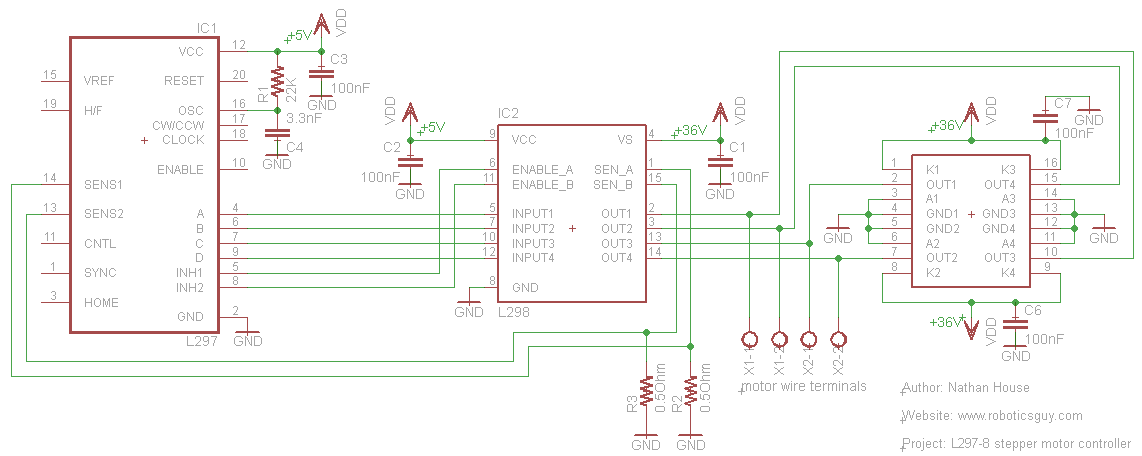

L297/298 Stepper Motor Controller

An efficient method for constructing a stepper motor controller involves creating a printed circuit board (PCB) and then placing the components onto it. Once the PCB is fabricated, the assembly and soldering of components is a quick process, especially when compared to the time-consuming assembly on a protoboard. The initial PCB version of the stepper motor controller has been developed, incorporating various enhancements. Notably, a Schmitt trigger has been included to effectively filter out noise. Acknowledgment is given to Phil for his assistance during the PCB design process, as he possesses extensive experience with stepper motor integrated circuits (ICs) and provided valuable advice. The concept of utilizing a Schmitt trigger was also inspired by his work.

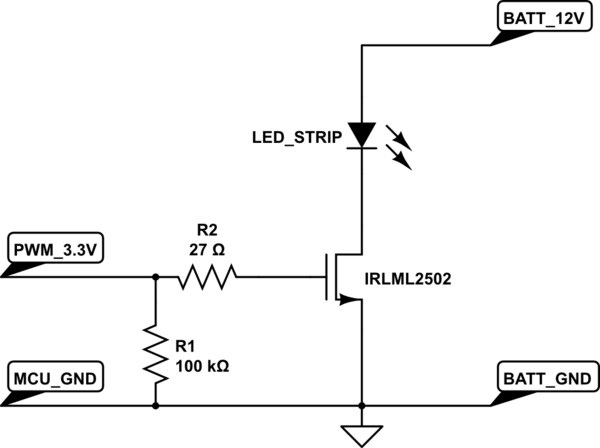

The stepper motor controller circuit is designed to facilitate precise control of stepper motors, which are commonly used in applications requiring accurate positioning. The PCB layout integrates various components, including a microcontroller, driver ICs, and power supply elements, ensuring efficient operation and compact design.

The microcontroller serves as the central processing unit, executing control algorithms that determine the stepping sequence of the motor. It interfaces with the stepper motor driver ICs, which amplify the control signals and provide the necessary current to the motor coils. The inclusion of the Schmitt trigger is critical, as it enhances signal integrity by providing hysteresis, which helps to eliminate false triggering caused by noise or voltage fluctuations. This feature is particularly beneficial in environments with electromagnetic interference.

The power supply section of the PCB is designed to deliver stable voltage levels required for the operation of both the microcontroller and the stepper motor. It may include voltage regulators to ensure that the components receive appropriate power levels, thus enhancing the overall reliability of the system.

In summary, the stepper motor controller PCB not only simplifies the assembly process but also incorporates thoughtful design improvements that enhance performance and reliability. The integration of experienced insights into the design process further contributes to the robustness of the final product.A better way to make a stepper motor controller is to make a printed circuit board, and then simply drop the components in. After making the PCB, placing the components and soldering them hardly takes any time at all, in contrast to the proto board which took a ton of time to make.

Here`s a picture of the first stepper motor controller I made in PCB-form: Here is the schematic for the PCB version of my stepper motor controller. Notice that some improvements were made, such as the Schmitt trigger to help filter out noise. I want to thank Phil for his help when I was designing the PCB. He has a lot of experience with these stepper motor ICs and gave me a lot of advice. I also borrowed the idea of using a Schmitt trigger from him. 🔗 External reference

The stepper motor controller circuit is designed to facilitate precise control of stepper motors, which are commonly used in applications requiring accurate positioning. The PCB layout integrates various components, including a microcontroller, driver ICs, and power supply elements, ensuring efficient operation and compact design.

The microcontroller serves as the central processing unit, executing control algorithms that determine the stepping sequence of the motor. It interfaces with the stepper motor driver ICs, which amplify the control signals and provide the necessary current to the motor coils. The inclusion of the Schmitt trigger is critical, as it enhances signal integrity by providing hysteresis, which helps to eliminate false triggering caused by noise or voltage fluctuations. This feature is particularly beneficial in environments with electromagnetic interference.

The power supply section of the PCB is designed to deliver stable voltage levels required for the operation of both the microcontroller and the stepper motor. It may include voltage regulators to ensure that the components receive appropriate power levels, thus enhancing the overall reliability of the system.

In summary, the stepper motor controller PCB not only simplifies the assembly process but also incorporates thoughtful design improvements that enhance performance and reliability. The integration of experienced insights into the design process further contributes to the robustness of the final product.A better way to make a stepper motor controller is to make a printed circuit board, and then simply drop the components in. After making the PCB, placing the components and soldering them hardly takes any time at all, in contrast to the proto board which took a ton of time to make.

Here`s a picture of the first stepper motor controller I made in PCB-form: Here is the schematic for the PCB version of my stepper motor controller. Notice that some improvements were made, such as the Schmitt trigger to help filter out noise. I want to thank Phil for his help when I was designing the PCB. He has a lot of experience with these stepper motor ICs and gave me a lot of advice. I also borrowed the idea of using a Schmitt trigger from him. 🔗 External reference