DIY Homemade SRSG Tesla Coil

Instructions for constructing a 1kW synchronous rotary spark gap (SRSG) Tesla Coil. This device operates using mains power and is powered by a 1kVA (10mA, 10kV) neon sign transformer (NST).

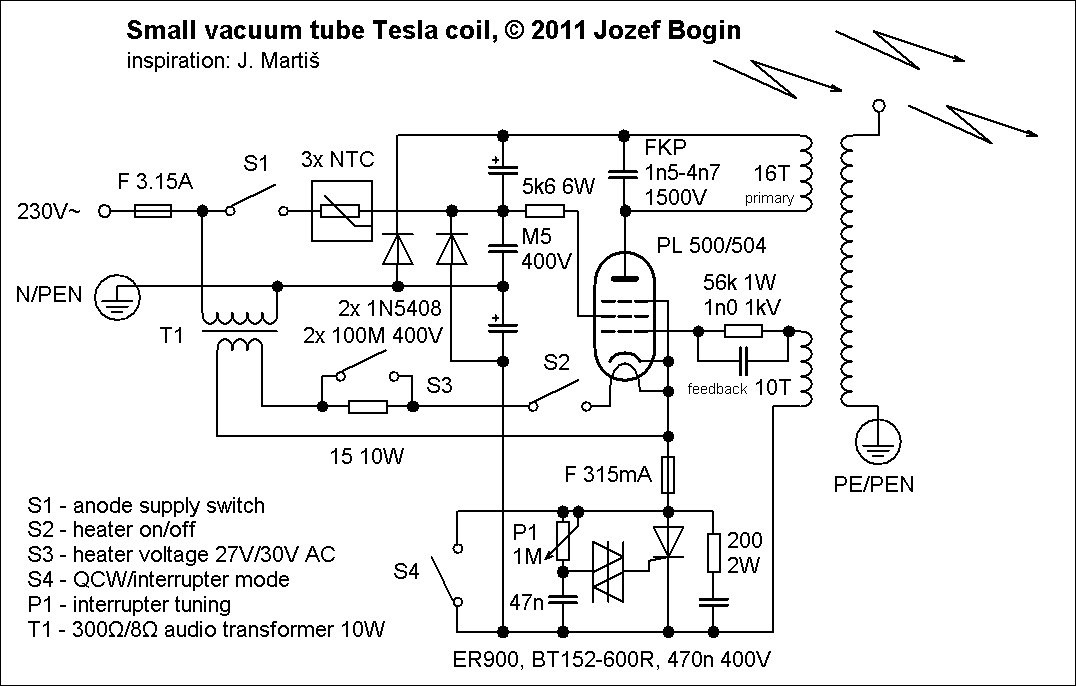

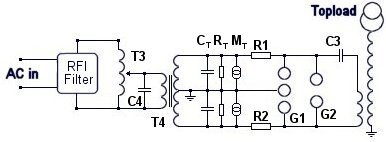

The construction of a 1kW synchronous rotary spark gap Tesla Coil involves several key components and careful assembly to ensure safety and functionality. The primary elements of the circuit include the neon sign transformer (NST), a rotary spark gap assembly, a high-voltage capacitor bank, a primary coil, and a secondary coil.

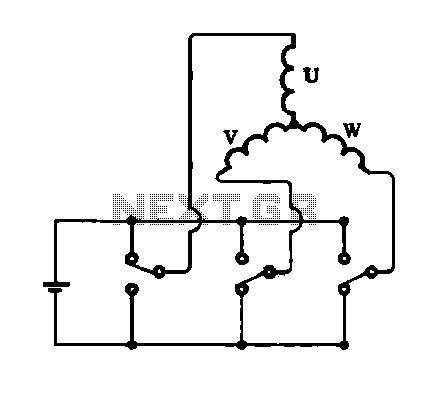

The NST serves as the power source, providing high voltage at a low current. It is crucial to select an NST with a rating of 10kV and 10mA to meet the operational requirements of the Tesla Coil. The output from the NST is connected to the rotary spark gap, which consists of a rotating electrode that intermittently creates a spark when aligned with a stationary electrode, allowing for the rapid discharge of energy.

The high-voltage capacitor bank is connected in parallel with the primary coil. This bank stores energy from the NST and releases it in bursts, generating a magnetic field in the primary coil. The primary coil is typically made of thick copper wire and is wound in a flat spiral or helical configuration. The design and number of turns in the primary coil will influence the efficiency and output of the Tesla Coil.

The secondary coil, which is wound around a cylindrical form, is designed to resonate at a frequency that matches the oscillations produced in the primary circuit. The interaction between the magnetic fields of the primary and secondary coils results in the step-up of voltage, producing high-voltage discharges at the top terminal of the secondary coil.

Safety precautions must be taken when working with high-voltage components. Proper insulation, grounding, and the use of protective equipment are essential to prevent electrical hazards. Additionally, the assembly should be conducted in a controlled environment to mitigate the risks associated with high-voltage operations.

Overall, constructing a 1kW SRSG Tesla Coil requires careful planning, precise component selection, and adherence to safety protocols to achieve an effective and safe high-voltage device.How to make a 1kW SRSG Tesla Coil. A Mains powered SRSG (synchronous rotary spark gap) Tesla Coil powered from a 1kVA (10mA 10kV) NST.. 🔗 External reference

The construction of a 1kW synchronous rotary spark gap Tesla Coil involves several key components and careful assembly to ensure safety and functionality. The primary elements of the circuit include the neon sign transformer (NST), a rotary spark gap assembly, a high-voltage capacitor bank, a primary coil, and a secondary coil.

The NST serves as the power source, providing high voltage at a low current. It is crucial to select an NST with a rating of 10kV and 10mA to meet the operational requirements of the Tesla Coil. The output from the NST is connected to the rotary spark gap, which consists of a rotating electrode that intermittently creates a spark when aligned with a stationary electrode, allowing for the rapid discharge of energy.

The high-voltage capacitor bank is connected in parallel with the primary coil. This bank stores energy from the NST and releases it in bursts, generating a magnetic field in the primary coil. The primary coil is typically made of thick copper wire and is wound in a flat spiral or helical configuration. The design and number of turns in the primary coil will influence the efficiency and output of the Tesla Coil.

The secondary coil, which is wound around a cylindrical form, is designed to resonate at a frequency that matches the oscillations produced in the primary circuit. The interaction between the magnetic fields of the primary and secondary coils results in the step-up of voltage, producing high-voltage discharges at the top terminal of the secondary coil.

Safety precautions must be taken when working with high-voltage components. Proper insulation, grounding, and the use of protective equipment are essential to prevent electrical hazards. Additionally, the assembly should be conducted in a controlled environment to mitigate the risks associated with high-voltage operations.

Overall, constructing a 1kW SRSG Tesla Coil requires careful planning, precise component selection, and adherence to safety protocols to achieve an effective and safe high-voltage device.How to make a 1kW SRSG Tesla Coil. A Mains powered SRSG (synchronous rotary spark gap) Tesla Coil powered from a 1kVA (10mA 10kV) NST.. 🔗 External reference