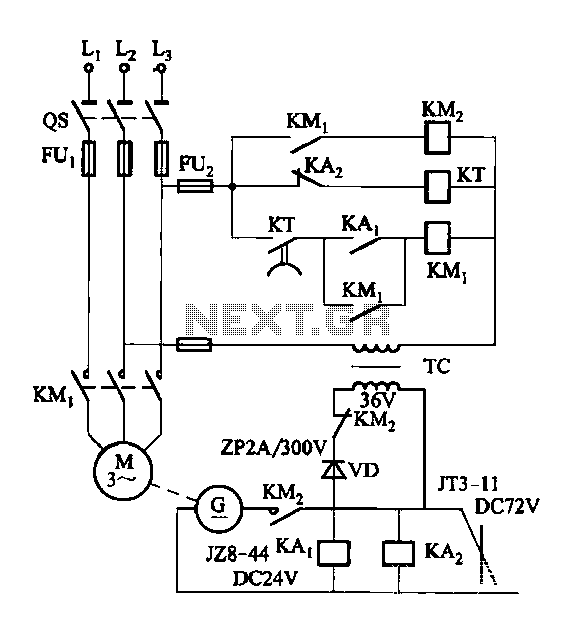

A DC arc welding machine has a load loss that is greater than that of an AC arc welder, making it essential to consider the installation of an idling stop mechanism. The circuit diagram for the no-load power path of the DC arc welding machine includes a contactor KMi, rated at CJ20-100A and 380V, and a contactor KMz, rated at CJ20-40A and 380V. Additionally, a time relay KT, model JS7-1A, is utilized, which operates at 380V with a time range of 0.4 to 60 seconds. The load path of the DC arc welding machine is interrupted during a power outage.

The DC arc welding machine operates by utilizing a direct current (DC) to create an electric arc between the electrode and the workpiece. This process is critical for achieving high-quality welds, particularly in applications requiring strong and durable joints. The specified contactors, KMi and KMz, serve as essential components in controlling the power supply to the welding machine. The KMi contactor, rated at 100A, is responsible for handling the main load during welding operations, while the KMz contactor, rated at 40A, may be used for auxiliary functions or additional features of the machine.

The inclusion of a time relay, such as the JS7-1A, plays a pivotal role in managing the operation of the machine. The adjustable time delay, ranging from 0.4 to 60 seconds, allows for precise control over the start and stop functions of the welding process. This feature is particularly beneficial in preventing overheating and ensuring the machine operates efficiently, especially during idle periods.

In the event of a power outage, the load path of the DC arc welding machine is designed to be interrupted, thereby safeguarding the equipment and preventing potential damage. The implementation of an idling stop mechanism is crucial for reducing unnecessary energy consumption and prolonging the lifespan of the machine. Overall, the careful selection of components and the design of the circuit contribute to the reliability and performance of the DC arc welding machine in various industrial applications.DC arc welding machine AC arc welder load loss than the loss of a large load, and therefore all the more necessary to consider installing idling stop motion. (1) DC arc welding machine from one of the no-load power path circuit is shown, contact KMi selection CJ20-100A, 380V, KMz selection CJ20-40A, 380V, time relay KT selection JS7-1A, 380V, 0.4- 60s. DC arc welding machine load path from one power outage

The DC arc welding machine operates by utilizing a direct current (DC) to create an electric arc between the electrode and the workpiece. This process is critical for achieving high-quality welds, particularly in applications requiring strong and durable joints. The specified contactors, KMi and KMz, serve as essential components in controlling the power supply to the welding machine. The KMi contactor, rated at 100A, is responsible for handling the main load during welding operations, while the KMz contactor, rated at 40A, may be used for auxiliary functions or additional features of the machine.

The inclusion of a time relay, such as the JS7-1A, plays a pivotal role in managing the operation of the machine. The adjustable time delay, ranging from 0.4 to 60 seconds, allows for precise control over the start and stop functions of the welding process. This feature is particularly beneficial in preventing overheating and ensuring the machine operates efficiently, especially during idle periods.

In the event of a power outage, the load path of the DC arc welding machine is designed to be interrupted, thereby safeguarding the equipment and preventing potential damage. The implementation of an idling stop mechanism is crucial for reducing unnecessary energy consumption and prolonging the lifespan of the machine. Overall, the careful selection of components and the design of the circuit contribute to the reliability and performance of the DC arc welding machine in various industrial applications.DC arc welding machine AC arc welder load loss than the loss of a large load, and therefore all the more necessary to consider installing idling stop motion. (1) DC arc welding machine from one of the no-load power path circuit is shown, contact KMi selection CJ20-100A, 380V, KMz selection CJ20-40A, 380V, time relay KT selection JS7-1A, 380V, 0.4- 60s. DC arc welding machine load path from one power outage