Hold-current-limiter

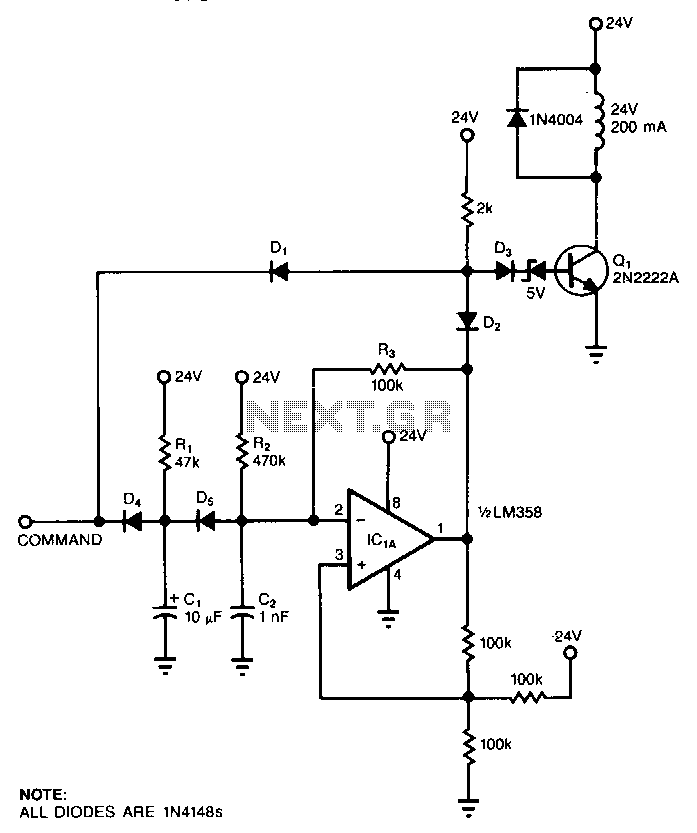

In many applications, a solenoid driver must first briefly supply a large amount of pull-in current, which quickly actuates the solenoid. Thereafter, the driver must supply a much lower holding current to avoid burning the solenoid out. To avoid using the customary, cumbersome, large capacitors or power-wasting resistors, a switch technique can be employed. As long as the input to the circuit is low, diode D1 keeps transistor Q1 off; a low input also prevents the op-amp circuit from oscillating. When the input reaches 24 V, Q1 switches on and actuates the solenoid. Concurrently, diode D4 is back-biased, and capacitor C1 begins charging. Once C1 charges, the op-amp circuit starts to oscillate, toggling Q1 on and off. The time constant defined by resistor R1 and capacitor C1 determines the duration during which the solenoid receives full power. Resistor R3 and capacitor C2 set the oscillator's frequency, while resistor R2 determines the oscillator's duty cycle. The holding current is directly proportional to the duty cycle. For the components specified, the full-power period is 300 ms, the oscillator's frequency is 3 kHz, and its duty cycle is 50%.

In this solenoid driver circuit, the operational strategy involves a two-phase power supply approach. Initially, a high pull-in current is necessary to activate the solenoid quickly. This is achieved by applying a 24 V input, which turns on transistor Q1, allowing current to flow through the solenoid. The diode D1 plays a crucial role in keeping Q1 off when the input is low, thus preventing unnecessary power consumption and ensuring the op-amp circuit remains stable by avoiding oscillations.

Once the solenoid is actuated, the charging of capacitor C1 begins. The back-biasing of diode D4 ensures that the circuit can transition smoothly into the holding phase without interference. The oscillation of the op-amp circuit is governed by the time constant created by R1 and C1, which regulates how long the solenoid receives the full pull-in current before transitioning to a lower holding current.

The frequency of the oscillation is determined by the values of resistor R3 and capacitor C2, which together define how often Q1 will switch on and off after the initial pull-in phase. The duty cycle, set by resistor R2, directly influences the holding current supplied to the solenoid. A 50% duty cycle indicates that the solenoid will receive power half of the time, ensuring it remains energized without overheating.

This design is efficient and compact, eliminating the need for large capacitors or resistors typically used in solenoid drivers. The specified parameters of 300 ms for the full-power period and a frequency of 3 kHz allow for effective control of the solenoid, providing a reliable solution for applications requiring precise solenoid actuation with minimal energy wastage.In many applications, a solenoid driver must first briefly supply a large amount of pull-in cnrrent, which quickly actuates the solenoid. Thereafter, the driver must supply a much lower holding cnrrent to avoid burning the solenoid out. To avoid using the customary, cumbersome, large capacitors or power-wasting resistors, you can use the switch technique.

As long as the input to the circuit is low, diode Dl holds Ql off; a low input also prevents the op-amp circuit from oscillating. When the input reaches 24 V, Ql switches on and pulls in the solenoid. Concurrently, D4 is back-biased, and Cl begins charging up. When Cl charges up, the op-amp circuit begins to oscillate, switching Ql on and off. The time constant defined by Rl and Cl determines the length of the period during which the solenoid receives full power.

R3 and C2 set the oscillator"s frequency, and R2 sets the oscillator"s duty cycle. The hold cnrrent is directly proportional to the duty cycle. For the components shown, the full-power period is 300 ms, the oscillator"s frequency is 3kHz, and its duty cycle is 50%.

In this solenoid driver circuit, the operational strategy involves a two-phase power supply approach. Initially, a high pull-in current is necessary to activate the solenoid quickly. This is achieved by applying a 24 V input, which turns on transistor Q1, allowing current to flow through the solenoid. The diode D1 plays a crucial role in keeping Q1 off when the input is low, thus preventing unnecessary power consumption and ensuring the op-amp circuit remains stable by avoiding oscillations.

Once the solenoid is actuated, the charging of capacitor C1 begins. The back-biasing of diode D4 ensures that the circuit can transition smoothly into the holding phase without interference. The oscillation of the op-amp circuit is governed by the time constant created by R1 and C1, which regulates how long the solenoid receives the full pull-in current before transitioning to a lower holding current.

The frequency of the oscillation is determined by the values of resistor R3 and capacitor C2, which together define how often Q1 will switch on and off after the initial pull-in phase. The duty cycle, set by resistor R2, directly influences the holding current supplied to the solenoid. A 50% duty cycle indicates that the solenoid will receive power half of the time, ensuring it remains energized without overheating.

This design is efficient and compact, eliminating the need for large capacitors or resistors typically used in solenoid drivers. The specified parameters of 300 ms for the full-power period and a frequency of 3 kHz allow for effective control of the solenoid, providing a reliable solution for applications requiring precise solenoid actuation with minimal energy wastage.In many applications, a solenoid driver must first briefly supply a large amount of pull-in cnrrent, which quickly actuates the solenoid. Thereafter, the driver must supply a much lower holding cnrrent to avoid burning the solenoid out. To avoid using the customary, cumbersome, large capacitors or power-wasting resistors, you can use the switch technique.

As long as the input to the circuit is low, diode Dl holds Ql off; a low input also prevents the op-amp circuit from oscillating. When the input reaches 24 V, Ql switches on and pulls in the solenoid. Concurrently, D4 is back-biased, and Cl begins charging up. When Cl charges up, the op-amp circuit begins to oscillate, switching Ql on and off. The time constant defined by Rl and Cl determines the length of the period during which the solenoid receives full power.

R3 and C2 set the oscillator"s frequency, and R2 sets the oscillator"s duty cycle. The hold cnrrent is directly proportional to the duty cycle. For the components shown, the full-power period is 300 ms, the oscillator"s frequency is 3kHz, and its duty cycle is 50%.