Gas-smoke-detector

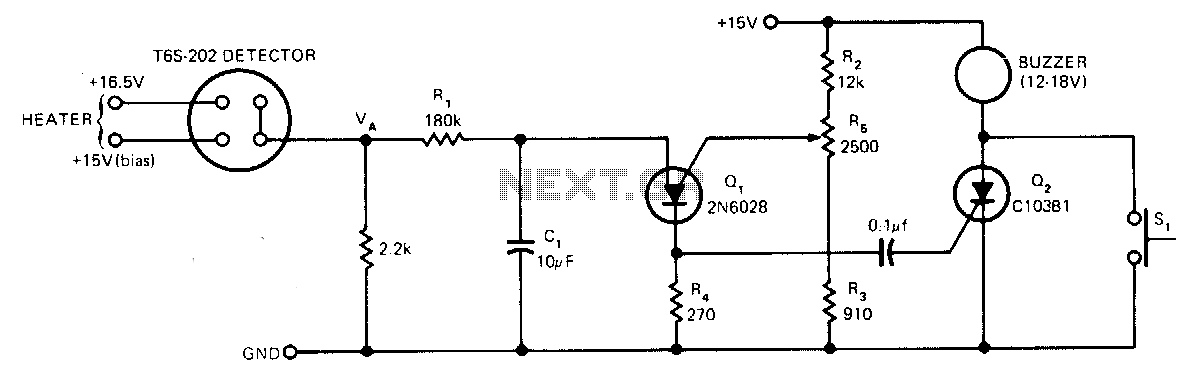

The sensor operates based on the selective absorption of hydrocarbons by an n-type metal-oxide surface. The device features a heater designed to eliminate hydrocarbons once smoke or gas is no longer detected in the immediate vicinity, allowing for reuse. Upon activation, a warm-up period of 15 minutes is necessary to achieve equilibrium (V = 0.6 V) in a hydrocarbon-free environment. When gas or smoke is detected near the sensor, the voltage (VA) will increase rapidly, with the rate and final equilibrium depending on the type and concentration of the gas, which subsequently triggers Q1, a programmable unijunction transistor. The voltage pulse generated across R4 activates Q2, which sounds the buzzer until S1 is pressed to reset the unit. R1 and C1 provide a time delay to prevent small transient waves of smoke, such as those from a cigarette, from activating the alarm. The triggering threshold is established by R5, R2, and R3, enabling the detection of hydrocarbons in concentrations between 50 and 200 ppm. Due to sensitivity to heater voltage, a regulated supply is required. The power requirements are 1.5 V at 500 mA for the heater and 15 V at 30 mA for the bias supply, depending on the type of buzzer used.

The sensor circuit utilizes a metal-oxide semiconductor (MOS) technology, which is effective for detecting hydrocarbons in various environments. The n-type metal-oxide layer is sensitive to the presence of hydrocarbons, changing its electrical conductivity in response to gas exposure. The heater component is critical, as it ensures that any hydrocarbons that may adhere to the sensor surface are burned off, maintaining the sensor's reliability and longevity.

The warm-up time of 15 minutes is essential for stabilizing the sensor's operating conditions, allowing the voltage to settle at the specified level of 0.6 V. The detection mechanism is highly responsive; when hydrocarbons are present, the voltage (VA) increases, indicating gas presence. This change is processed by Q1, which is a programmable unijunction transistor that plays a key role in triggering the alarm system.

The voltage pulse across R4 is crucial for activating Q2, which operates the buzzer, providing an audible alert. The inclusion of S1 allows for manual reset of the alarm, ensuring that the system can be easily silenced after a detection event. The time delay circuit formed by R1 and C1 is a significant design feature that prevents nuisance alarms from brief exposures to smoke, ensuring that only significant levels of hydrocarbons will trigger the alarm.

The sensitivity of the sensor is adjustable through the resistor network formed by R5, R2, and R3, allowing for detection of hydrocarbons in a range of 50 to 200 ppm. This flexibility is important for adapting the sensor to different environments and applications. The requirement for a regulated power supply is an important design consideration, as fluctuations in heater voltage can lead to false readings or reduced sensitivity.

Overall, the design emphasizes reliability, ease of use, and adaptability, making it suitable for various applications where hydrocarbon detection is critical.The sensor is based on the selective absorption of hydrocarbons by an n-type metal-oxide surface. The heater in the device serves to burn off the hydrocarbons once smoke or gas is no longer present in the immediate area; hence, the device is reuseable. When initially turned on, a 15 minute warm-up period is required to reach equilibrium (V, = 0.6 V) in a hydrocarbon-free environment.

When gas or smoke is introduced near the sensor, VA will quickly rise (rate and final equilibrium depend on the type of gas and concentration) and trigger Ql, a programmable unijunction transistor. The voltage pulse generated across R4 triggers Q2, sounding the buzzer until S1 resets the unit. R1 and C1 give a time delay to prevent small transient "-aves of smoke, such as from a cigarette, from triggering the alarm. Triggering threshold is set by R5, RZ, and R3; with the components shown, between 50 and 200 ppm of hydrocarbons can be easily detected.

Since it is somewhat sensitive to heater voltage, a regulated supply should be used. Power requirements are 1.5 V at 500 mA for the heater and 15 V at 30 mA, depending on type of buzzer, for the bias supply.

The sensor circuit utilizes a metal-oxide semiconductor (MOS) technology, which is effective for detecting hydrocarbons in various environments. The n-type metal-oxide layer is sensitive to the presence of hydrocarbons, changing its electrical conductivity in response to gas exposure. The heater component is critical, as it ensures that any hydrocarbons that may adhere to the sensor surface are burned off, maintaining the sensor's reliability and longevity.

The warm-up time of 15 minutes is essential for stabilizing the sensor's operating conditions, allowing the voltage to settle at the specified level of 0.6 V. The detection mechanism is highly responsive; when hydrocarbons are present, the voltage (VA) increases, indicating gas presence. This change is processed by Q1, which is a programmable unijunction transistor that plays a key role in triggering the alarm system.

The voltage pulse across R4 is crucial for activating Q2, which operates the buzzer, providing an audible alert. The inclusion of S1 allows for manual reset of the alarm, ensuring that the system can be easily silenced after a detection event. The time delay circuit formed by R1 and C1 is a significant design feature that prevents nuisance alarms from brief exposures to smoke, ensuring that only significant levels of hydrocarbons will trigger the alarm.

The sensitivity of the sensor is adjustable through the resistor network formed by R5, R2, and R3, allowing for detection of hydrocarbons in a range of 50 to 200 ppm. This flexibility is important for adapting the sensor to different environments and applications. The requirement for a regulated power supply is an important design consideration, as fluctuations in heater voltage can lead to false readings or reduced sensitivity.

Overall, the design emphasizes reliability, ease of use, and adaptability, making it suitable for various applications where hydrocarbon detection is critical.The sensor is based on the selective absorption of hydrocarbons by an n-type metal-oxide surface. The heater in the device serves to burn off the hydrocarbons once smoke or gas is no longer present in the immediate area; hence, the device is reuseable. When initially turned on, a 15 minute warm-up period is required to reach equilibrium (V, = 0.6 V) in a hydrocarbon-free environment.

When gas or smoke is introduced near the sensor, VA will quickly rise (rate and final equilibrium depend on the type of gas and concentration) and trigger Ql, a programmable unijunction transistor. The voltage pulse generated across R4 triggers Q2, sounding the buzzer until S1 resets the unit. R1 and C1 give a time delay to prevent small transient "-aves of smoke, such as from a cigarette, from triggering the alarm. Triggering threshold is set by R5, RZ, and R3; with the components shown, between 50 and 200 ppm of hydrocarbons can be easily detected.

Since it is somewhat sensitive to heater voltage, a regulated supply should be used. Power requirements are 1.5 V at 500 mA for the heater and 15 V at 30 mA, depending on type of buzzer, for the bias supply.