Interfacing to 7-Segment Displays

In industrial PLC applications, one of the older yet simpler methods of displaying numeric information involves utilizing one or more 7-segment numeric displays connected to an output card of a PLC. While it is feasible to construct such a display independently, it is more common to use a pre-manufactured product, such as the 4-digit panel mount unit mentioned. To effectively interface a PLC with such a display, it is beneficial to first understand the basic electronic components typically utilized in their construction and how this impacts the task of interfacing and programming such a unit. Although both LED and LCD numeric displays are readily available and interfaced in a similar manner, the focus will be on the more prevalent LED units in the forthcoming examples. Once 7-segment LED displays became widely accessible, a simple integrated circuit (IC) known as a "BCD to 7-segment decoder" was quickly developed to facilitate their use. Binary formatted data presented to the inputs of this IC results in the outputs being set to the correct state to display the corresponding numeral (0 to 9) on a 7-segment display. While BCD to 7-segment decoder ICs are available without built-in latches, this specific IC includes a built-in 4-bit latch that will be utilized in later examples. For the time being, the latch is configured to allow input data to pass freely through to the decoder. In the provided diagram, four toggle switches, SW0 to SW3, are employed to select the desired numeral (0-9) to be displayed on the 7-segment display. With the decoder in place, it is simply a matter of setting the appropriate 4-bit BCD pattern at the decoder's inputs, allowing the decoder to manage the rest. The decoder section also features two additional inputs. The Lamp Test (LT) input activates all segments, enabling verification that all display segments are functioning or identifying display units that require replacement. This input is typically maintained at logic 1. Conversely, the Blanking (BL) input forces the entire display off, often used to eliminate leading or trailing zeros from a lengthy display. The LT input takes precedence over the BL input, allowing for testing even when display digits are blanked. It is noteworthy that the same circuit could potentially be controlled by a PLC if four output bits from a 5VDC PLC output card were utilized in place of the four switches shown. If an 8-bit output card were available, two such circuits (2 digits) could be managed. A 16-bit card would enable control of four such circuits (4 digits), and so on. The figure provided is sourced from the LogixPro I/O simulator screen and illustrates a common method of interfacing with a 4-digit display. The figures on the right are extracted from the data sheet of a pre-manufactured 4-digit display unit that could be readily used in this specific application. The manufactured unit consists of four separate circuits, each with its own decoder. Compared to the earlier circuit example, this unit incorporates additional components and circuitry, making it significantly more versatile and user-friendly. It is important to note that there are four "Strobe" lines, one for each digit, which control built-in IC latches, providing the option to multiplex the digits or displays if desired. In the aforementioned non-multiplexed application, the strobes are continuously enabled, allowing data to flow directly from the BCD inputs and be displayed normally. Additionally, this particular unit is designed for 24VDC operation, which is the most prevalent DC voltage level used in industrial settings, making PLC I/O cards designed for such applications extremely common. In contrast to 5VDC circuits, 24VDC circuits can generally withstand greater supply voltage variations, are less affected by contact resistance, and are more resilient in electrically noisy environments. The built-in 4-bit latches of the 4511 IC are utilized to enhance functionality.

The integration of 7-segment displays in PLC systems offers a straightforward method for visualizing numerical data. The BCD to 7-segment decoder plays a crucial role in this process, converting binary-coded decimal inputs into the corresponding visual representation on the display. The addition of features such as the Lamp Test and Blanking inputs further enhances the usability of these displays, enabling easier maintenance and data management. The ability to multiplex displays through strobe lines allows for more efficient use of digital outputs, especially in systems where space and resources are limited. The design considerations for 24VDC operation ensure compatibility with industrial standards, providing robustness in various operational environments. Overall, the combination of these components results in a reliable and effective display solution for industrial applications, facilitating real-time monitoring and control in automation systems.In industrial PLC applications, one of the old, but simpler methods of displaying numeric information is to use one or more 7-Segment numeric displays connected to an output card of a PLC. Although it is possible to build such a display yourself, it is far more common to employ a pre-manufactured product such as the 4-digit panel mount unit shownat the top of this page.

To correctly interface a PLC to such a display, it helps to first understand what basic electronic components are typically employed in their makeup, and how this effects our task of interfacing to, and programming such a unit. Although both LED and LCD numeric displays are readily available, and interfaced similarly, we`ll concentrate on the more common LED units in the examples to follow.

Once 7-Segment LED displays became readily available, a simple IC known as a "BCD to 7-Segment decoder" was quickly developed to simplify their use. Binary formatted data presented to this IC`s inputs results in the IC`s outputs being placed into the correct state to display the equivalent numeral (0 to 9) on a 7-Segment display.

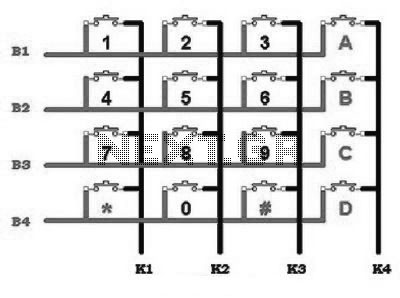

Although BCD to 7-Segment decoder ICs are available without built in latches, this particular IC includes a built in 4-bit latch which we will make use of in later examples. For now the latch is set to simply allow input data to freely pass through to the decoder. In the above diagram, the 4 toggle switches, SW0 to SW3 are used to select the desired numeral (0-9) that will appear on the 7-Segment display.

By using a decoder, it`s now simply a matter of setting the correct 4-bit BCD pattern feeding the inputs of the decoder, and the decoder takes care of the rest. The decoder section also has two additional inputs. Lamp Test (LT) turns all segments on so you can verify at once that all display segments are working, or identify display units that need to be replaced.

This input is normally left at logic 1. The Blanking (BL) input is just the reverse; it forces the entire display off. This is used in many cases to blank out leading or trailing zeros from a long display. LT will override BL so you can test even blanked-out display digits. One should also note that the same circuit could conceivably be controlled by a PLC, if 4 output bits from a 5VDC PLC output card were used in place of the 4 switches shown. If an 8-bit output card were available, then two such circuits (2 digits) could be controlled. A 16-bit card would in turn allow us to control four such circuits (4 digits). etc. The figure (above) on the left is taken from the LogixPro I/O simulator screen, and depicts a common method of interfacing to a 4 digit display.

The figures on the right are taken from the data sheet of a pre-manufactured 4 digit display unit which could be readily employed in this particular application. The manufactured unit does contain four separate circuits, and each circuit (digit) has it`s own decoder, but compared to our earlier circuit example, this unit employs additional components and circuitry making it far more versatile and easy to use.

Note that there are 4 "Strobe" lines shown; one for each digit. These strobe lines control built in IC latches which provide us with the option of multiplexing the digits, or displays, if we wished to do so. In the above non-multiplexed application, the strobes are permanently enabled allowing data to simply pass through from the BCD inputs and be displayed as normal.

Also note that this particular unit is designed for 24VDC use. This is by far the most common DC voltage level used in industrial installations, and PLC I/O cards designed for such use are therefore extremely common. In comparison to 5VDC circuits, 24VDC circuits can typically tolerate far greater supply voltage excursions, are less sensitive to the effects of contact resistance, and more tolerant of electrically noisy environments.

By making use of the 4-bit latches that are built into the 4511 IC 🔗 External reference

The integration of 7-segment displays in PLC systems offers a straightforward method for visualizing numerical data. The BCD to 7-segment decoder plays a crucial role in this process, converting binary-coded decimal inputs into the corresponding visual representation on the display. The addition of features such as the Lamp Test and Blanking inputs further enhances the usability of these displays, enabling easier maintenance and data management. The ability to multiplex displays through strobe lines allows for more efficient use of digital outputs, especially in systems where space and resources are limited. The design considerations for 24VDC operation ensure compatibility with industrial standards, providing robustness in various operational environments. Overall, the combination of these components results in a reliable and effective display solution for industrial applications, facilitating real-time monitoring and control in automation systems.In industrial PLC applications, one of the old, but simpler methods of displaying numeric information is to use one or more 7-Segment numeric displays connected to an output card of a PLC. Although it is possible to build such a display yourself, it is far more common to employ a pre-manufactured product such as the 4-digit panel mount unit shownat the top of this page.

To correctly interface a PLC to such a display, it helps to first understand what basic electronic components are typically employed in their makeup, and how this effects our task of interfacing to, and programming such a unit. Although both LED and LCD numeric displays are readily available, and interfaced similarly, we`ll concentrate on the more common LED units in the examples to follow.

Once 7-Segment LED displays became readily available, a simple IC known as a "BCD to 7-Segment decoder" was quickly developed to simplify their use. Binary formatted data presented to this IC`s inputs results in the IC`s outputs being placed into the correct state to display the equivalent numeral (0 to 9) on a 7-Segment display.

Although BCD to 7-Segment decoder ICs are available without built in latches, this particular IC includes a built in 4-bit latch which we will make use of in later examples. For now the latch is set to simply allow input data to freely pass through to the decoder. In the above diagram, the 4 toggle switches, SW0 to SW3 are used to select the desired numeral (0-9) that will appear on the 7-Segment display.

By using a decoder, it`s now simply a matter of setting the correct 4-bit BCD pattern feeding the inputs of the decoder, and the decoder takes care of the rest. The decoder section also has two additional inputs. Lamp Test (LT) turns all segments on so you can verify at once that all display segments are working, or identify display units that need to be replaced.

This input is normally left at logic 1. The Blanking (BL) input is just the reverse; it forces the entire display off. This is used in many cases to blank out leading or trailing zeros from a long display. LT will override BL so you can test even blanked-out display digits. One should also note that the same circuit could conceivably be controlled by a PLC, if 4 output bits from a 5VDC PLC output card were used in place of the 4 switches shown. If an 8-bit output card were available, then two such circuits (2 digits) could be controlled. A 16-bit card would in turn allow us to control four such circuits (4 digits). etc. The figure (above) on the left is taken from the LogixPro I/O simulator screen, and depicts a common method of interfacing to a 4 digit display.

The figures on the right are taken from the data sheet of a pre-manufactured 4 digit display unit which could be readily employed in this particular application. The manufactured unit does contain four separate circuits, and each circuit (digit) has it`s own decoder, but compared to our earlier circuit example, this unit employs additional components and circuitry making it far more versatile and easy to use.

Note that there are 4 "Strobe" lines shown; one for each digit. These strobe lines control built in IC latches which provide us with the option of multiplexing the digits, or displays, if we wished to do so. In the above non-multiplexed application, the strobes are permanently enabled allowing data to simply pass through from the BCD inputs and be displayed as normal.

Also note that this particular unit is designed for 24VDC use. This is by far the most common DC voltage level used in industrial installations, and PLC I/O cards designed for such use are therefore extremely common. In comparison to 5VDC circuits, 24VDC circuits can typically tolerate far greater supply voltage excursions, are less sensitive to the effects of contact resistance, and more tolerant of electrically noisy environments.

By making use of the 4-bit latches that are built into the 4511 IC 🔗 External reference