Lamp-life-extender

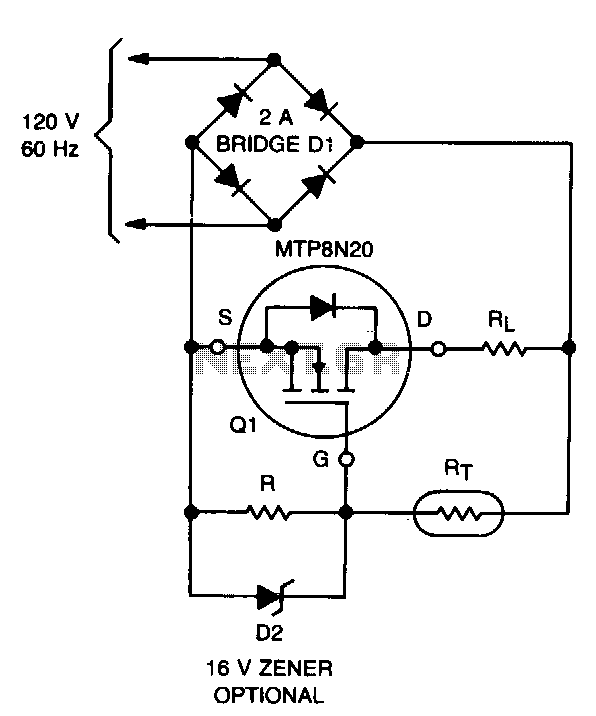

The lifespan of a lamp can be prolonged by enhancing the conditions under which its filament operates. This involves eliminating the inrush overcurrent surge and reducing the mechanical stress (vibration) on the filament caused by an AC source. The circuit presented regulates the inrush current to the lamp, avoiding the typical 10 to 15 times-rated current surge that occurs when power is applied to a cold lamp. It achieves this by modulating the inrush current over time to an inverse value compared to what is usually experienced. RL represents a standard tungsten lamp with a power rating ranging from 15 to 250 W, R is 10 ohms, and RT is a negative temperature coefficient resistor that initially has a resistance of 1.65 MΩ and decreases to 150 kΩ due to self-heating in approximately 0.5 seconds. The use of a TMOS device allows for high resistance values for R and RT, maintaining the drive power at a negligible level. This circuit offers several advantages: very low power dissipation, extended lifespan, low-cost components, minimal impact on lamp ratings, negligible effect on efficiency, minimal radio frequency interference (RFI), and suitability for hazardous environments.

The circuit design focuses on managing the inrush current, which is crucial for extending the operational life of incandescent lamps. The initial surge of current when a cold lamp is powered can be detrimental to the filament, leading to premature failure. By integrating a negative temperature coefficient (NTC) resistor, the circuit effectively reduces the initial inrush current. When the circuit is powered, the NTC resistor starts at a high resistance value of 1.65 MΩ, limiting the current flowing to the lamp. As the lamp heats up, the resistance of the NTC decreases to 150 kΩ, allowing more current to flow through the lamp without exceeding the rated current.

The TMOS (Trench MOSFET) device plays a vital role in this circuit by allowing for high resistance values while keeping the drive power low. This characteristic is essential for ensuring that the circuit does not waste energy and remains efficient. The low power dissipation achieved by this design contributes to the overall longevity of both the lamp and the circuit components.

The circuit's advantages extend to its application in various environments, including hazardous locations where traditional lighting solutions may pose risks. The minimal impact on lamp ratings ensures that the lamp operates within its specified limits, maintaining efficiency and performance. Furthermore, the low radio frequency interference produced by the circuit makes it suitable for sensitive electronic environments.

In summary, this innovative circuit design not only enhances the lifespan of lamps but also provides a reliable, efficient, and cost-effective solution for managing inrush currents in various applications.Lamp life can be extended by improving the conditions under which its filament is operated. This includes eliminating the inrush overcurrent surge and reduclog the mechanical stress (vibration) on the filament caused by an ac source. The circuit shown controls the inrush current to the lamp without the 10 to 15 times-rated current stage that normally occurs when power is applied to a cold lamp.

It does so by adjusting the inrush current over time to the inverse of the value normally experienced. RL is a standard tungsten lamp in the range of 15 to 250 W, R is 10-!:J and Rris a negative temperature coefficient resistance that is initially 1.65 M!:J and decreases, by self-heating, to 150 K!:J in approximately 0.5 s.

Use of the TMOS device allows high !:J values for R and R T. keeping drive power at a negligible level. This circuit has a number of advantages: very low power dissipation, long life, low-cost components, no significant effect on lamp ratings, negligible effect on efficiency, negligible RFI, and it can be used in hazardous environments.

The circuit design focuses on managing the inrush current, which is crucial for extending the operational life of incandescent lamps. The initial surge of current when a cold lamp is powered can be detrimental to the filament, leading to premature failure. By integrating a negative temperature coefficient (NTC) resistor, the circuit effectively reduces the initial inrush current. When the circuit is powered, the NTC resistor starts at a high resistance value of 1.65 MΩ, limiting the current flowing to the lamp. As the lamp heats up, the resistance of the NTC decreases to 150 kΩ, allowing more current to flow through the lamp without exceeding the rated current.

The TMOS (Trench MOSFET) device plays a vital role in this circuit by allowing for high resistance values while keeping the drive power low. This characteristic is essential for ensuring that the circuit does not waste energy and remains efficient. The low power dissipation achieved by this design contributes to the overall longevity of both the lamp and the circuit components.

The circuit's advantages extend to its application in various environments, including hazardous locations where traditional lighting solutions may pose risks. The minimal impact on lamp ratings ensures that the lamp operates within its specified limits, maintaining efficiency and performance. Furthermore, the low radio frequency interference produced by the circuit makes it suitable for sensitive electronic environments.

In summary, this innovative circuit design not only enhances the lifespan of lamps but also provides a reliable, efficient, and cost-effective solution for managing inrush currents in various applications.Lamp life can be extended by improving the conditions under which its filament is operated. This includes eliminating the inrush overcurrent surge and reduclog the mechanical stress (vibration) on the filament caused by an ac source. The circuit shown controls the inrush current to the lamp without the 10 to 15 times-rated current stage that normally occurs when power is applied to a cold lamp.

It does so by adjusting the inrush current over time to the inverse of the value normally experienced. RL is a standard tungsten lamp in the range of 15 to 250 W, R is 10-!:J and Rris a negative temperature coefficient resistance that is initially 1.65 M!:J and decreases, by self-heating, to 150 K!:J in approximately 0.5 s.

Use of the TMOS device allows high !:J values for R and R T. keeping drive power at a negligible level. This circuit has a number of advantages: very low power dissipation, long life, low-cost components, no significant effect on lamp ratings, negligible effect on efficiency, negligible RFI, and it can be used in hazardous environments.